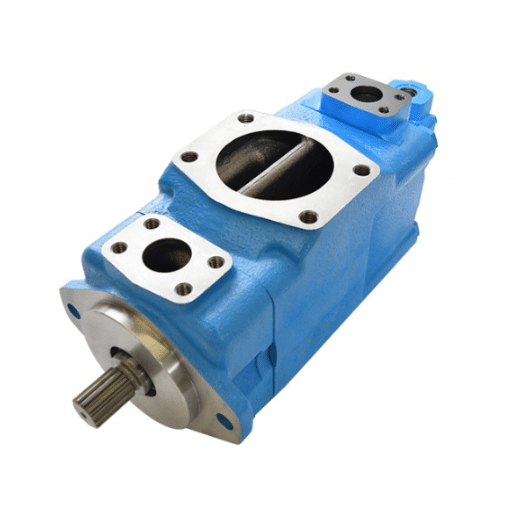

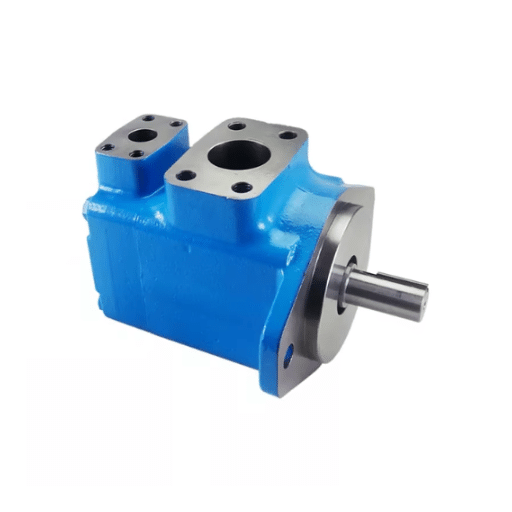

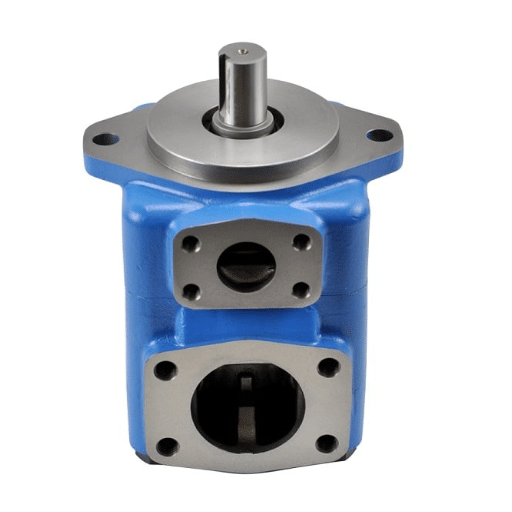

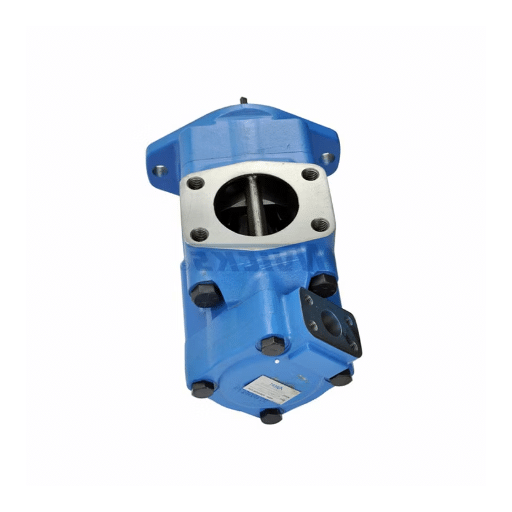

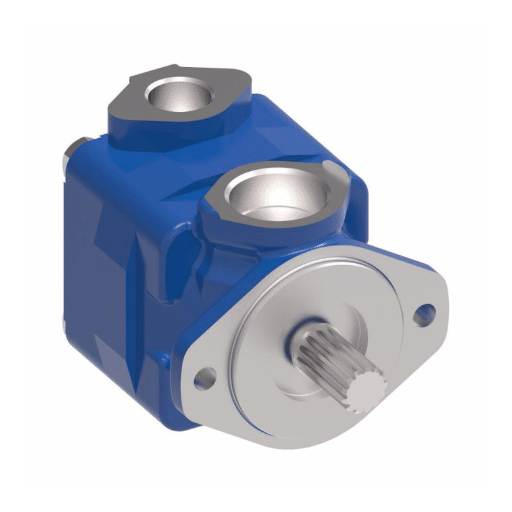

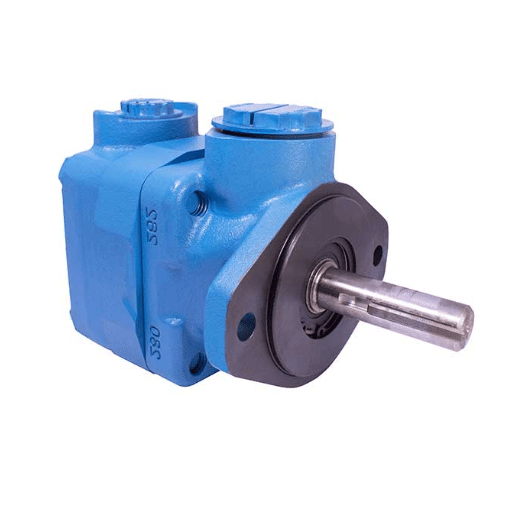

When it comes to hydraulic systems, reliability and efficiency are paramount. Vickers Triple Vane Pumps have become a trusted component in industries that demand consistent performance under challenging conditions. Designed with precision engineering, these pumps offer superior durability, reduced noise levels, and optimized energy efficiency, making them an ideal choice for a wide range of applications. This article explores the key features, benefits, and technical aspects of Vickers Triple Vane Pumps, demonstrating why they are a preferred solution for engineers and system designers looking for dependable hydraulic solutions. Whether you are maintaining an industrial system or designing a cutting-edge hydraulic setup, understanding the advantages of Vickers Triple Vane Pumps is essential for maximizing performance and long-term operational success.

Features and Benefits of Vickers Triple Vane Pumps

Key Features: Efficiency and Durability

Triple Vickers Vane-sided pumps are the best hydraulic pumps, bearing in mind that their design is highly advanced, and this permits high efficiency in every hydraulic system they are applied in. This is largely contributed to by the fact that their modular devices have a very limited fluid circulation in this transfer system and hence facilitate a relatively lower percentage of energy loss during function. As a result, it becomes quite attractive for the customers, due to which considerable savings in money will be included.

Whether even without the cost factor, is the third advantage of Vickers triple vane pumps. If these pump cylinders are constructed of strong materials like steel, then the expectation would be that they could withstand those environments that contain high or low pressure. The most integral effects brought by the design of the pump are destruction of internal parts and possibilities of leakage, and this in turn decreases the machine life, enhancing high service installations of the pump item.

