Some of the most critical machines are forced to do a number of operations in industries that range from heavy construction to advanced manufacturing. Fourth generation axial piston pumps are very important components in a hydraulic system. They not only generate the hydrostatic energy that is needed to drive machinery but also maintain higher levels of efficiency and performance. Therefore, to understand how axial piston pumps operate, their types of displacement, and factors affecting their efficiency is important for everyone intending to optimize the hydraulic system. In this article, we shall delve into the science behind axial piston pumps to understand what makes them so effective, then proceed to review how the performance of these machines influences the larger hydraulic system that they serve. Stay with us while we unfold this innovative technology and see how it can revolutionize the efficiency of your system.

Fundamental Working Principles of Axial Piston Pumps

How Axial Piston Pumps Operate

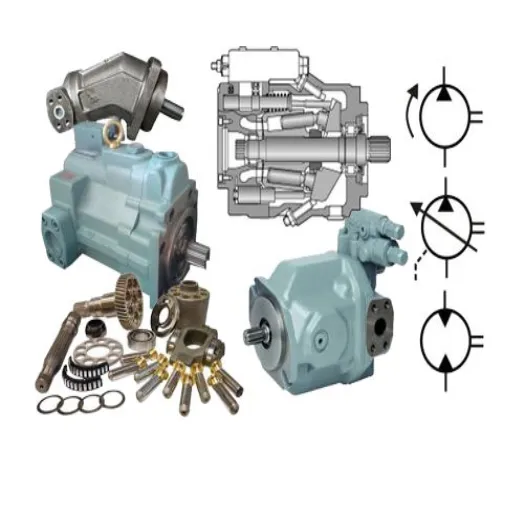

Axial piston pumps work by transforming mechanical energy into hydraulic energy through pistons moving within a cylinder block. The cylinder block, connected to a drive shaft, revolves, while the pistons reciprocate within the bores. This reciprocating movement generates alternate suction and discharge motions, pulling fluid into and forcing it out of the pumping chambers so that the pressurized flow may drive hydraulic systems.

The operation of the pump depends primarily on the swashplate or bent-axis angle, which determines the stroke length of the pistons. By adjusting this angle, the pump can vary the amount of flow and pressure to suit the system. This quality makes axial piston pumps very versatile and used in applications for precise flow control, variable displacement setting, etc.

The axial piston pumps require maintenance to uphold their performance level-it should be regularly lubricated, inspected for wear or leakage, and operated within recommended limits. High pressures and reliability levels make it a critical piece of machinery because in fairly high-pressure situations-performing efficiently, it finds application in construction, manufacture, and aerospace sectors, where hydraulic systems are integral in operational success.

The Role of Cylinder Blocks in Fluid Displacement

Cylinder blocks are crucial keeping-the-go of any hydraulic system during fluid displacement. In accepting the pistons at their center, it is performing compression of fluid and motion of fluid inside the system. Hence, any based description of the cylinder block class must show that from mechanical energy generation to hydraulic pressure generation, its influence dominates the pump’s output as well as pressure-handling capacity. Below are the detailed roles of the cylinder block in fluid displacement:

- Fluid Compression: The cylinder block provides the means for the piston to compress hydraulic fluid, thus converting mechanical input to pressurized fluid output.

- Sealing and Containment: The cylinder blocks seal the system to prevent fluid leakage and provide containment of fluid pressure.

- Alignment and Stability: Provides for the alignment and stability of piston motion and smooth operation.

- Heat Dissipation: Cylinder blocks absorb and control heat generated in the working head to maintain acceptable working temperatures and prevent any overheating.

- Providing Rotational Motion: Whereas the rotational motion may be furthered through the cylinder block in rotary pumps for pistons to operate and displace the fluid more efficiently.

Having these roles listed shows that cylinder blocks act as an assurance of reliability and performance of hydraulic systems scattered throughout many industries.

