A plunger pump is a high-performance device widely recognized for its efficiency and reliability in handling high-pressure fluid transfer applications. Whether used in industrial settings, oil and gas operations, or even agriculture, the unique mechanics of a plunger pump make it an indispensable tool in scenarios where precision and durability are paramount. This article dives into the intricate workings of plunger pumps, their core components, and the science behind their operation. Additionally, it explores the diverse industries that rely on these pumps to power critical processes, providing a comprehensive understanding of their practical applications. By the end, you’ll gain valuable insights into why plunger pumps are a preferred choice in some of the most demanding operational environments.

What is a Plunger Pump?

Definition and Functionality

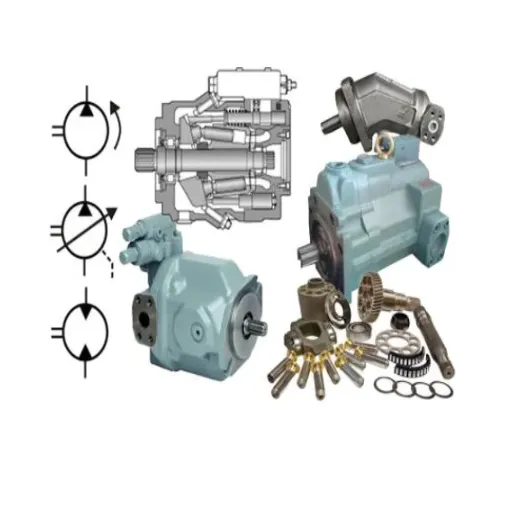

A plunger pump is a positive displacement pump used to push out liquids by means of a plunging reciprocating or sliding piston. This plunges the liquid into a high-pressure chamber that has a continuous rate of flow because it is also designed to handle a range of liquid viscosities and other types, like abrasive and corrosive fluids. Given that it is expected to deliver specific pressure levels at certain flow rates, such a pump is best applied in sectors that require a high level of precision and operational consistency.

The most essential elements that are vital to the optimum performance of a plunger pump are the plunger or piston, the cylinder, inlet and outlet valves, and the packing. The plunger goes up and down in the cylinder; this creates the space and decreases the pressure so that the fluid is inhaled during the intake phase, and then the pressure becomes bigger while the. The plunger goes up and pushes the fluid out during the discharge phase. This reciprocating movement assists the pump in achieving extremely high pressures, which are crucial when it comes to the functioning of hydraulic systems, chemical dosing systems, and water jet cutting.

The engineering of circuit-based circuits can surely improve circuit performance. Such circuits are often found in industries that specifically include those that operate in harsh environments. For example, plunger pump application is critically essential in the oil and gas industry for enhanced separation, in the pharmaceutical industry concerned with metered drug delivery, as well as in sludge and other mass transfer systems. The construction is rigid and can handle high pressures as well as harsh fluids, thus it is important in many processes.

Comparison of Plunger Pumps and Piston Pumps

The function and design characteristics of rod-type and piston-type pumping systems can vary significantly with respect to the ease of sealing, resistance to pressure, service life, requirements for upkeep, purchase pricing, and compatibility.

|

Aspect |

Plunger Pump |

Piston Pump |

|---|---|---|

|

Seal Location |

Fixed |

Attached to the piston |

|

Pressure Level |

High |

Low |

|

Longevity |

Long-lasting |

Moderate |

|

Upkeep |

Minimal |

Frequent |

|

Expense |

Affordable |

Costly |

|

Usage |

Industrial, Heavy-Duty |

Residential, Light-Duty |

Key Components of a Plunger Pump

A plunger pump includes numerous essential parts. All of these parts aim at maintaining the functioning of the pump under high pressure and extreme conditions. This section of the design is determined by industrial applications expecting a high degree of accuracy and performance reliability.

- Plunger: The plunger is usually a cylindrical rod made from rigid materials such as stainless steel, ceramics, etc. This component belongs to the set of parts that move during the operations and help in displacing fluid through the system. Such application of a pillar is useful when fluids have to be carefully discharged. The service life is a very important factor owing to the rough conditions that are bound to be experienced with every gas-theatric cycler.