Also, there is a range of values on the load dependability of these pumps due to their innovative design of the vanes, changeable to meet the wear. Such a quality is not to be dismissed, in that it not only increases the confidence levels of the users of Vickers HTBs but also facilitates the efficient and easy working of the oil circuit, making it suitable for use in areas like production, construction, energy, and even nuclear. To sum up, Standards s01A, s02A constitute some basic features combining high performance, reliability, and durability of Vickers contour vane pumps.

Benefits of Triple Vane Technology

The use of triple-vane hydraulics has a number of advantages. Three vanes have an interesting combination of properties that make them especially suitable for handling hydraulics even in the most demanding conditions. First of all, the most significant of them is the minimum maintenance required. Thanks to the self-adjusting design of the vanes, no losses are accrued from wear and tear, with the system provided that there is compensation for the variations of the working conditions. This makes sure that the pump can be able to function for a longer time with little maintenance, improves the downtime as well, and reduces the maintenance expense.

Secondly, an increased rate of output is another major benefit that is enjoyed with the triple-vane pump design in standard industrial pumps. The triple vane design, for example, addresses the issues of flow rate stability to guarantee a constant rate of hydraulic fluid and hence no pulsation and low to no pressure build-up. This is essential. In the proper functioning of any equipment attached to it. It is also, with the advances in the medical field, very critical to adopt methods that are low-cost in terms of energy. It is for this reason that most of the arc uses the below technology, which is how they end in the eye of the dam that generates power, that is, low energy consumption, and friendly consumption devices.