Understanding Variable Displacement Mechanisms

Variable displacement mechanisms serve as hydraulic components where the decoder makes changes to the fluid flow and pressure according to varying requirements. This could mean changing the displacement volume of the mechanism to work better with machinery in performing an assigned task. By increasing or decreasing the amount of fluid going through the system per unit time or volume, a variable displacement system inherently provides that the machine runs at lower power under changing loads or speeds.

Another great use for these mechanisms is energy conservation. Variable displacement pumps do not run at fixed loads but rather adjust to meet the system requirements, operating at lower loads to save energy whenever possible. It is a great feature of these pumps to ensure extreme control over a process while allowing much smoother operation and less damage to components from unnecessary stresses.

These mechanisms find widespread application in industries such as construction, factories, and aerospace, wherein versatility and efficiency are paramount. Axial piston pumps and vane pumps usually come built with variable displacement features to enjoy flexibility and reliability in such stringent environments. Thus, being variable and supporting energy saving, variable displacement mechanisms form the contemporary face of hydraulic technology.

Factors Affecting Axial Piston Pump Efficiency

Impact of Fluid Viscosity on Performance

Axial piston pumps and the nature of the viscosity of the fluids determine the efficiency and performance of pumps. It substantially influences various operations such as lubrication, heat generation, and volumetric efficiency. Here are five aspects of fluid viscosity and its effects:

- 1

Lubrication Efficacy: A higher viscosity allows sufficient lubrication to be present between the moving parts, decreasing wear and lengthening the life of the pump. If the viscosity is low, the lubrication will be insufficient, and that will lead to metal-to-metal contact, which will simply accelerate the rate of damage to the components. - 2

Internal Leakage: Thicker oils present better resistance to internal leakage, thereby increasing volumetric efficiency of the pump. If the viscosity is too high, it will impede flow through the pump paths, energy losses will occur, and performance will drop. - 3

Heat Generation and Dissipation: Heat generation in the pump is subject to viscosity. The lower the viscosity, the less heat it usually generates; though such fluids do not offer much lubrication. The opposite holds with higher viscosity fluids: they increase friction and heat generation, demanding better cooling arrangements for good operation. - 4

Pump Starting Performance: During a cold start, high viscosity causes problems with respect to pumping; it under-performs with response time and stressing components under load. It is indispensable that we select a fluid with suitable viscosity at varying temperature to ensure smooth operation. - 5

Resistance to Contamination in the System: Proper viscosity should ensure that the fluid always retains its filtration properties, preventing contaminants from circulating through the system. Meanwhile, fluids with inappropriate viscosity can adversely affect filtration capabilities, thus allowing the system to be damaged by debris or particles.

In any context, knowledge of and ability to manipulate these factors heavily impact the selection and satisfactory operation of axial piston pumps.

Effects of Operating Pressure and Temperature

In the case of axial piston pumps, the effect of pressure and temperature directly governs several crucial performance aspects. This will require the efficiency, durability, and generality of the system to perform adequately. Here are some major effects and considerations:

Viscosity Changes

At high operating temperatures, the fluid viscosity reduces, and this limits the lubrication that is afforded to some internal components of the pump, which therefore sustain wear. At very low temperatures, the fluid could thicken, which unintentionally restricts the flow and hampers efficiency of the system.

Thermal Expansion

Some components of the pump may expand when high temperatures are present and cause tighter tolerances, greater friction, accelerated wear, and hence reduced life span for the pump.

Pressure-Induced Stress

Higher working pressures instill greater stress on the internal components of the pump, including pistons, cylinders, and seals. When exposed to extreme pressures for extended durations, these components may fatigue and cause system failure.

Seal Degradation

Elevated temperatures and pressures will cause seals to weaken and degrade over time. The consequence of fluid leakage can lead to reduced efficacies in the processes and contaminations within the system.

Efficiency Losses

Pressure and temperature extremes can adversely affect pump efficiency. High pressures increase energy consumption; high temperatures affect fluid compressibility, thereby affecting volumetric efficiency.

Therefore, it is essential to monitor and control pressure and temperature levels so that the axial piston pumps can perform optimally for a long time.

