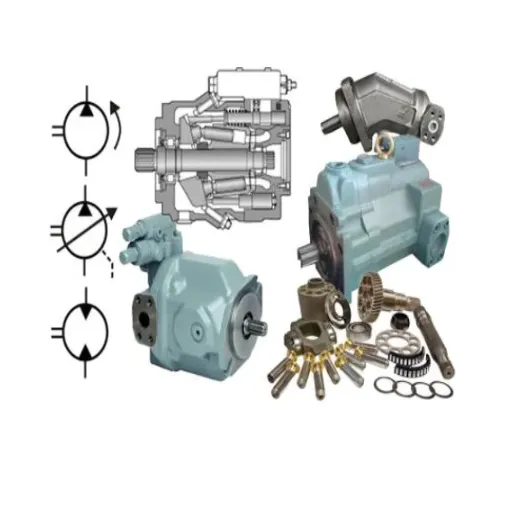

Hydraulic systems form the core of several industrial and mobile applications where accuracy, efficiency, and reliability rank high in requirements. Being the central element of any hydraulic system, the pump greatly affects the system’s performance and operational life. There being many types of hydraulic pumps, the truly globally accepted design among them is the Vickers Triple Vane Pump on account of its innovative design and extreme durability. This article wishes to discuss the engineering prowess behind Vickers Triple Vane Pumps, pointing out how their cutting-edge technology, combined with a robust design, makes them an apt choice for extremely demanding hydraulic environments. Whether you seek greater system efficiency or reliability or both, this will give you a few insights as to why these pumps have enjoyed universal acceptance in various sectors.

Applications Across Industries

Manufacturing and Industrial Applications

Vickers Triple Vane Pumps, synonymous with versatility and efficiency, are paramount in various manufacturing and industrial processes. Nevertheless, due to their state-of-the-art design, they can provide top performance in the harshest environments. Here is a detailed list of five specific applications where the pumps perform best:

- Metal Forming: Vickers pumps find extensive use in metal forming processes, including stamping, pressing, and forging. The pump’s graduation allows for control of flow with precision and consistency, which in turn reduces wastage and optimizes production-cycle time.

- Injection Molding: Injection molding processes need these pressurized pumps to maintain consistent pressure and flow rate, which are critical for making top-quality plastic components with minimal to no defects.

- Machine Tools: The Vickers Triple Vane Pumps form the hydraulic system that powers machine tools such as lathes, milling machines, and CNC systems. They assure dependable operation with limited heat generation and noise.

- Material Handling Systems: From conveyor lines to hydraulic lifts, the pumps provide good-quality operation for material handling plants, thus guaranteeing operational safety in warehouses and industries.

- Die-Casting: The pumps fulfill the huge pressure requirements in die-casting; excellent performance on both continuous and cyclical loads is thereby assured in improving total operational efficiency.

These applications demonstrate the versatility and dependability of Vickers Triple Vane Pumps in important industrial operations and thereby allow them to be among the internationally trusted solutions in hydraulic systems.

Construction Industry Utilization

Hydraulic systems are largely responsible for ensuring that the construction industry completes a variety of demanding operations within stipulated periods and reliably. The Vickers Triple Vane Pumps are provided as indispensable components to the hydraulic systems for fitting above all in terms of performance and durability. Here are five major areas where these pumps are highly demanded for construction purposes:

- Excavation Equipment: Vickers Triple Vane Pumps endow hydraulic power of really high pressure so that the excavators might work in seamless fashion. They work efficiently, assuring continuous digging and material handling in rough environments, eliminating downtime, and expediting this stage of the project.

1 - Concrete Pumping System: These pumps help maintain a steady pressure and pumping rate in the line so as to achieve uniform concrete disposition. For huge scale construction works, it is a technique where precision and speed gain great importance.

2 - Hoisting Equipment: Construction cranes require highly precise and powerful hydraulic systems. Vickers Triple Vane Pumps, in turn, provide the best kind of control and load-feasibility capabilities, promoting safety and killing operational uncertainties during lifting activities.

3 - Paving Machines: These pumps have an important role in regulating the hydraulic systems of asphalt and concrete paving machines to ensure even distribution of materials and to lessen potential operational wear due to uneven flow.

