The axial piston pump is at the heart of hydraulic mechanisms; efficient, versatile, and precise in effecting energy transfer. Their industrial novelty lies in the conversion of mechanical power to hydraulic energy and thus finds use in manufacturing, civil construction, aerospace, and many more. This article looks into the working and principle of axial piston pumps, giving an in-depth account of the design, working, and applications of these pumps. Be it an engineer or a curious soul interested in hydraulic systems, this guide is meant to endow one with all possible knowledge about why axial piston pumps are an important entity in modern engineering.

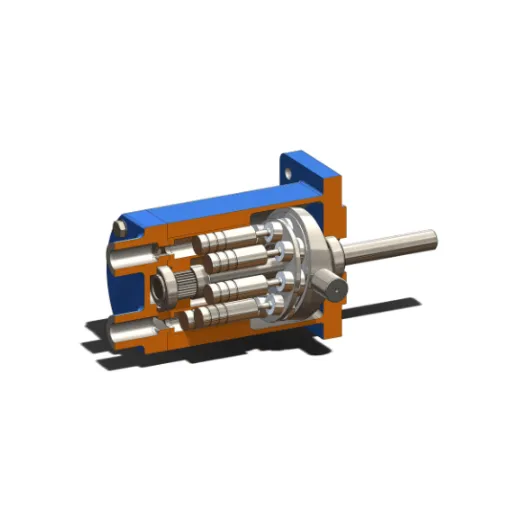

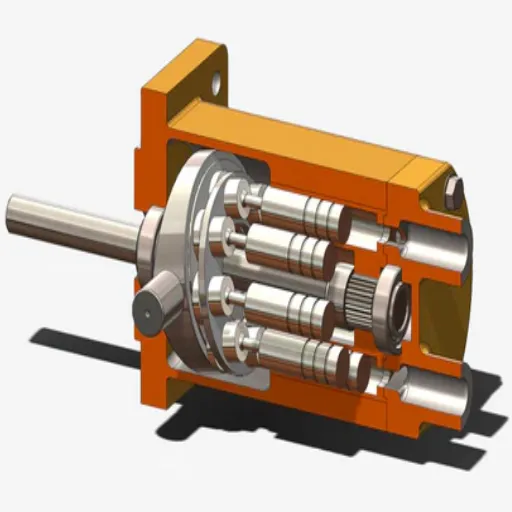

Key Components of the Axial Piston Pump

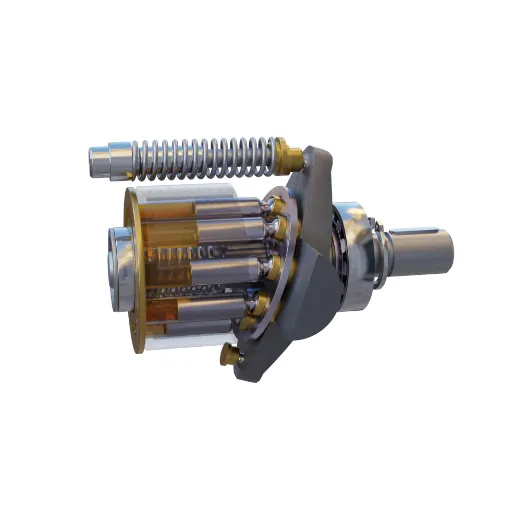

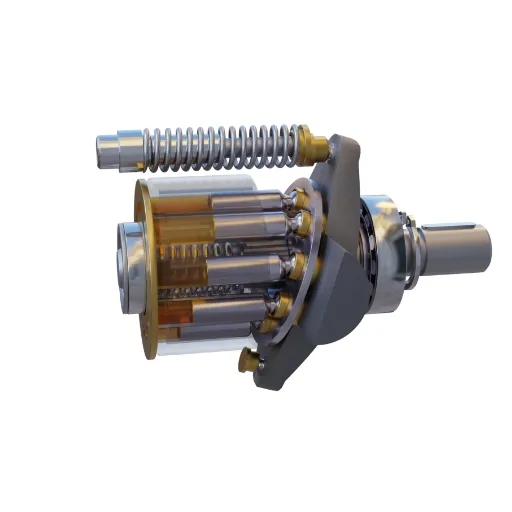

Swash Plate Functionality

The swash plate is an essential component of the axial piston pump, constraining the hydraulic fluid flow and pressure while being one of the elements. By tilting through an angle with respect to the pump shaft, it converts its rotation into the linear motion of the pistons. During one stroke, this motion allows the pistons to draw hydraulic fluid into the cylinder block, while during the other stroke, it presses out the hydraulic fluid under pressure.