Influence of Wear on Pump Efficiency

Wear also contributes to the axial piston pump down into their performance and efficiency. In time, the wear and tear of the pump’s components under friction, contaminants, and operating conditions result in the gradual diminution of efficiency to potentially eventual failure or downing of the system. Five detailed instances below describe the effects of wear on pump efficiency:

- ⚠️ Leakage from Worn Seals: Seal wear causes leakage, whether internal or external, resulting in a diminished overall efficiency in the pump. This means energy loss, making the system work harder to achieve the performance levels.

- 🔧 Damage to Pump Pistons: Wear on pump pistons leads to an irregular fit or improper movement within the cylinder block. This negatively affects both volumetric efficiency and the smooth functioning of the pump.

- ⚙️ Erosion of Valve Plates: The flow irregularities caused by wear of valve plates due to the continuous action of abrasive particles or aggressive fluids render the system unreliable.

- 🛡️ Corrosion of Metallic Surfaces: The metal components may over a period of time be subjected to the phenomena of corrosion, aiding the fluid by environmental factors. Thus, corrosion weakens the surfaces and interferes with the integrity of the important parts of the pump, lowering its service ability.

- ⚡ Bearings’ Wear and Failure: Bearings are important in the proper alignment and movement of internal parts. Wear or failure of the bearings causes misalignment, vibration, and heat generation, all detrimental to pump efficiency.

Wear on the pump can be minimized by good maintenance, timely replacement of worn parts, and regular inspection.

Practical Maintenance Tips for Enhancing Efficiency

Regular Inspection and Cleaning Practices

Real-time inspection and relevant cleaning procedures are the factors of utmost importance in ensuring the functional efficiency and long life for a pump system. This inspection will basically consist of sign-of-wear checks for cracks, leakages, or sensations of improper vibrations, all of which could hint calmly of mechanical problems. Inspections of seals, bearings, and shafts could also be conducted to identify the early processes or occurrences of deterioration. Early acquisition of these problems helps in repair costs, prevents unwanted stoppage of production, and greatly contributes towards operational reliability of the pump.

Here comes cleaning, equally important because the accumulation of debris, sediment, or contaminants might indeed spoil the performance of a pump. Filters clogged or impeller passages blocked are at least one example of the reduced flow capacity and increased consumption of energy. The cleaning carried out from time to time ensures the best condition for the pump to provide uninterrupted service practically. A cleaning schedule determined by environmental conditions, such as water quality or an exposure to chemicals, if needs be, is far reaching for better performance and less wear, differing as per the application of pumps.

Today’s pump, using modern technologies such as remote monitoring solutions and sensors, can make the inspection/cleaning process simpler. These systems provide real-time data on a few, ranging from pressure, temperature, and vibration to flow rates. Analyzing data from such could give clues to potential problems, which could then be solved before they worsened into some huge engineering problem. This, combined with periodic inspection and cleaning, helps to maximize the working efficiency of the pumps so that energy is well conserved and also imparts durability to the equipment itself.

Best Practices for Fluid Management

Fluid management must be made efficient for their longevity and optimal working capacity of mechanical systems. Some key aspects are as follows:

1

Real-Time Monitoring and Analysis

A real-time monitoring of parameters should be carried out such as viscosity, pressure, flow rate, temperature, contamination levels, etc. Analytics tools should be exploited to identify aberrations and perform predictive maintenance before actual failure occurs.

2

Fluid Selection

Selecting the fluid according to use is essential. Investigate lubricant or hydraulic fluid compatibility, temperature range it works in, and the environmental impact of the fluids.

3

Maintenance

Development of maintenance schedules with periodic inspections and fluid changes will ensure that contaminants do not infiltrate the fluid and that the fluid always meets the application requirements.

4

Filtration Systems

Choosing good filtration systems to filter dirt, particulates, and other contaminants from the fluid. Clean fluids do less wear and tear on equipment and contribute to faster system operations.

5

Leakage Detection and Management

Address minor leaks upon detection to avert waste, environmental contamination, or opportunities for damage to adjacent equipment. Leak detection ensures that leaks are identified early, and all modern technologies can assist in this.