Finally, in terms of use, it is quite evident that the most frequently used items that utilize triple-vane pumping technology are located in crucial mission areas. It is imperative that all possible measures are taken to specifically support the use of these pumps since the industries that use them are the automotive, aerospace, and heavy equipment industries. In particular, these pumps have been found to offer optimal performance even in challenging conditions, an aspect that ensures essential operations are not threatened. These benefits underscore that triple vane technology is a more preferred option by engineers who seek efficiency and quality in hydraulic system elements.

Cost-Effectiveness for Businesses

Various industries can realize substantial cost savings in their operations by adopting the triple-vane-pump-based technology. This is because these kinds of pumps offer a high level of operation, which means that over time, the amount of energy consumption, which correlates with the cost of system operation, will be reduced. Due to the large aspects of their performance, there are low chances of their systems being down due to mechanical breakdowns, due to the pumps, which will enhance the system uptime and also reduce such.

The notion of the service life of triple vane pumps can also serve to reduce the occurrence of replacements in terms of the equipment, thus reducing the firm’s outlays in all activities that are dependent on hydraulics. Appropriate metering and proportioning of the working fluid in the system reduces the use of such fluids, thus there is less wastage, hence promoting a clean environment.

On an economic level, the application of triple-vane pump technology guarantees several financial benefits that accrue immediately as well as in the long run. In many instances, the costs applied for purchasing these hydraulic systems can always be recovered because the resultant operating savings can cover the initial costs. In the same pattern, the lowering of the expenses relating to the operation of the system, coupled with the enhancement of its performance, makes the design and use of triple-vane pumps very helpful in managing the company’s efficiency gains. Other articles focus on ensuring their practical and achievable goals.

Applications Across Industries

Industries Utilizing Vickers Triple Vane Pumps

One key industrial application of Vickers triple vane pumps is the mechanical market. This is due to the superior performance, high reliability ,and high efficiency of other pumps. In the manufacturing clinic, these pumps are usually shipped to the hydraulic press systems, crane machinery, and mechanized molding machines, which are the primary focus for the pressure changes for the machine’s functioning. For building purposes, they are also of great advantage in the installation of earthmovers, road graders, and hydraulic systems that are used for heavy machines to provide the best services.

In the case of the agricultural field, the presence of Vickers triple vane pumps in machines such as tractors, sprayers, and harvesters is mainly to offer quick and uninterrupted services. Followed by advanced use of technology in the manufacture of dies, these pumps find their place in the hydraulic system of the assembly lines used in the production of vehicles. Interestingly, the oil and gas industries utilize these pumps in two primary applications: as part of the systems for drill pipes and mining belts, and as part of the systems for drilling and boring machinery going at depths in kilometers.

The numerous fields of use and applications show how Vickers triple vane pumps are a critical contributor in the advancement of hydraulic applications on a global scale.

Specific Applications in Hydraulic Systems

Vane pumps of the Vickers design are widely applied in various hydraulic systems because of the reasons that they are renowned for improved operational efficiency, power distribution, and simplicity of design. These five applications give a fairly good picture of the areas where these pumps are applied:

- Injection Molding Machine: Pressure control is one of the reasons for choosing Vickers torrents in an injection molding machine. That depends on altering the flow of the fluid to ensure the casting process is as precise as possible, in a way that only the volume required. It further addresses the issues related to moulds, as well as lowering the energy loss in the production process.

- Hydraulic Press: The Operation of the hydraulic Press cannot do without tri-vane pumps, since it is this particular equipment type that is required. Roll stability pressure is necessary for molecules in the solution to stamping, rolling or metal forming processes and do not let them to distore during the process of stamping and bending, an this allows to have even quality in the volume of products manufactured and also makes it possible to preserve the resourse of the utility over a quite longer period.

- Any industrial machine: Many complex tools and CNC machines will also utilize Edgar drain pumps to provide hydraulic power for actuation systems and lubrication systems. They work even quieter and are more reliable, making it possible to use them even in the most sophisticated, demanding production environment

- Mobile Hydraulic Systems in Heavy Machinery: Used in excavators, bulldozers, and wheeled equipment, Vickers pumps are employed to provide any needed power to the mobile systems. An important characteristic is that these pumps do not fail when applied in more demanding environments such as construction sites or mining.

