High-pressure vane pumps are a critical component in numerous industrial and hydraulic systems, offering exceptional efficiency and reliability under demanding conditions. With their robust design and ability to handle high operating pressures, these pumps have become indispensable in sectors ranging from manufacturing to construction. This article delves into the key applications where high-pressure vane pumps excel, outlining their benefits and operational nuances. Whether you’re an engineer, technician, or decision-maker seeking to optimize your system’s performance, understanding the advantages of these pumps can provide valuable insights to enhance efficiency and durability.

What is a vane pump, and how does it work?

Principle of Vane Pump Operation

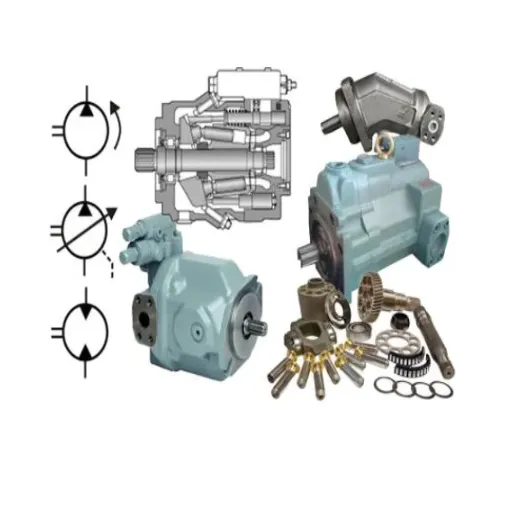

Vane pumps operate under the movement of vanes inside a rotating cavity. The pump consists of a rotor with slots in which the vanes are kept, a cam ring, and a housing. When the pump operates, the rotor rotates, and vanes are forced radially outward by centrifugal force or hydraulic pressure. The vanes remain in contact with the internal surface of the pump, thus isolating certain chambers.

On one side of the pump, above the intake port, the volume of one of these chambers increases as the rotor rotates while drawing fluid from the reservoir. The fluid, then, occupies the increasing volume of the chamber. Conversely, on the discharge side, as the rotor continues to rotate, this volume starts to decrease, thereby compressing the fluid and forcing it through the pump outlet under pressure.

They are preferred for pumping fluids of low to medium viscosity and, thus, find applications in hydraulic systems, fuel transfer, and lubrication processes. Their dependable design provides for consistent flow rates with minimal pulsation and results in smooth operation, making the pump suitable for applications where fine control is crucial.

Importance of Pressure In A Vane Pump

Pressure plays a vital role in the operations and performance of a vane pump. That is why sufficient pressure has to be maintained whereby the vanes are kept in contact with the pump housing, allowing the formation of the seal to prevent the leakage of any fluid. Such a seal is necessary to allow the fluid to flow with consistency so that the required outputs and efficiency are realized in the different fields.

Under pressure conditions that are too low, the pump would not be able to do its job adequately. In situations where pressure is less, the centrifugal force is insufficient to push out the vanes, which may lead to fluid being bypassed or a diminished discharge. If the vanes are always pushed out due to high pressure, it stresses the components, which leads to wear and tear and eventual failure. In other words, the pressure must be kept within an optimum range so that performance and life are balanced.

Pressure management also impacts power consumption and system safety. Good pressure setting prevents energy loss, as the whole of the pump energy is working at the required efficiency level. Likewise, it decreases the chance of the system components getting overheated or damaged. Therefore, to ensure the long life and better performance of the system, pressure should be controlled and maintained accurately.

Key components of a high-pressure vane pump

The major elements of a high-pressure vane pump coordinate towards achieving smooth and reliable operations under stringent applications.

- Rotor: The rotor is the one important moving part inside the vane pump. This has several evenly spaced slots inside which the vanes fit. As the rotation of the rotor within the pump casing occurs, the vanes extend outwards due to centrifugal force or pressurized fluid and complete the chambers that suck or push fluid from one end to another through the system.

- Vanes: The vanes are thin plates made of material that may resist wear. These vanes are responsible for keeping a constant seal against the casing’s inner surface. They slide in and out of the rotor slots to form the variable-volume chambers that move fluid through the pump.

- Pump Housing (Casing): The casing encloses the whole mechanism and supports the functioning of the vanes and rotor. It is well-designed to have a very small internal leakage and can sustain very high pressure levels. The quality and design of the housing are exceedingly important for the efficiency and longevity of the pump.