These practices, fed by the latest technologies combined with data analysis, allow for optimal fluid management where that translates, minimizing downtime, guaranteeing system reliability, and conserving energy and materials.

Guidelines for Monitoring Wear and Tear

Effective wear and tear monitoring ensures smooth operations and prolongs the lifespan of equipment. Some critical points need to be followed to enable proactive maintenance and sustain reliability:

👁️ Regular Visual Checks

Perform regular visual checks to spot signs of wear and tear such as corrosion, cracks, or any deformation at the surface. The sooner such signs are detected, the more possibilities to halt potential big failures down the road.

📊 Follow Up Performance Metrics

Continuous monitoring of vibration levels, operating temperature, and efficiency metrics should be maintained. Any sudden spikes or falls seen in those parameters are telling signs of either wear or damage.

🔧 Use Predictive Maintenance Tools

Employ vibration analysis, thermal imaging, or ultrasonic testing to correct issues before they grow. These high-level methods aim at highlighting very subtle signs of wear that are hard to detect through manual inspection.

📋 Maintain Full Records

Drive Records for All Maintenance Activities, Inspection Results, and Replacement Histories into a Centralized System. Keeping accurate records serves for making decisions backed by data and understanding wear patterns of equipment through time.

🔄 Schedule Periodic Replacement

High-wear components, such as seals, bearings, or belts, get replaced at intervals set forth by the manufacturer or determined by wear trends observed. Preventive part replacement will always save you more money than repair due to sudden failure.

Following these guidelines-backing trends in condition monitoring and data science-will help lessen risks and optimize maintenance scheduling, resulting in the overall improvement of operational performance.

Comparative Analysis with Other Hydraulic Pumps

Efficiency Advantages of Axial Piston Pumps

Because of their high efficiency and top performance in numerous industrial applications, axial piston pumps are highly common. Additionally, their design and operational capabilities present some benefits:

- ⚡

High Volumetric Efficiency: Axial piston pumps have great volumetric efficiency: values often greater than 90%. Thus, the amount of internal leakage is low and nearly all the displacement volume of the pump is delivered at full pressure.

- 📊

Wide Operating Pressure Range: They are high-pressure pumps, usually working above 400 bars, hence suitable for the highest demanding industrial environments, like construction, mining, and manufacturing.

- 📦

Compact: When compared to other pump types, these pumps have an extremely compact and lightweight design that offers high power. They are well suited in installations with stringent space considerations.

- 🔧

Variable Displacement Capability: Many axial piston pumps are incorporated with variable displacement mechanisms so as to allow the precision control of flow rates and improve energy efficiency during the operation.

- 🛡️

Durability and Long Service Life: With better materials and engineering, axial piston pumps have longer life cycles even in harsh conditions, so in that way, they get reduced downtime and maintenance costs.

These very advantages highlight why axial piston pumps are majorly preferred in those systems where efficiency, reliability, and flexibility play crucial roles.

Disadvantages Compared to Radial Piston, Gear, and Vane Pumps

Axial piston pumps are costlier and more complex to manufacture and more destructible in nature. Whereas radial piston, gear, and vane pumps are comparatively cheaper, quieter, and simpler, they are not efficient at high pressures.

| Key Point | Axial | Radial | Gear | Vane |

|---|---|---|---|---|

| Cost | High | High | Low | Medium |

| Efficiency | High | Medium | Medium | Medium |

| Noise | Moderate | High | High | Low |

| Pressure | High | Very High | Medium | Medium |

| Maintenance | High | Medium | Low | Medium |

| Durability | Medium | High | High | Medium |

| Flow Rate | High | Low | Medium | Medium |

| Size | Compact | Compact | Small | Medium |

Choosing the Right Pump for Specific Applications

When selecting the appropriate pump for an application, I typically consider the key operational requirements of the process and the unique advantages of any given type of pump. If ever a situation demands a very high pressure, I would go for the radial pump. That is where it shines: giving you very high-pressure output. On the other hand, if we were to prioritize flow, then the axial would be the choice, as it can provide very high flow at a compact dimension. These are the factors that ensure compatibility of the pump with the application requirements.