- Power generation systems: This pump type is very useful in hydro and Mini-hydro power plants, and also in thermal power plants where it regulates the system inside the turbine, governing and auxiliary. This, in turn, means that the effectiveness of power production is achieved with fewer halts and downtimes.

In every case, these functions attest to the adaptability and performance reliability of the Vickers triple vane pumps and cement their status as one of the crucial elements in hydraulic systems all over the world.

Fluid Transfer Systems in Various Sectors

Fluid transfer systems are truly indispensable tools in a bunch of sectors, enabling the controlled carrying out flow of liquid or gas. They embrace pumps, valves, piping systems, and assessment means. They offer insight on how to work with a particular efficiency and care.

- Industrial Manufacturing: In industrial manufacturing, fluid transfer systems are of great importance when it comes to lubrication, cooling, as well as technical or partly processed material. For example, the incorporation of well-structured pumps in these systems guarantees the provision of lubricants in the right amount and frequency, hence preventing heating and eventual wear of machines. Likewise, since chemical production processes are already preset, low accuracy in the transport fluids is needed, for example, stirring, reactions, and handling of highly sensitive matters, including volatile materials, if their fluidity is affected.

- Automotive and Aerospace: Two other areas where fluid transfer systems are necessary to propel these activities are the automotive and aerospace fields. Automobiles, as an example, employ the principle of how these machines work on the fuel intake with the help of pumps. This ensures that the fuel in the tanks of the vehicles is used very efficiently, and much less energy is lost as exhaust gases. Increasingly, however, in the aerospace industry, the absence of such materials adds greater value since there is a need for these components to be able to withstand high pressure and have a low mass even in extremely harsh conditions.

- Oil and Gas Industry: Transfer of oil and gas, as well as intermediate products, has led to the paramount use of fluid transfer systems in that particular industry type. Cost-effective advances in monitoring and flow control skills will ensure that no energy is lost or unnecessary pollution caused due to the leakage of hydrocarbons. In addition, the use of high-performance seals and pressure management components under extreme conditions, such as in the sea, makes the system more reliable in such conditions. platforms, to its reliability in offshore drilling platforms is further enhanced.

- Food and Beverage Processing: Preparation of food and beverages will entail a number of processing stages, all of which call for utmost cleanliness and accuracy. Such fluid transfer systems will host cleanroom quality products to adhere to all required standards for the degradation of materials. Moreover, these essential systems are employed from food sterilization and bottling to washing and waste disposal and are envisioned to preserve the integrity, flavor, and healthiness of consumer goods.

- Pharmaceutical and Biotechnology: Evaluating the demands placed by the various sectors like pharmaceutical and biotechnology, the fluid transfer systems in place evolve as appropriate. With integrated technology ranging from machinery to sophisticated processes, the management of fluids continues to align services with the current industry trends. Their usage across industries is adjustable or flexible, hence showing how crucial they are in the objectives, existing consistency in operations as well as safety if it efficiency.

By integrating cutting-edge materials, automation, and monitoring technologies, fluid transfer systems continue to evolve, catering to the specific demands of modern industries. Their adaptability across sectors underscores their crucial role in maintaining operational consistency, safety, and efficiency.

Maintenance Tips for Optimal Performance

Best Practices for Pump Maintenance

The maintenance of pumps must be practiced regularly, as it is this very practice that contributes towards their longevity, operational purpose, and safety. Avoidance of malfunction decreases the probability of any major breakdown and extends the function of a piece of equipment.

- Visual and Statistical Monitoring: One benefit of scheduling regular inspections is that wear, damage, or misalignment in parts can be easily identified. It is possible to use high-tech surveillance and inspection methods such as vibration analysis and thermal imagery to trigger an alarm well in advance an alarm before there is any damage to the equipment.

- Proper handling of lubricants: Do not just use any lubricant; rather, strictly follow the recommended lubrication schedule provided in the equipment manual. Be sure that the appropriate force lubricant is designed specifically for the given type of pump and also for the working conditions. Another concern is their improper use, which can lead to abnormally high wear of the components of the equipment, thereby aiding the over- or under-lubrication.