- Seals or Packing: These are required components that prevent the liquid from leaking and ensure the energy efficiency of the pump, which is achieved by ensuring that the plunger is held in place with no gaps or slight openings. These are constructed from well-performing tetrachloroethylene rubber polymers or any other elastomeric material tough enough to resist hard usage and various forms of chemical degradation.

- Piston: The piston in a pump functioning simiralry by drawing in fluid on one stroke and then producing more fluid. Is is manufactured to withstand the constant variations in presure stress exerted during its operation.

- Valves: The fluid control inlet and outlet valves of the piston pump for fluid motion. These types of valves ensure that the fluid does not flow back by facilitating the inlet of the required direction flow with the least resistance and constantly support against overpressure backflowing.

- Drive Mechanism: The reciprocating motion of the pistons is usually driven by a crank or a cam system. This serves the purpose of translating the rotational energy from either a motor or an engine into the back-and-forth movement necessary for pumping.

With this set of crucial components, plunger pumps have been proven to be highly effective and reliable thus making them a must-have in high pressure liquid handling industries. It is mandatory for each item to be serviced to maximize their performance and keep the device working for more than the specified period.

How Plunger Pumps Work

Mechanism of Action

Plunger pumps work on the mechanism of positive displacement, where a vertical cylinder having a plunger in the center moves forth and backward in the housing to create pressure. The cycle commences when the crank, impelled by an external source like a motor or any other engine, begins to revolve and transmits the motion to a connecting rod. This rod, in its turn, moves the plunger by converting the motion into thrust (linear) motion. At the time when the plunger comes back into the chamber during the ‘suction stroke’, a reduced pressure, that is a paranterial, is created inside the chamber. This enables the upper liquid, like water, you can add a stopper for this purpose, or any solid, like a process fluid, to be drawn into the cylinder through an inlet valve.

In order to compress the working body, the plunger is shifted to the right, and the pressure of the working fluid in the chambers increases. On the necessary level, the outlet valve located in the pump opens, and liquid is forced in the discharge line under high pressure. Very efficient sealing mechanisms protect existing packings or O-rings from leakage, providing better efficiency of the system. Well-developed solutions may anticipate many plungers working with each other and making the flows stroke continuously with less pulsation because this is necessary for final consumers, such as industry, to get the fluid pressure always consistent.

Plunger type pumps today are made from materials that do not corrode and can withstand a range of fluid viscosities, pressures, and temperatures. These pumps are suitable in various operational environments.

Pressure Generation in Plunger Pumps

When it comes to plunger pumping, there are several ways that the system depressurizes. By moving the plunger back inside the cylinder, it will pull the fluid forces open the check valve and fill the cylinder as a cavity. In the push phase, retract the plunger, creating high pressures and thus compressing the stored fluid, which can push out via the exhaust valve. The strain of the pressure caused by this will depend on the punch geometry, side length, stepping stops per minute, as well as, Yom user, any other noteworthy fluids properties include: viscosity and compressibility of the fluid.

The most advanced plunger pumps today have been combined with new technology and machining techniques to regulate pressure with limited energy usage. These limit flow rates and the attainable delivery with the use of stroke length or speed controllers, which can be set specifically for each application. Further, in the last days, much research has shown that wear and tear on the seal and the concentric reducers used on the piston assemblies are good determinants of system efficiency and how long the system will be in operation, especially when operating at pressures above 10,000 PSI.

Such issues have driven the development of plunger pumps to cater to certain industries like petroleum, petrochemical, chemical, and water.

Understanding the Cycle of Operation

The cycle of operation in plunger pumps is a sequential series of events that allows fluid to be transferred at high pressures. The cycle consists essentially of two phases: the suction (or intake) stroke and the discharge (or compression) stroke. During the suction stroke, the plunger retracts, creating a vacuum within the cylinder. This vacuum reduces the pressure inside the cylinder so that the fluid is sucked into the pump chamber through the inlet valve. Effective sealing mechanisms prevent any leakage so that the maximum amount of fluid is taken in, ensuring volumetric efficiency.

