In the hugely complex world of motorcycle engineering, the carburetor throttle valve is a fundamental part often misunderstood by the very people that ride them or who consider themselves motorcycle enthusiasts. The cartridge-based powerful mechanism controls air and fuel mixture into the engine, thereby affecting the performance, fuel efficiency, and responsiveness of a motorcycle. For very technical-insightful motorcyclists or curious beginners wanting to know what makes their engines tick, this article will unravel the mysteries of the carburetor throttle valve. Allow this article to walk you through what it does, why it matters, and what it does for your motorcycle’s performance-and a little bit of pro insight into riding smarter and maintaining your motorcycle with your own two hands.

What is a Throttle Valve?

Definition and Function

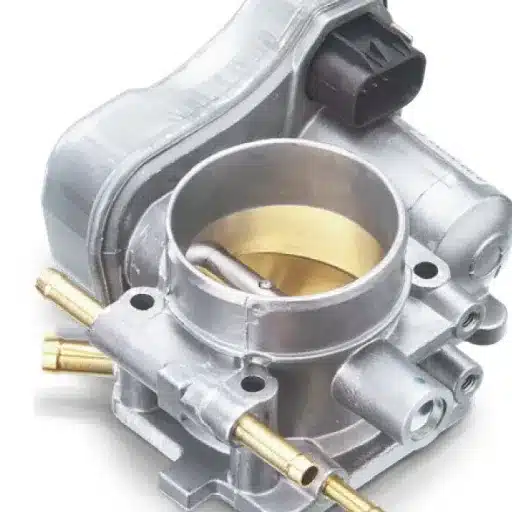

The throttle valve is one of the motorcycle’s carburetor parts, functioning mainly to regulate the airflow into the engine. By modifying the valve’s position, the rider thereby controls the amount of air entering the carburetor which is mixed with the required fuel in preparation for combustion in the engine. This process influences the engine’s power output and speed, thus giving direct control to the rider for acceleration and deceleration.

When opened, the valve permits more air to enter the carburetor; the increase in airflow is simultaneously matched by a greater fuel supply, as this richer air-fuel mixture is required for higher power output. Closing the throttle means restricting airflow, thereby reducing fuel-air mixture and slowing down the engine. This mechanism ensures easy handling and responsive performance.

The throttle valve is an important engineering component, and it is not just about regulating power; it affects proper working of the engine and stability. Better-placed throttles help improve fuel economy by delivering the appropriate air-fuel mixture for different speeds and conditions. Appropriate performance is maintained while cruising at steady speeds or undergoing sudden acceleration. Knowing its function can help a rider understand their motorcycle’s subtle mechanics and care for the machine better.

Types of Throttle Valves

Throttle valves are usually classified by their general design and functions. The main types are butterfly valves, slide valves, and barrel valves.

- Butterfly Valve: Probably the most common engine throttle valve used in motorcycles. It is a simple air valve made of a rotating disc that opens and closes flow. When the throttle is opened, the disc rotates and allows more air into the engine and increases power output. Butterfly valves are simple and extremely reliable.

- Slide Valve: Found mainly on carbureted engines, slide valves introduce airflow either by moving a cylindrical slide or a flat slide. They are very responsive and accurate in controlling the air-fuel mixture. While efficient, slide valves have become less common in modern motorcycles as the drive for fuel injection systems gained ground.

- Barrel Valve: Being cylindrical in shape, they regulate air passing through the throttle barrel by rotation. It is a compact design giving a balanced airflow. They are known for their maximum efficiency, often found in high-performance or racing motorcycles.

Each valve type contributes to a motorcycle’s functioning and performance; hence there is something related to the riding experience. Understanding these can increase awareness; hence, riders can make informed decisions on their bikes.