I also consider cost, noise, and maintenance. When budget considerations come into play and moderate pressure would still be acceptable, my choice would lean toward the gear pump, being inexpensive and durable. In contrast, for certain applications where noise may present a serious concern, such as indoors or in noise-sensitive environments, the vane pump presents itself as a viable alternative with fair noise levels, admittedly at the cost of medium efficiency and medium durability. With these trade-offs in mind, I align criteria with client requirements in order to enhance decision-making.

Lastly, evaluation of long-term reliability and operating conditions plays a vital role in my selection process. Whenever it’s a matter of fairly constant operations over time, I suggest pumps of higher reliability, such as gear or radial pumps. If I expect wear to occur more often under harsher conditions, then I go for maintenance because I want to sustain that. And then finally, with these considerations in mind, I am able to make decisions for the best and more efficient pump fitting for his application.

Real-World Applications of Axial Piston Pumps

Common Industries Utilizing Axial Piston Pumps

Because axial piston pumps must be highly efficient and reliable in hydraulic systems, industries have seen them as common applications. In contrast, in the construction industry, these pumps are used on heavy machinery such as excavators, loaders, and bulldozers, which demand precision and steady power from the hydraulics. Similarly, the agricultural sector uses axial piston pumps in tractors and harvesters to maximize performance under intensive farming operations.

🏗️

Construction Industry

Heavy machinery such as excavators, loaders, and bulldozers, which demand precision and steady power from the hydraulics.

🚜

Agricultural Sector

Used in tractors and harvesters to maximize performance under intensive farming operations.

🏭

Industrial Manufacturing

Used in controlled movement applications, including injection molding machines and presses.

✈️

Aerospace & Defense

Perfect for aircraft hydraulic systems and military equipment where precise control is essential.

⚡

Energy Sector

Used in oil and gas exploration for drilling and other high-pressure applications.

🌱

Renewable Energy

Wind and hydro energy projects benefit from modernized axial piston pump designs.

In renewal energy projects, such as wind and hydro, the modernization of the axial piston-type pump design has further increased the uses of axial piston pumps. Because of their high efficiency and flexibility, axial piston pumps will remain a key component with an ever-growing number of industries, be it traditional or new.

Tangible Benefits of Improved Efficiency in Industrial Settings

The industrial sector has traditionally depended on efficiency as the driver for prosperity, waste reduction, and environmental sustainability. One major advantage of higher efficiencies is the huge cut in energy consumption. In industries, with the deployment of technologies such as axial piston pumps with optimized designs, huge savings in energy and operational costs can be achieved. To cite an example, modernized hydraulic systems can cut down on the inefficiency associated with fluid power applications so that energy conversion takes place with a little loss. This means reduced costs but also meets the global environmental goals, which have been set to reduce emissions of obnoxious gases and the sharpening of non-renewable energy sources.

Another tangible benefit while enhancing production output at the same level of or superior quality to goods is that efficient systems enable industries to perform their tasks much faster while maintaining complete precision in fulfilling demands. For example, the highly efficient machines in manufacturing settings reduce downtime due to equipment failure or overheating, hence maximizing productivity. In this regard, these developments also scale operations, as companies scale their systems to respond to workload variations without giving up performance.

Fewer breakdowns mean workshops become less busy and this, in turn, further enhances maintenance. Reduced wear goes along with innovative technology cuts down instances of breakdowns and costs of maintenance. In the heavy industries, this translates into production cycle interruptions being kept to the barest minimum and being able to extend through most of the days of the-life- span of costly machinery. By adopting this philosophy, companies gain the muscle to invest the savings into expansion, upskilling, or reinvest in technology, which create a positive growth and innovation loop.

Case Studies: Success Stories of Efficiency Gains

1

Manufacturing Optimization Through Predictive Analytics

A mainstay automotive manufacturer found predictive analytics enhancing operations on their assembly lines. With advanced sensors and AI-driven data analysis, they predicted when machines would fail before they did. Downtime was cut down by 20% around their production facilities. Energy consumption was further optimized by 15% with machine tuning, serving the company’s environmental targets and reducing operational costs.

