Efficient fluid movement is a fundamental aspect of countless industrial and engineering applications, and at the heart of this process lies the hydraulic power of a pump. But what exactly does hydraulic power mean, and why is understanding it key to optimizing performance? This article dives into the mechanics behind hydraulic power, exploring how pumps convert mechanical energy into the flow of fluid, and more importantly, how their efficiency can be calculated and improved. Whether you’re an engineer seeking to enhance operational outcomes or a curious professional aiming to deepen your technical knowledge, this guide will provide a clear foundation for mastering the essentials of hydraulic power and its practical implications.

Factors Influencing Pump Efficiency

Impact of Fluid Viscosity on Hydraulic Power

If a presentation of fluid properties is to be considered in hydraulic systems and subsystems, the role played by viscosity is of paramount importance in the working of any system. Viscosity can be defined as the cohesion of a fluid that resists its movement from one location to another. Energy transfer within the system is influenced by the magnitude of viscosity to which the fluids are subjected. High-viscosity fluids need a lot of energy to be moved, and during this movement, the internal friction goes up, which reduces the whole system’s efficiency. These are fluids that may cause the wrong quantity of lubricants to be supplied to protect and thus grease or wear the parts of the pump. Thus, several types of viscosity-related interferences upset the pump.

The efficiency of a hydraulic pump is largely affected by the viscosity characteristics of the working fluid. The higher the viscosity, the more force the pump must apply to overcome resistance, exhausting more energy and producing a large amount of heat. This heat, therefore, must be taken care of to avoid thermal inefficiencies within the system. Conversely, low-viscosity fluids may provide insufficient sealing in the pumps, thereby decreasing volumetric efficiency and leading to leakage or cavitation that, in turn, diminishes system performance.

The hydraulic power will only be optimized if the fluid selected for use has a viscosity appropriate for the operational temperature range and system design. A well-matched viscosity means efficient energy transfer, adequate lubrication, and an insignificant amount of mechanical loss. Understanding how viscosity affects performance and compensating for it provides better efficiency, longer machine life, and reduced maintenance costs. This serves as one of the fundamental principles in the design and maintenance of hydraulic systems.

Temperature’s Effect on Pump Performance

Temperature has a direct impact on pump performance through fluid viscosity, which is highly relevant in hydraulic work. Increasing temperatures usually mean decreasing viscosity, hence thinner fluids aged by too little lubrication, internal leakage, and poor volumetric efficiency within the pump. On the opposite side, when the temperature drops, fluid viscosity tends to increase and makes the fluid thick, thus creating more losses within the system owing to resistance and strain applied to pump components. Both situations deteriorate the system performance if not contained in time.

Excess heat may turn thermal expansion of pump components into a reality, thus disturbing critical tolerances, speeding up wear, and possibly leading to system failure. The higher temperature may also promote fluid oxidation or breakdown of additives, thus compromising the hydraulic fluid’s performance and stability. An effective cooling system designed for the particular need and appropriate fluid choices, regular maintenance can temper temperature-induced inefficiencies.

Designing against temperature effects necessitates the use of heat exchangers, temperature-guarded fluid tanks, and thermostatic control. By making sure that the average operating temperature is kept within its design performance range, the related risk of viscosity change and thermal stress are alleviated. Controlling temperature is the fundament to prolonged equipment life, energy efficiency, and unexpected breakdown.

System Pressure and Its Role in Efficiency

System pressure is a vital factor, significantly influencing the efficiency, lifespan, and trustworthy operation of any fluid-driven system. Pressure being a direct factor that is adjusted for energizing pumps, compressors, and so on, is energy wasted when pressure heads are too high, as heat dissipation and mechanical stress against implications in bonds, seals, and system elements. On the contrary, lower pressure levels will bring down the level of fluid flow to the system, thereby creating cavitation and system instability. The need here is to maintain the range of pressure suitable to the operational requirements and the capacity for which the system is designed.

A pressure system that is fine-tuned to achieve optimal energy transfer efficiency is the best. For example, in a hydraulic system, the pressure should be managed to deliver the force required for operations without damaging pressure peaks being applied against the components. Overdependence on high-pressure settings without providing adequate design compensations can result in the early onset of material fatigue, resulting in wear-and-tear or stressing of components to where constant maintenance or replacement is needed. Such systems may be made more efficient through dynamic regulation of performance by load distribution with control arrangements such as pressure relief valves and variable frequency drives.

