Hydraulic systems are the backbone of many modern machines, and John Deere equipment is no exception. Ensuring the proper functionality of hydraulic pumps is critical for optimizing performance, minimizing downtime, and extending the lifespan of your machinery. However, like all mechanical components, hydraulic pumps can encounter problems over time, potentially causing operational inefficiencies or complete system failure. This guide is designed to help you diagnose and address common hydraulic pump issues in John Deere equipment with precision and confidence. Whether you’re dealing with low fluid pressure, unusual noises, or erratic operation, this article will provide step-by-step instructions and valuable insights to keep your machinery running smoothly.

Identifying Common Hydraulic Pump Problems

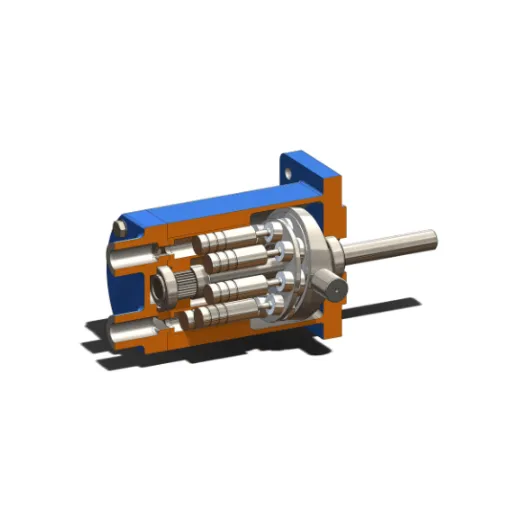

Early Signs of Hydraulic Pump Failure

Pump failure is often initiated with subtle indications that can become more and more prominent if not cared for. One of the most common signs that hydraulic pressure can be felt dropping is that the equipment works slowly or seems unresponsive as the pump tries to maintain the optimum flow rates. The operators may find problems of decreased efficiency as their tasks involve a constant hydraulic force.

At another stage, unusual noises emerge as one of the first warning signs. Whining, knocking, or grinding noises are caused by cavitation and aeration or by defective internal components such as worn-out gears and damaged seals. Such noises should never be disregarded, as they always point towards internal deficiency or lack of maintenance that can cause further damage.

Finally, overheating of the hydraulic system is a prime factor that indicates a likely pump failure. Excessive heat may be caused by conditions such as contaminated fluid, internal leakage, or even overloading. Its consequences include an impact on the pump’s performance and degradations on hydraulic oil and system components, thereby setting off a domino effect of failures. Monitoring fluid temperature and system performance regularly forms half of the battle towards preventing alignments.

Unusual Noises and Their Implications

Unusual noises occurring inside the hydraulic system are early indications of a mechanical or operational issue. It is knocking, whistling, or banging that could be signs of aeration, cavitation, or damaged internal parts. This occurs when air enters the hydraulic fluid, making it possible for bubbles to collapse after being subjected to pressure, thus producing knocking or rattling sounds. Should it go unaddressed, it will result in the oxidization of the hydraulic fluid along with increased wear upon the system’s components.

In cavitation, a high-pitched whining or humming sound comes about, causing vapor bubbles in a pump lacking in sufficient fluid supply, which reduces efficiency and causes localized intense pressures that erode pump surfaces. Grinding or scraping may arise from worn-out pump bearings, sealing surfaces, or internal components, where a failure to attend to will cause a catastrophic failure of the system.

One cannot simply ignore unusual noises-fix them to ensure system integrity. Start by checking fluid levels and confirm the use of clean and proper hydraulic oil. Check for leaks that can inject air into the system or cause fluid pressure drop. Also, inspect the pump and its components for wear or misalignment. Walking the extra mile with ordinary maintenance while keeping an ear on system sounds could well prevent an almost worse failure.

Performance Issues and Fluid Leaks

Leaking can be the root cause of most performance issues in hydraulic systems, which can diminish efficiency and service life. When a leak occurs, pressure may drop and reduce the ability to engage actuators or other components properly. Before attempting to work on a leak, it is important to locate and identify the origin-all too often, these leaks arise from seals, joints, or connections that are worn, damaged, or improperly installed.

To limit leak potential, check all seals and fittings for any visible signs of wear or cracking, and ensure that these are strongly fastened. If there are any seals compromised, replace them, making sure replacements adhere strictly to manufacturer specifications. Another reason that may speed seal failure rates is overheating, which causes hydraulic oil to break down, while viscosity-wise things become less good, so maintain checking temperatures within the standard operating range at all times.