Importance in Engine Performance

The throttle valves contribute significantly to engine performance since they determine the air and fuel quantity entering the combustion chamber. This balancing act determines the power output, gasoline mileage, and responsiveness of the motorcycle. Opening the throttle valve lets in large quantities of air and fuel into the engine, hence producing massive power. A closed or partially opened throttle restricts the air-fuel flow, thereby diminishing power output as per the speed or load requirement.

The type of throttle valve in use is, therefore, the primary consideration while setting up any engine for efficiency. Slide valves are better because they control the air very precisely and thus increase throttle response, while butterfly valves combine ease of operation and efficiency. They are best in the case of barrel valves for motorcycles that seek maximum air intake power—for all their racing. Having the right throttle valve ensures the engine smoothly integrates into any given condition and improves the operation.

The throttle valves should also be maintained correctly for continued working health. Suitable inspections, adjustments, and air-to-fuel ratio changes may lead to a reduction in performance, fuel economy, and engine damage. Those riders that learn about their throttle system and take care of it help their motorcycle to perform splendidly along with giving added life to the engine.

How Does a Carburetor Work?

Basic Components of a Carburetor

A carburetor has many crucial parts, which all together blend the right mixtures of air and fuel, to efficiently run an engine. In the main body of the carburetor dwell the throttle valve and all air passageways entering the engine. These limit the volume of air; thus speed and power are increased or decreased depending upon airflow. The other major component is the float chamber, which keeps the fuel level constant to prevent starvation or overflowing of fuel, allowing the engine to run smoothly under any condition.

The venturi piece of a carburetor is one of the most complicated parts; it is a constricted passage with a drop in air pressure as air blows through it. From this pressure differential, fuel is sucked from the main jet which is designed to meter the right amount of fuel needed. The main jet is supplemented by other jets, such as the pilot jet, to ensure the steady flow of fuel during idling and slow operations. These mechanisms constitute a finely calibrated system that guarantees an optimum air-fuel mixture at all running conditions.

Moreover, some carburetors may incorporate enrichment systems like choke valves and accelerator pumps to assist with performance in specified situations. The choke valve aids in starting an engine during cold weather by restricting air flow into the carburetor and increasing the percentage of fuel in the air-fuel mixture during these conditions. Accelerator pumps, though, add extra fuel as the throttle is opened quickly, thereby reducing any risk of the engine stalling or hesitating. Showing the versatility and adaptability of carburetors, these systems optimize performance without affecting fuel economy. They also give insight into each of the systems so riders and mechanics can maintain them or at least help in troubleshooting when errors develop.

Role of the Carburetor Throttle Valve

The carburetor throttle valve has a vital function in controlling the volume of air entering an engine. It determines the strength or torque and speed of the engine. Depending on the actuation of the throttle by the driver, a certain amount of air-fuel mixture is admitted to the engine. Depending on the driving condition, this amount is always optimized so as to produce proper combustion, which further smoothens the running of the engine. Here are five key functions and some details regarding the functions of the carburetor throttle valve:

- 1

Airflow Regulation: The throttle valve opens and closes to regulate the airflow to the carburetor. The more that the valve is opened, the more the air admitted, thus giving the engine all its power. Conversely, at nearly closing, the valve restricts the air and hence speed. - 2

Speed Regulation: The throttle valve regulates the speed of the engine by controlling the volume of air-fuel mixture entering the engine. When opened wide, the engine reaches high revolutions per minute (RPM), and when half-closed, the RPM decreases. - 3

Managing fuel delivery: The valve works alongside other carburetor components in maintaining the right air-to-fuel ratio, depending on throttle position, to fulfill different performance requirements. - 4

Idle Control: At low throttle openings, the valve allows air to flow at a rate that enables engine idling. It keeps the air and fuel supply steady when the vehicle is stationary or moving at low speeds. - 5

Acceleration Assistance: With quick throttle movements, an ability to let air rush through the valve exists while the other carburetor components continue to supply fuel. This would avoid the engine of going hesitating during acceleration.

