Hydraulic systems serve as the primary force behind countless industrial processes, driving machines for tasks that range from construction activities to automating manufacturing processes. Pumps are the heart in the hydraulic system, keeping fluid engine running smooth and fulfilling all performance requirements. With a large array of pump designs to choose from, fixed displacement pumps and variable displacement pumps are usually the most common pump types. But what really differentiates one from the other, and how would you select the output for your respective application? The article explores the primary differences between fixed and variable displacement pumps per their functioning, benefits, and best-case applications. This guide shall give that much-needed clarity for any engineer, technician, or curious mind looking to make informed choices about hydraulic systems.

Understanding Hydraulic Pumps

Definition and Functionality

Hydraulic pumps are machinery that convert mechanical energy into hydraulic energy, engendering fluid movements inside the system. Hydraulic pumps generate a flow of hydraulic fluid that is used in the transmission of power for the running of machinery or for doing work, like lifting, moving, or pressing objects. Being core components of any hydraulic system, these pumps are found to be extensively used in such industries as construction, manufacturing, and transportation.

Generally, hydraulic pumps are classified into two main groups depending on their operation: fixed displacement pumps and variable displacement pumps. The first category delivers an amount of fluid volumetrically that is constant and perfect for applications with constant pressure demands. They are considered straightforward and reliable means to provide hydraulic power when required. In contrast, pumps of variable displacement have an adjustable flow rate capable of being tuned according to the requirements of the system, thereby rendering them more suitable and energy-efficient for applications with varying pressure/flow requirements.

When choosing between a fixed or variable displacement pump, the need of the application plays the determining factor. Those applications with fixed hydraulic output, typical of power for heavy equipment or industrial presses, call for fixed displacement pumps due to their straightforwardness and cost-efficiency. In contrast, variable displacement pumps are recommended where the applications require hydraulic flexibility and energy efficiency, maybe from mobile equipment or sophisticated machinery that works under varying conditions. Being aware of such differences helps to guarantee that the best pump is chosen for optimum performance and efficiency in any hydraulic system.

Types of Hydraulic Pumps

While the goal of hydraulic pumps is to move hydraulic fluid and therefore, to create hydraulic energy, conversion of mechanical energy into hydraulic energy must take place. There are three widely recognized types of hydraulic pumps-frequently applicable from diverse points: gear pumps, vane pumps, and piston pumps.

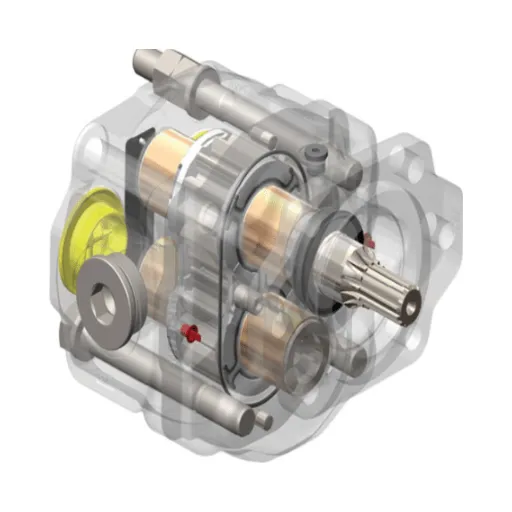

🔧 Gear Pumps

One can consider them a standard because of their hardiness and simplicity. The design permits a steady and uniform flow, depending on two intermeshing gears rotating to transport fluids. These pumps operate from low pressure to medium pressure. Because of their inexpensive character and maintenance, these pumps are all too common in agricultural machines and industrial equipment.

⚙️ Vane Pumps

Vane pumps offer versatility for higher efficiency at a medium pressure. The vanes move fluid from inside to outside of the pump with the vanes mounted on a rotor. These pumps are best suited for mobile machinery, like forklifts and aerial work platforms, as they ensure smoother operation with less noise than gear pumps.

