Axial piston pumps serve in critical functions throughout industrial and mobile processes and form the backbone of hydraulic systems that demand precision, durability, and efficiency. Of the many varieties available of axial piston pumps, fixed displacement types hold the highest esteem for their relative design simplicity and reliability, thereby ensuring a constant flow rate. This article takes a look at fixed displacement axial piston pumps and their fundamentals while explaining how their design and operation offer optimal teachings in strenuous settings. Searching information is useful for engineers, technicians, and industry professionals so that they fill provide thorough details about their operation and application-oriented benefits to help make better decisions about their hydraulic system needs.

Introduction to Axial Piston Pumps

The Importance of Axial Piston Pump Design

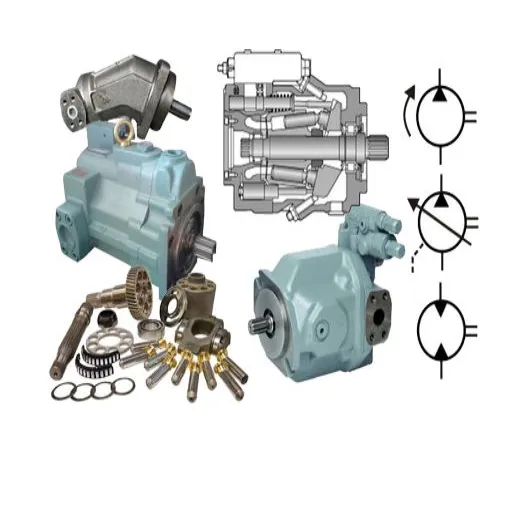

The design of axial piston pumps is essential for high efficiency, reliability, and durability in varying hydraulic applications. Their compact and accurately manufactured design ensures precise fluid displacement with constant flow rates and pressures required in arduous operations. They are capable of high pressure beyond 350 bar and are thus employed in high-performance industrial, mobile, and aerospace systems.

A primary benefit achieved through the very nature of the design is high volumetric efficiency attained by close tolerances and critical setting of internal parts such as pistons, cylinders, and valve plates. This efficiency cuts down on internal leakage and energy losses, thus attaining good overall system performance. Another plus: engineers and operators can choose between the swash plate and bent-axis design variation to meet a wide variety of specific application requirements in the machine.

Longevity and versatility are the other prime attributes of this design type of axial piston pumps. Advanced materials and surface treatment techniques-among others, could be: hardened steels, or coating methods-for passing the wear and tear test and preventing any possibility of failure in exceptionally severe environmental settings. Thus, their modular design allows for easy disassembly during maintenance and repairs, which helps reduce downtime in operation, making it ever so cost-effective. Such attributes have made the choice of an axial piston pump design a popular one for attaining precision and reliability in critical hydraulic systems.

Challenges Faced in Design and Application

The design and application of axial piston pumps pose several technical challenges that potentially affect performance, lifetime, and efficiency. Here are five key challenges experienced in this field:

- Cavitation and Aeration: Cavitation occurs when the pressure within the pump falls below the vapor pressure of the fluid, thereby causing the formation of vapor bubbles that rapidly collapse as the pressure rises. Such a collapse can progressively damage the pump internals. Aeration gets in the way of efficiency and accuracy when air gets mixed into the hydraulic fluid. Both phenomena can cause an increase in noise levels, a decrease in volumetric efficiency, and eventual catastrophic failure if not attended to seriously.

- Thermal Stability: Axial piston pumps must operate under a wide temperature range. Thus, thermal stability is a critical design consideration. Excessive heat may degrade seals, lubricants, or hydraulic fluid, reducing the pump’s efficiency and causing possible failure. In such a high-temperature environment, with ever so prolonged operation time, advanced thermal management systems and materials that can sustain temperature fluctuations are required.

- Contamination Sensitivity: Like other hydraulic systems, this can be highly tempered or compromised by contamination in the form of dirt, particles, or moisture in the fluid. The contaminants accelerate wear and erosion of internal components and shadow fluid dynamics. According to industry studies, up to 80% of hydraulic system failures are due to contamination. Hence, a solid filtration and monitoring technique must be in place.