The displacement of the pump depends on the angle of the swash plate: the larger the angle, the bigger the movement of the pistons, hence a greater fluid flow and output of the pump. By reducing the angle, the length of the piston stroke is decreased, which means reducing the flow and pressure. Some axial piston pumps are therefore characterized by the variable-angle swash plate, allowing for fine control of the hydraulic output; such pumps are thus desirable for applications where the fluid flow has to be adjusted.

The swash plate ensures efficient transfer of power, and it also plays a key role in the adaptability of the pump. Axial piston pumps are most frequently used in heavyweight machinery, aviation, and industrial automation where pressure requirements are high, and performance must be guaranteed. By controlling pressure and flow actually, the swash plate assures the pump to satisfy diverse application needs, precisely and efficiently.

Piston Mechanism Explained

For the axial piston pump, the piston mechanism is central to functioning, converting rotary energy into hydraulic energy. Pistons are placed in a cylinder block and arranged parallel to its axis of rotation. As the cylinder block rotates, the pistons reciprocate within their chambers due to the inclined angle of the swash plate, which generates alternate suction and discharge cycles. Thus, fluid is drawn into the chambers during one-half of the rotation and discharged at high pressure during the other.

The angle of the swash plate is an important for piston displacement and, consequently, for the pump displacement under consideration. By increasing the angle of the plate, a longer stroke is imparted to the piston, which displaces a greater amount of fluid. With a decreasing angle, the piston strokes get shortened and, therefore, lower fluid displacement. Due to this, piston pumps can flow the variable flow and pressure demanding of precise applications.

This installation allows axial piston pumps to generate high pressure, exhibit superior efficiency, and accommodate varied operational requirements. They are continuously run at a specific pressure and precision hydraulic power suited to the advancement of industrial systems, mobile working apparatuses, and aerospace technology policy. Hence, the piston configuration lends a controlled and reliable course of action to avoid these marks, enhancing pump serviceability.

Cylinder Block Role in Pump Operation

The cylinder block constitutes an essential part for the operation of axial piston pumps since it houses the pistons upon which hydraulic pressure is applied. It has very precisely machined cylindrical bores that permit the pistons to slide accurately and smoothly during operation. The movement of the pistons is essential to ensure that hydraulic fluid continues to flow without disruption for power transmission from one element to another.

The cylinder block must ensure proper alignment and sealing of pistons with other members, such as the valve plate or port plate, to minimize internal leakage while maximizing volumetric efficiency. The cylinder block and valve plate interface must be so designed that the hydraulic ports open and close at the correct times for accurate intake and discharge of fluids. This timely synchronization is required to get the high performance demanded by the application.

Furthermore, the impetus is on the cylinder block being durable since it works under much mechanical stress and high pressure. It is generally built from high-strength materials, which may include hardened steel or cast iron, so that it can be resistant to the wear and deformation that could come over time. Proper lubrication and cooling are also vitally important, as these prevent frictional wear and heat buildup. By performing these jobs, cylinder block contributes to the dependable life of an axial piston pump, allowing its use in industrial, mobile, and aerospace hydraulic systems.

Working Principle of Axial Piston Pumps

How the Components Interact

The working of an axial piston pump is a highly coordinated mechanical process to ensure efficiency and durability. The operational procedure begins with the rotation of the drive shaft, which develops power from sources like an electric motor or an internal combustion engine. This rotational energy is conveyed to the cylinder block, allowing it to rotate accordingly. The pistons are housed in the cylinder block’s bores and are forced to reciprocate due to the action of the tilted swashplate or bent axis, depending on the pump design.