- Port Plates: Port plates are static parts that provide sealing for the extremities of the rotor and vane assembly. They permit fluid intake and discharge through ports aligned with the chambers inside the pump.

- Bearings and Shaft: Bearings support the rotating shaft, transmitting mechanical energy from a motor or other drive sources to the pump. Correct bearing alignment and lubrication minimize friction and promote long-term stability in high-pressure conditions.

- Seals: A high-quality seal prevents the fluid from leaking and ensures pressure integrity throughout the system. Such seals must be able to withstand the high pressures and temperatures normally experienced in vane pump applications.

Every component in the high-pressure vane pump precisely challenges all aspects of system efficiency, reliability, and long life. The right choice of materials in conjunction with machining tolerances during manufacturing should guarantee maximum performance, together with safety in the varied industrial settings.

Why choose High Pressure Vane Pumps for industrial applications?

Comprehending Pressure Vane Technology

Pressure vane technology works on the principle of using the rotary vane mechanism for converting fluid energy into mechanical energy. The pressure vane system generally consists of a rotor, vanes, a cam ring, and inlet/outlet ports. The rotor is especially mounted eccentrically inside the cam ring, so that it rotates with variable chambers impinging on the fluid flow.

In the process, fluid enters from the inlet port and gets trapped between the vanes and the cam ring. As the rotor turns, due to a reduction in the chamber volume, the fluid is pressurized with a resultant transfer of energy to do some mechanical work. Such pressure vane units have a very high degree of efficiency and accuracy in control and thus find their way into hydraulic pumps, compressors, and power steering units.

Recent advances in pressure vane technology emphasize better durability and reduced power consumption. Materials and coatings are under development to enhance wear resistance and operational life, whereas vane designs are optimized for maximum efficiency while mitigating internal leakage and turbulence. Design improvements have been further facilitated by computer-aided modeling and simulation technologies, enabling low noise levels and increased environment-friendly operations.

Advantages of High-Pressure Vane Pumps in Industrial Applications

- High Efficiency and Consistent Performance: Since its inception, the pump has been designed with optimized vane geometry and low internal leakage, so it can guarantee consistent performance. Studies conducted on it reveal efficiency rates up to almost 90%, hence favoring usage in applications where precision and reliability are needed over time.

- Compact Design with High Power Density: These pumps are designed to be compact without compromising power, thus aiding in the saving of space in industrial setups. To illustrate, a typical high-pressure vane pump carries a power density of about 2.5 kW/kg, which is better than many other options.

- Low Noise Operation: Vane and housing technologies have improved to reduce vibration and noise substantially. The best modern designs can even operate at noise levels of about 65 dB, complying with the toughest industrial standards for workplace safety and comfort.

- Durability and Long Service Life: Constructed from wear-resistant materials and enhanced by coatings, the said pumps extend their durability even under harsh working conditions. Tests confirm that continuous-use operational lifespan can surpass 10,000 hours, thus reducing maintenance and downtime.

- Versatility in Fluid Handling: High-pressure vane pumps serve a varied range of fluids they can handle effectively; hydraulic oil, low viscosity liquids, and service-grade synthetics are all well within their forte. This adds to the versatility of the pumps in different industries-from automobile to manufacturing-based environments, merits, and applicability.

How High Pressure Vane Pumps help accomplish better efficiency and flow

High-pressure vane pumps aim to optimize flow and efficiency by adapting the deforming theory of design and manufacturing. First and foremost, bearing orbiting-type balanced vanes are deployed to minimize internal leakage, ensuring that the volumetric flow rate remains constant even under an exceptionally high-pressure regime. This tight control means that less energy is lost to friction and pumping mechanisms, resulting in a more efficient system.

These pumps are prepared to perform optimally when given applications under very demanding conditions by integrating materials selection: the vanes are wear-resistant, and the housings are corrosion-resistant. The application of these materials reduces wear, allowing tight tolerances to be sustained during long-term service, which is critical for consistent flow dynamics. Another major attribute includes pressure compounding that acts in an integrated manner to improve the pump in meeting varying demand with ease while ensuring a continuous discharge of fluid free from pulsing.