- Noise Pollution: As far as noise and vibration are concerned, axial piston pumps generally remain a problem despite several engineering improvements attempting to curb sound generation. At high operating speeds and pressure differentials, formation of acoustic emissions might exceed levels that are permitted in some applications. Designing for quieter operation of a pump without sacrificing its performance is perhaps still an area where the engineers are working.

- Energy Efficiency: The increasing need for energy-efficient hydraulic systems places strong pressure on the pump manufacturers to optimize their designs. Inefficient energy transmission, primarily due to internal leakages or bad design, wastes energy and increases the cost of running these systems. To develop pumps offering high efficiency under varying loads and speeds, innovative designs combined with precise control schemes are required.

The challenges give credence to perpetual innovation in materials, designs, and operational standards to meet the real-world application-related complexities and address issues of long-standing reliability and efficiency.

Different Types of Axial Piston Pumps

Fixed Displacement Axial Piston Pumps

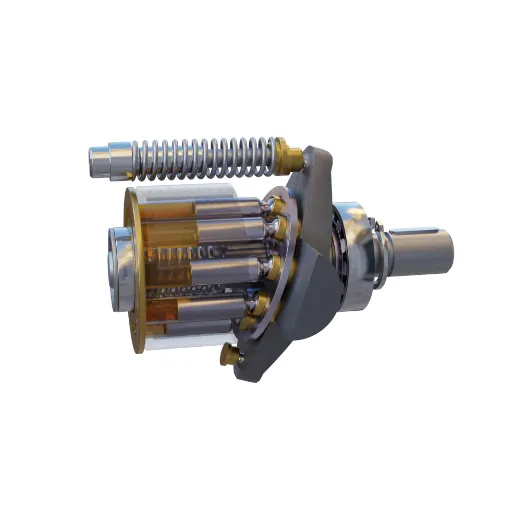

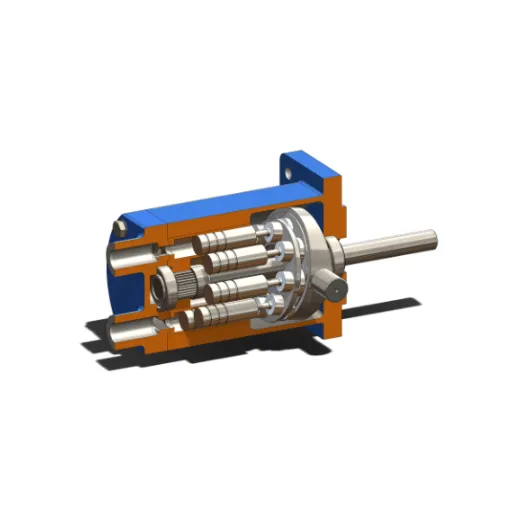

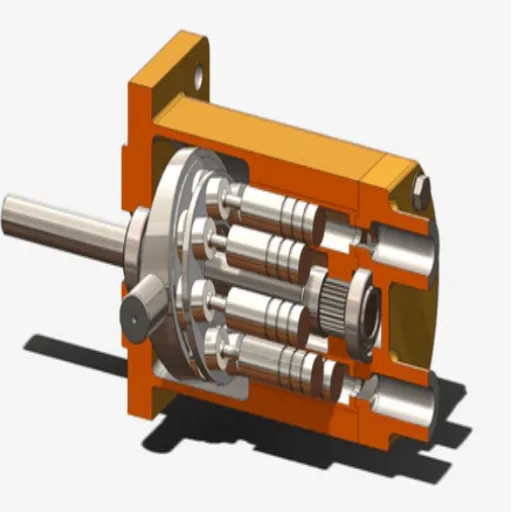

Fixed displacement axial piston pumps are hydraulic pump types designed to deliver flows at a steady rate in spite of changes in pressure within the system. These pumps operate with a fixed geometric displacement per revolution, hence giving them high reliability where output consistency and predictability are crucial. Usually, they find application in industrial and mobile machinery where the application of exact fluid power is involved-for instance, in conveyor systems or injection molding machines, or agricultural equipment.