When the pistons move inward because of altered angles of the swashplate during the cylinder block’s rotation, a suction and compression procedure takes place sequentially. During suction, pistons are withdrawn within their bores, causing a low-pressure zone that sucks the fluid into the pumping chamber. During compression, the pistons extend, imposing pressure on the hydraulic fluid and forcing it through the outlet port. The amount of fluid pumped out per rotation of the plate is called displacement and is controlled by the actual angle of the swashplate, which also controls the stroke of the pistons and thus the flow of fluid.

In cases where the swashplate angle is manually or automatically set in variable displacement axial piston pumps, it is the hydraulic power output that is varied with time to meet system needs. The interface between the slippers of the pistons and the swashplate has a thin film of hydraulic fluid for lubrication, thus minimizing friction and wear and enhancing the service life of the pump. When performed properly and in harmony, these combined functions constitute a dependable and highly efficient hydraulic energy conversion mechanism forming the basis for several industrial and mobile applications.

Understanding Displacement Mechanisms

Hydraulic pumps are separated into two principal categories based on their displacement mechanisms, viz., fixed displacement and variable displacement types. Fixed displacement pumps produce a flow at a fixed rate, regardless of system pressure variations, which are, therefore, found to be useful in applications demanding steady output. Some common types are gear pumps, vane pumps, and fixed axial piston pumps, the choice among these being based on specific operational requirements.

With the variable displacement types, though, the flow rate can be changed by adjusting the swashplate angle or by any other means. They are designed to be efficient because they can generate hydraulic power as per the system’s hydraulic demand in real time. Thereby causing energy loss to be minimized and performance index maximized. Variable displacement pump systems of high level further incorporate feedback and control mechanisms for automatic adjustment of flow and pressure, ensuring best operation and durability.

Nowadays, new materials and engineering approaches are being discovered, leading to even greater precision and durability of actuators. High-strength alloys, advanced surface treatments, wear-resistant features, and intelligent algorithms ensure performance stability in the most demanding applications. An understanding of displacement categories is necessary to help design and select pumps for heavy industrial and mobile hydraulics.

Pressure Generation in Hydraulic Systems

The creation of pressure in a hydraulic system is fundamentally dependent on resistance opposing the flow of fluid in a closed system. A hydraulic pump will provide a flow of hydraulic fluid, while an external load or system component will provide opposing resistance to fluid flow, thereby causing pressure to be created. The opposing resistance force-the pressure-is based on overcoming resistance, which varies with factors such as load, system geometry, and fluid properties.

Positive displacement pumps, such as gear, vane, or piston pumps, are almost universally seen in modern hydraulic systems, as these pumps can provide flow without regard to the resistance they face. For example, piston pumps are being used a lot as high pressure pumps; they are able to handle pressures well beyond 10,000 psi, which makes them suitable for industrial and mobile equipment operations.

Further pressure regulation takes place by means of pressure relief valves and pressure compensators that safeguard efficiency of the system. With the advent of intelligent sensors and control systems, one has the ability to monitor and regulate pressure in hydraulic circuits in real time, thus achieving efficiency of performance and longevity of the system. With such technological enhancements, pressure generation and control can be performed with such finesse as to minimize energy wastage and possibly pre-empt system overload and failure.

A good grasp of how pressure is generated and the newer developments are important in designing hydraulic systems for use in particular industrial applications where the industries are now seeking increasingly complex and efficient solutions. This continuous development ensures that hydraulic systems are reliable and adaptable to various types of operational requirements.

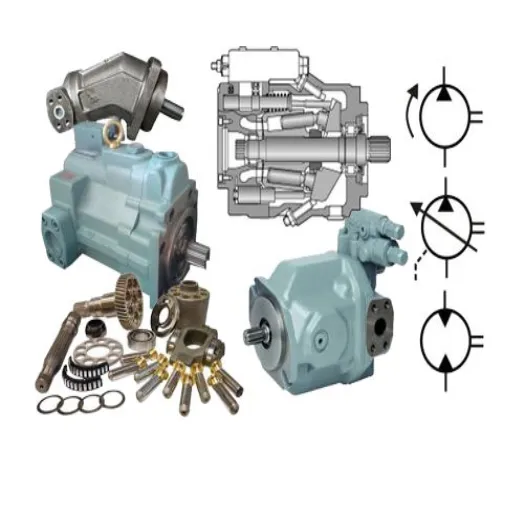

Types of Axial Piston Pumps

Swash Plate Type vs. Bent Axis Type

Swash Plate Type pumps are compact, quickly responsive, and require clean oil; on the other hand, the Bent Axis Type pumps are rugged, efficient, and handle higher pressures.