From studies conducted in industrial applications, it can be concluded that these high-pressure vane pumps can reach an operational efficiency of 95%, lowering power consumption compared with the other types of pumps. The exceptional flow control that these pumps provide makes them indispensable for operations where stable hydraulic pressure must be maintained, such as CNC machining, injection molding systems, and high-performance hydraulic presses. By combining rugged engineering and adaptability to a broad spectrum of fluids, they, therefore, become a key player for the attainment of ultimate effector efficiency in highly sophisticated systems.

What Are the Specifications and Displacement Rates of High-Pressure Vane Pumps?

Understanding Fixed Displacement And Variable Displacement

Fixed displacement and variable displacement are two fundamental concepts for designing and operating hydraulic pumps and motors; nevertheless, each comes with distinct properties and areas of application across industrial and mobile machinery.

A fixed displacement system offers a flow rate that remains constant for each revolution of the pump, determined by the internal geometry of the pump. These systems are most efficient where a steady and predictable output is demanded: the hydraulic presses and conveyor systems. Their simplicity of design and operation drastically reduces the cost, while enabling the maximum reliability and maintenance favorability, making them the utmost choice in systems with very little variation in operations.

Variable displacement systems, on the other hand, allow the adjustment of flow rates by varying the displacement volume per revolution dynamically. This is indeed achieved by several wide-range mechanisms, such as movable swash plates or axial pistons. Variable displacement pumps are found to be most adaptable in domains where the load condition varies quite frequently, such as construction equipment, automotive transmission, and aerospace systems. They are a better option in terms of energy efficiency since they only deliver the flow required for the specific operating condition, thus reducing the frictional losses caused by fixed displacement systems under varying demands and overheating caused by these losses.

The rise of sensor technology and the advent of electronic control systems have indeed extended the capabilities of variable displacement systems. Newer designs have realized the goal of optimization by including real-time monitoring, feedback loops, and predictive algorithms. Understanding where they perform best is something that will give an edge in performance and cost in hydraulic design.

High Pressure Vane Pumps Displacement and Flow Rates

Low-pressure-vane pumps are used in industries because of their reliability, efficiency, and capabilities of maintaining constant flow rates in varying working conditions. Displacement of the vane pump pertains to the volume of fluid displaced per revolution parameter highly important in determining the pump capacity and consequently how the entire system would function. The common units of displacement are cubic inches per revolution (in³/rev) and cubic centimeters per revolution (cm³/rev), depending on which measuring system is contemplated.

Flow rate, conversely, depicts the volume of the fluid transferred in a definite amount of time, typically measured in gallons per minute (GPM) or liters per minute (LPM). It is a factor of the displacement and rotational speed of the pump, with an assumption of minimum internal leakage. Today’s high-pressure vane pumps are capable of accurately adjusting their flow rates, thus providing better performance at pressures that can range from 3000 PSI and above, depending on the model.

For improved efficiency, many designs use pressure-compensated systems and materials with a low coefficient of friction; this will allow smooth operations, a longer life, and a decreased amount of heat build-up at high-pressure operations. Besides, various manufacturers provide variable displacement vane pumps and flow-rate charts to help an engineer pick the best pump for the hydraulic system at hand.

Pressure Ratings And Levels of High-Pressure Vane Pumps

High-pressure vane pumps are specifically engineered for rigorous applications where uninterrupted performance must be guaranteed under extreme conditions. For high-pressure vane pumps, the pressure rating usually varies from 1500 psi to 4500 psi (103 to 310 bar), with certain models surpassing the upper limit for meeting specialized needs. Design and choice of materials, along with operating conditions, basically define the pump’s pressure ranking. The manufacturers usually provide various kinds of pressure details, including continuous operations or intermittent pressure, and on-peak ratings to help select the unit for multiple setups. It is therefore vital that pressure ratings be strictly observed in order to avoid any catastrophic failure in any system and ensure long-term optimum performance.

Keeping high pressures calls for the use of hard materials like hardened steel and some composites that are best at resisting wear and fatigue. Costly machining of tight tolerances became almost mandatory for newly developed designs to help in reducing internal leakage under high-pressure conditions. A pressure compensation feature in the design ensures stability by a change in the flow rate from spilling to maintain the desired pressure without causing an overload to the system. The high-pressure vane pumps find good applications in metal forming, injection molding, and heavy-duty construction equipment industries, wherein working under constant pressure is crucial.