Usually, such pumps consist of a certain number of pistons arranged in parallel within a cylinder block. During operation, these pistons move back and forth relative to the rotation of the drive shaft and the angle of the swashplate to give rise to a pumping action under control. For continuous-duty applications, these pumps are constructed from high-grade steels and exotic alloys to increase durability and reduce wear.

Key Benefits:

- High volumetric efficiency, generally above 90%

- Compact design for space-constrained applications

- Working pressure limits up to 450 bar

- Consistent flow delivery for demanding industrial applications

Maintenance-wise, it consists mostly of routine checks for wear and tear of pistons, bearings, and seals, as any sign of wear will lead to poor performance, or even worse, contamination of hydraulic fluid. Newer bearing materials and seal concepts have set various limits to further edge their working life under high pressure, with many of them topping the charts at a working pressure limit of 450 bar.

Variable Displacement Axial Piston Pumps

Due to their variable displacement, axial piston pumps present vast flexibility to a hydraulic system, allowing users to specify how much flow or pressure equals any given requirement. This configures the pump’s variability into an adjustable swashplate to vary the stroke length of the pistons and, thus, pump displacement. In doing so, it enables pumping of fluid in precise amounts corresponding exactly with the needs of an application, thereby conserving energy and preventing wastage.

The latest designs incorporate electronic counter controls for monitoring and adjusting operations on the fly. For example, using an electro-hydraulic servo system, displacement can be adjusted on the fly to minimize energy consumption versus output performance-fine balance, perfect for motion control equipment precision requirements in injection molding machines, industrial robotic systems, and aerospace tooling.

Variable displacement axial piston pumps excel in high-duty cycles and pressure ranges, and many contemporary models can run at pressures up to 500 bar. Better materials and wear-resistant coatings have been developed for longevity, even in much harsher environments. Advanced embedded diagnostics and IoT-enabled sensors allow for predictive maintenance, which further improves reliability and cuts operational downtime; thus, these pumps have carved out their strong presence in the modern industrial scenario.

Applications in Industrial vs Mobile Settings

Hydraulic pumps are definitely used in a variety of activities, whether in industrial or mobile situations, and of course, the required specifications and configurations differ.

Industrial Applications

Industrial configurations lean toward high capacity, accuracy, and durability. When pressure-holding or high flow rates become vital in processes like metal stamping, injection molding, or clamping systems, the pumps see their application. For instance, an axial piston pump would be selected because the operating pressures can be as high as 350 bar or more, while still enabling very accurate control of flow.

Key Features: IoT integration, centralized monitoring, predictive analytics, precision control, and high-pressure capability.

Mobile Applications

In contrast, compactness, weight efficiency, and accommodation for possible varying conditions are the keys to a mobile hydraulic system. These pumps are generally fitted into construction machinery, agricultural equipment, and material handling vehicles.

Key Features: Compact design, variable displacement for fuel efficiency, real-time terrain adaptation, and high-grade sensors for optimization.

Advantages of Axial Piston Pumps

Efficiency in Performance

These pumps have been known for their energy efficiency and operational performance. These pumps maximize energy losses with the constant flow of fluid moving through them. Here are five key details and measurable data that make these pumps efficient:

Very High Volumetric Efficiency

Axial piston pumps have a volumetric efficiency that typically exceeds 90%, minimizing fluid leakage and delivering optimally even at very high pressures.

Low Energy Consumption

Modern designs can reduce energy consumption by up to 15% compared with that of traditional pumps in many applications, resulting in significant energy savings.

High Pressure Capability

Axial piston pumps maintain efficiency levels, constant pressure levels, and run efficiently at pressures of up to 500-bar high-pressure hydraulic systems.

Variable Displacement Control

The variable displacement mechanism affords precise control in defining fluid output, thereby further increasing process efficiency and allowing wastage of hydraulic power.

Thermal Efficiency

Improved heat management systems diminish heat production and bolster cooling capability, resulting in a prolonged working life in the pump and constant performance when working under unfavorable conditions.