Being able to understand these functions will enable the riders or mechanics to diagnose and service the throttle valve for continuous performance of the car.

Fuel-Air Mixture Regulation

Fuel-air mixture regulation is an important aspect affecting an engine’s optimum efficiency. This involves balancing the amount of fuel in the air entering the combustion chamber, which will affect the way the engine performs, fuel consumption, and emission. Usually, for gasoline engines, the air-fuel ratio is taken as stoichiometric and is about 14.7:1 air to fuel, that is, there are 14.7 parts of air to one part of fuel by weight to ensure that complete combustion takes place.

These factors, depending on the environmental setting, might call for varying adjustments in the mixture. An enriched mixture is created for a while to ease ignition during cold starts. Lean mixtures (air-rich mixtures) are used for cruising free from any power demand so as to save fuel. Modern-day carburetors and fuel injection systems are further equipped with sensors and mechanisms capable of dynamically adjusting the volume ratio of gasoline and air under any operating conditions, so as to best balance performance.

Therefore, an accurate fuel-air mixture combined with an adaptive control system ensures that the engine will respond quickly and produce fewer pollutants in accordance with strict environmental regulations.

Throttle Body vs. Carburetor Throttle Valve

Differences Between Throttle Body and Carburetor

In essence, the cast that separates the throttle body and carburetor would go like: air intake is controlled electronically in present-day vehicles by a throttle body, whereas car carburetors mix air and fuel mechanically and in older vehicles.

| Aspect | Throttle Body | Carburetor |

|---|---|---|

| Operation | Electronic | Mechanical |

| Control | Automatic | Manual |

| Fuel Delivery | Injection | Mixed |

| Adjustment | Auto-adjust | Manual tuning |

| Efficiency | High | Moderate |

| Maintenance | Low | High |

| Cold Starts | Easy | Difficult |

| Cost | Higher | Lower |

When to Use Each Type

The option between a throttle body and a carburetor mostly depends on what a vehicle is meant for and the choice of the user. Choosing a throttle body is ideal for a current vehicle that values performance, fuel economy, and lowered emissions. Carburetors provide an accurate fuel solution and beauty intervention to wash, in particular, to meet environmentally friendly intervention and the need for greated efficiency.

Thus, for these classic or antique vehicles, a carbide major highlights authenticity and easier maintenance procedures. Carburetors are usually deemed attractive among sportspersons due to their complex yet user-friendly way of working, their affordability, and their willingness to be controlled on older vehicle engines. If budget presents a serious constraint in any area of concern, then carburetors offer a cheaper solution, albeit leaning more towards having a maintenance cycle closely followed and tuned.

By being aware of the advantages that the various systems offer, users are able to make decisions tailored to their needs, vehicle selections, and future expectations. Such knowledge, complemented with proper and indepth data, generates clear directions for many different kinds of automotive applications.

Advantages and Disadvantages

✓ Advantages

- •

Better Fuel Economy: Fuel injection systems generally provide better fuel economy than carburetors because of how precisely they control the fuel-air mixture so that no fuel goes wasted. Data shows that a typical fuel-injected engine has broken away with about 10-15% better mileage than its carbureted counterpart. - •

Better Performance: The injector delivers the proper fuel quantity for best performance, delivering better torque and acceleration. Research shows an increase in torque and horsepower of 5 to 10 percent when using a fuel injection system. - •

Lower Emissions: The modern injection engine provides for the minimization of emissions amidst cleaner combustion. One such case is where engines fitted with electronic fuel injection systems have been found to reduce hydrocarbon emissions by up to 20% compared to carbureted systems. - •

Reliable Under Different Conditions: The fuel injection systems operate reliably at varying altitudes and temperatures, unlike carburetors. They auto-adjust to suitable fuel-air ratios, giving them more leverage in adversarial environments. - •

Less Maintenance: Fuel injectors are less frequently maintained than carburetors, which require cleaning and tuning on a regular basis. It is generally accepted that, within a 5-year period, fuel injection systems cost 30% less to maintain than carburetors.