Having IoT-enabled platforms communicating with real-time pressure sensors allows engineering personnel to track any deviation from the normal range of pressure for take corrective measures swiftly. In case of such corrective measures, that may have led to system downtimes, the pressure control system would entail a heavy cost; largely, it preserves pressure levels, ensuring minimal wear and tear of the components affected. The use of modern techniques in pressure control, therefore, found application in furthering the sustainability of systems in line with industrial energy-saving considerations.

Applications of Hydraulic Pumps

Hydraulic Pumps in Manufacturing

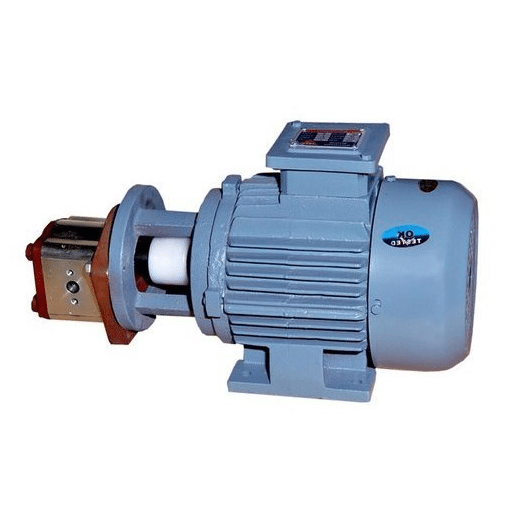

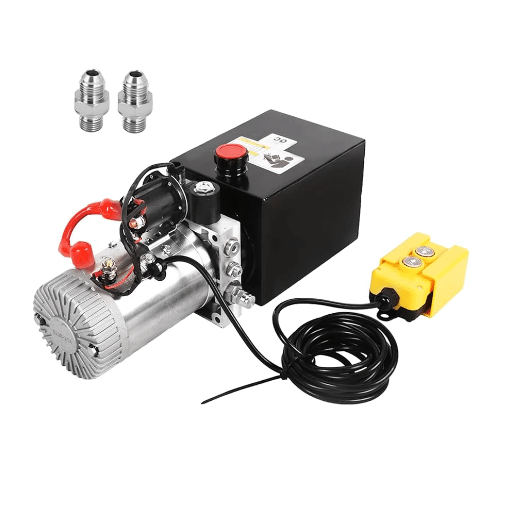

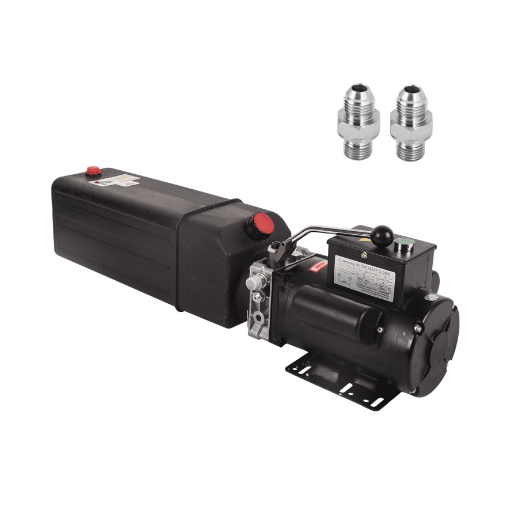

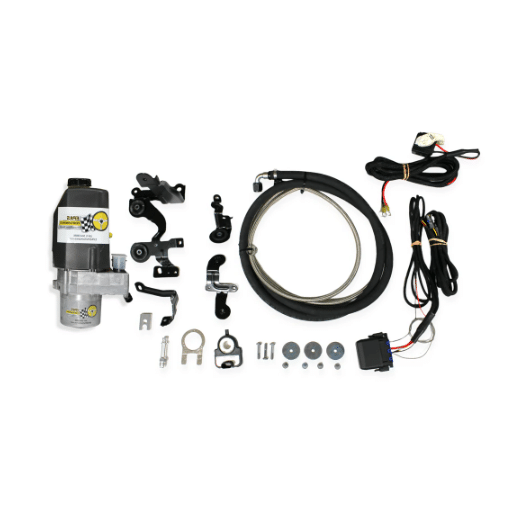

Hydraulic pumps are vital for the manufacturing process since they power machines that need finely controlled and reliable force transmission. They also run the controlled movement of fluids being worked on under high pressure to perform certain lifting, pressing, or machining jobs. Gear pumps, vane pumps, or piston pumps find their places commonly in the manufacturing industries, each working for certain application needs based on flow rate, pressure range, and efficiency requirements.

For instance, piston pumps are frequently used in heavy manufacturing processes demanding high-pressure output and performance, such as metal forming and plastic injection molding. This design ensures constant pressure in varying load situations, where precision and durability are paramount. In contrast, gear pumps rank among the simplest types in construction but somehow also rugged and therefore suitable in medium-pressure scenarios like conveyor systems or automated assembly equipment.

Modern hydraulic pump technology has ushered in even higher uplift in efficiency and reliability for manufacturing settings. Features like variable displacement will save energy by changing fluid output depending on demand. At the same time, smart sensors provide real-time monitoring to detect wear, fluid leaks, or pressure variations and inconsistencies before the equipment fails. By making use of such innovations, manufacturers may ensure the best uptime, lowest energy consumption, and productivity against all odds.

Role of Hydraulic Pumps in Agriculture

In modern agricultural practices, hydraulic pumps increase efficiency and operational capacity. Since they convert mechanical energy into hydraulic energy, they can power various types of machinery and equipment in this sector. Here are five main applications of hydraulic pumps in agriculture:

- Irrigation Systems: Modern hydraulic pumps regulate the pressure and water flow in irrigation systems such as center pivot and drip irrigation, allowing for precise water management. This condition aids in better crop yields and conserves water resources.