Simultaneously, during the discharge stroke, the plunger moves ahead, applying pressure on the fluid trapped within the cylinder. This pressurization expels the fluid into the downstream system through the outlet valve. Ensuring the valves are tight and correctly operating holds against the backflow fourth in the consistency pressure in operation maintained by means of the suitability of the materials of the plunger and the cylinder.

To help optimize these cycles, modern plunger designs use materials such as tungsten carbide coatings or elastomers for seals that could operate in extreme conditions. Now, other technologies in sensor-based monitoring can provide real-time feedback about pressure, flow rate, and wear patterns so that actionable data reduce maintenance costs and prevent downtime.

Applications of Plunger Pumps

Applications in Manufacturing

Due to their ability to move fluids at high pressures with complete accuracy and reliability, plunger pumps find use in many forms of manufacturing. Some of the major manufacturing applications of plunger pumps are outlined below:

- Chemical Processing: For aggressive chemical fluids such as acids, alkalis, and solvents, plunger pumps are used for their precision in transfer and injection. The higher pressure ensures adequate mixing and optimum conditions for reaction within the chemical processes. For example, the pump can produce 10,000 PSI pressure, so these substances can be treated safely and effectively with quick reactions.

- Food and Beverage Production: High-pressure plunger pumps can be used for homogenization, especially for foodstuffs like milk and cream. These pumps produce a uniform texture and have a shelf life. They are constructed with FDA-approved materials to meet stringent hygienic standards in food manufacturing.

- Oil and Gas Industry Applications: Within Oil and Gas, these plunger pumps are the best and are used to inject water, chemicals, and several fluids into oil wells for enhanced oil recovery. Pumps working above 20,000 PSI are considered necessary in the entire upstream operation to keep it efficient and safe.

- Pharmaceutical Manufacturing: Plunger pumps are great for metering and dispensing liquid components accurately in pharmaceutical manufacturing plants. This precision is important for mixing correct doses for tablet coating, sterile filling, and vaccine production.

- Water Treatment Systems: Plunger pumps work in conjunction with RO systems and high-pressure cleaning applications in water treatment plants. These pumps provide pressures of up to 1,500 PSI for RO processes and enable the removal of contaminants and purification of water to be carried out in environmentally friendly ways under set regulations.

This numerous utilization only cares to emphasize the versatility of the plunger pumps and their capability to withstand the demanding requirements of modern-day manufacturing industries with precision manufacturing techniques, durability, and engineering.

Role in Agriculture

Modern agriculture considers plunger pumps a key element for the efficient delivery of water, fertilizer, and pesticides to crops. Their high pressure, precision, and ability to withstand wear and tear render these irrigation pumps a must in sustainable agricultural practices. Here are five agricultural applications where plunger pumps markedly assist the processes:

- Irrigation Systems: High-pressure-type plunger pumps are used in precision irrigation systems such as drip or sprinkler-interfaced irrigation systems to deposit water evenly and efficiently on the fields that will conserve water and promote good crop growth conditions.

- Fertilizer Injection: Plunger pumps inject liquid fertilizers into irrigation lines to supply essential nutrients to the crops in a controlled and uniform way. This reduces waste and increases soil fertility.

- Pest Control: These are the pumps involved in spray systems for spraying pesticides and herbicides over large areas of agricultural land. Their capability of holding the pressure steady allows an even application; otherwise, pest infestations or damage to crops may occur.

- Livestock Farming: Plunger pumps are used in cleaning and disinfecting livestock houses, thus improving hygiene and disease control. In other words, these pumps wash the stables, feeding, and equipment using high-pressure water.

- Aquaculture Applications: Plunger pumps are used to maintain water circulation and aeration in breeding tanks or ponds, making ideal conditions for fish and other aquatic organisms to grow in. They may also be used for the correct dosing of nutrients or treatments to aquaculture systems.

By way of these different applications, plunger pumps facilitate agricultural efficiency, sustainability, and productivity by way of reliable solutions to the complex needs of the sector.

Benefits of Using Plunger Pumps

Durability and Longevity

The main advantage of plunger pumps is their extraordinary durability and long service life due to their sturdy design and high-grade materials. Usually, these pumps are designed for high-pressure and abrasive conditions, so they find vast applications in demanding fields such as agriculture and aquaculture. In consequence, the precision components with wear-resistant seals and corrosion-resistant materials keep these machines running smoothly for great lengths of time.

