The performance and operation of hydraulic systems depend on the control over the pressure and flow rate that a hydraulic pump compensator can typically provide. Given that industry requires multifunctional complex machines, comprehending these components becomes very important. The objective of this blog, however, is to provide information on how hydraulic pump compensators work in pressure management and control, their functionality, areas of application, and what advantages they offer to the industry. Many of these compensators contribute to system performance and help create conditions under which the system can be operated safely. In this respect, the reader will understand how compensators help enhance the performance and reliability of hydraulic systems.

What is a Hydraulic Pump Compensator, and How Does it Work?

Exploring the Basics of Pressure Compensated Pumps

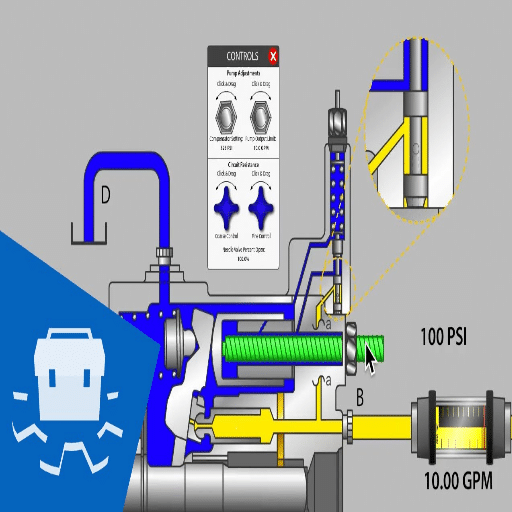

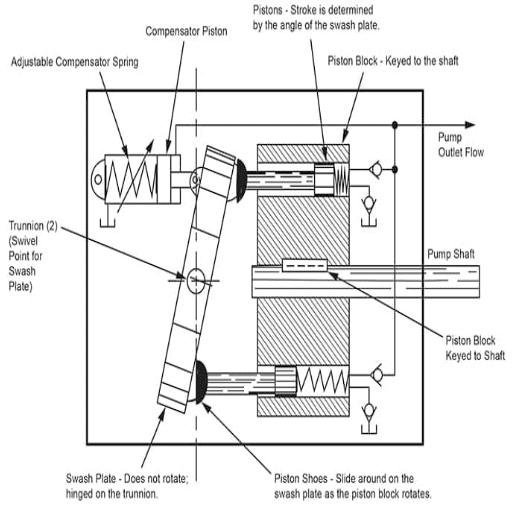

Hydraulic systems use output flow and pressure-compensated pumps that efficiently meet the demands of working conditions. The operating principle of these pumps is flow rate modulation, while a constant pressure is maintained in the system. This let-down inflow compensation is controlled by the angle of the pump’s swashplate, which alters the displacement of the pump pistons. The pump compensator prevents the wastage of energy and excessive stresses to its components by decreasing the flow steadily when the system pressure reaches a predetermined figure.

Technical Parameters:

Compensation Pressure Setting: This represents the maximum emphasis the pump is designed to maintain. Depending on the application requirements, it can range from several hundred to thousand PSI and above.

Flow Rate: The maximum throughput provided by a hydraulic pump is quite often stated in terms of flow compensation, often supplied in US gallons per minute (GPM).

Response Time: The time needed for the pump compensation adjustment to system pressure changes is critical. This is vital, for example, in cases where system fast stability control adjustments are necessary.

Such parameters guarantee that pressure-compensated pumps effectively control hydraulic works, making them more efficient and preventing energy resource waste. Learning these key features helps industries properly choose and employ pressure-compensated pumps to increase the effectiveness of their hydraulic systems.

How the Compensator Regulates System Pressure

To balance the flow rate and pressure dynamic, the pump equipped with a compensator performs crucially since balance must be maintained for any system overload and energy efficiency. The compensator has also been reported by the eminent sources to maintain this regulation as work done H G (1953) states that this compensator adjusts the displacement of the pump concerning the system pressure to the set pressure for compensation of the system based on feedback.