This recording of fine fluid will prevent leaks and general performance concerns. Use the correct type of hydraulic fluid as specified by the system’s design parameters. Fluid contamination by air, water, or debris should be eradicated to the maximum with proper filtration and keeping reservoirs well-sealed. All of this will certainly not just take care of any existing leaks but also guarantee that the system will perform flawlessly and rely on time.

Common Causes of Hydraulic Pump Issues

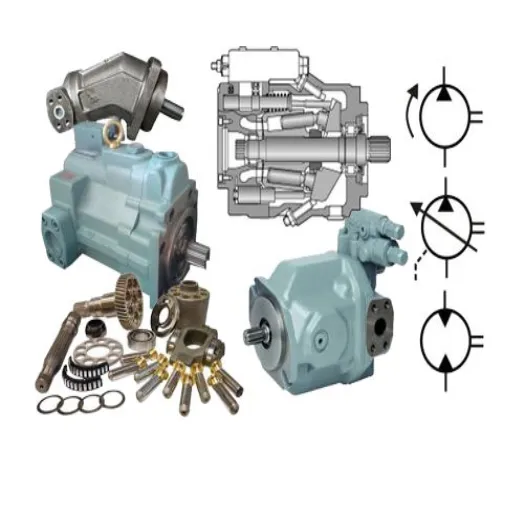

Contaminated Hydraulic Fluid

Contaminated hydraulic fluid is often responsible for a wide variety of hydraulic pump failures, thereby reducing efficiency, impairing performance, or risking total system breakdown. Contaminants enter in the form of dirt particles, water, air, or sludge through reservoirs where seals are not perfect, or due to inadequate filtration, or simply wrong maintenance procedures being adopted. While in the system, these contaminants abrade internal pump components, facilitate wear, and block fluid pathways with sludge, all functioning to thwart the pump.

Hydraulic oils have basically three types of contamination: particulate contamination, water contamination, and air contamination. Particulate contamination contains solid matter, like dust or metal shavings, that causes scratches and leaks in the hydraulic system. Water contamination occurs either due to the formation of condensation or due to some external leakage, thereby emulsifying the fluid and corroding its system components. The air contamination imparts cavitation, i.e., an occurrence of violent implosion of air bubbles within the hydraulic fluid, which, in the long run, causes huge damage to the pump surfaces and their components. Each type of contamination presents a specific problem that must be addressed before the effects can be successfully diminished.

Contamination prevention should be stringent with the filtration systems being installed, wherein both suction filters and return-line filters should be employed to trap debris. Oil sampling and fluid analysis should be performed at regular intervals to ensure monitoring of levels of contamination and to ascertain problems before these attain serious levels of concern. Also, secure sealing of the reservoir and the connections must be ensured to restrict contaminant entry. Strict maintenance schedules coupled with modern techniques in filtration and sealing solutions can mitigate almost all risks related to contaminated hydraulic fluids, thereby augmenting the working life and reliability of hydraulic pumps.

Worn-Out Seals and Their Effects

Worn-out seals give hydraulic systems a great challenge, affecting application efficiency, reliability, and safety. As the seals deteriorate, they lose their barrier properties and they start leaking fluid either internally or externally. Internal leakage reduces the efficiency of hydraulic pumps by reducing the pressure that pushes the fluid out to do the work, while external leakage lays the threat of environmental pollution and an accident.

Deteriorated seals also allow contaminants such as dirt, debris, or moisture to enter the hydraulic fluid. Contamination, in turn, speeds up component wear with increased friction, corrosion, and poor lubrication. If these situations are not handled when mature, they could result in whole system failure, downtime, and high-maintenance costs.

Seals, therefore, need to be checked regularly and replaced whenever necessary based on operational hours or signs of wear. Recent developments in material science have led to the production of seals that can resist abrasion and chemical degradation longer under extremes of temperature and pressure changes. By investing in good quality seals and employing preventive maintenance practices, the hydraulic system will run smoothly while reducing damages caused due to seal wear in the long run.