4 - Drilling Operations: On drilling rigs in foundation construction activities, Vickers Triple Vane Pumps of durability and even high pressure are needed to withstand the forces and requirements of deep excavation and boring types of work.

5

Such applications speak of the ruggedness and versatility of Vickers Triple Vane Pumps, hence representing a crucial component in the machinery inventory of the construction trade where reliability and performance are paramount for various operations.

Automotive and Agricultural Use Cases

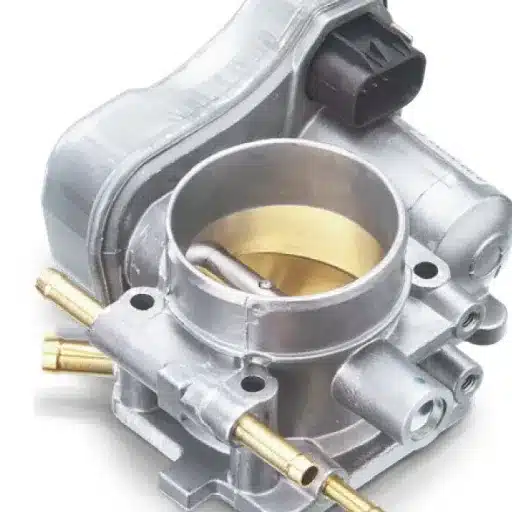

🚗 Automotive Industry

The Vickers Triple Vane Pumps are particularly favored in the automotive industry due to their precision, reliability, and the ability to stand up to demanding conditions. They are commonly used in power steering systems and provide a steady hydraulic pressure to smoothly and precisely control the vehicle. These pumps adjust their performance under different load demands, thus forming an integral part of modern automotive design. Besides offering durability and good service life even under high pressure, they enhance the efficiency while minimizing maintenance costs within the application, where any compromise on reliability is a mere constraint.

🚜 Agricultural Industry

In agri-industries, the Vickers Triple Vane Pumps remain the backbone of hydrosystem power for machines, including tractors, combine harvesters, irrigation systems, etc. These pumps provide a constant hydraulic flow to keep these vehicles operational through systems like lifting, steering, and braking. The pumps are highly efficient in performance for long hours, even in adverse environmental conditions, rendering them extraordinarily vital in agricultural sectors where downtime and operational efficiency directly affect productivity.

In essence, the ability of Vickers Triple Vane Pumps to cater to both the automotive and agricultural industries bestows them with a reputation of design intuitiveness and multi-dimensional application ability. Their robust design, resistance to wear, and variable pressure operating ability make them essential constituents of an industry or discipline wherein accuracy and durability take on surface value.

Benefits of Using Vickers Triple Vane Pumps

Durability and Longevity

Vickers Triple Vane Pumps bestow a very high level of durability and life expectancy due to the precision of their engineering and strong materials that find application in very demanding industrial fields. Below are five factors that ensure that these pumps receive higher durability and longer service life:

🔧 High-Grade Material Construction

The pump is built of wear-resistant alloys and advanced composite materials designed to withstand high pressures and resist wear and tear during the pump’s long working life.

⚖️ Optimized Hydraulic Balancing

Internal components are designed with precise hydraulic balancing to reduce friction and promote the even distribution of loads upon critical parts, thus prolonging their working life.

🛡️ Corrosion-Resistant Coating

Vickers pumps have special coatings, which protect the internal surfaces from corrosion caused by exposure to different hydraulic fluids or adverse environmental conditions.

🌡️ Low Operating Temperatures

The pumps will keep lower operating temperatures over long use, thereby reducing heat-induced stresses on components and keeping their behavior consistent over time.

🔒 Advanced Seal Technology

Top sealing keeps leakage from inside, contaminates internal parts, and reduces maintenance upkeep.

Thus designed, these pumps could effectively serve in very harsh conditions, where their reliability is assured, thus maximizing their service life in critical industrial works.