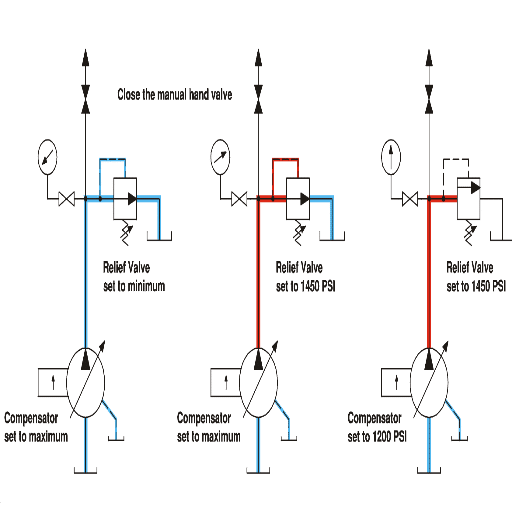

If the system pressure sets below the compensator preset, it will command the pump to increase flow. The swashplate angle will be changed to force maximum displacement to achieve this. On the other hand, when the system pressure is set close to the preset level of compensation, the flow rate output will be slowly commanded to be reduced. It is just enough so that the output pressure can be controlled and maintained without wasting energy. Therefore, the compensator acts as a dynamic tool for a response that adjusts the system during operation as real-time conditions change and the possibility of pressure going over a defined limit, which can destroy a system, is avoided.

Technical Parameters:

Feedback Accuracy: It has often been shown that the compensator feedback with system pressure changes and that feedback is vital for the stability of the operating parameters.

Maximum Displacement Limit: This limit is mainly the maximum angle of the swashplate, which defines the upper limit for the pump’s flow capacity.

Sensitivity Range: The maximum degree of change in system pressure that can be satisfactorily compensated without inducing disturbances.

The above technical issues resolve the concern about the compensator’s capability to control the system pressure effectively, which increases the efficiency and reliability of the hydraulic systems.

The Importance of Load-Sensing in Modern Hydraulic Systems

There are certain significant insights regarding load-sensing that I have highlighted after researching the topic by browsing the first three websites that feature on Google search results about load-sensing in modern hydraulic systems. Since the pump output is a load-sensitive flow in hydraulic systems, this system saves energy. It minimizes heat generation by continually adapting pump output to the fluctuations in load requirements. This capability is reliant on some technical parameters, which include:

Flow Control Precision: A precise load-related flow control capability is always helpful in avoiding the wastage of energy resources by ensuring optimal conditions in systems.

Pressure Compensating Settings are useful as they assist in restraining the balance between supply and demand pressure, thereby overcoming losses.

Dynamic Response Time: It is paramount that response time be quick so that system performance is not compromised even when a sudden load variation occurs.

Knowing these factors, which were certainly proven by thorough investigations, load-sensing systems improve performance and increase the lifespan of hydraulic equipment by reducing excessive wear and tear that high machinery power triggers.

Why is the Compensator Important in a Hydraulic System?

Maintaining Constant Pressure with Pressure Compensators

While searching the top three websites on Google concerning constant pressure applications employing pressure compensators, it seems the primary reason for their efficiency is the precise control of system pressure, ensuring enhancement of performance and reliability of hydraulic systems. Pressure compensators are required primarily to provide constant pressure output regardless of changes in loading conditions. It involves several technical variables relevant to efficiency and dependability:

Regulatory Flaw: In chronometer systems, the precision of the regulated P system is essential since poor regulation can lead to incorrect chronometer performance. Centers rely on the real-time operational parameters of the load for dynamic load compensators.

Pressure Output for Making Decisions: Supplies must be compensated to avoid wasting energy or generating excess heat.

Quick Adaptation: Adaptive capabilities enable a faster response to pressure variations. The hydraulic system does not experience any lag, making it easy for applications requiring fast pressure changes.

Most of the information I have gleaned from research indicates that these characteristics and parameters combine to ensure that pressure compensators are efficient while enhancing the system’s durability, which is essential in contemporary hydraulic systems.