Versatility in Applications

The pumps have become incredibly versatile and must, therefore, serve a broad industrial and mobile applications spectrum. These pumps provide the benefits of high-pressure hydraulic power, manually handled for different operational needs. We now look at five noteworthy applications of axial piston pumps:

- Construction Machinery: Hydraulic power generated by axial piston pumps aids the operation of cylinders and attachments in excavators, loaders, and bulldozers. Such operations involving high-pressure loads under grievous construction conditions entrust their reliable performance to axial pumps.

- Agricultural Equipment: These pumps are used in tractors, harvesters, and irrigation systems for accurate control of hydraulic functions such as lift, steer, and spray operations. The durability required of them comes in handy for employing them in the field for very long periods.

- Industrial Manufacturing: In industrial environments, axial piston pumps find applications in hydraulic presses, injection molding machines, and assembly line systems. They are chiefly considered in precise manufacturing processes because of their compact design and constant flow output.

- Aerospace and Defense: Axial piston pumps find very important applications in aircraft hydraulic systems, running the flight controls, landing gear, and braking systems. Their design is such that it is light yet sturdy to withstand and perform efficiently even under the harshest of conditions.

- Marine and Offshore Operations: Normally used in marine hydraulics and offshore drilling equipment, axial piston pumps will assist in offshore steering, winching, and subsea machinery. Their applications are vital because they operate well even in such corrosive, high-pressure underwater conditions.

Compact Design Benefits

The axial piston pumps are small in dimension, affording major advantages, making them very desirable in applications wherein space, efficiency, and performance are important. Below are five essential benefits of their compact design with detailed explanations and insights:

- Space Efficient: Having been toned down in size, axial piston pumps still fit into quite tight nooks; such miniaturized engineering machinery or industrial setups are just some scenarios. Especially offshore platforms, where solutions are heavy on instrumentation, thus space is highly coveted.

- Reduced Weight: Being small weigh less than almost all other sorts of pumps in the same output capacity; this reduced weight can decrease the load on structural balance, thus relevant to mobile equipment, aerospace systems, and other applications with a big push on lightweight components.

- Installation Flexibility: Thanks to their optimized design, installation is made simpler, even when working within tight-space configurations. The possibility to deal with a large variety of mounting orientations enhances the flexibility of pump application in varied machinery arrangements, thus making the design of the system more efficient.

- Less Energy Consumption: Smaller design entails minimized internal friction and consequently, more efficient hydraulic flow. Therefore, energy is lost less during operation, energy consumption is brought down, and operating costs are kept at a minimum, while the pump keeps working at peak efficiency.

- Improved Maintenance Access: Axial piston pumps, with their slim profiles, permit easier access to vital components for maintenance or repair. The elimination of downtime, coupled with easy maintenance procedures, results in the long-term operational reliability and cost-effectiveness of the system.

Disadvantages and Limitations

Maintenance Considerations

Proper maintenance will always favor longer life and better operational efficiency in compact hydraulic pumps. Five major aspects of maintenance are discussed below.

- Regular Change of Fluids: With time, a hydraulic fluid may degrade, thus lowering its performance and increasing the wear and tear of the internal components. Studies also show that hydraulic systems whose fluids were changed at the stipulated time lasted 30% longer. Contamination from particulates or moisture may corrode or clog, thus making fluid monitoring essential.

- Filter Inspection and Replacement: A clogged or damaged filter will invariably lead to a drop in flow rate plus pressure of the system. Studies have confirmed that a deteriorated filter impairs the efficiency of a system by as much as 20%. Regular inspection every 100 hours of operation and subsequent replacement are recommended to keep the system at its peak of performance.

- Seal Integrity Monitoring: One of the most common causes of leakage in hydraulic systems is damaged seals. At times, the leaks may cause a pressure drop, hence increasing energy. According to experts, unplanned downtime can be decreased by 25% when seal integrity is maintained through various inspections. Moreover, to further provide for life, high-quality seals should be employed.

- Pump Alignment Checks: Extra vibration and premature wear may result due to any misalignment in the pump and motor shaft. They are said to consume 15% more energy than properly aligned systems. Checks for alignment should be done during installation as well as maintenance to avoid such setbacks.