Energy Efficiency in Operations

Energy efficiency remains an issue of utmost importance in industrial pump systems because it affects operational costs, environmental sustainability, and legislation. Pumping systems are now engineered to operate with the minimum amount of energy while presenting maximum performance with respect to the integration of innovative technologies and engineering practices. Operational energy efficiency is enhanced by the following five vital methods and technologies:

-

🔄 Variable Frequency Drives (VFDs)

VFDs enable controllability of motor speed to achieve a pump output that is in accordance with process demands. It gives an opportunity to conceivably reduce energy wastage through the unnecessary functioning of pumps at full capacity. Studies have established that VFDs tend to halve energy consumption where variable loads occur.

-

💧 Hydraulic Optimizations

Advanced hydraulic designs minimize friction losses and enhance flow dynamics so that energy is not lost with the transfer of fluids. Hydraulic optimization with CFD simulations has gained popularity in refining pump designs and improving them by 10-15% in select operations.

-

⚡ High-Energy Efficiency Motors

Adopting IE3 and IE4-class motors under international standards of energy efficiency limits energy consumption within the work cycle. Depending on the conditions of operation, these motors consume approximately 20 to 30% less energy compared to conventional motors.

-

📐 Correct Design and Sizing of the System

This prevents scenarios where inefficiencies are generated by oversizing or undersizing due to poor design. Studies suggest that inappropriate sizing of pumps by oversizing leads to the wastage of energy between 10 and 30%, hence underscoring the need for utmost accuracy in system design.

-

📊 Advanced Monitoring and Control Systems

These monitor real-time data and use algorithms that allow the early detection of inefficiencies and their remediation, optimizing the process related to their functioning. This optimization could significantly reduce energy consumption by between 5% and 15% due to proactive adjustment and maintenance-oriented strategies.

About the adoption of energy-efficient technologies and practices, industrial pumping systems are not only able to bring forth huge cost savings but also aid in attaining large-scale sustainability targets.

Performance Under High-Pressure Conditions

Industrial pump systems working in the realms of high pressure are faced with challenges that influence their overall efficiency, working life, and reliability. To do this right, one needs to focus on some critical performance considerations and strong engineering solutions. Here are some significant provoking issues and data points relevant to performance under high-pressure conditions:

🔩 Material Strength and Durability

Being high-pressure applications, pump components are required to be built of materials that possess very high tensile strength and corrosion resistance. The common materials used are stainless steel, duplex alloys, and titanium when the pressure goes beyond 10,000 psi in critical systems.

🔒 Seal Integrity

Preventing leaks in extreme atmosphere is due to the reliability of mechanical seals. Double mechanical seals and cartridge seal designs are maintained for the best performance under high-pressure applications with minimal maintenance requirements.

⚡ Efficiency Losses

Higher pressure means higher energy losses produced due to fluid friction and fluid turbulence inside pumps. These inefficiencies can be reduced by optimized impeller design and advanced coatings, which typically restore about 20% of the operational efficiency.

🌡️ Thermal Management

Higher temperatures of fluids result from increased pressure, and hence thermal management systems are a need. Heat exchangers or cooling jackets may be integrated within the pump design for this purpose to avoid fluid temperatures from getting high and disrupting stable performance.

📊 Vibration and Noise Control

Stress increase under high-pressure systems increases vibration and noise levels, which may lead to premature wear. Deployment of state-of-the-art monitoring systems comprising vibration analysers and active damping methods can heavily contribute towards limiting this risk and lengthening the life of the equipment.

Ensuring that these have been thought of will ensure that the industrial pump systems maintain the best performance and reliability under the most demanding high-pressure conditions.

Maintenance Practices for Optimal Performance

Routine Maintenance Guidelines

To witness the pump system performance and reliability over time, a maintenance schedule is a must-keep. Inspections can be visual for leaks, corrosion, and any physical damage to components such as seal types, bearing types, and impeller types. Measuring vibration intermittently and aligning pumps serve as early warnings against mechanical failures that may cause unscheduled downtime.

Another aspect of testing lubrication management involves selecting the correct type and quantity of lubrication so that there is no friction and heat build-up that may lead to accelerated wear of components. Flow and pressure levels are tracked to make sure that the equipment is working, thus avoiding overloading and inefficiencies.