| Key Point | Swash Plate | Bent Axis |

|---|---|---|

| Size | Compact | Larger |

| Efficiency | Moderate | High |

| Pressure | Medium | High |

| Oil Cleanliness | High Need | Moderate Need |

| Response | Fast | Moderate |

| Durability | Moderate | High |

| Cost | Lower | Higher |

Advantages and Disadvantages of Each Type

Swash Plate Type

✓ Advantages

- Compact Design: With their smaller and compact designs, swash plate-type pumps fit nicely into any limce space-constrained applications.

- Variable Displacement Capability: Precise control of flow rates is offered because of their variable displacement features.

- Lower Cost: Manufacturing them is usually cheaper; hence, they are more cost-effective options for industry.

- Ease of Maintenance: Simpler construction can also signify easier and less costly maintenance over time.

- Energy-Efficient: Due to their steady performance, they provide energy efficiency wherever used in applications of low and medium pressure.

✗ Disadvantages

- Higher Wear: They can wear out quickly due to frictional issues between the swash plate and pistons.

- Less Capacity at Very High Pressures: The swash plate type is less suitable for high-pressure applications compared to those of bent axis.

- Heat Generation: Heat generated by swash plate pumps may be excessive; thus, an extra cooling mechanism is required.

- Sizes: Range available is typically small when compared with bent axis pumps.

Bent Axis Type

✓ Advantages

- High Pressure Efficiency: Can perform efficiently at high pressures due to its construction.

- Durability: Its rugged construction allows it to perform well even in heavy-duty applications for the long term.

- Reduced Wear: Less stress and wear occur on the components since the pistons are more aligned with the forces.

- Noise Levels Low: Operates at a low noise level, making it suitable for sensitive noise applications.

- Ranges Large: Larger displacements assure more versatility in industrial applications.

✗ Disadvantages

- Large Design: The larger size of the pump necessitates more space for installation.

- Large Initial Costs: These pumps are generally more costly to design and manufacture than swash plate types.

- Maintenance Complexity: Needs especial skills and tools for maintenance, which could increase upkeep costs.

- Energy Consumption: It may consume slightly more energy in certain applications, depending upon the system configuration, etc.

- Weight: Pump in total weighs more and might influence arrangements on portability and mounting.

Choosing the Right Pump Type for Applications

When a suitable pump type is to be selected for a particular case, my focus is mainly on analyzing the essential operational requirements and limitations at hand. For such selection, one must consider pressure requirements, flow rates, efficiency, and physical constraints of the system. For instance, if weight is a major factor whereby the pump should be easily portable, then maybe one should consider a swash plate pump, as this pump is comparatively lighter in weightage. And axial piston pumps should be selected in cases where energy efficiency and flow control under variable conditions are the dominant criteria, notwithstanding their initial setup cost being comparatively higher.

Maintenance complexity, along with long-term maintenance, could also be considered. If the operational environment itself offers limited access to highly skilled technicians or proper equipment or tools for servicing, then a fairly simpler alternative should be preferred for obvious reasons of preventing maintenance glitches and keeping maintenance costs at the bare minimum. It becomes necessary then to consider the question of trade-off in terms of whether or not the higher performance and greater flexibility of an axial piston pump justifies its own comparative complexity as against a simple solution which can deliver operational requirements in basics with relative ease.

The criteria from application-specific conditions, such as high or low operating temperature environments, or working fluids, and the consideration of environmental contamination on noise, are all nearly equal. By analyzing in detail the operating environment of the application, I match the pump specification to the application’s need and make certain that I select the most effective and reliable pump for the system needs.