Overheating and Its Consequences

In hydraulic systems, overheating is one of the most critical factors leading to equipment failure and inefficiency. With the generation of heat, hydraulic oil is compressed and squeezed out by the circuit components, at very high pressures, thereby producing heat due to friction. Over time, this heat hurts the hydraulic fluid, degrading it to lose viscosity, causing oxidation, or causing the formation of toxic sludges. This deterioration impairs the lubrication properties, thus increasing wear on components critical for operation such as pumps, valves, seals, etc.

Besides, thermal expansion may increase at high temperatures, which may cause misalignments and reduce tolerances. Hence, system performance gets destabilized, and there is an increase in the pressure imbalance at the circuit level. For every 18°F (10°C) above the operating temperature range considered ideal, the life of hydraulic fluid was considered halved by up to 50%. Such findings further prove the utmost necessity to equip the system with the highest cooling capabilities, with heat exchangers and thermal dissipators working for the goal of perfect operating temperatures.

One could check and account for the effects of overheating by controlling fluid temperature with thermal sensors or working within the time frames stipulated in a maintenance schedule laid by the equipment manufacturer. Thus, considering heat management within the dimensions of innovative system design and using modern-day fluids having high thermal stability will allow operators to curtail heat problems in mounting and ensure reliable operation over time.

Step-by-Step Troubleshooting Tips

Conducting Initial Inspections

To begin troubleshooting effectively, initial inspections should pinpoint any external entities acting upon the equipment’s performance. A glance at the system’s essential components, like connectors, hoses, wiring, or mounts, will reveal wear, damage, or faulty connections. There must be some visible signs-whether fluid leakage, overheating melt marks, or corrosion that can direct one’s attention toward a root cause. Make use of ample light and magnification to detect extremely minute defects or hairline cracks that may have otherwise escaped attention. Recording observations will be most helpful later either in diagnostics or in maintenance logs.

Next, ensure the environmental conditions of the system allow it to function optimally. Assess whether temperature, humidity, and cleanness of the operating environment favor or go against the performance abilities of such machinery, mainly if it contains sensitive-influencing factors. Then, a review of the voltages, currents, and grounding of the power supply system is made to check against the manufacturer’s stipulated levels. Record any deviations, power fluctuations on the input, or non-compliance; such instances may present early manifestations of a wider system instability.

Lastly, compare the outcomes of the external inspections with imposing disruptions from the equipment’s past operations and maintenance record. This step in the troubleshooting process requires verifying the presence of error codes or irregularities through system logs or diagnostic software outputs. Get conversant with faults recurring throughout the equipment’s lifecycle and related trends of performance degradation and malfunctioning. The inspection data, diagnostics aligned with the manufacturer, and adherence thereto make up a logical method that quickly isolates the root cause of an issue and forestalls potential misdiagnosis, thereby paving the way for genuine remedial actions.

Using Diagnostics to Identify Issues

Diagnostics are of utmost importance in modern systems operation and maintenance since they provide micro-level insights into irregularities in performance and failure patterns. Enhanced diagnostic systems acquire and collect real-time data for analysis to detect deviations of actual performance from an accepted norm. Combining data mining and machine learning enables these systems to forecast with a high probability of accuracy the time of potential failure so that risks of catastrophic failures can be reduced by taking preemptive maintenance actions to maximize uptime and reduce operational costs.

In diagnostics, it is important that in general, tools are deployed for data acquisition and penetration at different levels into system components. For instance, onboard sensors generate telemetry data that reflect mechanical and electronic such as temperature, pressure, and voltage level. These are then assessed in comparison with predetermined thresholds and, whenever deviations are noted beyond the set thresholds, they raise flags for further analysis. The diagnostic software correlating these anomalies with past failure data plays a key role in identifying hidden defects and isolating their root causes, facilitating focused remedial actions and thereby avoiding unnecessary downtime.

In this way, remote diagnostics improved the speed of diagnosis and remediation of possible failures. The cloud-based platforms give a centralized view of diagnostic data: technicians can monitor the performance of the system from anywhere in the world. This is particularly useful for industries such as aerospace and manufacturing, wherein downtime translates directly to great loss of revenue. Whatever the processing technologies, with secure communication protocols, remote diagnostic has made these procedures more efficient and scalable, enhancing system robustness toward keeping them alive across geographically distributed sites.