In terms of problem-solving, thermographic imaging and ultrasonic leak detectors also help find issues hiding in the shadows that would normally go undetected in a regular inspection. With the integration of these considerations in a punctual preventive maintenance scheme, organizations will see improvements in performance while a greater life span of the equipment is assured, together with an associated decreased total cost of ownership.

Troubleshooting Common Issues

🔍 Data Collection Process

The first step is to establish a proper data collection process of the scene under the problem. This would involve checking the system under performance (aggregated) measures, looking into maintenance records, and recognizing all deviations from standard operating procedures. This approach dictates the use of advanced tools such as real-time system monitoring, vibration analysis, or thermal imaging, each characterized by precision in diagnostics, so that the resolution can be then enjoyed by specialist engineers at a targeted level.

📋 Problem Categorization

Having collected the data, the next step is sorting the problem into symptom-based categories, narrowing down possible causes: electrical, mechanical, or process-related. Hence, say, the machinery overheating too often might be a signal of insufficient lubrication, a worn-out part, or misalignment. Implementing analyses such as root cause analysis (RCA) or following the Five Whys approach can help explore what really happened to begin with, so that remedies can deal with the root incident itself.

Furthermore, AI-based predictive analytics, pattern recognition, and anomaly detection can provide the added layer of visibility rarely achievable by manual means. These tools further assist in downtime reduction via speedy fault detection and fast resolution, limiting expensive operational interruptions.

Prolonging the Lifespan of Vickers Pumps

To maximize the operational lifespan of Vickers pumps, the maintenance schedule should be adhered to in a stringent manner, in sync with good practices of operation of the system. With regular checks made on the hydraulic fluids, as contamination is the principal cause of wear and tear on components, it is best to ensure that the hydraulic fluid is kept free from contaminants and meets standards specified by the manufacturers to avoid internal damage caused by the presence of dirt or a lack of sufficient lubrication.

From the pump onward, a further advanced filtration system may be fitted to eliminate contaminants from entering the pump and the hydraulic circuit. Keeping a careful eye on the pressure and delivery of the system by means of precision instruments also allows for recognition of deviations at the earliest stage and corrective actions before catastrophic failure ensues. In addition, proper maintenance of system components, such as seals and hoses, can prevent unintended leaks or pressure losses that stress the pump unduly.

The intent is to receive adequate training for the personnel who use this equipment. If the system is misused, for example, by operating the pump at pressures higher than recommended or in temperature conditions not recommended, excessive and accelerated wear would follow. By employing condition-monitoring technology such as vibration or thermal imaging, the operator can get the latest status information about the health of the pump. Having this data, maintenance workers can act upon it and thus enhance the life of Vickers pumps while keeping the system reliable and efficient.

Comparison with Alternative Pump Types

Vickers Triple Vane Pumps vs. Gear Pumps

The triple vane pumps from Vickers are excellent in precision, efficiency, and noise control, and gear pumps are for basic usages because they are simple, cost-effective, and sturdy.

| Aspect | Triple Vane Pumps | Gear Pumps |

|---|---|---|

| Performance | High | Moderate |

| Sound Level | Quiet | Noisy |

| Pressure Limit | 2500 psi | 3000 psi |

| Flow Capacity | 10-200 GPM | 1-100 GPM |

| Lifespan | Long | Very Long |

| Upkeep | Minimal | Moderate |

| Price | Expensive | Affordable |

| Usage | Precision Tasks | General Tasks |

| Energy Saving | High | Moderate |

| Fields | Aerospace, Auto | Oil & Gas, General |

Vickers Triple Vane Pumps vs. Piston Pumps

Vickers triple vane pumps remain efficient, silent, and cheap to operate, while piston-type pumps work at higher pressure with precision and are more costly and complicated.

| Aspect | Triple Vane Pumps | Piston Pumps |

|---|---|---|

| Efficiency | High | Very High |

| Noise | Quiet | Moderate |

| Pressure | 2500 psi | 5000+ psi |

| Flow Range | 10-200 GPM | 1-100 GPM |

| Durability | High | Very High |

| Maintenance | Low | High |

| Cost | Moderate | Expensive |

| Applications | General | Precision |

| Energy Use | Efficient | High |

| Industries | Auto, General | Aerospace, Oil & Gas |

Advantages and Trade-offs of Each Type

⚙️ Triple Vane Pumps

Triple vane pumps are generally efficient with at low noise levels, the combination of which makes such a pump perfect for general industrial purposes where moderate pressure and steady flow are required. The pumps are built to last and need little maintenance, posing further advantages in environments where equipment reliability and operational costs are a concern. Their pressure ability is, however, limited when compared to piston pumps, hence diminishing their utility in high-pressure applications.