- Temperature Regulation: Overheating reduces efficiency and lifespan greatly in the case of hydraulic pumps. Being exposed to high temperatures may accelerate the wear or outright failure of internal components. It has been found in studies that temperatures in operation exceeding 180°F(82°C) decrease the oil viscosity by 40% and likewise the system reliability. Ensure to install proper cooling systems and keep an eye on any temperature fluctuations.

Cost vs Performance Trade-offs

When considering cost-performance trade-offs concerning compact hydraulic pumps, a few important factors must be taken into consideration to provide optimum efficiency without compromising operational integrity. Such pumps, due to advanced materials used in their construction, precision engineering, and thermal management systems, view the price to remain much higher than their lower performing counterparts, which ultimately is compensated in the long run through greater system ageing, retaining ability, reduced downtime, and accident losses.

Performance Benefits vs Higher Costs:

- Extended Life: Composite/alloy materials increase wear resistance by ~30%

- Energy Savings: Variable displacement pumps reduce energy consumption by 20-25%

- Lower TCO: Higher upfront costs offset by reduced maintenance and downtime

However, cheaper choices do exist if line applications generate less pressure and fewer operational needs. A slimmed-down pump design reduces procurement and maintenance costs but may lack the ruggedness some industrial systems demand. Operators must study the duty cycles, geographical and atmospheric conditions, and load requirements to pinpoint a delicate, almost indefinable balance between cost and performance.

Potential for Hydraulic System Issues

My main focus when considering failures that may arise in hydraulic systems is contamination, absence of proper maintenance, and operational stress. Contamination is a leading cause of hydraulic system failure and can be due to the presence of particulates, moisture, or air in the fluid. This will, of course, call for proper filtration systems and tests on the fluid at frequent intervals to ensure timely detection and hence treatment of any contaminant. The next line of defense I would propose to guard against this risk would be to enforce a strict cleanliness policy.

Another critical area I would look into would be maintenance practices. Regular maintenance schedules are essential to ensure the long life and optimum functioning of the hydraulic components. I would inspect seals, hoses, or connectors for any weakness or wear, for the fear that the failure might have already occurred. Also, proper fluid adjustment, as well as fluid type as recommended by the manufacturers, will help keep the system working within design parameters. Any sort of planned or systematic maintenance would certainly minimize the chances of surprise downtime or catastrophic failure for me.

Finally, I would convey the effects of operational stress on hydraulic systems. Operating conditions like overloading, pressure fluctuations, or the generation of excess heat generally result in the premature wearing away or failures in components of the system. To overcome such conditions, I would analyze in detail the limits under which the system operates and confirm that the equipment is operated well within its rated capacities. The application of cooling systems to reduce thermal loading and carefully observing the pressure levels would also prevent failure from occurring due to stress. Working on these considerations would allow me to enhance the reliability and efficiency of the hydraulic system while alleviating the possibilities of operational disturbances.

Maintenance Best Practices for Axial Piston Pumps

Routine Inspection and Maintenance

Operate the equipment as recommended in usual conditions to achieve high performance and prolong the life of axial piston pumps. Strict procedure inspection and maintenance should be trained to be annually met in points like checking fluid levels, viscosity, and cleanliness. Any suspicion of contamination of the hydraulic fluid or contaminants is seen to be one of the most severe causes of pump wear and failure. Check the filtration system occasionally, depending on set-time stipulations, and change filters if necessary to avoid the risk of damage through fine particulates.

Internally, components should be checked for wear and degradation, such as seals, bearings, and pistons, which undergo mechanical stresses that, if not changed timely manner, cause inefficiency or even system failure. Detect unusual noises, vibrations, or leaks and record them as irregular observations, which are useful signs that the pump may be wearing, malfunctioning, or even correcting itself.

Other frequent actions are to check for system pressure settings and remain within recommended specifications by the manufacturer. Overpressure or improper settings may induce stress on pump components, diminishing their efficiency and increasing potential failure. Implementing predictive maintenance technologies such as vibration analysis and thermal imaging may, therefore, enhance reliability again by providing real-time diagnostic data concerning the evolution of a particular problem, before its escalation.

