Hydraulic pumps form the core of any log splitter, converting mechanical energy into hydraulic power so that the machine can deal with even the toughest wood. If you’re pondering what makes your log splitter efficient and reliable, it’s this component. This article focuses on the essential role of hydraulic pumps in log splitters, their function, types, and how they help enhance performance. Whether you’re venturing into the world of hydraulics for the first time or looking to refine your knowledge as an experienced professional, this article will help you understand how these powerful pumps are the driving force of your log splitter.

Overview of Hydraulic Pumps

What is a Hydraulic Pump?

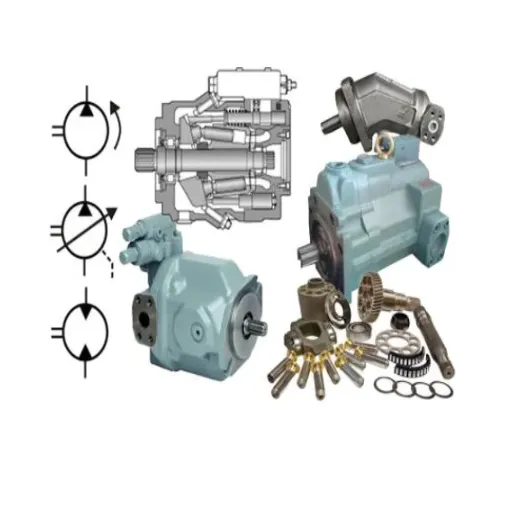

A hydraulic pump is defined as a mechanical device that converts mechanical energy to hydraulic energy. It imposes functions on the hydraulic machinery and subsequently generates flow and ducts through the system. It is important to note that a hydraulic pump is not like other pumps because it does not generate pressure. It generates a flow, which is then constrained by the system to generate the operating pressure.

Different applications require various hydraulic pumps. The gear, piston, and van pumps are the most notable and widely used. Gear pumps are noted for their modest functions as well as their efficiency, which allows them to be used in light-functioning machinery. Vane pumps are efficient in fulfilling the functioning of moderate van systems as they are efficient in providing flow at higher performance levels. For piston pumps, precision and efficiency are hallmark features, and thus they are used in industrial systems where functioning under high pressures is required. To ensure that the system works well for a long time, the right pump has to be selected.

Key Point: Hydraulic systems like log splitters would not be able to function properly without hydraulic pumps, and the system would no longer be able to generate the splitting force. As such, the GPM capacity and pressure rating of the pump directly determine the speed and splitting force of the log splitter. Use of the proper log splitter pump would allow for a balance between power output and energy use, while ensuring reliable and effective operation of the splitting mechanism.

How Hydraulic Pumps Work in Log Splitters

The mechanical work of an engine is transformed using a hydraulic pump to apply the needed force for log splitting. The pump first pulls the hydraulic fluid out from the reservoir and then increases its pressure, sending it through the hydraulic system to the cylinder operating the splitter wedge. The force needed to push the wedge through the log is created using the energy of the pressurized fluid.

The effectiveness of the splitting is mostly dependent on the design and characteristics of the pump. Whereas most wood splitters rely on either gear or axial piston type pumps, gear pumps are the most widely used because of their robustness and low cost. With rotating gears to pressurize the hydraulic fluid, gear pumps are the easiest to operate. Their ease of operation ensures dependable functionality, which is essential in log splitting for reliable forces. Axial piston pumps are more complicated and costly, but they are capable of achieving higher pressures and thus are used in industrial-grade or heavy-duty log splitters.

For the splitter to function optimally, the hydraulic pump must be maintained properly and be compatible. Making sure the pump does not exceed its rated pressure limits saves the pump from excessive stress and possible damage. Hydraulic fluid levels, system cleanliness, and hydraulic fluid integrity should also be checked from time to time to maintain efficiency and durability. Simply by recognizing the functions of the pump and maintaining them as required, consistent and powerful output from the splitter can be ensured.

The Importance of Hydraulic Pumps for Efficiency

Any hydraulic system requires a hydraulic pump, which acts as the system’s core and energy conversion and transmission controller. Agricultural, energy, construction, manufacturing machinery, and equipment rely on various machinery’s specific functions, which the pumps fuel by energy conversion into mechanical and hydraulic energy. Such pumps’ performance, directly equal to the conversion efficiency, depends on specific design, operational, and maintenance conditions.