They also stress the need for the right integration of the system and constant pressure monitoring for optimum results. Operators must consider aspects like the viscosity of the fluid, temperature range, and compatibility concerning the pump’s seals and internal components. Also, with the advent of sensor technology and IoT analytics, pressure levels and operation metrics are being monitored in real-time, thereby optimizing predictive maintenance and uptime. Armed with the backing of a reliable design and modern diagnostics, high-pressure vane pumps give their full strength to high-performance hydraulic systems.

How do vane pumps compare to other types of pumps?

High Pressure Vane Pumps vs gear pumps: key differences

Although high-pressure vane pumps are commonly used in industries compared to similar designs such as gear pumps, they have different design features, performance features, and sizes. High-pressure vane pump qualities, particularly its volumetric efficiency above 90%, which comes about due to self-adjusting vanes that keep it sealed against the housing, are important factors to consider when purchasing them. This mechanism allows some leakage but ensures consistent flow rates while maintaining optimal sealing over a long period. Conversely, internal gear slippage and wear typically result in lower volumetric efficiencies ranging between 75-85% for these types of machines.

Vane pumps show significant advantages in handling various viscosity levels of fluids. These designs allow them to process low-through-high viscous liquids without compromising performance due to suppressed fluid shearing internally within their structure. For example, gears within pump mechanisms tend to encounter challenges associated with fluid mixtures that have high viscosities due to increased friction, hence causing problems arising from possible mesh wear.

Further differentiation between these pump types lies in their operational pressure capacities. Vane pumps are designed to handle high pressures of up to around 3000 psi because of their heavy construction and good sealing. On the other hand, gear pumps operate optimally within a range of approximately 1000-2500 psi, though some high-pressure models exceed this range. However, they tend to wear out very quickly under such continuous pressure conditions.

In maintenance terms, vane pumps require less frequent servicing thanks to their self-compensating vanes and lower wearing rates, which result in shorter down times and overall low life cycle costs. Gear pumps, on the other hand, are easier to service because they are simple, but they have more maintenance intervals in terms of gear wear and oil contamination issues.

Finally, high-pressure vane pumps offer higher efficiency, versatility in fluid handling, and reduced downtime due to less frequent servicing required by self-adjusting vane technology and their inherently low wear rate. Comparatively, a gear pump is not ideal for these applications where reliability is key; hence, trade-offs can be made regarding efficiency levels and pressurized environments.

Benefits of Rotary High-Pressure Vane Pumps Compared to Fixed Displacement Pumps

Compared with fixed displacement pumps, rotary high-pressure vane pumps are more efficient, flexible, and easier to maintain. The most significant advantage of having these machines is that there is no need to alter their rotating speed for them to change flow rates. This flexibility would help cut down energy consumption through power reduction consumption as opposed to fixed displacement pumps whose duty is constant flow regardless of demand level.

Rotary high-pressure vane pumps achieve the best volumetric efficiency in terms of technical specifications, often above 90%. This implies low fluid leakage and increased operational economy. Their designs are robust enough to efficiently work under pressures up to 3000 psi, thus making them suitable for demanding industrial applications. However, fixed displacement pumps, being as reliable as they are, usually have a lower efficiency level because of their unchanging displacement nature with typical operative pressures at 1000 – 2500 psi.

Rotary high-pressure vane pumps also have maintenance advantages over others. The vanes self-correct as they wear; hence, performance remains optimal over long periods of time, leading to minimal maintenance activity with a resultant reduction in downtime. Conversely, fixed displacement pumps are normally subjected to frequent maintenance due to wear and tear-related problems, increasing operational costs.

Lastly, rotary high-pressure vane pumps can handle fluids with different viscosity levels and contamination amounts without significant performance deterioration due to their strong construction and advanced sealing technology. However, fixed displacement models might have limitations concerning this aspect since they experience greater sensitivity to fluid conditions, which causes accelerated wear and reduced life expectancy.

Comparing Displacement Rates: Vane Pumps vs. High-Pressure Vane Pumps

Standard vane pumps typically operate with displacement rates ranging from 0.5 cc/rev up to 200 cc/rev, depending on the model or application used. They generally function at pressures up to 1500 psi, with volumetric efficiencies around 85% to 90%. Consequently, such a flow rate is directly proportional to its rotational speed since these devices are constant in volume transport.