Optimizing Lifespan and Performance

Axial piston pumps would, presumably, have a longer life and better performance when maintained with modern technology. Hence, oil analysis is regularly carried out to check the level of contamination in hydraulic fluid and maintain it at the standard viscosity and cleanliness level. Internal surface contaminants can interact with abrasive materials to damage valve plates and pistons, leading to the premature wear of parts and lower efficiency.

Also, one can employ an advanced condition monitoring system to continuously monitor pressure, temperature, and flow rates. Such systems permit corrective measures even before serious damage occurs in the anticipation of a departure from the standard set of operating conditions. For example, thermal sensors would detect overheating that could signify severe internal friction or poor lubrication.

Choosing the right parts and oil, therefore, should always be done with OSHA specifications in mind. Any compromise on parts would accordingly reduce the pump’s efficiency, along with incompatibilities in the system.

Key Takeaway: By taking a holistic approach to the problem supported by data-driven diagnostics and OEM recommendations, operators will enhance the strength and efficiency of an axial piston pump.

Frequently Asked Questions (FAQ)

Q: What is the principle behind axial piston pump design?

A: Piston axial pumps are designed using an axial cylinder block with pistons. The pistons are fitted in the barrel, which rotates about its axis. This rotation creates pressure differences that result in the inlet and discharge of fluid to do respective work for diverse applications.

Q: How does the design of an axial piston pump affect its performance?

A: The performance of an axial piston pump depends, among other things, on its design features such as the swash plate angle and movement involved. A well-designed pump will yield efficient operation by best exploiting piston stroke and minimizing resistance, while simultaneously being more reliable in construction equipment and various other applications.

Q: What is the role of the swash plate in axial piston pumps?

A: The swash plate design in axial piston pumps is very critical because it controls the angle of operation of the pistons, which in turn affects the total amount of fluid displaced during one piston stroke. This means it can change the discharge volume of the whole pump or the efficiency of the whole pump.

Q: How does a bent axis design differ from the usual axial piston pump design?

A: The bent axis design is one in which the shaft is offset from the axis of the pump, so from the operational point of view, it differs from the conventional axial piston pump. This kind of design accounts for low friction and hence greater efficiency and is chosen for various high-end applications.

Q: What are the most commonly serviced outputs of axial piston pumps related to construction machinery?

A: Axial piston pumps find their great applications in construction equipment for hydraulic systems, where the weight of heavy machinery is transferred. They work great for high-pressure generation (in terms of psi) and for very fine control of fluid for carrying out lifting, digging, and material handling.

Q: How do the number of moving parts in an axial piston pump affect its maintenance?

A: The number of moving parts in an axial piston pump affects its maintenance. Ordinarily, fewer moving parts mean less wear and less failure, therefore less maintenance. This very parameter in a pump’s design constitutes the core for the extension of life and dependable applications.

Q: What questions should be asked when selecting an axial piston pump for a certain circuit?

A: When choosing an axial piston pump for a particular circuit, the required flow rate, operating pressure, and fluid being pumped are considerations to keep in mind. Further, the design factors such as housing material, piston and valve plate configuration, and efficiency must be consistent with the requirements of the application.

Q: Could you describe how the pistons rotate inside the axial piston pumps?

A: In an axial piston pump, the pistons rotate inside the barrel in a circle as the swash plate oscillates, allowing the pistons to be pushed in and out of their chambers so that suction happens at the intake and pressure at the end of discharge, thus moving the fluid in the system.

Q: What bearing does the piston stroke have on axial piston pumps?

A: The piston stroke has a pretty significant role in that it determines the volume of fluid displaced during every pump cycle. Basically, the longer the piston stroke, the greater tends to be the volume of fluid being pumped, which is all-important in connection with those applications demanding a lot of hydraulic power. A good design assures efficiency and effectiveness by way of providing a suitable length.

Conclusion

Axial piston pumps represent a cornerstone technology in modern hydraulic systems, offering unparalleled efficiency, reliability, and versatility across industrial and mobile applications. Understanding their design principles, operational advantages, and maintenance requirements is essential for optimizing system performance and maximizing return on investment.