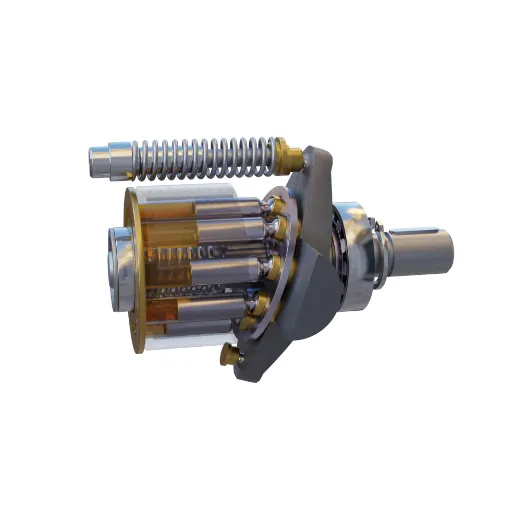

Addressing Cavitation and Pump Shaft Problems

Cavitation and pump shaft problems do pose cutter issues for fluid handling systems, requiring thorough analyses for targeted interventions. Cavitation, concerning the formation and collapse of vapor bubbles within the liquid, arises when some localities in the system pressure go low. The effects of cavitation on pump parts, particularly the impeller and casing, are severe. These impacts range from loss of efficiency and increased vibrations to operational downtime.

Pump shaft issues, such as misalignment, excessive vibrations, and mechanical fatigue, in the regulatory stability of the system. These usually arise from improper installation, unbalanced loads, or wear and tear of material as time goes by. Vibration analysis and ultrasonic testing offer advanced diagnostic testing that can detect any deviation in these areas. With predictive maintenance techniques, these problems could be addressed well, as well as employing all best practices, such as barrel alignment and ensuring correct load distribution.

By the expedited use of modern technological ways-real-time monitoring sensors and predictive maintenance software- engineers can increase system reliability. With readily available high-fidelity data and thorough performance analytics, the teams working to solve cavitation and pump shaft problems are proactive, thus associated with fewer liabilities and costly interruptions in industrial processes.

Preventative Maintenance for Hydraulic Pumps

Regular Inspection Practices

A systematically structured inspection routine is vital to maintain the efficiency of hydraulic pumps and their general longevity. The inspection must be carried out in all respects: visual inspections for leaks, damage, or wear occur on items such as seals, hoses, or fittings. Additionally, the tightness and alignment of the pump shaft must be checked to prevent premature failures.

Another essential way to keep users alert is by regularly monitoring the quality of the fluid. Hydraulic systems need clean, uncontaminated fluid to work well. Regular sampling and testing of the fluid can bring issues to light, such as contamination, a change in its viscosity, or the presence of particulates that usually indicate excessive wear or the beginning of degradation of components. Ensuring results are compared against OEM specifications is necessary to maintain the highest standard of performance in the system.

Checks on performance, namely flow rate, pressure, and temperature, should be carried out routinely. Irregular data suggests that the onset of faults like cavitation or improper lubrication urgently needs rectification. The application of suitably advanced diagnostic tools and condition monitoring systems further enhances these inspection activities and allows for the early detection of potential damages whilst lessening system downtimes.

By incorporating this highly detailed inspection approach into a preventive maintenance schedule, operational risk can be greatly lowered, thereby increasing the system life and global reliability of hydraulic pumps.

Fluid Changes and Their Importance

Nothing can overshadow the need to change the fluid regularly in hydraulic systems. Hydraulic fluid achieves vital functions in power transmission, lubrication of moving parts, dissipation of heat, and contamination control. Over time, the hydraulic fluid could weaken through the effect of thermal degradation, contamination through particulates, and chemical degradation, seriously affecting its performance, and thereby affecting the entire hydraulic system. I understand the significance of these changes and regularly ensure they are done, respecting manufacturer recommendations and adherence to a strict timeline.

Once hydraulic fluid is contaminated or degraded, it can cause increased wear in parts, reduce the efficiency of the system, cavitate, or maybe even dangerously lead to equipment failure. I believe that from my side, monitoring the condition of the fluid is the same as changing the fluid. Using modern methods, all types of fluid analyses are conducted in the tests-the viscosity, contamination level, and chemical stability, so that a change is carried out only when it is necessary, but never too late to circumvent having problems. This proactive approach will help to reduce unscheduled downtime and increase the operational reliability of the system.

A strong fluid management system, which includes regular fluid changes and thorough testing, will increase the life of a hydraulic plant while cutting maintenance expenses. I see these steps as a core part of preventive maintenance, which I consider critical in ensuring the integrity of the system. This would ensure consistency in operation, enhance the longevity of the equipment, and finally foster productivity and efficiency in rough environments.