From my experience, plunger pumps need less maintenance than most other pump types. Specified in maintenance, examinations, and timely replacement of various parts, including seals and plungers, avert wear-and-tear and, therefore, prolong the working life of the equipment considerably. Thanks to this high reliability, downtime and maintenance costs are greatly reduced—a prime factor to ensure uninterrupted productivity in critical applications.

Plunger pumps, being efficient yet long-lasting, would perfectly complement an aquaculture or farm system. These pumps are built to meet very harsh operational conditions, although they assure steady performance in all operational conditions. Thus, they offer more value for money as they run overtime in maintaining efficiency and cost of operation in instances where durability and reliability are critical.

Efficiency in Fluid Delivery

The exceptional efficacy of plunger pumps in delivering fluids stems from their being of the positive displacement type, ensuring precise and constant flow rates regardless of any variations in pressure. By virtue of this, there is a negligible amount of energy loss during the operation, as it brings about fluid transfer in a straight, linear movement. By virtue of their steady flow, plunger pumps are beneficial in processes that require exact metering and wastage prevention.

The advances of the times have enhanced the plunger pump’s abilities and now combine the use of modern materials and engineering methods to ensure reduced wear under long-term use. Data analyzed from recent studies suggest that plunger pumps can maintain volumetric efficiencies of greater than 90% even at high-pressure conditions. Instead, this offers more energy preservation when compared to other methods of pumping and thus exists as an economic and environmentally friendly choice.

Moreover, versatility is added to a pump’s character due to its compatibility with varied liquid types, such as clean water, viscous, or corrosive liquids. This makes it essential in industries where fluid delivery must be assured, such as chemical, oil and gas, and wastewater treatment.

High-Pressure Capability

The high-pressure requirement is characteristic of an advanced pump system that can handle applications that demand high pressures. Modern designs can sometimes operate under unusually hard conditions, achieving pressures of up to several thousand psi-from model to use case. This makes them quite suited for industrial purposes where high-pressure cleaning, hydraulic power generation, and chemical injection are concerned.

For durability and stress or fatigue resistance under pressure, the systems generally use strong materials such as stainless steel or special alloys. Advanced sealing techniques are usually adopted to keep the pressure intact, minimize leakage, and prevent deterioration over prolonged operational periods. This precisely engineered setup ensures minimal energy loss, which is the best compromise between high-pressure performance and operational efficiency.

The importance of such pumps lies in industries where the fluids have to be delivered reliably and consistently at high pressures-these are petrochemical plants, power generation plants, and mining industries. They find relevance in the modern industrial framework because they can retain their performance indices even under harsh conditions.

Maintenance and Troubleshooting

Regular Maintenance Tips

High-pressure pumping maintenance requires a system approach to ensure long-term operational viability and reduce expensive downtime. These are some of the finer points of maintenance detail to consider:

- Routine Inspection of Seals and Valves: Inspect pump seals and valves regularly for wear or leakage, as these components uphold pressure integrity. Immediately replace any damaged parts to avoid further operational problems.

- Lubricate Appropriately: Make sure that lubrication for moving parts, such as bearings and shafts, is maintained as per the manufacturer’s requirements. Without proper lubrication, components will overheat from friction and wear prematurely.

- Fluid Quality Monitoring: Use only clean liquid and filter it to keep out contaminants, because foreign substances damage internal parts and lessen pump efficiency. Change the liquid periodically so as to keep its texture and quality to an optimum.

- Check for Cavitation and Vibration Issues: If you hear abnormal vibrations or cavitation noises within the system, it could have lessened performance or an internal damage issue; therefore, immediate attention must be given to checking the impeller, suction line, and inlet conditions of the pump.

- Have Pressure-Flow Calibration Performed: At certain times, ensure that the pump delivers the expected flow rate and pressure. Any deviation from the rest parameters serves to indicate a blockage, wear, or inefficiency in the system that needs attention.