Applications of Axial Piston Pumps

Industrial Uses of Axial Piston Pumps

The axial piston pump’s immense efficiency, very precise, and operational in the toughest situations makes it a preferred choice. One may find below in detail five applications where pumping finds direct use in industries:

- Hydraulic Press Systems: In metal forming, molding, and forging operations, axial piston pumps are usually employed in hydraulic press systems. As they are capable of producing high pressure hydraulic fluids with very precise control, they are extremely crucial in applying force and accuracy needed for such processes.

- Mobile Machinery: Used in construction equipment such as excavators, bulldozers, and cranes, these pumps service hydraulic systems of lifting, digging, and movement. They work well under varying loads and on diverse terrains, ensuring systems’ reliability in harsh conditions.

- Injection Molding Machines: In general manufacturing, injection molding machines demand axial piston pumps for hydraulic circuits, requiring very precise operation. These pumps will vary the flow of fluid and pressure to accommodate precise mold cycles and conform to the product quality.

- Oil and Gas Industry: Being subjected to hydraulic power units for drilling rigs and offshore platforms, axial piston pumps are ever so critical. They are the essence of the system’s reliability under the harshness of oil extraction operation due to the fact that they can withstand the pressures involved.

- Power Generation System: The pumps are applied in the hydraulic system of power plants such as turbine control systems or cooling systems. Their durability and accuracy enable efficient fluid handling to realize stable operations of power generation.

Because special needs are offered in these industries, the axial piston pumps continue to be the very life of these performance-driven and high-demand systems.

Mobile Hydraulics and Their Requirements

Where hydraulics prove useful in heavy machinery for construction, farming, and transport, mobile hydraulics have to meet certain operational criteria to perform efficiently and reliably while having to contend with rough conditions. Below are five detailed requirements that are crucial to mobile hydraulics:

- Compactness and Light Weight: The mobile hydraulic system components must be compact and lightweight, thereby ensuring ease of mobility for the machine and reducing the overall weight. To this end, it becomes more critical when this machinery has to work in tight spaces or has to be moved many times within a day.

- High Power Density: A lightweight mobile hydraulic system must give a high-power output. For instance, a hydraulic system in construction equipment such as excavators has to generate huge forces while maintaining a small footprint.

- Energy Consciousness: Cutting down on energy losses is essential in aiming at decreasing fuel consumption and hence from an operational cost-effectiveness point of view. Load-sensing systems, among other advanced designs, optimize the power usage based on actual demands, thus increasing system efficiencies.

- Durability and Resistance to Harsh Conditions: Mobile hydraulic systems should be designed for the stand against very high temperature extremes, pressure spikes, and exposure to dust, water, or debris. Components made from corrosion-resistant materials and with robust sealing mechanisms are required for durability over time.

- Precision and Responsiveness: Perfect control of hydraulic functions is needed in applications where very high precision is necessary, such as in agriculture for planting or irrigation. Mobile hydraulic systems are used in conjunction with advanced control technology to deliver instantaneous and precise responses to operator demand.

The given requirements emphasize the important engineering considerations that one must account for when designing mobile hydraulics for various industrial applications. If these factors are addressed, then mobile hydraulic systems will be considered to have ensured optimal performance and longevity in arduous operational conditions.

Case Studies in Various Industries

🏗️ Construction and Heavy Equipment

Mobile hydraulic systems are the heart of construction equipment, such as excavators, loaders, and cranes, where precision and power are of the essence. For example, advanced proportional-valve systems enable an excavator to carry out delicate operations-like trenching or pushing down utilities-while maintaining heavy load-bearing capacity. Modern construction hydraulic systems are load-sensing and pressure-compensated, so they become fuel-efficient by supplying just the acceptable power for a particular task. Therefore, component wear is minimized, operational costs brought down, and equipment reliability and service life enhanced.

🌾 Agricultural Machinery

Hydraulic technology is an essential mechanism for the large-scale agricultural operation involving harvesting, seeding, and irrigation. The best example lies in integrating variable displacement pump hydraulics to combines and balers. Such pumps vary their flow as per their load requirement, so they are always operating at a fixed speed irrespective of the field. IoT-enabled hydraulics improve productivity even further by virtue of allowing maintenance operators to monitor and control hydraulic operations online in real time using cloud-based platforms, thus facilitating prediction of maintenance and reducing equipment downtime during critical planting or giant harvesting time.