2

Streamlining Logistics with Real-Time Data

Supply-line renewal by an international retail corporation came about with real-time tracking and data analytics methods. By integrating IoT-enabled devices and a centralized analytics platform, the company gained increased visibility into their transportation network, resulting in the reduction of delivery delays by 25% and fuel consumption by 10%. The initiative also improved customer satisfaction, proving that logistic efficiency can be scaled when technology is on its side.

3

The Energy Saving in Chemical Industries

One chemical production company set up a smart energy management system integrated with AI algorithms to manage the energy use of their processing plants. The system generated insights by studying the consumption patterns of energy and aligning operations to off-peak hours. The energy costs were reduced by 30% over a period of two years, showing that green pathways can be walked alongside profitability.

Businesses qua success stories are examples that underscore the fact on how businesses across industries can harness innovative technologies to make significant strides in efficiency, profitability, and sustainability.

Frequently Asked Questions (FAQ)

❓ Frequently Asked Questions

Q: What could be meant by the factors affecting axial piston pump efficiency?

A: Several factors affect axial piston pump efficiency, such as pump construction, speed of rotation, and swash plate design. Pump leakage and cavitation can also cause a considerable loss in performance. The efficiency varies according to pressure load and the fluid system employs.

Q: How does the design of the swash plate affect pump performance?

A: The design of the swash plate has a great impact on the performance of axial piston pumps. It controls the piston angles with the output displacement and flow rate; operating the swash plate at angles to permit maximum output flow will maximize pump flow rate and efficiency and minimize energy loss during conversion to hydraulic power.

Q: How important is the leak in axial piston pumps?

A: Leakage severely impacts the efficiency of axial piston pumps. Losses of output flow and reduction of the overall hydraulic power being transmitted into the system take place. Efficiency can be improved, and life can be prolonged through the reduction of leakage, which could be achieved with better sealing land design with proper maintenance.

Q: What are the efficiency comparisons between fixed and variable displacement pumps?

A: Fixed displacement pumps usually have a high efficiency under steady-state conditions but may perform poorly under varying loads as compared to variable displacement pumps. Variable displacement axial piston pumps adjust their output flows with changing loads and hence may provide better efficiency at varying operating conditions.

Q: What does oil temperature have to do with the efficiency of axial piston pumps?

A: Oil temperature has a pronounced effect on hydraulic fluid viscosity, which affects axial piston pump efficiency through a series of mechanisms. At high temperatures, the viscosity decreases, and the pumps do not run efficiently and, therefore, wear more. An optimal oil temperature must be maintained to obtain the best performance of the pumps.

Q: Can axial piston motors be better than gear pumps and motors in terms of efficiency?

A: Yes, axial piston motors, due to their design, in high-pressure applications, usually have a better power-to-weight ratio and efficiency than gear pumps and motors. They allow for better torque output and also provide smoother operation that may result in even more efficient fluid power systems.

Q: What are the consequences of cavitation on the efficiency of an axial piston pump?

A: Cavitation causes pressure drops in axial piston pumps and damages the pump components, which finally leads to decreased efficiency due to cavitation. When the pressure inside the pump falls below that of the vapor pressure of the fluid, vapor bubbles form; these vapors collapse violently, causing potential wear and tear and eventually reducing the service life of the pump.

Q: How does the design of piston pump technology affect efficiency?

A: Design in piston pump technology, which includes the piston configuration and overall pump construction, is a major factor influencing efficiency. Advanced designs such as bent axis piston arrangements enhance fluid dynamics and reduce power losses, which enhance the total efficiency of the pump.

Q: What is the relation between pressure and flow in axial piston pumps?

A: The pressure-flow interplay in axial piston pumps is fundamental to their operation. The pressure may fall as the flow rises if certain pumps are not designed to handle the increased load. Knowledge pertaining to this interaction dictates the performance of pump optimization so that the pump operates efficiently within its designed parameters.