Modern models of hydraulic pumps take advantage of newer technologies, such as digital controls, high-efficiency materials, and variable displacement hydraulics engineering. Pumps that feature variable displacement not only lower hydraulic fluid viscosity but also adjust flow rates according to system demand, thus cutting unnecessary energy and improving system efficiency. Eliminating wear or contamination, as well as adjusting hydraulic fluid viscosity, yields additional benefits to pump performance and life.

Efficiency Tip: Observing maintenance ahead of its schedule as well as carrying out system enhancements can increase hydraulic efficiency in general by up to 20-25%. This stands as evidence that the use of in-depth practical expertise and modern developments to reduce energy operational as well as environmental expenses to maximize hydraulic pumps’ operational dependability, life, and performance is indeed crucial.

Choosing the Right Log Splitter Pump

Compatibility with Your Log Splitter

Ensuring a log splitter pump works with your existing equipment is a fundamental step in achieving efficiency and reliability in your operations. To begin with, the hydraulic system’s pressure requirements, usually stated in PSI, must be aligned with the pump’s capacity; not only must the pump meet the system requirements, but it is best that it slightly outperforms them. The flow rate in gallons per minute (GPM) is another critical metric that influences how fast the pump can actuate the log splitter’s cylinder. Balancing the flow rate of the pump with the size of the cylinder and the targeted cycle time is imperative.

Another essential compatibility consideration pertains to the horsepower of the engine. Different pumps come with varying power requirements, and choosing one that the engine has the capacity to drive spares the system from unnecessary wear and inefficiency. In addition, the mounting arrangement of the pump needs to be compatible with the log splitter; for example, whether the structure calls for a direct mount or a bracket mount, the pump should fit.

Hydraulic fluid compatibility is equally crucial. Following the guidelines from the pump and log splitter makers for using the correct type and viscosity of hydraulic fluid helps in smooth operation and minimizes wear and tear of the internal parts. Rather than overlooking these details, taking them into account aids in the procurement of a pump that fits the system, thereby optimizing the efficiency of log splitting and ensuring the operations are dependable.

Power Requirements and Flow Rate Considerations

Selecting the right pump for a log splitter requires knowledge of the synergy between power needs and flow rate. The flow rate, usually expressed in gallons per minute (GPM), influences how fast the log splitter functions. While faster cycling times can be achieved with a higher flow rate, it demands increased hydraulic horsepower for effective functioning. On the other hand, a slower flow rate can save energy but will slow down the operation.

Hydraulic Horsepower Calculation

HP = (Flow x Pressure) / 1714

Using flow in GPM and pressure in pounds per square inch (PSI), the required hydraulic horsepower (HP) can be calculated using this formula. This helps in understanding if the pump specs suit the power output of the motor or engine.

As an example, a standard two-stage gear pump can need from 4 to 8 HP based on flow and pressure settings. When such needs are not fulfilled, it can result in inefficiency, undue wear, or damage to the system.

In addition, exact compatibility can be ensured by consulting the manufacturers’ guidelines for the best working. Pressure-compensated or variable-displacement pumps, for instance, sophisticated modern developments, can tailor their flows to suit different workloads while conserving energy. When such technical considerations are properly evaluated, the pump selected can provide optimal performance and dependable service in log splitting tasks.

Understanding Pressure Ratings

Pressure ratings—usually noted in pounds per square inch (PSI)—are vital not only for the safe operation but also for the overall functionality of hydraulic and log-splitting systems. To understand their significance, consider that such ratings indicate the maximum allowable pressure a hydraulic pump, valve, or cylinder can sustain without damage. For example, medium to hard-density logs can be efficiently split using residential log splitters functioning at 2,500 to 3,000 PSI.

If the pressure on any of the components is higher than the specified ratings, the components can undergo serious damage that ranges from efficiency reduction to structural failure. Structural failure and other damages could lead to costly repairs. Hydraulic system components, as designed by manufacturers, come with a safety factor—meaning that some oversized pressure bursts can be accommodated without damage. Even so, hydraulic system overpressure that lasts for a long duration must be avoided. It is the responsibility of the users to verify system’s operational safety, which requires all components (including hoses and fittings) of the hydraulic system to meet or exceed the pressure rating and be compatible with the pump’s maximum output.