- Maintain a Cleaning Schedule: Keep the pump clean, including inlets, filters, and casing, to avoid the accumulation of debris, which could interfere with the pump’s performance and efficiency.

- Document Maintenance: Keep records of all maintenance works, such as parts replaced, lubrication frequency, calibration data, etc. Such documentation promotes proactive maintenance and helps in diagnosing recurrent problems.

The proper adherence to these guidelines can only augment the lifespan and performance of high-pressure pumps such that they always remain up to industrial demands.

Ensuring Optimal Performance

To maintain the optimum functioning of high-pressure pumps, one needs to have a stringent timeline and ensure routine and predictive maintenance methods are applied. Routine maintenance is one where components of the pump, like seals, bearings, and impellers, are all inspected for any wear or blockage. Predictive maintenance, however, uses a much more advanced technology to spot problems before they happen, including vibration analysis, ultrasonic testing, or thermographic inspection. It is by using both of these maintenance methods that one can alleviate the incidence of sudden failure or downtime and keep the pumps working for a longer duration.

Another vital aspect of the continuous quality operations comprises the exact calibration and alignment of pump systems, as misaligned shafts or an incorrect setting of a valve could create vibrations, consume more energy, or damage the machine. Regular calibration ensures the pump works at optimal pressure and flow conditions, with operational parameters conforming to the manufacturer’s specifications. Monitoring fluid viscosity and preserving the chemical integrity of the medium to be pumped are also crucial factors, because any changes could either affect performance or corrode the pump components internally.

Incorporating modern monitoring systems gives the operators data about pump performance and operational anomalies in real time. Advanced Industrial Internet of Things (IIoT) systems are now able to assist in the remote monitoring of pressures, temperatures, and flow rates and alert technicians whenever irregularities occur. Through the tracking of performance trends and the presentation of predictive views, these systems enable better decision-making to ensure that the pump is still able to deliver performance in an industrial load. Data-driven adaptations to maintenance, combined with pragmatic check-up procedures, thus constitute the best infrastructure for maintaining the efficiency and longevity of high-pressure pump systems.

Frequently Asked Questions (FAQ)

Q: What is a plunger pump?

A: A plunger pump is a type of positive displacement pump that uses a reciprocating plunger to move fluid through the pump. This design allows for high-pressure applications, making it suitable for various industrial uses.

Q: How does a plunger pump work?

A: A plunger pump operates by using a smooth cylindrical plunger that slides within the pump’s cylinder. As the plunger moves, it creates a vacuum that draws fluid into the pump and then forces it out under high pressure.

Q: What are the advantages of plunger pumps vs piston pumps?

A: Unlike piston pumps, plunger pumps maintain a stationary seal, which reduces wear and tear. This makes them more efficient for high-pressure applications and less prone to leakage compared to piston pumps, which have seals that move with the piston.

Q: In what applications are plunger pumps commonly used?

A: Plunger pumps are used in various applications, including pressure washers, hydraulic systems, and other industrial processes where high flow and pressure are critical. Their ability to handle viscous fluids makes them versatile in the pump industry.

Q: What materials are used in plunger pump construction?

A: Plunger pumps are constructed using durable materials such as stainless steel or hardened iron for the cylinder and plunger. These materials ensure longevity and performance, especially in demanding environments.

Q: Are plunger pumps reciprocating pumps?

A: Yes, plunger pumps are indeed reciprocating pumps. They utilize the reciprocating motion of the plunger to create pressure peaks in the pump, effectively moving fluid through the system.

Q: What is the difference between rotary piston and plunger pumps?

A: Rotary piston pumps use a rotating mechanism to move fluid, while plunger pumps use a reciprocating plunger. This fundamental difference in operation affects their applications and efficiency in various scenarios.

Q: Can plunger pumps handle different types of fluids?

A: Yes, plunger pumps can handle various types of fluids, including viscous and abrasive materials. Their design allows for consistent flow rates, making them suitable for diverse industrial applications.

Q: How do piston and plunger pumps compare in terms of performance?

A: Piston and plunger pumps are both reciprocating displacement pumps, but plunger pumps generally offer higher pressure capabilities and better sealing options. This makes plunger pumps preferred for applications requiring precise fluid handling under high pressure.