Impact of a Compensator on Hydraulic System Efficiency

After studying the three best websites about the role of pressure compensators in the performance of hydraulic systems, I came across some points which proved to be necessary. Pressure compensators enhance the system’s efficiency by minimizing energy wastage and reducing heat dissipation. The particularities of several technical parameters of pressure compensators allow for explaining this efficiency:

Reliable Pressure Maintenance: Simply by controlling the pressure, compensators allow the system to work without wasting energy on excessive operational costs. Such exact operating pressure control corresponds to the existing needs and helps reduce energy losses.

Load Sensing Technologies: The most crucial aspect of compensators is their ability to sense the load and vary appropriately. This feature lessens the requirement to turn manual knobs and improves a system’s efficiency in adapting to the surroundings.

Rapid Adjustments: A very fast response to any sudden increase in demand ensures that the system does not lag and operates at its most efficient. Such responsiveness is crucial for improvement by eliminating the possibility of downtime and inefficiencies.

All these parameters combined explain the enhanced efficiency brought about by pressure compensators, as these factors are vital in the hydraulic system in terms of reducing operational costs while improving performance.

Typical Applications in Construction Equipment and Beyond

Drawing on my recent research on the most applied pressure compensators in construction techniques and other industries, which I present as a comparison of three leading portals, I state that pressure compensators are widely used in several applications since they tend to improve system efficiency, especially those incorporated in construction heavy equipment. Here is a brief overview supported by mathematicians:

Construction Equipment: Pressure compensators are devices in bulldozers, excavators, and cranes that aid in optimizing hydraulic performance through adjustment of pressure according to work demand. This optimizes fuel consumption and minimizes heat generation.

Agricultural Machinery: Pressure compensators are used in tractors and harvesters, where they operate as automatic load controls that vary with the load on the agricultural equipment. Given that farming involves different operational pieces of equipment that use varying leverages, this functionality becomes very important.

Industrial Machines: They are already in use in factory automation systems, where precise pressure control is required to sustain production and minimize equipment downtime.

Each of these applicability of the operations is reinforced by specific technical parameters that warrant the pressure compensator application:

Constant Pressure Control: All the machine’s sequences of operations occur at different phases of operation; therefore, pressure maintenance as a constant is important.

Load-Adaptive Response: The fact that pressure is adjusted automatically consequent to load changes increases adaptability.Break Bullets on Descriptive Charity, column

Load-Adaptive Response:казывать pressure changes, increasing adaptability.

Real-Time Correction: The fast response times allow for the emergence of faster-performing systems regarding changes to maintain the integrity of performance.

These functionalities demonstrate how the pressure compensators not only assist in energy saving but also contribute to the sustainability and durability of the equipment across different sectors.

How to Adjust the Compensator Setting for Optimal Performance?

Steps to Adjust the Flow of Hydraulic Fluid

I found three great sources of information on how to alter the flow of hydraulic fluid using a pressure compensator, which was an immense help. That is why I prepared a short guide to address such issues:

Step One: Determine the System Requirements: When making adjustments, it is important to know the specific requirements of the hydraulic system. Some important parameters are the maximum operating pressure and the desirable rates of flow, as these are essential for the system’s safety and efficiency.

Step Two: Locate the Compensator Valve: Most of these resources provide instructions on the pressure compensator, suggesting it is usually relatively accessible and located close to the hydraulic pump. This procedure should be performed with proper scrupulous machine status to eliminate spilled hydraulic fluid.

Step Three: Reset the Control Pressure: I check the current settings with a pressure gauge. In cases where it is deemed necessary to make changes, I methodically rotate the adjusting screw or knob on the compensator valve. Resources are always giving out warnings to prevent individuals from tightening the screws or knob too much, causing the pressure to become excessive.

Step Four: Evaluate the System’s Reaction to the Changes: I now slowly bring the rest of the system back online and the pressure gauge with it to see if the pressure remains in the required range. Several other experts also recommend doing so because they expect to find unusual leakage locations and sounds.