🔩 Piston Pumps

Piston pumps offer very high efficiency and are suitable for high-pressure applications. A certain series of reciprocating pistons displace the fluid, ideal for a highly demanding environment such as construction equipment and hydraulic presses. They are commonly expensive, but because they perform very well and can adapt to varying demands, these types of pumps are among the best choices for elaborate systems.

💡 Key Insight: Knowing the nature and capabilities of each hydraulic pump will make it easier to determine the equipment best suited for a particular purpose and to provide maximum performance as well as extended life of the hydraulic system.

Importance in Industrial Applications

This is a hydraulic pump. It is a major force in working capability, enabling machines to perform difficult tasks with utmost precision and really efficiently. Across industries, their importance is conspicuous, serving machinery and attendant equipment for smooth operation. Let’s now touch upon five practical applications of the industry hydraulic pump in brief:

- 🏭 Manufacturing Machinery: Hydraulic pumps, power injection molding machines, and metal stamping presses-the crucial manufacturing equipment. Good performance of the pumps ensures consistent yields and quality in the manufacturing process.

- 🚧 Construction Equipment: The heavy machines, such as excavators, bulldozers, and cranes, use hydraulic pumps in low-level lifting, excavation, and material handling. The pumps provide sufficient pressure under which these labor-intensive tasks can be carried out.

- 🚜 Agricultural Machinery: Tractors, harvesters, and plows utilize hydraulic systems for power steering, lifting of implements, and adjustment of machinery settings to improve productivity.

- ✈️ Aerospace Systems: Hydraulic pumps in an aircraft work for flight control systems, operation of landing gear, and cargo door mechanisms, where, contrary to civil works applications, extreme conditions challenge their effective performance, endangering aviation safety and reliability.

- 🚗 Automotive Industry: With hydraulic pumps used in vehicle power steering and braking systems, smooth driving experiences are assured, and this further helps in improving safety on the road.

📊 Impact Summary: Such applications manifest the industrial usage of hydraulic pumps. The right choice of several hydraulic pumps receives good maintenance, thereby noticeably affecting efficiency, safety, and the overall system lifespan.

Fixed Displacement Pumps

Working Principle of Fixed Displacement Pumps

With each rotation or cycle, a fixed displacement pump moves through the chambers a fixed amount of fluid. It thus maintains a constant flow rate regardless of any changes in pressure. It achieves this in a mechanical way by enclosing and shifting the fluid through predetermined chambers, which could be through gears, vanes, or pistons. These types of pumps are used in heavy applications where a steady flow is essential, such as hydraulic power systems or industrial applications.

The main fixed displacement pumps are gear pumps, vane pumps, and piston pumps, respectively, and these have their efficiencies and utilizations under different conditions. For instance, gear pumps are rugged and inexpensive, whereas piston pumps are used for higher-pressure applications.

Fixed displacement pumps are those that allocate fluid at a constant flow rate, enabling systems to be controlled accurately. Their capacity, reliability, and mechanism provide applications where performance predictability is paramount. High-quality units combine precision engineering with surface-hardened materials for improved efficiency and wear characteristics, thus yielding excellent service life even in high-stress operations.

Advantages of Fixed Displacement Pumps

📊 Constant Flow Rate

Being fixed displacement pumps, they provide a constant flow at all pressure variations. Therefore, the performance is very precise and predictable, making them suited for applications requiring steady operation.

⚡ Higher Efficiency

Through precision engineering of fixed displacement pumps, surface-hardening materials are often applied; therefore, wear and energy losses are greatly minimized. Efficiency will ultimately lower operating costs.

🛡️ Longer Life and Durable

Owing to their sturdy construction, fixed displacement pumps can quite comfortably handle high-pressure conditions and continuous operation. Many units have service life records of more than 10,000 operating hours even under high-stress environments.