- Tractors and Harvesters: Modern tractors and harvesters have several functions hydraulically operated that including lifting, steering, and working of attachments. These systems distribute power optimally, which favors working efficiency and minimizes manual effort.

- Planting Equipment: Hydraulic pumps operate the mechanisms of seed drills and planters, which place the seeds uniformly and are vital for crop germination and growth.

- Livestock Farming Equipment: Hydraulic systems equip feed mixers, manure spreaders, and automated gates to ensure high productivity with less manual input in livestock farming.

- Farm Machinery Attachments: Hydraulic pumps perform actions such as lifting, tilting, and spraying for various attachments, including loaders, plows, and sprayers. This allows an agricultural vehicle to be highly versatile, meaning a single machine can be used for multiple operations very effectively.

The operation of hydraulic pumps enables farmers to optimize performance, conserve energy, and manage resources for sustainable farming with high-yield outputs.

Construction and Hydraulic Power: Key Applications

The efficient and effective handling of nearly innumerable tasks comes with hydraulic power systems. These systems provide high force-to-weight ratios combined with accurate control to handle very heavy loads and precise operations. With hydraulics, construction machines become faster, suffer less downtime, and are safer. Let’s look at five areas where hydraulic power is crucial in construction:

- Excavators and Diggers: Hydraulic pressure moves the boom, arm, and bucket of an excavator, so an operator can dig, lift, and trench with precision. Huge forces from hydraulic pumps and cylinders are needed for heavy-duty excavation, which involves stripping material from a construction site in the most efficient manner.

- Cranes and Hoists: The modern-day crane works on hydraulic power to lift, lower, and move heavy loads at construction sites. Hydraulic actuators provide smooth and controlled movements, while the compact design of the system offers increased maneuverability within restricted spaces.

- Earthmovers and Bulldozers: Hydraulic-driven systems within the bulldozers provide precision to the lifting and tilting movements of the blade, for the efficient clearing of the land, grading, and pushing of the soil. With the reliability of hydraulics, these machines can work consistently under harsh conditions.

- Concrete Pumps: Concrete pumps utilize the hydraulic force to aid in the placement and movement of concrete. This hydraulic pressure acts to pump concrete through long pipelines to reach difficult-to-access areas on construction sites, ensuring an even and reliable placement of concrete.