Today, there is an increase in the reliability and real-time monitoring of system performance with the advent of digital pressure transducers and automated relief valves. These devices provide ample system feedback to maintain performance while ensuring accuracy. Such devices are crucial in high-duty cycles or commercial operations, where steady pressure is important to the system’s lifespan and productivity. In light of this, it is imperative to understand and comply with the stipulated pressure ratings in order to utilize hydraulic systems in a dependable, economical, and secure manner.

Maintenance Tips for Log Splitter Hydraulic Pumps

Cleaning Techniques for Longevity

If you want your hydraulic pumps to work well and last a long time, you need to clean them properly. To maintain proper safety, make sure to turn off the power connected to the hydraulic system. Look closely at the outer part of the pump and see if there are any pieces of dirt or debris that can affect its functionality. With a gentle cleaner solution that is both industrial grade and specialized, remove the dirt with a soft-bristle brush, but make sure no damage is done to the surface or the seals of the pump.

As for the internal parts, flushing the system with hydraulic fluids compatible with the manufacturer’s requirements is recommended. This is useful for removing any particles or sludge residues that can affect the performance of the pump. I should mention that filters should be checked and replaced on time because clogged filters are the number one contamination source in hydraulic systems. Cleaning intervals should, therefore, be respected as stated by the OEM (Original Equipment Manufacturer) so that cleaning is not done too frequently on the system components.

Reassembling the system after the cleaning process is just as important as the rest of the cleaning process. Upon reassembly, make sure the connections are all sealed and that there are no leaks. To sustain the system, conducting a pressure test is useful in determining that the pump is functioning within the set limits. Within the context of the methods described and with the addition of constant monitoring, you are able to increase the efficiency and expected life of your hydraulic pump and reduce the amount of time taken for system maintenance.

Lubrication Best Practices

Any hydraulic system requires proper lubrication to work effectively and last as long as possible. The correct lubricant to use is determined by factors such as the system materials, viscosity, and the operating temperature range. As a rule of thumb, the right viscosity grade of lubricant should be used so that it provides the necessary film strength to reduce wear and striking of components while also ensuring smooth flow through the system. Perform oil condition monitoring regularly to check for the presence of water, particulates, or broken-down additives. Left unchecked, these contaminants can cause breakdowns of components, increased downtime, and expensive repairs.

Important: Over-lubrication leads to overheating and higher energy use, and under-lubrication leads to early wear. For maintaining the balance, automated lubrication systems should be considered where applicable, as they allow for accurate lubricant application, eliminate human error, and ensure maintenance is done at the right intervals.

Recent developments in lubrication technology shed light on the synthetic fluids and their benefits in extreme pressure conditions or wider operating temperature ranges. Synthetics are known to have better oxidation stability and longer life, thus reducing the operating costs. Keeping track of analysis of lubrication performance and using predictive maintenance methods such as oil analysis software can greatly reduce unexpected system breakdowns and ensure uninterrupted, efficient operation.

Regular Inspections to Ensure Performance

To keep equipment functioning well and prevent expensive downtime, lubrication systems must be regularly inspected. Such inspections should systematically check every part of the system, including the reservoirs, pumps, and filters, for any indication of wear, contamination, or leakage. By making inspections a routine part of operations, the staff can catch problems early and avoid failures. The use of advanced diagnostic equipment, such as infrared thermography and vibration analysis, can be used to capture detailed information about the moving components, which in turn facilitates more effective maintenance scheduling.

One of the best ways to enhance equipment reliability is by incorporating oil analysis into the regular maintenance checks. Oil analysis reveals important details about the oil, such as viscosity, contamination, and even wear debris. This information helps maintenance personnel to make informed decisions regarding the oil–whether to keep it or change it. For example, this can help detect increased levels of silicon or aluminum, which can indicate an early stage of contamination caused by dirt or other abrasive particles. This approach helps preserve equipment functionality and minimize unexpected breakdowns.

In addition, modern lubrication management software can further optimize the inspection procedures. As these software platforms retain data and generate both performance and trend analyses, well-informed decisions become easier to make. Conforming to best practices becomes simpler, as a unified system keeps track of both equipment history and lubrication schedules. This, together with a strict inspection schedule, helps preserve machinery and reduce operational costs in the long run.