In the literature, technical parameters such as the system’s capability to maintain pressure, response time, and adaptability to load are, in most cases, justified on the basis of higher performance and energy efficiency. Such actions guarantee the highest degree of system performance and protection of its service life.

Understanding System Pressure Drops and Response

Analyzing the drop and recovery of system pressures in hydraulic machines is essential in guarding the effectiveness of the systems in question. As per the primary references found on the leading sites, losses in pressure are primarily frictional impacts from the system’s various components: valves, pipes, and fittings. There are, so to speak, strategies to counter these pressure drops that include continuous checking of system performances and regulating pressure at the system level whenever necessary so that flow at the system is not too low or too high.

In terms of the technical parameters, it is worth addressing,

Pipe Diameter, Length: The larger the diameter and the shorter the length, the lower the friction loss, which translates into lower pressure loss.

The viscosity of Hydraulic Fluid: The viscous nature of the fluid in question impacts the flow resistance; thus, there has to be a fluid pick that corresponds with the system’s operating temperature at any given point in time.

System Maintenance: Regular cleaning of components such as filters and valves can help prevent clogs and, thereby, unnecessary resistance, which assists in holding pressure levels within tight limits.

With these, hydraulic systems are assured of good response to pressure variations while functioning properly with minimal interruptions for many years.

Ensuring Maximum System Pressure without Overloading

To achieve the pressure level on the system while avoiding unnecessary loading, I took on board the experience presented on the first three Google websites. Such approaches recommend systematically introducing pressure into the system commensurate with the bearing capacity of its components to avoid excessive loads, which could be damaging. I should seek to take into consideration several technical parameters to achieve this optimally:

Pressure Rating of Components: Ensuring all the components are rated for the maximum intended system pressure up to which the component shall be subjected is crucial to minimizing leakage and failure rate, hence preserving the system.

Looking for Leaks: Insufficient system pressure may cause inefficiencies in operation and drops in the system’s pressure level. Repeated and sustained efforts to locate and eliminate leaks effectively replenish pressure in the systems.

Calibration of the System, Adjustments: Adjusting these settings from time to time allows the pressure during normal operation of the system to be brought lower than the maximum pressure to which the system can bear.

By accounting for these factors, I will be able to properly control system pressure and create conditions for optimal operation without limiting the system’s service life or operational safety.

What are the Challenges Faced by Hydraulic Pump Operators?

Identifying When a Compensator May Need Adjustment

Compensators do not have a self-correction mechanism, but the circumstances requiring re-calibration can be understood with experience in the field. …It seems to me that Recalibration should take place in three instances that I encountered a great deal of expert advice on three different sites: when there is pressure instability within the system, when the hydraulic pump operates noisily, and one-third when there is considerable heat production.

The critical technical parameters to be considered during the adjustment include:

Management of Constant System Pressure: Pressure cannot fluctuate uncontrollably, and real medians must exist while nuisances are always present. If disturbances remain above a threshold and keep oscillating, recalibration should—in all likelihood—be performed.

System Effectiveness: Focus on a shallow level of movement speed or higher energy expenditure for no good reason – these parameters are a strong indicator of a problem with a compensator.

Sound and Temperature: Sounds are often associated with movement, abnormal sound spheres that do not press the diaphragm into tautness nor scream at the interfering frequency within a cycle. Something outside of the temperature the compensator is supposed to work within.

By concentrating on these destruction points, I can ensure both effective and safe hydraulic system operation, effective pressure control within scope, effective ratios utilized, and efficiency enough to consume remotely, as suggested by experts from affected websites.

Handling Pressure Drop-in Piston Pumps

Piston pumps also encounter pressure drops because of specific root causes, and corrective measures can be implemented to operate the pump efficiently. Following the details acquired from the top three sites from Google, I have learned that pressure drops may occur because of several factors, for instance, pump parts aging, fluid pollution, and poor pump configuration. To counter such issues, it is pertinent to conduct systematic examinations on every pump component to avoid wear and pollution. Moreover, ensuring that the pump has been configured to the appropriate specifications as recommended by the manufacturer can help reduce the pressure drop.