- Pile Drivers: These pile drivers play an essential role in foundation works by driving piles deep into the ground to give support to buildings and structures. Hydraulic systems regulate hammering force accordingly to attain accuracy and effectiveness while controlling vibrations and major minimization to environmental impact.

From the above uses, the importance of hydraulic systems in modern construction, where efficiency, reliability, and precision are paramount, is seen.

Proper System Design for Enhanced Efficiency

Proper hydraulic system design contributes to maximizing efficiency, reliability, and operational longevity in construction applications. Good design starts with proper analysis of load requirements, system pressures, and flow rates so that the components of the system can be sized for the operational conditions without unnecessary energy consumption. Choosing high-grade materials, together with precision-built components, is paramount to minimize wear and maximize durability-whether pumps, valves, or actuators.

Advanced modeling techniques and simulation software are used during the design to predict the system’s behavior during operational conditions or scenarios. This knowledge allows engineers to determine inefficiencies or potential failure issues before the physical implementation of the system. The design efficiency is increased even further by incorporating real-time monitoring systems consisting of sensors and IoT connectivity, providing vital performance data that informs predictive maintenance strategies.

This, in turn, brings much-needed appreciation of the design’s working potentials and pitfalls upon implementation. Consideration has to be given to the routing of the hydraulic lines as well as the selection of filtration systems to combine minimal pressure drops, contamination avoidance, and fluid-flow consistency. Another key energy-efficient and environment-friendly modern hydraulic system feature is that variable displacement pumps and energy recovery systems are largely implemented.

Thus, the hydraulic systems designed based on these principles would comprise high design efficiency, minimum downtime, and guarantee sustainable, precise performance by the exact requirements of the modern construction project.

Optimized System Design: Elevating Hydraulic Pump Efficiency

Advanced Technologies for Pump Optimization

Pump system optimization has become more technologically driven, integrating data-driven algorithms, new-age materials, and manufacturing processes. One such innovation regards smart sensors and IoT integration. These sensors monitor variables such as flow rates, pressure, and temperature at all times, feeding real-time data to a central system for analysis. Operators can thus address inefficiencies or impending failures proactively, avoiding downtime considerably and allowing for overall system performance enhancement.

Another significant innovation helping pump optimization is provided by CFD simulations. Engineers use CFD to model flow characteristics within pump designs and to search for turbulence or inefficient areas prior to production. Such simulative procedures combine with advanced manufacturing procedures, like additive manufacturing, to allow pump components to be created with precision and in an energy-efficient manner.

The glories of energy recuperation systems are being recognized more presently, especially where utmost minimization of energy loss is sought. Regenerative turbine or variable speed drive technologies help reverse the energy flow for recapturing application, thereby enhancing the operational efficiency. Innovatively, with the aid of machine learning and artificial intelligence, pump optimizations would start evolving based on intelligent adaptation of pump performance vis-à-vis predictive analytics and systems behaviors. Together, these enhancements would work toward providing maximum efficiency and sustainability within hydraulic and fluid control systems.

Challenges and Solutions in Hydraulic Power Systems

Addressing Energy Losses in Hydraulic Systems

The primary sources of hydraulic power losses are fluid flow inefficiency, friction, and heat generation. These losses are further categorized into pressure and mechanical losses. Pressure losses occur in turbulent flows that resist motion through hydraulic lines, while mechanical losses arise from friction within the mutual interactions of components like pumps, motors, and valves. These factors largely diminish system efficiency and a subsequent increase in energy usage along with operational costs.

Several methods can be employed to lessen these losses. Properly matching hydraulic fluid viscosity with the working temperature and employing state-of-the-art filtration systems reduces losses caused by fluid friction and contamination. Newer hydraulic components have been engineered with precision to minimize internal leakage and mechanical inefficiencies. Variable speed drives (VSDs) can also be a solution as they allow the pump operation at speeds required by the demand, avoiding the operation of pumps at standstill conditions. Lastly, an efficient hydraulic circuit design with as few bends and fittings as possible reduces pressure drops and turbulence, allowing the system to operate more efficiently.