🔧 Easy Maintenance

Fixed displacement pumps are easier to maintain than variable ones because of fewer moving parts and a very simple design. This reduction in downtime also cuts down maintenance costs.

💰 Cheaper Choice

Fixed-displacement pumps typically present a lower capital cost as compared to variable pumps, and with their durability and maintenance benefits, they make a cost-effective solution for a number of industrial and hydraulic applications.

Common Applications of Fixed Displacement Pumps

Fixed displacement pumps serve a vital role in various industrial applications thanks to their dependability and economical nature. Below are five common applications:

| Industry | Application Description |

|---|---|

| 🚜 Agricultural Machinery | Fixed displacement pumps serve agricultural machinery, including tractors, combine harvesters, etc., supplying hydraulic power for lifting, steering, and other functions consistently. |

| 🚧 Construction Equipment | In operating hydraulic cylinders and motors for digging, lifting, and grading, these pumps are used in excavators, bulldozers, and backhoes. |

| 🏭 Industrial Hydraulic Systems | Manufacturing equipment, such as presses and conveyor systems, depends on fixed displacement pumps for steady and efficient functioning. |

| ⚓ Marine Applications | These pumps work in steering systems, winches, and several other hydraulic devices critical in navigation and cargo handling in marine vessels. |

| 🚗 Automotive Systems | Fixed displacement pumps are usually coupled with power steering systems to generate constant hydraulic pressure for smooth and quick action. |

🎯 Application Summary: From the above applications, one can infer that fixed displacement pumps have a wide range of applications and are hardworking across sectors, making them imperative in hydraulic systems.

Variable Displacement Hydraulic Pumps

How Variable Displacement Pumps Operate

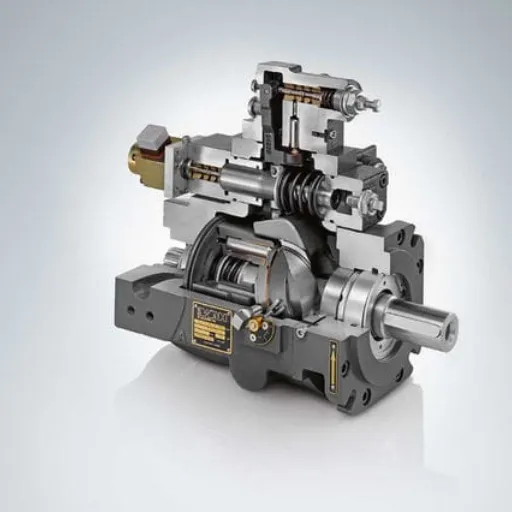

Variable displacement hydraulic pumps adjust the flow of hydraulic fluid dynamically according to the demand of the system. In comparison, fixed displacement pumps produce constant flow without regard to the system requirements, whereas variable displacement pumps adjust their flow by changing the angle or position of their swashplate inside the pump body. Changing the angle of the swashplate changes the stroke length of the pistons inside the pump, thereby affecting the volume of fluid displaced in each pumping cycle.

This change helps to make the working of hydraulic systems more efficient by conserving energy and reducing heat generation in applications where load demands vary with time.

⚡ Energy Conservation

One major advantage of variable displacement pumps lies in their capacity to conserve energy. At low load conditions, the pump output is decreased, and so wasteful consumption of energy is prevented. For example, from an industrial perspective, when a machine is idle, variable displacement pumps reduce the flow rate so as to save on costly fuel or power while keeping the system ready.

🎯 Modern Control Systems

More modernized designs of variable displacement pumps entail sensors and electronic controls that allow for monitoring in real time and subsequent adjustments matched to exact system specifications, thereby greatly enhancing the overall system efficiency.

This is quite in contrast when compared with fixed displacement pumps that persistently discharge maximum flow, which consequently leads to massive wasting of energy.