📦 Material Handling and Logistics

Mobile hydraulic systems enable forklifts, pallet stackers, and AGVs to achieve high accuracy under different load conditions. A few stages or multi-stage telescopic cylinders in the case of forklifts for vertical lifting, show how hydraulics can accommodate large heights without losing stability. Also, modern hydraulic fluid-energy recovery systems have found wide use in forklifts for increased energy efficiency in material handling operations.

⛏️ Mining Equipment

Hydraulics are of the utmost importance in mining environments as very high pressures can be exerted in small diameter systems. Mining haul trucks and underground loaders are urban systems with working equipment under harsh environmental conditions, even in continuous operation. High-pressure hydraulic circuits perform rock drilling and ore-extracting in constant demanded speeds and torques. Regenerative hydraulic braking systems are brought in to be the very face of a green-efficient industry.

Every single one of these applications has a good story to tell regarding the indispensability and multipurpose nature of mobile hydraulic systems in industrial machinery, spun under the lens of further design and technological development of the system. By maintaining adaptability and endurance, manufacturers keep stretching the limits of what is possible for some of the harshest operational environments in the world.

Efficiency and Control Mechanisms

Variable Displacement and Its Benefits

Variable displacement hydraulic systems stand as key design innovations in the pursuit of efficiency and precision in hydraulic machinery. The system employs pumps that modulate per stroke displacement as the requirements change so that the flow rate may be adjusted dynamically with pressure. A fixed displacement system, on the other hand, will supply fluid at a constant flow irrespective of whether the actual flow requirement demands so. Hence on the contrary, with variable displacement systems, the output can be scaled down to minimize energy loss, thus maximizing the overall efficiency of the system.

The chief advantages of variable displacement stem from energy consumption. Fulfilling fluid output to the workload can drastically cut down on required power. In return, this reduces operational costs and environmental impact. Front-line designs today usually incorporate electronical controls, creating the possibility for real-time adjustment. Electro-hydraulic proportional control valves provide an example of how to give exact feedback and enable finer tuning.

These pumps are even able to help prolong the system lifetime. The local wear of components is minimized because the fluid flow is controlled; hence, they last longer and demand less maintenance. They also stand for flexible operation, as such systems operate fairly well over a wide range of pressures and speeds and thereby be applicable to construction, manufacturing, and energy industry sectors.

There is an integration of smart sensor technology that amplifies the efficiency of these systems by supplying pressure, flow, and temperature data to optimize hydraulic performance in real-time. These advancements highlight the necessity of keeping industrial machines with variable displacement systems at the cutting edge for energy efficiency, operational accuracy, and life expectancy.

Comparative Efficiency of Different Pump Types

The design, operational principles applied, and application context play pivotal roles in the efficiency of pump systems. Among still commonly found types of pumps, centrifugal, gear, and piston pumps have efficiency characteristics that vary, at times conflictingly, under different conditions.

🔄 Centrifugal Pumps

These pumps transform as much as a motor’s rotational energy into kinetic energy and then into pressure energy imparted upon the fluid. For fluids of low viscosity operating at moderate to high flow rates, the pumps offer high efficiency. However, for high-viscosity applications or when operating away from their best efficiency point (BEP), centrifugal pumps are inefficient. Improved performance of impeller designs and materials will further influence their usage by the industrial systems.

⚙️ Gear Pumps

Being one of the highest viscosity liquids, these pumps work by moving the liquid through the operation of the intermeshing gears. This mechanical simplicity leads to great reliability and uniform operation. They have a lower efficiency overall as compared to the centrifugal ones, especially with increasing pressure during operation. This reduction in efficiency occurs partly because of internal leakage, which is more evident in aged or worn-out systems under high-pressure conditions.