🔧 Piston Pumps

Piston pumps, alternatively, are used primarily where the demand for utmost pressure and control exists, as in aerospace and oil and gas industries. Such pumps guarantee an almost total hermetic realization of energy conversion and durability in extreme circumstances. High energy consumption, procurement costs, and maintenance, however, are considerable drawbacks. Due to its complex mechanical nature, it requires maintenance quite often, which renders it hard to operate.

In any case, the choice between a triple vane or piston pump depends very much on the needs of the particular situation. Another way to put it would be that if very quiet performance with less maintenance and moderate cost are of prime concern, then the answer to your selection would be the triple vane pump. But if precision and very high pressure are the requirements, then justifying the price of the piston pump is essential. An appropriate balance of fulfilling operational needs and economic consideration of the system’s overall performance is placed into motion by choosing the correct pump.

Real-World Applications and Case Studies

Case Study: Vickers Pumps in Manufacturing

Vickers Pumps, in all their refinements, have found outstanding usage in the birth of many technical fields-all because of their reliability, efficiency, and adaptability to somewhat harsh industrial environments. Their applications exemplify how hydraulic components can serve production systems. Five examples below must explain their real-life application in detail:

🚗 Automotive Industry – Press Machines

In operating hydraulic press machines for the stamping, molding, and forming of automotive components, hydraulic press machines use Vickers vane pumps. The pumps assure a steady flow of pressure, which lends to higher precision and enhanced efficiency in production. For instance, the increase of production efficiency in a manufacturing plant had been corroborated by a 15% cut in cycle time after switching to Vickers pumps for its hydraulic presses.

🍽️ Food Processing Machinery

Food processing lines demand sterile conditions and pressure measurements. Vickers piston pumps provide high-pressure outputs for homogenization and bottle filling to guarantee results. There has been a notable 10% increase in the throughput of the packaging line as a result of the use of Vickers pumps, according to the case study.

🏭 Steel Industry – Rolling Mills

Rolling mills function under harsh environments and demand very rugged hydraulic systems. Hydraulic cylinders powered by Vickers pumps maintain precise control over the speed and pressure of the rollers. A steel plant recorded improved dimensional accuracy of its products leading to about 8% reduction in material wastage.

✈️ Aerospace Manufacturing – Assembly Jigs

Vickers pumps find great usage in hydraulic systems for the working operation of complicated aerospace assembly jigs. The pumps ensure the components are positioned accurately through their ability to develop high pressures. An esteemed aerospace company experienced a 20% reduction in assembly errors in the time period using Vickers pumps.

🏭 Injection Molding Machines

The plastic manufacturing industry depends on Vickers pumps for injection molding operations where constant flow and pressure are critical for product quality. One leading molding company witnessed a 25% reduction in energy consumption and improvement in operational stability after integrating Vickers vane pumps.

All these examples establish the wide applications and effectiveness of Vickers pumps in diverse manufacturing processes while providing solutions meeting high-pressure and precise operational requirements. It enunciates the fact that with the installation of Vickers pumps into the hydraulic systems, they almost turn up as catalysts for industrial efficiency.

Case Study: Agricultural Applications

Vickers vane pumps are of extreme importance in agricultural equipment for their efficiency, reliability, and aptitude for operating under variable load conditions. These pumps are employed in numerous forms of farm machinery that require pinpoint accuracy and performance so that systems do not go down and productivity is at an optimum level. Here are five instances in agriculture when Vickers vane pumps give top value:

🚜 Tractor Hydraulic Systems

Vickers vane pumps are used commonly in tractor hydraulics to run implements such as plows, loaders, and seeders. Through supplying a smooth flow of hydraulic oil, these pumps guarantee expeditious operation of the attachments in the field.