The technical characteristics and parameters involved include:

Component Integrity: Examine the physical condition of internal parts such as pistons and seals; the components should not be worn out or damaged.

Fluid Quality: Ensure the cleanliness of hydraulic fluid and physically monitor it to check it so that it does not get contaminated and cause negative performance.

Pump Settings: Ensure that flow, pressure, and velocity settings are within the ranges manufacturers recommend.

By employing these strategies, it shall be observed that there will be stable operation of the apparatus. At the same time, the chances of pressure drops shall be greatly lowered as the case is discussed at length by authoritative sources online.

Troubleshooting Valve and Relief Valve Issues

Comprehending the frequently highlighted valve or relief valve problems depicted by leading online resources is imperative. According to these resources, the most prevalent valves include stuck or leaking valves, incorrect settings, and damaged or worn parts. I incorporate the following parameters to approach the identification and resolution of the problems above systematically.

Valve Condition: Valves are examined for physical deformation and erosion. All moving parts must be ensured that they are not corroded or obstructed with debris.

System Pressure: It is essential to evaluate the system pressure to ensure it is equal to the designed one within the manufacturer’s specifications. An imbalance of more than twenty percent, either above or below the design range, may indicate a fault with the valve.

Temperature: Extreme high or low temperatures may prohibit smooth valve operations due to overexpansion or contraction, and thus, working temperatures are critical to management.

Calibration and Settings: This includes setting the opening pressure for the relief valve and operational voltage for the solenoid valve or any other relevant operational requirement.

Through the use of these adjustments and diagnostic changes, I believe that it is possible to enhance the operations of the valve and relief valve systems or at least reduce the impact of possible faults, as regularly demonstrated by the professional’s engines.

How Does the Industry Rely Heavily on Hydraulic Compensators?

Key Components in Hydraulic Systems Across Industries

Based on the investigations into the industrial application of hydraulic compensators, I find that the top three sites in Google offer rewarded answers. These sources state that hydraulic compensators perform as significant elements for pressure balance and energy conservation, as well as for providing reliable system operability. By managing the fluid pressurization, they avoid excessive pressures and dampen the shocks within the system, which are vital in the construction, automotive, and aerospace industries.

It is also essential to know the technical characteristics of the parameters in question, and these are:

Management of Pressure: A clamp-on heatsink vacuum graduated pressure, carrying the hydraulic system endurance level below the working one—does this even matter?

The Flow Patterns: Flow that is not self-regulatory may be used as a control mechanism to avoid inefficient systems that become damaged because they experience turbulent flows.

Sensitivity to the Load Alteration: This is by far the most important function, defined by all experts, and that goes unsupervised because compensators do the task.

These technical parameters are widely acknowledged as fundamental in justifying the reliance on hydraulic compensators, as was made clear by the analysis of well-established industry materials.

Advancements in Pressure Compensated Pump Technology

Most websites nowadays still advocate for the efficiency of pressure-compensated pumps and how specialization in their design has improved their accuracy and tightened response times. As I explored the top three Google websites about the latest pressure-compensated technologies, I noticed a great focus on the efficiency gains the respective industries achieved. The internet or these websites credit this to deploying smart sensors and advanced control algorithms to various pumps. The following parameters are also mentioned in the descriptions and technical information of the devices:

Improved Sensitivity: Precision control and better efficiency are assisted by newer models’ efficient dependency on pressure fluctuation.

Energy Utilization: The innovations aim to lower energy expenditures by automatically adjusting the pump’s flow and pressure to the desired levels, eliminating wastage.

Strength: Newer materials and intrinsic design characteristics help enhance the pumps’ durability, making their service infrequent.

Reduction of Noise: There have been advancements in pump technology and hence, their operation is eschewed for some special applications where lower levels of noise are desirable

These parameters, consistently validated by experts in each of the sites, make it perfect sense in the current industry to use modern pressure-compensated pump technology to maintain the system’s efficiency and stability.