🔧 Piston Pumps

Having a more complicated mechanism, piston pumps serve higher volumetric efficiency, suitable for applications demanding exact flow control, and offer considerable outputs under pressure. They are more efficient than other types when variable displacement systems are used, mainly as modern electronically controlled actuators minimize energy usage based on system demand. Nonetheless, in all this good said, piston pumps demand more upkeep on account of their complex components, which are problematic on wear.

From comparing these pump types, we find the importance of selecting a specific technology depending on operational requirements. Innovations such as adaptive control algorithms and Internet of Things-sensing capabilities are creating avenues to further enhance the performance of these systems. Through these improvements, the systems themselves, at least in theory, can implement predictive maintenance with real-time monitoring of performance metrics, thereby minimizing downtime and operational expenses.

Frequently Asked Questions (FAQ)

Q: What is an axial piston pump and how does it work?

A: In the axial piston pump hydraulic system, each piston is installed in a cylinder, with the cylinders arranged around a central drive shaft. The pistons move in and out depending on the angle of the swash plate. It thereby gives Volumetric movement to the fluid. In effect, it becomes a fluid power transmission system, so axial piston pumps are used in many applications.

Q: Explain the major components of an axial piston pump.

A: The major components of an axial piston pump are the swash plate, pistons, cylinder block, inlet and outlet ports, and the drive shaft. The angle of the swash plate determines the stroke length of the piston. The cylinder block contains the pistons, which are moved by the swash plate to pressurize and draw fluid. These components work together in bringing pressure to maximum during operating conditions, depending on output control of the pump.

Q: How does the swash plate angle influence the working of an axial piston pump?

A: The swash plate angle determines the stroke length of pistons inside an axial piston pump. With a bigger angle, the stroke length is more and hence the output flow and overall efficiency of the pump also increase. Alternatively, a smaller angle will give a smaller stroke, sometimes considered as a good thing when variable pump control or low flow rates are desired.

Q: Can axial piston pumps be used in both single-acting and double-acting configurations?

A: Yes, axial piston pumps may be either single-acting or double-acting. In single acting pumps, pistons move fluid in one direction on one side of the piston, whereas double acting allow fluid to move on both sides. Through this design, certain applications may benefit from one configuration or the other, depending on their hydraulic system needs.

Q: What is the maximum pressure of an axial piston pump?

A: The maximum pressure of an axial piston pump usually depends on the design of the pump and the materials of construction. Most axial piston pumps are high-efficiency pumps and can produce pressures anywhere from a few hundred to a few thousand psi. It is important to check the specifications of the pump so that it can provide the required pressure for any application under which it is expected to operate.

Q: How does the number of pistons influence the performance of an axial piston pump?

A: The number of pistons in an axial piston pump directly impacts the pump performance in terms of output and efficiency. More pistons allow for smoother output flow and higher pressure, whereas fewer pistons imply a simpler design with less output capacity. The choice of number of pistons should be made in consideration with the specific requirements of the application as well as the operating efficiency desired.

Q: What are the benefits of axial piston pumps over radial piston pumps?

A: Compared with radial piston pumps, axial piston pumps are more efficient and compact. There exist fewer moving parts in an axial piston pump, so the wear-and-tear factor is indeed lower and also maintenance is easier. Axial piston pumps can work with even higher pressure and also offer a better means of flow control, thus making them suitable for a wider variety of hydraulic systems and applications.

Q: How is the flow rate controlled by axial piston pumps?

A: Flow control in an axial piston pump is accomplished principally by variation of the swash plate angle and by variation of the speed of the pump, expressed in rpm. Adjusting the swash plate angle causes a change in the piston stroke length, directly varying the volume of fluid pumped each cycle: The greater the stroke length, the higher the output flow. This allows variable axial piston pumps to respond to changing requirements and assist their efficiency.

Q: Where are axial piston pumps used commonly?

A: The reason for using axial piston pumps in hydraulic systems is that these work across various industries, including construction, manufacturing, and automotive. They enjoy applications in hydraulic presses, cutting machines, excavators, and any working tools requiring reliable fluid power by virtue of high efficiency, variable output, and strong pressure capability.

Understanding axial piston pumps is crucial for anyone working with hydraulic systems. Their versatility, efficiency, and precision make them indispensable in modern industrial applications.