These methods, coupled with sophisticated diagnostic tools and prediction-oriented maintenance technologies, ensure enhanced energy efficiency and extended component life for hydraulic components. Rigorous system monitoring can shed light on areas of energy loss for targeted intervention and fine-tuning of system performance. This comprehensive approach guarantees that hydraulic power systems will be cost-effective and sustainable.

Mitigating Equipment Wear and Tear

Effective mitigation of wear of equipment, therefore, entails a multifaceted approach with advanced materials, precision engineering, and proactive maintenance strategies as its components. Wear-resistant materials can be used, like high-strength alloys or composite coatings, to lessen surface deterioration due to friction, corrosion, or thermal stresses. On top of that, precision-engineering methodologies can be employed. Such methodologies encourage the use of manufacturing tolerances and component geometry, thereby reducing stress concentration, which may become a cause of early failure.

Condition-based monitoring (CBM) systems are used to spot indications of wear before they develop into a critical problem. A CBM system that integrates sensors and real-time data analytics to monitor variables such as vibrations, temperatures, and pressures for anomalies that could be signals of excessive wear. Then comes lubrication management; an effective lubrication management approach can greatly reduce friction by ensuring that mechanical components slip against one another smoothly with proper usage of lubricants.

When combined with predictive maintenance technologies, such as machine learning algorithms that crunch past and live data for patterns, forecasting of wear behavior becomes pertinent, thus enabling the scheduling of maintenance activities on a quotation basis. This mode of operation prolongs the operational life of the equipment and curtails unplanned downtimes and maintenance costs. With such detailed planning and target approaches, these are the things that guarantee the utmost highest level of equipment reliability and equipment longevity.

Emerging Trends in Hydraulic Pump Technology

Integration of IoT for Real-Time Monitoring

The Internet of Things (IoT) has brought a sea change in real-time monitoring and equipment management. Hydraulic systems today are embedded with sensor networks and IoT devices to let operators continuously watch key parameters such as pressure, temperature, flow rate, vibration, etc. At any time, the approach of data collection from the field alerts the operator towards any deviation from ideal operating conditions so that the concerned person can decide about proactiveness and take corrective action immediately.

In addition, IoT services serve predictive maintenance by analyzing historical data trends coupled with the real-time trends while making use of sophisticated algorithms and machine learning, predicting component failure or degradation with more accuracy, thereby lessening sudden downtimes. Being fully connected through various types of infrastructures, IoT allows an uninterrupted flow of data from the field to centralized systems or cloud platforms, from where engineers and stakeholders located in different locations can access it.

By blending IoT with innovations that are new, hydraulic systems are poised to become more efficient, reliable, and long-lived. Transitioning from manual inspections and reactive maintenance to data-driven maintenance optimizes operational costs and boosts system performance. This future-oriented stance firmly establishes the need for embracing IoT made solutions in hydraulic pump technology.

Advancements in Energy-Efficient Pump Designs

Energy-efficient pump designs have undergone drastic changes, integrating newer technologies to save power yet ensuring that the performance remains high. One such improvement is the development of variable-frequency drives, or VFDs, wherein the motor speed is varied as per the real-time demand of the pump so that energy is not wasted during low-load-zone operation. Advanced impeller designs, such as those that have been optimized through 3D CFD, minimize turbulence and friction loss and therefore maximize hydraulic efficiency.

Materials science also plays a crucial role by allowing the inclusion of lightweight, corrosion-resistant materials that reduce wear and extend the working life of pumps. Besides, the adoption of magnetic coupling mechanisms has been increasing to eliminate shaft seals and leakage, hence pumping away mechanical losses and improving energy efficiency.

There has been an observable increase in attention toward permanent magnet synchronous motors (PMSMs) for pump systems, as they offer higher energy conversion efficiencies over traditional induction motors. Modern pumps, alongside these, incorporate intelligent control systems utilizing machine learning algorithms for self-diagnosis of inefficiencies and autonomously optimizing performance, as a result of which, pumps now satisfy strict energy codes and regulations, reduce operational costs, and support global sustainability agendas through a smaller carbon footprint.