Variable displacement pumps excel in industries where precision and flexibility are invaluable. In the construction machinery sector, being essential for excavators and loaders, these pumps provide responsive hydraulic power for lifting and digging operations, allowing operators to perform complex movements with enhanced control. And again, in aerospace systems, these pumps allow an efficient hydraulic system operation at varying pressures and temperatures. The variable displacement hydraulic pumps are of great importance in modern engineering, combining energy efficiency, precise control, and durability to address the demands of various high-performance applications.

Advantages of Variable Displacement Hydraulic Pumps

-

⚡ Energy Efficiency

Variable displacement hydraulic pumps regulate their flow rate according to what the system demands, thus minimizing the consumption of energy. For example, in certain systems, it has been shown that energy utilization can be reduced by up to 30 percent with the use of such pumps when compared to fixed displacement ones.

-

🎯 Fine adjustments

They provide very fine control over the hydraulic output, thus enabling an operator to adjust flow or pressure as necessary. This is very important when very fine control is needed in an application, such as in machining or some robotic systems.

-

🌡️ Heat Generation

Heat generation by these pumps is less than that of conventional fixed flow pumps because the former produce the exact amount of fluid demanded by the system, and energy, of course, is wasted in heat whenever excess fluid is produced. This favorable condition extends the life of hydraulic components and alleviates cooling load.

-

🛡️ Increasing System Life

Because there is optimal performance stressing against the components, the machinery lasts longer. According to industrial analysis, systems using variable displacement pumps have shown up to 20% increase in the average time between failure (MTBF).

-

🔄 Application Flexibility

Because of their ability to perform under different loads and conditions, they find a wide variety of industrial applications, including manufacturing, aerospace, automotive, and construction. This ensures that these pumps cater to all types of demanding systems.

Application Scenarios for Variable Displacement Pumps

Since these pumps are considered efficient, flexible, and adaptable to changes in operational loads, their use spans many industries. The five main points below pinpoint situations in which these pumps prove to be very functional:

🏭 Manufacturing Hydraulics

They are used in hydraulic systems for manufacturing. By adjusting fluid output according to the machine’s requirements, they conserve energy and avoid unnecessary operational losses.

✈️ Aerospace Actuation Systems

The importance of these pumps becomes high in aerospace actuation, which needs utmost precision and reliability. These pumps manipulate the landing gear, wing flaps, and several other aircraft installations.

🚗 Automobile Power Steering

Variable displacement pumps find use in power steering systems in the contemporary automotive industry to allow smooth and responsive steering for the driver.

🚧 Construction Equipment Hydraulics

These pumps are utilized by heavy equipment like excavators, loaders, and cranes to handle dynamic loads. The adaptability ensures reliable performance even under adverse conditions.

⚡ Energy Sector Applications

From wind turbines to oil and gas operations, variable displacement pumps provide precise control in energy generation and extraction processes.

📈 Market Demand: The example presents the constant demand for variable displacement pumps, made to fit the specialized needs of countless industries, hence proving their effectiveness and flexibility.

Comparing Fixed and Variable Displacement Pumps

Performance and Efficiency

In my opinion, in applications where an irregular flow rate is required, the variable displacement pump is usually more efficient. These pumps adjust the output flow rate and pressure to suit the requirements and thus avoid wastage of energy. On the other end of the spectrum, a fixed displacement pump pumps at a constant flow rate, irrespective of the system requirements; this might use energy in some cases.

🔧 Fixed Displacement Benefits

Fixed displacement pumps can be useful in simple operations with reliable demand as they are simple in design and often cost-effective. They excel when constant volume is required, making them a better choice for simpler or more predictable systems.

⚡ Variable Displacement Benefits

Variable displacement pumps have the flexibility that makes them excellent where precision and adaptability are required. Being able to change pump flow rates on the fly is enormously helpful for tasks involving complex machinery and varying loads.

Generally speaking, I understand that the choice of one or the other pump depends largely on the operational requirements of a given instance: When energy savings and flexibility are a must, variable displacement pumps will be the right choice; for the rest, fixed displacement pumps can fit the bill equally well if simplicity, effectiveness, and constant flow are the values at hand.