✗ Disadvantages

- •

Initial Cost: Being more expensive than carburetors, in the initial top-up, fuel injection systems range from $300 to $700 depending on the system and vehicle type. - •

Complexity: The complexity of the advanced design of fuel injection systems requires special tools and expertise for repairs and replacements. - •

Resilient dependence on Electronics: Modern fuel injection systems are highly dependent on electronic components, so their reliability is endangered if either the electrical circuitry or the sensors fail. - •

Higher Repair Costs: While it is true that fuel injection systems require far less maintenance, repairs can be quite costly, more than $500 in most instances, including parts and labor. - •

Not Ideal for Older Cars: Installing the fuel injection system in older cars may prove to be tedious and rather expensive. In such cases, carburetors work ever so well.

Common Issues with Carburetor Throttle Valves

Symptoms of a Malfunctioning Throttle Valve

Changes in engine performance due to a malfunctioning throttle valve are quite noticeable. One common symptom is a rough idle, wherein an engine struggles to maintain steady RPM when the car is standing still. It causes vibrations or, in some cases, may even lead to stalling. Also, one feels hesitation or delays when trying to accelerate because the throttle valve is malfunctioning in managing air efficiently, a hesitation that becomes evident with gas pedal pressure under high-demand scenarios like merging into traffic or climbing up steep inclines.

Another clear indication is a poor fuel economy. Incomplete combustion occurs either due to the disproportionate mixture of air and fuel in the cylinder when the throttle valve is not functioning optimally. The inefficient combustion thus renders the engine to burn more fuel than necessary, which leads to poor mileage and excess emission. Black smoke emitting from the exhaust may be an indication of either a skewed or stuck throttle valve as this is a signal of excessive fuel burning. The driver may also have difficulty in maintaining a steady-speed, which means the irregularity of airflow is being caused by the malfunction.

In case of any malfunction in the throttle valve, the engine warning light or, more specifically, the check engine light will light up. The modern-day vehicles are armed with sensors that capture anomalies in throttle operation and trigger such warnings. A complete diagnosis should be carried out if there are any symptoms accompanying the above description. Leaving these unattended can compound problems and possibly cause damage to other engine parts, thus resulting in costly repairs. The early detection and repair of a malfunctioning throttle valve, therefore, help sustain vehicle longevity and ensure safe and efficient driving.

Troubleshooting Tips

- Search for Fault Codes: Using an OBD-II scanner, connect it to your vehicle to read DTCs (diagnostic trouble codes). These codes will help you determine if the throttle valve or associated system is under fault.

- Inspect Throttle Body: Examine the throttle body for dust, dirt, or carbon deposits and clean it if required. Sometimes cleaning the throttle body with a suitable throttle cleaner is good enough to solve minor issues like the car idling rough or slow acceleration.

- Verify Electrical Connections: Confirm that all electrical connections to the throttle body, sensors, and wiring harness are firm and corrosion-free. If not, it can very well prevent the throttle from functioning correctly.

- Check the Pedal Sensor: If the problem still persists, it is important to inspect the TPS and accelerator pedal sensor for possible faults since these are the ones sending crucial signals to the throttle body.

- Test Air Leak: Lint washes air leaks in intake systems–hoses, seals, and gaskets, for example. Air leaks can not only affected the air-to-fuel ratio, but they carry unintended performance penalties.

- Idle Relearn Procedure Monitoring: Ensure that an idle relearn procedure is done should the throttle body have been cleaned or replaced. This in turn lets the vehicle computer recalibrate and synchronize with the throttle body.

Each of these steps may be a step in finding the primary cause of throttle problems. For more complicated issues or if the problem remains following these basic checks, take it to a qualified mechanic, or consult the service manual of the manufacturer for detailed instructions.