The other type, the high-pressure vane pump, is, however, made for more challenging settings. They most often have a displacement rate of up to 250 cc/rev and can operate at pressures up to 3000 psi, with volumetric efficiency often surpassing 90%. They are constructed heavily and designed based on advanced technology, enabling them to sustain higher operational requirements without substantial loss in efficiency. The self-compensating vanes of high-pressure vane pumps adapt to wear, ensuring consistent performance and reducing the need for frequent maintenance.

In summary, high-pressure vane pumps are better able to handle bigger displacement rates and operating pressures while maintaining good efficiency levels that minimize maintenance costs. They are more applicable in situations requiring reliability under extreme conditions.

What are the common applications of high-pressure vane pumps?

Mobile equipment requiring high pressure

Mobile equipment working under high-pressure conditions is critical for industries such as construction, mining, oil, and agriculture. These machines usually run hydraulic systems, generating the enormous forces required for activities such as lifting, drilling, or compacting. Depending upon their use, these hydraulic circuits in the equipment operate anywhere between a low pressure of around 2,000 psi to 6,000 psi, with advanced setups exceeding these limits to satisfy special applications.

In simple terms, high-pressure hydraulic systems are used in excavators and cranes for powerful and exact motion, while these systems are also capable of being used to apply chemicals over large areas by agricultural sprayers. By witnessing developments in materials science and component design, we can say that these systems have been optimized to perform efficiently and reliably under very harsh conditions. It would be of utmost importance that these environments utilize synthetic or fire-resistant fluids coupled with high-quality sealing technologies, along with perfect filtration mechanisms to reduce wear and contamination.

Current-trend analysis indicates that pressure-control developments, such as electro-hydraulic proportional valves, are improving efficiency and response time to a high degree. Additionally, the use of IoT (Internet of Things) technologies brings in the real-time monitoring and predictive maintenance of high-pressure systems that will reduce downtime and, hence, improve the overall efficiency of operations.

Widespread industrial application scenarios

Systems capable of exerting huge pressure with advanced control schemes or with IoT integration are used across industrial sectors extensively, mainly for precision and productivity-related reasons. For instance, in the oil and gas sector, they are responsible for managing drilling operations wherein precise pressure regulations are necessary to avoid equipment failure or blowout accidents. Similarly, in manufacturing, hydraulic presses are optimized with pressure-control valves to improve production accuracy during metal stamping and injection molding.

These IoT-enabled monitoring systems assume a crucial role in chemical processing plants where abnormal pressures can mean disaster. Systems of this nature, with real-time analytics and predictive diagnostics, ensure consistent quality of output and enhanced safety protocols. Data gathered from operational feedback shows that the growing application of IoT in high-pressure settings reduced unplanned downtimes by up to 25% in specific instances. Compared and diversified at the high end of performance criteria, such systems are also whipped out for rigorously testing aerospace and automotive industries under simulated high-pressure conditions to ascertain the resilience and safety compliance stipulations of their products.

A development narrative for these pressure control systems emphasizes their need in the industrial transformation as a response to the increasing demand for automation and smarter operations.

How to maintain and troubleshoot a high-pressure vane pump?

Commonly done maintenance practices on vane pumps

Routine maintenance involves various important procedures that help improve vane pump productivity over long periods while still keeping them running efficiently. Initially, it is crucial to examine and clear filters and strainers frequently. Such actions prevent the entrance of debris and contaminants into the vane cavity, thereby minimizing the wear on the internal parts’ life expectancy. Clean filters should be replaced based on the manufacturer’s specifications, which recommend changing them after every 500 hours’ usage or when soiling conditions necessitate it, subject to the pump operation environment.

Secondly, close attention must be given to the hydraulic fluid being used. Use recommended fluids from manufacturers, using their viscosities as guidelines. Operating temperatures are usually between 32 and 68 °C (centigrades). Ensure oil cleanliness by conducting regular oil analysis.

Thirdly, internal components of vane pumps, especially vanes and seals, need to be periodically checked. Check the wear, deformation, or damage of vane tips and seals. Vanes should be replaced when their wear exceeds 75% thickness-wise or they present significant scoring. Similarly, once leaks are noted in any seal or if they become stiff, they must be replaced to maintain pump integrity.