Adaptability in Various Operational Scenarios

| Pump Type | Operational Scenarios | Key Characteristics |

|---|---|---|

| Fixed Displacement | Applications demanding even, unvarying output with predictable operational conditions | Simple design, low maintenance, cost-effective, constant flow rate |

| Variable Displacement | Dynamic and challenging applications with variable loads and energy optimization needs | Flexible control, energy efficient, adaptable to varying conditions |

The accommodation of hydraulic pump systems in various operational settings is the most eminent factor for their efficient placement in industrial and mechanical systems. Owing to their simplicity, fixed displacement pumps are generally used in applications demanding an even, unvarying output. Industries that require low upkeep and cheap solutions tend to go for these pumps because of their unfailing ability to maintain a constant flow rate for as long as the operational conditions in terms of temperature and pressure do not vary. With this type of flow, these pumps suit the systems where the operational load remains steady or behaves predictably.

On the contrary, variable displacement pumps operate efficiently under dynamic and challenging application conditions. These pumps are crafted in a manner so that the flow rate and pressure can be controlled at any instant as per the requirements of the user. This capacity of control is very well suited for any application wherein the load is variable, or energy consumption needs to be controlled with respect to time. The construction, aviation, and automotive manufacturing industries highly benefit from the energy efficiency and application versatility of such pumps. Waste energy is minimized, which implies a direct reduction in costs and promotes more sustainable practices along with industrial processes.

🚀 Future Technology: Cutting-edge technologies that include data-driven monitoring systems and automation also promote the adaptability of hydraulic pumps. The smart sensors and real-time analytics of pump operations provide information on performance so as to preemptively schedule maintenance and optimally distribute resources. This embrace of cutting-edge technology ensures the reliability of both fixed and variable displacement pumps but further secures their relevance as workable solutions for the contemporary operational scenarios that demand precision, efficiency, and responsiveness.

Cost-Effectiveness and Maintenance Considerations

Fixed and variable displacement pumps are designed to meet high-performance demands. They also need to be economical in the long run. Employing newer technologies to help them cut down on energy consumption largest fraction of operation costs in hydraulic-system-using industries-variable displacement pumps adjust flow rate to conform to system requirements, thus efficiently utilizing energy with less wastage. This adaptability means that an enterprise may realize greater savings if it has sustainability and cost reduction profiles.

💡 Maintenance Insights

From the viewpoint of maintenance, they offer several benefits supported by smart design and monitoring systems. Predictive maintenance aided by IoT sensors tracks performance metrics-real-time tracking of pressure, temperature, flow rates, etc., thereby reducing unexpected breakdowns that might cost businesses in emergency repairs and downtime. At the same time, maintenance intervals can be optimized through data analytics, allowing cost reduction while ensuring maximum operational efficiency.

For fixed displacement pumps, simple designs allow easy routine checks and repairs, though the preventive care needs to be maintained regularly to keep away from wear or tear.

Improved manufacturing techniques and a vast array of materials utilized today increase their aspect of long-term affordability. Hence, components last longer and underwater hazardous environmental stresses, thus needing very rare replacements. When combined with well-planned maintenance alternatives geared toward enhancing the operations of a business, these technological improvements ensure businesses fulfill their operational requirements within a budget. A nice balance between upfront costs, operational efficiencies, and modern solutions for maintenance, thus still keeps both fixed and variable displacement pumps very attractive yet cost-effective options in various industries.

Choosing the Right Pump

Key Factors to Consider

-

🎯 Application Requirements

Understand the particular needs of the application from which to select a pump. It takes into account fluid type, pressure conditions, flow rate, and operating conditions. For example, high-viscosity fluids may require special pumps, whereas low-pressure systems may do with a cheaper one.