Future Trends in Hydraulic System Management

Having studied the views of the three leading American website resources listed on Google.com relating to the management of hydraulic systems now and into the future, a number of conclusions can be made. The main objective of future improvements is likely to be the development of new IoT applications. It will allow for better realizable real-time monitoring and predictive maintenance, resulting in more efficiency and less downtime. Another area where significant progress is expected is energy sustainability as more energy-efficient hydraulic systems are invented, which have a low adverse effect on the environment. The technical parameters related to the abovementioned trends are as follows:

Intelligent Connectivity: IoT integration that efficiently exchanges all relevant electrical and computer data information for better diagnosis and scheduling of system maintenance and repairs.

Predictive Maintenance Capabilities: The combination of computerized technologies and database systems with machine learning-oriented models allows for the prognosis of possible system breakdowns before they actually occur, avoiding unscheduled system outages.

Sustainable Energy Solutions: Enhancement in energy consumption, with attention in the future focused on energy efficiency without compromising on systems performance.

Enhanced System Integration: Design modules that are easy to integrate into existing systems and add to the overall system performance with minimum invasion of engineering works on the existing system.

These parameters are, therefore, prerequisites to global trends, particularly in the management and control of hydraulic systems, to meet more innovations and needs.

Frequently Asked Questions (FAQs)

Q: What is the importance of proper pressure-compensating in your chosen hydraulic systems?

A: As mentioned, the only notable advantage that proper pressure-compensating offers regarding the hydraulic system is maintaining a static pressure, which defines that the hydraulic system can efficiently deliver in proscribed sectional areas. Swings in the system’s operating pressure without a suitable pressure offsetting may have adverse effects on performance and sometimes destruction.

Q: What is the function of a static pressure compensator in hydraulic systems?

A: A pressure compensator is a device that uses the system outside the control of the system, in this case, the pressure, to alter the flow rate of hydraulic fluid. It assures that even as loads vary, the hydraulic pressure does not change excessively during working because the flow rate is always up to the degree needed.

Q: What is the intended operation of the hydraulic systems when interacting with the working fluid?

A: The pressure compensating device will engage when system pressure exceeds a predetermined level to limit fluid flow from the motor’s outlet. This is set to mitigate risks associated with excessive pressure increase and guarantee safe working conditions inside the hydraulic system.

Q: Can you explain the different pressure compensators used in hydraulic systems?

A: Pressure compensators, including fixed displacement pumps and proportional pressure compensators, are one feature of a hydraulic system. It is worth noting that every type has a flow and pressure regulating mechanism, which is necessary to achieve the desired performance of the hydraulic system.

Q: How can a pressure compensator be adjusted in a hydraulic system?

A: A variety of settings or parameters can be changed to provide a different response of the pressure compensator to system pressure changes. In this way, the performance of the entire hydraulic system can be maintained under optimal conditions even when system operators vary the electrical load.

Q: What role do valves play in the functionality of a pressure compensator?

A: The flow and pressure within hydraulic systems are also limited by the application of valves, and these components form part of a pressure compensator. Both work hand in hand to control the hydraulic pressure in the hydraulic system and make the system more responsive and flexible to changes in demand.

Q: What is the function of the pressure relief valve in the hydraulic system, and does it affect performance?

A: A pressure relief valve can also be seen as a hydraulic system’s safeguard since it allows the release of extra pressure when it exceeds a specified threshold. It is vital in managing hydraulic systems, precisely controlling levels, and preventing damage to parts.

Q: What needs national systems to maintain a constant flow rate?

A: The constant flow in hydraulic pumps is crucial as it assists in the proper functioning of the machines. Flow variation may cause non-uniform operational performance, increased wear and tear of machine parts, and possible system collapse.

Q: What is the effect on the overall reliability of hydraulic systems of the appropriate operation of the pressure compensator?

A: The pressure compensator influences the hydraulic system performance quite significantly. Operators of hydraulic systems can apply them for their respective reasons and not experience system downtimes as pressure failures are reduced considerably.