Proper Usage Techniques to Extend Lifespan

Maintenance and usage practices constitute one of the essential features to optimize the life span of hydraulic systems. One should emphasize the use of equipment within its designed operational limits, that is within a pressure, temperature, and flow rate prescribed range. Operating beyond these limits for a while begins accelerated wear of components, then component fatigue, leading to eventual failure of the system itself.

The other consideration is that a clean hydraulic environment must always be maintained. One should install advanced filtration systems to keep the contamination levels low. Research proved that contamination contributes to around 80% of component failures in hydraulic systems. Periodically inspect or replace filters, and monitor contamination levels with particle counters, and the risk factor can be significantly reduced.

Thermal management is another aspect that prevents overheating, which would degrade hydraulic fluids, reduce metal lubrication, and finally increase metal corrosion. Cooling systems or heat exchangers would ensure thermal stability during heavy-duty operations.

Train the operators on best operating practices and early signs of system stress, so that steps can be taken to avoid long-term damage. Following the above-detailed recommendations on an ongoing basis yields maximum efficiency, minimum downtime, and extended system life for hydraulic systems.

Safety Recommendations When Working on Hydraulic Systems

Essential Safety Gear and Precautions

When performing tasks on hydraulic systems, ensuring safety is a need, especially with high-pressure fluids involved. Heavy machinery and electrical components are also threats to consider. Operators must equip themselves with the PPE (personal protective equipment) which should usually include safety goggles to safely protect the eyes in case of any splashing of fluid; heavy-duty gloves for protection from high temperatures or sharp edges; and steel-toed safety shoes to help prevent injuries in case objects fall off. Use of flame-resistant clothing is desirable if there is any risk of fire arising out of the hydraulic fluids. Making PPE use mandatory in all operations, concurrently with existing procedural guidelines, provides safety in such operations.

Maintenance has to be preceded by system shutdown in order to keep from accidentally activating any components. After proper shutdown of the hydraulic system, pressure must be released from the system through adequate release points. Also, if any maintenance is being done, lockout-tagout (LOTO) procedures must be observed to ensure that no one accidentally restarts the system. Considerable caution must be exercised while handling pressurized fluid lines, as sudden releases could pose hazards to life and equipment. Hoses, seals, and connectors must be inspected frequently to identify signs of wear or damage that may lead to failure under operating stresses.

Environmental issues should always be considered when working with hydraulic fluids. Immediate containment of spills is necessary, either using absorbents or spill kits, to minimize their impact on the environment and increase hazards in the workplace. Disposal of waste fluids must be handled according to local and international regulations, so as not to violate any environmental standards. Therefore, the observance of safety procedures, combined with updated knowledge of hydraulic systems, will greatly diminish hazards, thus making working conditions safe and efficient.

Best Practices for Handling Hydraulic Fluid

- Storage: Hydraulic fluid should be stored in clean, dry, and temperature-controlled environments to avoid contamination or degradation. Container lids must be firmly secured so as not to allow slip-in misuse, and labels must be correctly written to avoid confusion. Using an inventory management system helps in allocating the oldest stock first, thus preventing spoilage.

- Filtration and Cleanliness: Contaminants are one of the major reasons for system failure in a hydraulic system. Hence, it makes utmost sense to choose the best filters and maintain cleanliness whenever the fluid is being handled. Equipment for transferring or maintaining hydraulic fluid should be cleaned so that neither debris nor moisture finds its way into the system.

- Monitoring and Analysis: Hydraulic fluids are subjected to routine laboratory tests concerning viscosity, water content, and the number of particulates present. Particle-counters and spectrometric oil analysis are the latest methods to check the premature contamination or degradation of hydraulic fluid with the view of taking timely remedial action, thus minimizing system downtime.

- Spill Management: Spill kits and absorbent materials must be maintained within ready reach in all areas dealing with hydraulic fluids. A speedy reaction to a spill situation will lessen environmental contamination and increase workplace hazards, while employees need to be taught to follow spill cleanup protocols for the best containment and disposal of spills.

- Employee Training: Employees must be regularly trained to handle hydraulic fluids safely, recognize contamination signs, and abide by safety procedures. This also includes using protective equipment to avoid any contact with hydraulic fluid through inhalation or skin exposure.