Use of Eco-Friendly Hydraulic Fluids

Environmental hydraulic fluids are developed keeping in mind the various ways in which equipment may harm the environment during its operation, maintenance, and fluid disposal. Mostly, these fluids are made from biodegradable, nontoxic base oils-that is, from vegetable oils or synthetic esters-and enhanced with additives to provide performance on par with usual mineral oils. Their benefit is greatly reduced environmental damage when accidentally leaked or spilled. However, they naturally degrade in the environment and cause less contamination to soil and water systems. When selecting a green hydraulic fluid, it is worth considering properties such as thermal stability, oxidation resistance, and lubricity to suit the application and fulfill system requirements at maximum efficiency.

The switch to eco-friendly hydraulic fluids is often seen as linked to environmental and corporate compliance. Agriculture, marine, forestry, and construction industries have led in the adoption of biodegradable fluids because the hydraulic equipment runs in sensitive ecosystems. Additionally, lifecycle cost analysis indicates that although the expense of eco-friendly fluids might be higher from the outlay standpoint, their further service life, together with less environmental liability and lesser need for clean-up, generally favors them economically in the longer run.

Technology, however, is now allowing for the design of green fluids that will still maintain the life of the system and keep wear at a minimum in intense conditions. For example, these modern formulations promote excellent viscosity performance over a broad temperature range, thus enhancingthe efficiency and productivity of the system. In addition, the incorporation of advanced anti-wear additives and oxidation inhibitors ameliorates earlier concerns relating to fluid degradation and mechanical wear. Thus, bridging operation and environmental promotion with eco-friendly hydraulic fluids is a tremendous leap toward sustainable industrial practices, ensuring environmental preservation and long-term operational viability.

Frequently Asked Questions (FAQ)

Q: What is the hydraulic power of a pump?

A: The hydraulic power of a pump refers to the energy that is transmitted to the fluid by the pump. It is determined by the flow rate and the working pressure of the hydraulic system, and is typically measured in kilowatts (kw) or horsepower (hp).

Q: How is the pump power calculation performed?

A: The pump power calculation can be performed using the formula: Power (kw) = Flow Rate (L/min) x Working Pressure (bar) / 600. This calculation helps determine the required power to achieve optimal performance in hydraulic systems.

Q: What factors affect the efficiency of the pump?

A: Several factors affect the efficiency of the pump, including the design of the pump, the type of fluid being pumped, the flow rate, mechanical losses, and the power rating of the motor driving the pump. Ensuring proper maintenance can also enhance the pump’s efficiency and performance.

Q: What is the role of the pump shaft in hydraulic systems?

A: The pump shaft transmits mechanical power from the motor to the pump impeller or piston, enabling the rotation of the pump. The shaft design is critical in determining the overall efficiency and longevity of the pump.

Q: How do you measure the volumetric efficiency of the pump?

A: Volumetric efficiency of the pump is measured by comparing the actual flow rate of the pump to the theoretical flow rate. It is calculated as a percentage and indicates how effectively the pump transmits hydraulic energy to the fluid.

Q: What tools are available for pump power calculations?

A: There are various pump power calculators available online that can help users determine the hydraulic power required for their specific applications. These calculators take into account factors such as flow rate, working pressure, and efficiency.

Q: What is the significance of hydraulic and shaft power?

A: Hydraulic power refers to the energy transmitted to the fluid, while shaft power is the mechanical energy supplied to the pump. Understanding both is essential for optimizing the performance of hydraulic systems and ensuring efficient energy consumption.

Q: How does the size of the pump affect its performance?

A: The size of the pump plays a crucial role in determining its flow rate, power requirements, and efficiency. A properly sized pump ensures that the hydraulic system operates within its optimal parameters, minimizing energy consumption and maintenance costs.

Q: What types of pumps are commonly used in hydraulic systems?

A: Common types of pumps used in hydraulic systems include piston pumps, vane pumps, and gear pumps. Each type has unique characteristics that make it suitable for specific applications in various industries, including aerospace and manufacturing.

Q: How can one improve the mechanical efficiency of a pump?

A: To improve the mechanical efficiency of a pump, one can optimize the design, ensure proper alignment of the motor and pump, regularly maintain components, and select the appropriate type of pump for the specific application. This helps in reducing energy losses and enhances overall performance.