Setting up a proper pressure is also necessary for them. Adjust relief valves and verify that they fall within operating pressures that lie between 1000 and 2500 psi, depending on the specific application. Moreover, check malfunctioning components or improper adjustments to rectify any inconsistencies in pump pressure as soon as possible.

A structured maintenance log should always be kept, indicating all inspection results on replacement experiences, together with fluid checking results. This eases identification of recurrent malfunctions while ensuring that schedules for maintenance are met, hence extending longevity and dependability of high-pressure vane pumps

How to deal with high-pressure vane pumps

- Understanding and Managing High-Pressure Vane Pumps: A high-pressure vane pump is an essential piece of equipment in hydraulic systems. Their reliability and precision in flow render them efficient. To keep the pump performance intact and ensure the highest possible working life, it is imperative to follow detailed maintenance procedures and operations. Below are some important points to consider for high-pressure vane pumps:

- Fluid Selection and Maintenance: The quality of hydraulic oil and its bearing condition play a vital role in the performance of the high-pressure vane pumps. The oils must always be used according to the viscosity and temperature limits of the system as prescribed by the OEM. Dust particles may induce internal wear, and water may cause corrosion. Thus, a good filtration system must be used. Oil sampling should be done at regular intervals along with an analysis to determine the level of degradation and contamination of the fluid.

- Pressure and Temperature Monitoring: It is imperative to keep the pump operating within the stipulated pressure and temperature to avoid premature failure. Overpressurization subjects the internal parts, such as vanes and rotors, to excessive stresses, while temperature variation may reduce fluid efficiency and expedite wear. Use precise pressure gauges and temperature sensors to keep all values within appropriate tolerance limits.

- Routine Inspection and Preventive Maintenance: During inspection, check for wear and damage on the housing, seals, vanes, and bearings at regular intervals. Replace the seals if any leakage is detected to avoid further inefficiency in the system. Preventive maintenance shall be carried out by cleaning and re-lubrication at predetermined intervals, and this will greatly reduce the chances of unforeseen breakdowns.

- Noise and Vibration: Unusual noises or vibrations are a sure sign of impending problems in high-pressure vane pumps. These characteristics are generated by cavitations, misalignment of shafts, or deteriorated parts. Immediate troubleshooting should therefore confirm suction line restrictions, inspect the alignment of the drive mechanism, and confirm the integrity of the vanes and rotor.

- Assembly and Installation: During installation, perfection in mounting is necessary so that the pump will have minimum misalignment and stress to the coupling or drive shaft. Torque all bolts and connections to the value recommended by the manufacturer so they will not come loose during high-pressure operation. Systematically prime the pump so it will never be dry-started and damage itself internally.

- Industry Standards and Latest Technology: High-pressure vane pumps are governed by stringent industry standards, including ISO 13709 and API 676, specifying criteria for performance and safety. Manufacturers continue truthful incorporation of emerging technologies such as variable displacement methods and materials of construction at an advanced level to improve life and efficiency. Keeping abreast of these developments would assist in a better choice when selecting or upgrading equipment.

With proper maintenance procedures and knowledge of the system, the failure of high-pressure vane pumps can be limited to a minimum, ensuring higher operational efficiency for a long time.

How mechanical failures can be avoided in vane pumps

Mechanical failures in vane pumps are often due to improper maintenance, material fatigue, or suboptimal system design. These problems can be addressed by following a multi-pronged approach involving sound engineering principles and proper operating practices.

- Regular Maintenance and Inspection: Developing a maintenance routine will allow operators to observe parameters indicative of component wear or degradation. Such parameters would include surface scoring on the vanes or excessive clearances of bearings and shafts, oil leakage, and so on, which may decrease efficiency. Other diagnostic tools, such as vibration analysis and thermography, can assist in the early detection of mechanical stresses.

- Lubrication Control: Proper lubrication is necessary to reduce frictional and thermal stress in moving components. Hydraulic fluids should be chosen following the manufacturer’s recommendations and should be properly matched to the hydraulic pressure and temperature range of the pump. Where contaminants, particulate matter, or even moisture are allowed to enter the fluid, such impurities must be removed through high-efficiency filtration systems so as not to abrade the mechanism.

- Precision Installation and Alignment: If the installation of the pump is not mounted properly, misalignment with the crankshaft of its driving motor shall cause tangential stresses to be exerted. Over time, wear will simply accumulate unevenly and cause a premature failure. The use of fine alignment tools should be standard practice, as should adherence to specified torque requirements in assembling.