- Care of Seals and Excavators: Leakage of the mechanical seal indicates wearing or skewing of seals in the system (seal system). The bearing should be checked for proper alignment and maintained as necessary when in good order, aside from installation of an existing NPSH condition; otherwise, excessive noise and vibration would indicate impending failure of the bearing, which should be overhauled.

- Provide the Required System Pressure and Assess Performance: It is good practice to regularly record the pressures at levels, i.e., at the ‘inlet’ and ‘outlet’ heads, to ensure that the pump is conforming to its specified operation. Change in the pressure in such a case suggests that there could be a problem of blockages, cavitation, or air entrainment, etc.

- Clean the Filters and Strainers: Any filters or strainers that get clogged have the potential to affect the efficiency of flow and exceed the pump ratings. These items have to be extracted according to a timetable, and they need to be washed or replaced so that the system is never blocked.

- Inspection of the Impeller and Casing: Investigate any signs of corrosion, erosion, or pitting on the Impellers and pump casings, especially in systems where the fluids are corrosive. Impellers that are impaired will make the pump less effective, and they have to be taken out whenever this need arises.

- Survey and Realignment: The Pump should be calibrated properly and aligned with its resistance or driving unit. Misalignment would result in high wear on the couplings and bearings. Adequately use available laser alignment tools for proper calibration.

- Maintenance of the Operational: Take care of the pump’s surroundings by preserving it from excessive heat, such as being situated near heat sources, cold, dust, and moisture. The installation of elements such as canopies, ventilation systems, and other environmental protections helps maintain the performance of a pump despite external influences.

- Laying Records and Archive Keeping Techniques: Make sure that every action, maintenance, especially, is documented alongside the day it was carried out, the parts that were changed, and any unusual findings. Augmented by records maintenance, a database with readily available information helps in spotting recurring as well as predictive actions.

- Qualification and Training: Make sure that your mechanics and operators have the requisite skills to handle and operate the pump systems. Following these rules will help in preserving the pump system and avoiding waste.

These steps offer an overview for the efficient and reliable operation of that pump system. The consistent use of such policies will bring down the unexpected costs that come with repair and replacement of failed parts, improve performance among others, and hence save on costs.

Importance of Genuine Replacement Parts

Employing veritable spare units with an apparatus makes its performance the best, the service lifetime the longest, and the operational capacity the most productive. They are fabricated and optimized to meet the standards of all original equipment manufacturer (OEM) specifications and are the most effective for enhancing and ensuring the maintenance of the degree of accuracy and dexterity of the machine. Other parts may seem like the real thing, but in most cases, misplaced tolerances, abrasion, or other issues become apparent, leading to systemic breakdowns. Empirical evidence confirms that fitting non-original components leads to a 30% Reduction in the amount of time wasted when a device suddenly fails for the second time due to the known inefficiency of its cut-rate equivalent.

There are also emissive parts supplied alongside the machine, which are usually tested intensively for quality and often operate when such certification is issued in respect of safety items or to the purpose of meeting set industrial requirements, and hence no fear of any breakdown. Also, the present or forthcoming components are usually provided with some warranties, which make customers or final users pay more attention to the concerns because one would not want to lose that amount of money. In cases of the parts of the machinery, such as pumps and compressors, detailed technical and operation manuals are available, and other types of support, including assistance from the original manufacturers.

In conclusion, even though in the interim, the price of veritable spare parts may seem costly, they are worth the investment since they control or even reduce maintenance costs, minimize operation risk, and prolong service life. These measures yield substantial benefits over time, saving the functioning as well as the effectiveness of the business.