Troubleshooting Common Hydraulic Pump Issues

Identifying Leaks and Solutions

After a system overview to locate the components, it is crucial to inspect the system thoroughly to check for hydraulic pump leaks. These leaks are of two types, namely, internal and external. External leaks are usually visible and occur because of damaged fittings, worn-out seals, or improperly torqued connections. External leaks can be corrected by replacing the fittings, worn-out seals, or tightening connections.

Internal leaks are a sign of worn-out hydraulic pumps and are usually difficult to identify. They are usually caused by worn-out piston rings, eroded valve seats, or degraded internal surfaces. To identify internal leaks, I would recommend performing diagnostic pressure tests to locate pressure drops in the system that point to leakage and internal wear. Fixing internal leaks may require hydraulic pump disassembly, worn part replacement, or, in cases where the hydraulic pump is no longer serviceable, a full replacement.

To avoid leaks in the future, I would suggest a proactive inspection program that schedules regular inspections, ensures correct lubrication, and replaces components that have a high rate of wear on time. Keeping the system within the pressure and temperature limits will help protect the hydraulic pump and help avoid premature wear and reduce leak incidents over time. Following these inspection schedules will help enhance the reliability and effectiveness of the system.

Addressing Loss of Pressure

In addressing pressure loss in hydraulic systems, my approach would be to systematically diagnose its cause. This begins with checking the fluid levels to verify if they are within the required operating range. Hydraulic fluids that are low in quantity are prone to cavitation and an overall drop in system pressure. I would also verify the fluid quality, as degraded fluid or contaminants tend to decrease the efficiency of the system and contribute to pressure problems. Thus, fluids should be regularly analyzed as part of the maintenance schedule.

Following that, I would check for any possible damage or wear on critical components such as valves, seals, and hoses. Seals that are worn out or system cracks could cause leaks, which in turn lead to a slow drop in system pressure. It is important to replace any damaged parts as soon as possible and select good-quality seals that match the specs of the system. Additionally, correcting and fine-tuning control valves is mandatory to ensure that the pressure targets are in line with the system’s operational needs.

To conclude, I would conduct a detailed investigation of the hydraulic pump. I would inspect to see if the hydraulic pump has wear on the inside and also confirm that the pump is working within its intended operating range. Wear on the inside of the pump will decrease its ability to keep the pressure maintained. If a vibration analysis is implemented, it is possible to gain more information about the mechanical soundness of the pump. For all of the steps mentioned, using diagnostics tools that are more advanced and follow the manufacturer’s instructions will keep the hydraulic system in good working condition, as well as reliable, and will extend its life. Using all of the steps in the correct order will be effective in solving the problem of loss of pressure and preventing it from happening again.

Dealing with Unusual Noises

A hydraulic system not operating properly creates strange noises that signal a probable mechanical malfunction. Catching these noises as soon as they arise can help prevent more extensive system failures. The two most common issues fuelled by an abnormal sound are the formation of “bubbles” within the pump (also known as cavitation) and the sucking of air into the system (also known as aeration). Cavitation sounds like a “gravel-like” noise, whereas aeration produces a high-pitched whine. Knowing the differences between these two will help reduce unnecessary interventions and provide more targeted diagnostics when issues arise.

Sound Identification Guide

- Cavitation: Gravel-like noise

- Aeration: High-pitched whine

The most effective way to fix a problem is to investigate the root causes. In the case of cavitation, pump inlet conditions must be examined. Perhaps there is an overly viscous fluid, a poorly designed system, or a restricted inlet that is fostering cavitation. A few strategies are the cleaning of suction strainers, proper servicing of fluid and piping properties, and appropriate sizing of inlet piping. For aeration, all hydraulic lines must be checked for damaged fittings, broken seals, or any kind of air-permitting cracks. The use of ultrasonic leak detectors can make pinpointing leaks much easier.

To prevent the recurrence of strange noises, it is crucial to adopt continuous monitoring procedures. The use of acoustic emission sensors and pressure transducers as part of the condition monitoring systems can detect deviations from standard system functions. Such systems can also be integrated with predictive maintenance tools to alert the organization of potential problems associated with system noises, thereby eliminating downtime and saving on costs. In addition, having a maintenance schedule that includes a review of system and component cleanliness, fluid condition, and component wear will safeguard against the absence of abnormal noises, thus ensuring optimum operation. The adherence to these procedures will provide the means to comply with a set of standards that help protect the quiet and efficient operation of the hydraulic system.