-

⚡ Energy Efficiency

Modern pump systems incorporate energy-saving technologies with an aim to reduce their overall power consumption. Enhancements such as the variable frequency drive VFD allow the pump to operate at more precise levels according to the demand for energy and thus substantially reduce operational costs over time.

-

🔧 Durability and Maintenance Costs

The evaluation is important because of the material and construction of the pump concerning its wear and tear. Only corrosion-resistant ones, such as stainless steel, represent the best materials for a severely corrosive environment, while a modular design fosters maintenance activities, reducing downtime.

-

🌱 Environmental Impact

Pumps with green technology, such as low-leakage hydraulic fluid or biodegradable fluids, are becoming popular. They assure stricter environmental regulations for businesses while highlighting their spirit of sustainability.

-

💰 Initial Investment Versus Life Cycle Cost

Although the initial cost is important, it is equally important to determine the total life cycle cost of the pump. It includes maintenance costs, energy costs, and the possibility of expenditure for repair. Buying a good, efficient pump is likely to be more cost-effective in the long run.

📊 Decision Summary: After considering all the above elements, enterprises can confidently select the pump best suited for their operational and financial needs. Along with the current market trend and the judicious choice, this will lead to success in the long run, avoiding some common pitfalls in selection.

Budget Constraints and Project Needs

While selecting a pump, an imperative must be maintained to ensure the decision remains informed by balancing an available budget against project constraints. Any assessment of initial purchase price should not be neglected, for it carries heavy implications for the overall financial feasibility of a project. The lowest option may seem tempting in view of cost considerations, but one problem with making the decision solely on upfront costs is that it could result in higher maintenance and operational costs in the long run. Enterprises should study the total ownership costs, including not only purchase price but also energy consumption, maintenance requirements, and costs arising from potential downtime.

🔍 Project-Specific Considerations

Project-specific needs influence further choice of a pump. Fluid type, flow rate requirements, pressure heads, and environment all have their say in compatibility. Considerations such as temperature extremes or corrosive substances may require materials and designs able to cope with those challenges. Furthermore, for projects situated in remote areas or difficult-to-access locations, consideration should be given to durable pumps that require infrequent support and are simple to maintain.

A good way of putting the decisions into sharper focus amidst these considerations would be to use the industry’s latest inputs and market stats. Such up-to-date information regarding the latest innovations, say energy-efficient pumps or pumps engineered with newer materials, allows organizations to make their choice on sound grounds that offer better protection. Through extensive research, along with access to actual performance data of pumps coupled with expert opinions, enterprises can achieve just the right balance between budget constraints and technical considerations required for their projects. This approach holistically avoids risks and embraces ecological and operating efficiency.

Common Misconceptions about Fixed and Variable Pumps

❌ Misconception #1: Variable Pumps Are Always More Efficient

When discussing fixed and variable pumps, one misconception that is usually raised is that variable pumps are always more efficient than fixed pumps. Variable pumps are extremely flexible and can respond to changes in demand, but their efficiency is largely based on the applications and operating conditions. Whereas fixed pumps can often be more efficient than variable pumps when a constant volume is required, rendering them a better choice when working in simpler or more predictable systems.

❌ Misconception #2: Variable Pumps Always Pay Back the Initial Investment

Another misconception is that variable pumps, due to their initial costs, always repay that investment through energy savings. Variable pumps will save energy in systems with fluctuating loads and loads that are high in energy consumption, but for applications that are steady in operation, immediate or great payback may not be realizable. Thus, there should be consideration of life-cycle costs involved in deciding one over the other, including aspects such as maintenance, durability, and energy consumption.

❌ Misconception #3: Similar Maintenance Requirements

Some think that the maintenance requirements of both types of pumps are alike. Variable pumps tend to have more complex components, including electronic controllers, some of which may require more maintenance than fixed pumps. Evaluate system complexity and technical expertise required for maintaining these systems in the long run.