Comparison with Other Pump Types

Vickers Triple Vane Pumps vs. Gear Pumps

In terms of hydraulic efficiency, flow regulation, and pump noise, Vickers triple vane pump advancements are notable than worm gear pump ones, which have fewer parts and are less susceptible to the fluctuations caused due to high viscous fluids.

|

Aspect |

Vane Pumps |

Gear Pumps |

|---|---|---|

|

Flow Type |

Smooth |

Pulsating |

|

Performance |

Efficient |

Reliable |

|

Sound Level |

Quiet |

Noisy |

|

Pressure Range |

Moderate-High |

High |

|

Fluid Type |

Thin-Medium |

Thick |

|

Lifespan |

Moderate |

Long |

|

Upkeep |

Moderate |

Minimal |

|

Price |

Higher |

Lower |

|

Usage |

Precise |

Heavy-duty |

|

Form Factor |

Compact |

Bulky |

Advantages of Vickers Pumps Over Piston Pumps

- Depth in Application of even Aspirating Devices: In such scenarios where a representation in which lubricants are controlled, Vickers Pumps are appropriate as they are more efficient. The higher efficiency due to the construction of Vickers Pumps will ensure minimum power loss and make them ideal for performing precision maneuvers.

- Reduced Noise Levels: As such, motions of Vickers pumps Ct are less noisy compared to those of more popular designs of piston pumps. This advantage has great applications, like sound-proof rooms for various equipment, for example, laboratory equipment or medical devices. The internals are similarly loud on this one, but Vickers is better amplified.

- Smaller Size: The Pumps by Vickers have this distinctive feature, a smaller size, which enhances their efficient installation within systems having an inadequate space allocation. This constructional parameter offers several other applications without the expense of space-consuming mechanisms.

- Lower Maintenance: The maintenance of Vickers Pumps is comparatively less compared to that of piston pumps. Their ruggedness and few parts mitigate the risk of wearing out as well as lessen the frequency of servicing.

- Maintainability for Low to Medium Viscosity Fluids: Vickers pumps perform well when used for the service of low to medium viscosity fluids and provide a balance of pressure and performance to ensure that no performance degradation is experienced. Such pumps, therefore, have found heavy use in industries that entail accuracy.

Identifying Strengths and Weaknesses

- Strengths of Vickers Pumps

- Durability and Longevity: Due to strong construction, Vickers pumps are highly durable, especially under tough industrial conditions. Most importantly, with their extended duration of bearing operational efficiency with minimal maintenance, they help reduce downtime.

- Energy Efficient: Designing Vickers pumps to operate at better energy efficiency often incorporates advanced designs to minimize power consumption. This supports marketing industries aiming to conserve energy without compromising on their performance.

- Precise and Reliable: Vickers pumps are designed with accuracy and can perform at steady pressure and flow rate in even changing workload conditions. They are glued to systems requiring precision. They are very valuable for hydraulic equipment and automation systems.

- Weaknesses of Vickers Pumps

- Limited Compatibility with High-Viscosity Fluids: Vickers pumps perform great for thin to medium viscosity fluids; however, when confronted with high-viscosity fluids, they tend to lose efficiency, or the pumps can undergo mechanical strain. It lessens their application range in some special environments.

- Initial Cost: With advanced technology and the use of quality materials in the fabrication of Vickers pumps comes a higher initial cost than the cheaper, simpler pump design. Hence, smaller operations may find it financially prohibitive to pay.

- Specialized Maintenance Need: Potential servicing and repairs of Vickers pumps tend to be more costly, with longer delays commonly experienced during unexpected breakdowns, especially in far-off sites.

Pulling together these various sides of these pros and cons, industries should then decide whether Vickers pumps fit their operational requirements and cost. Theoretically, their upsides in efficiency and reliability will outweigh their downsides; yet, they must consider the application context to gain the best out of these pumps.

Guide to Selecting the Right Pump for Your Needs

Factors to Consider When Choosing a Pump

Selecting the right pump for the application is an all-encompassing view, considering, firstly, the technical, operational, and economic factors. Mostly, the fluid is pumped. Associated with the pump are its viscosity, chemical reactivity, and temperature of the fluid. Highly corrosive fluids impregnate resistant materials to corrosion or coatings; high viscous fluid-based flow rate could be in a dynamic setup of pumping mechanisms competing with leak-proof seal methods.

The pressure and required flow rate are two other factors to consider. The capacity of a pump, i.e., gallons per minute (GPM) or liters per second (L/s), ought to be enough for your operation. And the operating pressure, expressed in PSI or bar, should meet the application requirements in terms of output as well as constraints of the system, like pipe friction losses and head height. Inadequate compromise between these two leads to inefficiency and a tiring existence of the pump.