💧 Irrigation Systems

These pumps are designed for high-pressure applications and play a crucial role in the irrigation systems of pivot and drip irrigation systems. Their ability to maintain a steady flow rate ensures uniform distribution of water to crops, thus improving yields’ consistency.

🌾 Spraying Equipment

Precise pumping is required for applying fertilizers, pesticides, and herbicides, and agricultural sprayers depend on it. Vickers vane pumps help the high-performance spray systems to maintain constant pressure and flow for correct coverage.

🌽 Harvesting Machinery

These hydraulic systems must be able to cope with the heavy loads involved in cutting, threshing, and unloading by a harvester. Vickers pumps apply the power and reliability to make the harvesting process effective and to reduce energy consumption.

🐄 Feed Mixing Systems

Vickers pumps put feed mixers in operation, disagreeing for even distribution of feed components. Their finer control assures equal co-mixing, which in turn enables greater nutrition and health of livestock.

The usage of Vickers vane pumps in such important agricultural applications is the best testimony for their rugged design, energy efficiency, and accuracy in operation. Their noninterference capabilities with a variety of machinery systems stand for long-haul productivity and reliability for growers and farming industries across the globe.

Frequently Asked Questions (FAQ)

❓ What are Vickers triple vane pumps?

Vickers triple vane pumps are a class of hydraulic vane pumps designed for high efficiency and durability. The three vanes create several chambers that allow a smooth and steady flow of fluid. Their use carries significance in many hydraulic applications because of their reliable operations and flexibility.

⚙️ What is the working principle of Vickers hydraulic vane pumps?

These pumps operate by rotating the rotor with multiple vanes on it. With the rotation of the rotor, the vanes move in and out of their slots to change the volume of the chambers, drawing in fluid from the inlet and expelling it out under pressure. They deliver fluid efficiently and hence are often used in high RPM applications.

🛡️ Are Vickers hydraulic vane pumps sturdy?

Yes, Vickers hydraulic vane pumps are durable. Making use of machinery manufactured from high-quality materials that stand strong under harsh operating conditions, Vickers hydraulic vane pumps ensure durability, thus helping reduce maintenance interventions and replacements required often, a factor that is necessary for continuous operation in hydraulic systems.

🔧 What are common pump parts for Vickers triple vane pumps?

Typical common parts for these Vickers triple vane pumps would be rotors, vanes, housings, and end covers. Every part is very important for the operation of the pump. Regular inspection of each component will lead to continued good performance, avoiding untimely failures.

⭐ What are Vickers triple vane pumps said to be in comparison with an equivalent hydraulic vane pump?

Because of their unique design and engineering, Vickers triple vane pumps have often been judged to be superior to the equivalent hydraulic vane pumps. They usually provide better efficiency, quieter operation, and better performance at varying load conditions, therefore being an area of preference in numerous industrial applications.

⚡ What is the importance of RPM with a Vickers hydraulic vane pump?

RPM or revolutions per minute is a crucial parameter to Vickers hydraulic vane pumps in that an increase or decrease in RPM directly influences the flow rate and pressure output of the pump. Wherever the pump is running at the correct RPM, it will do a good job of operating well for an extended period while protecting the interior of the components from wear.

🚛 Can Vickers triple vane pumps be used in mobile hydraulics?

Yes, Vickers triple vane pumps find plenty of uses in mobile hydraulics. These pumps’ compactness and the ability to operate under varying flow conditions make them suitable for use in construction machinery, agricultural equipment, and other mobile equipment where reliable hydraulic power is required.

🔧 What maintenance is necessary for Vickers hydraulic vane pumps?

Maintenance required for Vickers hydraulic vane pumps includes measurements of fluid level, testing for wear of pump parts, and guaranteeing alignment and mounting. With the cleanliness of the hydraulic system and the replacement of worn components under consideration, the pump will perform better and have a longer working life.

Ready to Upgrade Your Hydraulic System?

Experience the reliability and efficiency of Vickers Triple Vane Pumps in your industrial applications. Contact our experts today for personalized recommendations and solutions tailored to your specific needs.