- Disposal and Recycling: The disposal of used hydraulic fluid has to meet the standards of waste management laid down locally, nationally, or internationally. Recycling of used hydraulic fluid ought to be tried as far as practicable to save Mother Nature.

These best practices attempt to assist operations and technicians in preserving system efficacy while nullifying threats to equipment, personnel, and the environment.

Emergency Procedures in Case of Failure

Preventing hydraulic system breakdowns because of an emergency protocol requires risk mitigation and measures to restore operational functionality. Once the system failure is observed, all system operations must immediately stop to prevent further damage or hazard escalation. Operators should proceed with emergency power isolation measures to ensure that all sources of electrical and hydraulic energy are removed.

Next, people need to be sent to look at the failure site in detail to ascertain whether the components, such as valves, seals, and pumps, are damaged or worn out. The whole surrounding area must be checked for any fluid leakage, as hydraulic fluids may be flammable and pose environmental or safety risks. Where necessary, absorption material and containment kits should be applied to absorb or contain the fluid spilled.

Emergency repairs should be designed to re-establish containment while addressing those interruptions of critical system performance. This will typically embrace the replacement of impaired components or the resealing of leaking interfaces. Technicians have to be very systematic in documenting failure conditions and repair procedures so that the root cause analysis process can be well aided, and recurrence prevented. Also, all work shall be undertaken by observing all safety standards, including OSHA and ANSI, to ensure the safety of the workers and equipment.

Such detailed emergency procedures help organizations in decreasing downtime, prevent system damage due to a series of unnatural events, and maintaining operational safety standards.

Frequently Asked Questions (FAQ)

Q: What are common hydraulic problems in John Deere tractors?

A: Common hydraulic problems in John Deere tractors include low hydraulic fluid levels, clogged filters, damaged hoses, and issues with the control valve. Regular maintenance and proper John Deere hydraulic pump troubleshooting can help identify these issues early.

Q: How can I check the hydraulic fluid level in my John Deere tractor?

A: To check the hydraulic fluid level in your John Deere tractor, locate the hydraulic fluid reservoir and inspect the dipstick or sight glass. Ensure that the fluid is at the recommended level as indicated in the manual to avoid potential problems during John Deere hydraulic pump troubleshooting.

Q: What should I do if my hydraulic pump isn’t delivering adequate pressure?

A: If your hydraulic pump isn’t delivering adequate pressure, check for air in the system, verify the oil level, and inspect the relief valve. Low pressure may indicate several factors, including clogged filters or a failing main hydraulic pump.

Q: How often should I replace hydraulic filters in my John Deere tractor?

A: It is recommended to replace hydraulic filters in your John Deere tractor regularly, typically every 400 hours of operation or as specified in the owner’s manual. This ensures proper flow of fluid and prevents hydraulic issues.

Q: What could a drop in hydraulic flow indicate?

A: A drop in hydraulic flow may indicate a blockage, such as clogged filters or damaged hoses. It can also mean that the hydraulic pump on a John Deere is not functioning correctly, which requires immediate John Deere hydraulic pump troubleshooting.

Q: How do I troubleshoot low hydraulic fluid levels?

A: To troubleshoot low hydraulic fluid levels, start by checking the oil level in the reservoir. If the levels are low, add the appropriate hydraulic fluid as specified in the manual. Ensure there are no leaks or damaged hoses that may be causing fluid loss.

Q: What are the signs that my hydraulic pump may need to be replaced?

A: Signs that your hydraulic pump may need to be replaced include unusual noises, low-pressure delivery, or the pump not receiving enough oil. Additionally, check for signs of wear inside the pump, which may indicate the need for replacement.

Q: How can I manually override the hydraulic system?

A: To manually override the hydraulic system, locate the manual override valve as outlined in the tractor’s manual. Engaging this valve can help troubleshoot hydraulic issues temporarily, allowing for further inspection of the system.

Q: Can air in the hydraulic system cause issues?

A: Yes, air in the hydraulic system can cause significant issues, including erratic hydraulic performance and decreased pressure levels. Proper John Deere hydraulic pump troubleshooting should include checking for air and bleeding the system if necessary.

Q: What maintenance steps can prevent common hydraulic issues?

A: Regular maintenance steps to prevent common hydraulic issues include checking the oil and hydraulic fluid levels, replacing hydraulic filters, and inspecting hoses for damage. Following the guidelines in the troubleshooting guide can help maintain the optimal performance of your John Deere hydraulic pump.