Another factor to consider when selecting a pump is energy efficiency and lifecycle cost analysis. Pumps with a high-performance rating demand a high initial capital investment but reduce energy usage costs as time passes. Assessing the pump’s total cost of ownership, which includes maintenance, energy consumption, and expected lifespan, will be of great help when making a choice. Other factors, such as sound levels, ease of maintenance, and availability of spare parts, contribute to ensuring the reliability and sustainability of this pumping solution. A proper systematic assessment of these factors will lead industries right into performance optimization and long-term value for investing in proper pumping technology.

How Vickers Pumps Meet Operational Demands

Vickers pumps are designed through advanced design, accurate manufacturing, and innovative hydraulics to meet the severe requirements imposed by present-day industries. Equipped with utmost efficiency, durability, and flexibility, they fit in almost any working environment. With respectable pressure heads and flow rate parameters, Vickers pumps provide dependable service in the fields of fabrication, power generation, industrial construction, and other heavy industries.

One major strength of Vickers pumps is that their structure can withstand excessive wear and tear resulting from adverse operating conditions. The modular construction makes them easier to maintain, which reduces downtime, first increasing productivity. Another feature in which great care was taken is reducing energy usage via the pumping. This energy efficiency reduces the operating expense necessary for industrial consumers.

For keeping flexibility intact, Vickers pumps can be serviced for different fluid types and customized for certain system specifications. Reliability is based on worldwide industrial standards, while the manufacturer offers all-around support functions to facilitate incorporation and thus guarantee long-term operational success. Together, these characteristics make Vickers pumps a trustworthy and technically sophisticated answer to various industrial demands.

Frequently Asked Questions (FAQ)

Q: What are Vickers Triple Vane Pumps used for?

A: Vickers Triple Vane Pumps are ideal for applications that require reliable and efficient fluid flow in hydraulic systems. They are commonly used in mobile equipment and various hydraulic components due to their versatility and capability to handle different hydraulic fluids.

Q: How do I troubleshoot a Vickers Triple Vane Pump?

A: Troubleshooting a Vickers Triple Vane Pump involves checking for leaks, ensuring proper installation, and confirming that adequate lubrication is maintained. Regular maintenance is essential to prevent contamination and ensure the pump operates at optimal performance.

Q: What are the benefits of using Vickers hydraulic vane pumps?

A: Vickers hydraulic vane pumps offer high-pressure capabilities, low noise operation, and variable flow rates, making them suitable for a wide range of applications. Their design ensures reliable operation under extreme temperatures and conditions.

Q: How can I choose the right Vickers pump model for my needs?

A: Choosing the right Vickers pump model involves assessing your specific requirements, including desired flow rates, the type of fluid, and operating conditions. Models like V10 and V20 have different specifications that cater to various hydraulic applications.

Q: What maintenance is required for Vickers Triple Vane Pumps?

A: Regular maintenance for Vickers Triple Vane Pumps includes checking the pump parts for wear, ensuring proper lubrication, and monitoring for contamination. This helps maintain their excellent performance and prolongs their lifespan.

Q: Can Vickers Triple Vane Pumps operate at different RPMs?

A: Yes, Vickers Triple Vane Pumps can operate at various RPMs, allowing them to deliver variable displacement and flow rates suited for specific applications. This adaptability enhances their usability in hydraulic systems.

Q: What makes Vickers Triple Vane Pumps reliable?

A: The reliability of Vickers Triple Vane Pumps stems from their robust design and quality materials, which ensure they can handle high-pressure applications while providing consistent performance over time. Their ability to lubricate effectively also contributes to their reliability.

Q: Are Vickers Triple Vane Pumps suitable for mobile equipment?

A: Absolutely, Vickers Triple Vane Pumps are designed with versatility in mind, making them suitable for mobile equipment and other applications that require dependable hydraulic performance in various environments.

Q: How does the delivery time for Vickers hydraulic products vary?

A: Delivery time for Vickers hydraulic products, including triple vane pumps, can vary based on the model, availability of pump parts, and specific order requirements. It’s advisable to check with the supplier for accurate estimates.

Q: What are the common applications for Vickers Triple Vane Pumps?

A: Common applications for Vickers Triple Vane Pumps include hydraulic systems in industrial machinery, construction equipment, and automotive applications where reliable fluid flow and high-pressure capabilities are essential.