- Optimal Operating Conditions: Operating the pump beyond its designed limits, in terms of pressure and flow, can cause overloading or cavitation, gradually erode internal surfaces, and damage the structure. Pressure relief valves must be installed against unforeseen spikes, and performance testing against balancing systems must be carried out regularly.

- Use of Advanced Materials and Coatings: Wear-resistant coatings and high-strength alloys are found in modern vane pumps for critical areas subjected to high stress. These coatings and materials promote very good advancement in terms of the life of crucial parts under severe operating conditions.

By applying the above in-depth methods with a thorough grasp of the system requirements and environmental factors, the possibilities of mechanical failure of vane pumps may be considerably minimized, contributing to high reliability and operational efficiency.

Reference sources

- Processing Magazine

- Source: Gear and Vane Pumps — The Benefits of Both

- Summary: This article highlights the strengths and benefits of both gear and vane pumps in fluid-handling applications. It provides an authoritative comparison, emphasizing the efficiency and reliability of high-pressure vane pumps for various industrial uses.

- Pump School

- Source: Vane Pumps

- Summary: This resource offers a detailed overview of vane pumps, including their ability to handle thin liquids at relatively higher pressures. It discusses the mechanical design that compensates for wear and the suitability of vane pumps for solvents and liquefied petroleum gas (LPG), showcasing their practical applications and benefits.

- Harvard Filtration

- Source: How Hydraulic Vane Pumps are Used in Industrial Applications

- Summary: This article explains the advantages and disadvantages of hydraulic vane pumps, focusing on their high efficiency, compact size, and versatility in various industrial applications. It provides a comprehensive understanding of why high-pressure vane pumps are preferred in specific scenarios.

Frequently Asked Questions (FAQs)

Q: What is a high-pressure vane pump?

A: A high-pressure vane pump is a type of rotary vane pump designed for high-pressure applications, often used in hydraulic systems to provide consistent flow rates and maintain optimal pressure levels on the job.

Q: What are the benefits of using a high-pressure vane pump?

A: High-pressure vane pumps offer several benefits, including efficient hydraulic balance, the capability to handle high flow rates, and consistent flow rates and maintain optimal pressure levels. Additionally, many of these pumps feature replaceable parts for ease of maintenance.

Q: What are some common applications for high-pressure vane pumps?

A: High-pressure vane pumps are commonly used in heavy machinery like backhoes and tractors, as well as in industries requiring the transfer of vapor and liquefied gases. These pumps are also utilized in flow control applications to ensure precise pressure levels are maintained.

Q: How do high-pressure vane pumps maintain optimal pressure levels?

A: These pumps are designed to provide consistent flow rates and maintain optimal pressure levels through the use of advanced hydraulic balance techniques and precise construction that allows for efficient operation even under high pressures.

Q: What is the significance of a rotary vane pump within high-pressure systems?

A: A rotary vane pump is crucial within high-pressure systems due to its design, which allows for continuous and efficient operation under high-pressure conditions. The pump can maintain optimal pressure levels and deliver consistent fluid flow, thus better filling its role in various hydraulic applications.

Q: Are there any optional components available for high-pressure vane pumps?

A: Yes, many high-pressure vane pumps come with optional components such as a 2-bolt mounting system, double pump configurations, and various flow control devices to better customize the pump for specific applications.

Q: How does one go about installing a high-pressure vane pump?

A: Installation of a high-pressure vane pump generally involves mounting the pump using a 2-bolt or other compatible system, connecting the necessary hydraulic lines, and ensuring all seals and fittings are secure. Manufacturers typically provide detailed instructions to guide through the installation process.

Q: Can high-pressure vane pumps handle liquefied gases?

A: Yes, high-pressure vane pumps are designed to handle a variety of fluids, including liquefied gases. Their robust construction and efficient design make them suitable for such demanding applications.

Q: How can I ensure consistent performance from my high-pressure vane pump?

A: To ensure consistent performance from your high-pressure vane pump, regularly inspect and replace any worn or damaged parts, maintain proper fluid levels, and follow the manufacturer’s guidelines for operating pressure and flow rates. Regular maintenance and timely replacements are key to keeping the pump running efficiently.