Current Trends in Hydraulic Pump Technology

Advancements in Hydraulic Pump Design

The latest developments in hydraulic pumps are centered around energy efficiency, device reliability, and hydraulic class environmental impact. There is a specific focus on variable displacement pumps that can adapt fluid flow and pressure based on system requirements. When compared to fixed-displacement models, they offer tremendous energy savings. Advanced materials like lightweight composites and wear-resistant alloys further enhance the pumps’ performance and life span. In turn, they reduce maintenance and operating expenses.

Deploying smart technologies and IoT-enabled hydraulic system devices is another area of focus. Modern hydraulic pumps incorporate smart sensors to track and analyze their pressure, temperature, and flow rate. Predictive maintenance and system performance optimization remove the chances of system downtime. Such advanced analytics enable the devices to function optimally even in advanced engineering.

Eco-innovation has led to the design of hydraulic pumps that make use of biodegradable fluids and operate at reduced noise levels. Such eco-innovations not only comply with environmental laws but also satisfy industry requirements for green technology. In essence, hydraulic technology today incorporates eco-innovation, advanced analytics, and energy-efficient technology to meet industry expectations.

Eco-friendly Alternatives in the Market

The increasing concern for sustainability has a direct impact on the innovation of hydraulic systems and their components. The petroleum-based hydraulic fluids used for years can now be replaced with biodegradable ones, produced using synthetic esters or vegetable oils. The environmental impact in cases of leakages or spills is greatly reduced using these. Furthermore, hydraulic pumps can now be energy-efficient, incorporating advanced energy lift control, including variable-speed drives. They can also use less noise-dampening technology. In industrial and urban environments, operational technologies are expanding and increasing the need to reduce noise pollution.

From a larger perspective, new composite materials facilitate component production by using recycled metals, reducing the environmental footprint. Industries, especially modular ones, benefit from hydraulic systems that are more compact and modular, which require less material and catalyze space efficiency. Using such systems is also analyzed to be beneficial for industries, as these, along with meeting international environmental regulations such as ISO 14001, help reduce maintenance and operational costs, providing substantial savings in the long term.

These data points illustrate the progress towards implementing green solutions, which align operational efficiency with ecological responsibility, and set a new standard for sustainable engineering practices.

Frequently Asked Questions (FAQ)

Q: What is a log splitter’s hydraulic pump?

A: A log splitter’s hydraulic pump is the pivotal part of the hydraulic system. It creates the pressure required to drive the splitter wedge to cut logs. Its performance determines how fast and effectively the splitting will be.

Q: What does 16 GPM mean in relation to hydraulic pumps?

A: In this context, 16 GPM stands for 16 gallons per minute and refers to the hydraulic fluid flow rate of the splitter’s pump. The flow rate, along with the maximum attainable pressure, determines the splitting speed, especially when a two-stage pump is used.

Q: What are the benefits of using a two-stage hydraulic pump for a log splitter?

A: A two-stage hydraulic pump is beneficial because it has two operating stages. The first stage serves high flow and low pressure for fast splitting, and the second stage serves low flow and high pressure for tough splitting. This makes it both efficient and effective, serving both light and heavy splitting.

Q: How can I tell if the hydraulic pump is suitable for my log splitter?

A: You should check the hydraulic pump’s flow rate (like 16 GPM), its pressure rating, and whether it is compatible with the splitter model. Also, verify if it has a detent valve for no-hold continuous operation.

Q: Are Electric Log Splitter Hydraulic Pumps Intended for Residential Use?

A: There’s no shortage of electric log splitter hydraulic pumps, and, in fact, they are an excellent choice for residential use. The maintenance is simpler, noise levels are lower, and they are designed for residential use, which is why they are favored among homeowners needing efficient log splitting.

Q: What Should I Think About in Relation to a Hydraulic Pump Purchase for Log Splitter Sales?

A: In relation to a hydraulic pump purchase for log splitter sales, you’ll want to look at the flow rate, pressure specifications, and type of hydraulic fluid. The warranty and support from the manufacturer are also worth looking into, so you have peace of mind that what you purchase will fit your needs.

Q: What Happens When a Splitter Uses a Hydraulic Pump With a GPM Lower Than Recommended?

A: As a general rule, you’ll end up with slower operation and inefficiency by using a hydraulic pump with a GPM lower than recommended. Matching the pump specifications with the splitter’s requirements, especially in the case of heavy splitting, is vital to performance.