💡 Expert Recommendation: A consideration of what a particular application requires, as well as seeking the advice of those versed in pump applications, can help clear such misconceptions and guide one to an informed choice of the right pump for a particular task.

Frequently Asked Questions (FAQ)

❓ What are the main differences between fixed and variable displacement pumps?

The primary differences between fixed and variable displacement pumps lie in their ability to adjust output flow. A fixed displacement pump has a constant output per revolution and cannot change the volume of fluid it pumps. On the contrary, a variable displacement pump can vary the displacement of the pump, which in turn affords it far greater opportunities of solving hydraulic system performance requirements in different applications.

❓ How do axial piston pumps differ from variable displacement vane pumps?

Both axial piston pumps and variable displacement vane pumps are hydraulic pumps. Axial piston pumps make flow by using pistons connected to the swash plate, while variable displacement vane pumps make use of vanes that slide in and out of a rotor. The main difference is that axial piston pumps are generally of higher pressure and efficiency and are thus most suited for applications wherein system pressures vary.

❓ What is the role of the pressure compensator in variable displacement pumps?

Validation of system pressure through altering pump displacement in correspondence to load requirements is the original conception of pressure compensators fitted in variable displacement pumps. The pump can, therefore, save energy in addition to providing an adequate hydraulic system. The compensator will divert or relieve in such situations of excess flow, guaranteeing maximum efficiency of the pump.

❓ Do variable displacement pumps save on energy consumption?

They do! Variable displacement pumps help in energy saving. When the output flow varies and matches the exact need of the application, less energy is wasted and efficiency gains are maximized. This ability to impart change to flow renders such pumps quite attractive amongst those used in industrial machines and other applications where energy conservation is prime.

❓ What kind of internal parts consist of a variable displacement piston pump?

A variable displacement piston pump consists internally of pistons, a swash plate, and a bias piston relief valve. These units all work in conjunction to vary the displacement and, thus, flow of liquid to meet load variations and have the pump assisting in the performance of the system.

❓ For which interests does the variable displacement pump offer the greatest advantage?

Variable displacement pumps are mostly advantageous in applications with hydraulic systems under variable load, such as industrial machines, mobile equipment, and construction machinery. They serve well in systems requiring exacting control and efficiency due to their ability to regulate flow and pressure.

❓ How does the revolution of the pump influence its operation?

In general, the revolution of the pump would dictate how much fluid gets displaced per cycle, affecting the performance of the pump. In fixed displacement pumps, this is a constant value, while in variable displacement pumps, the number of revolutions may vary depending on the system demand. This flexibility allows variable pumps to maintain optimal pressure and flow across different operating conditions.

❓ What are the advantages of radial pumps as compared to variable displacement pumps?

Radial pumps are commonly considered to provide a more straightforward design and are easy to manufacture, which would consequently put costs lower. But in contrast, variable displacement pumps provide more hydraulic performance and a functional efficiency mode of control. The choice then is made between radial and variable displacement pumps based on the specific application and requirements of the hydraulic system.

❓ How do the parts of a variable displacement pump affect the operations of the pump?

Variable displacement pump parts, such as the swash plate, pistons, and compensators, affect how the pump adjusts flow and pressure. For example, the angle of the swash plate affects the displacement of the pump while the compensator maintains pressure to be constant in relation to variable loads. These attributes enhance the greater efficiency of the pump and hence make it more effective in fluid power applications.

🎯 Conclusion

Understanding the differences between fixed and variable displacement pumps is crucial for making informed decisions in hydraulic system design. While fixed displacement pumps excel in applications requiring constant flow and simple operation, variable displacement pumps offer superior energy efficiency and adaptability for varying load conditions. The choice ultimately depends on your specific application requirements, budget constraints, and operational priorities. By considering factors such as energy efficiency, maintenance costs, and system complexity, you can select the optimal pump solution that delivers both performance and cost-effectiveness for your hydraulic system needs.