When to Seek Professional Help

Diagnosing and correcting throttle problems can sometimes be an intimidating affair, especially with my having done the basic checks that could give a solution. When rough idling, less power on acceleration, or engine stalling still persisting symptoms even after I have gone through the initial set of troubleshooting checks, it obviously calls for a qualified mechanic because such problems are beyond the usual simple inspections on their own, needing special knowledge and tools.

It also struck me that I should seek help if my dashboard lights like the check engine light stay on. These warnings most of the time are indications of problems that need an advanced diagnostic equipment to properly look into. If left unattended, they may bring more harm or more expensive repairs, which means better late than never for me to get the situation sorted by a professional.

Finally, if I do not feel comfortable performing certain technical tasks, I might seek professional assistance when these have to be done-throttle sensor replacement or system recalibration will come to mind. However, an incorrect approach to these components can cause the problem to increase or even develop into a safety issue. For my peace of mind and car safety, any time I find myself feeling unsure or out of my depth, the next thing I do will be to call an experienced mechanic.

Maintenance Tips for Carburetor Throttle Valves

Regular Inspection Procedures

Carburetor throttle valves must be inspected correctly to keep the vehicle running smoothly and ensure maximum fuel efficiency. Visual inspection involves keeping an eye out for dirt, carbon deposits, or any other signs of wear and tear on the throttle valve. Debris accumulated on the valve may hinder the proper movement of the throttle and may cause inefficiencies or operational problems. With the use of a flashlight, inspect hard-to-reach places and make sure the surface of the valve is clean and free of obstructions. Also, check that the connecting cables and linkages are tight and not frayed toward damage.

Check the movement of the throttle in the next step. It must work perfectly by opening and closing smoothly without any stickiness. Use your hands to open and close the throttle when the engine is switched off and observe how responsive it is. In case you feel any kind of resistance or hesitation, then it must mean that it needs lubrication or cleaning. Keeping the throttle clean using a throttle body cleaner helps in cleaning out grime and thus prevents buildup, ultimately prolonging the life of your carburetor.

Finally, keep an eye on engine performance as it offers critical clues about the state of the throttle valve. A faulty throttle valve could be responsible for irregular idling, difficulty starting, or slow acceleration. Persistence of such symptoms after a cleaning could mean something more serious could be wrong there, like some component of the valve assembly not working. Such scenarios warrant an experienced mechanic carrying out a professional diagnosis and calibration to make sure the work is reliable in the long run and safe to rely on. Investing in regular vehicle checks and paying immediate attention to problems as they arise will go a long way toward getting your vehicle to perform well and keeping the repairs at bay.

Cleaning and Adjusting the Throttle Valve

To ensure optimal engine functioning, the throttle valve must be properly maintained. Follow the next steps to effectively clean and adjust the throttle valve:

- 1

Preparation: Before starting, check to ensure that the vehicle’s engine is off and we can guarantee that it has cooled off enough not to burn one. Gather together a screwdriver, throttle body cleaner, microfiber cloths, gloves, and safety glasses. - 2

Locate the Throttle Valve: The throttle valve usually lies between the air intake hose and engine intake manifold. Refer to your vehicle’s manual for the exact location. - 3

Remove the Air Intake Hose: Use the screwdriver to loosen any screws holding the air intake hose connected to the throttle body. Be very careful not to damage the surrounding parts. - 4

Inspect and Clean: Build-up inspection of the throttle valve should be done; this may be carbon deposits or dirt. Spray the throttle body cleaner on the valve surface and gently wipe with a microfiber cloth. Take all precautions not to allow any spray to go down into sensitive areas. - 5

Manual Adjustment: If car performance problems are arising from an incorrectly aligned or set throttle valve, therefore it has to be set per manufacturer specification. This may require adjusting the throttle stop screw or reprogramming of electronic throttle control by use of special tools. - 6

Reassemble the Components: The air intake hose can be reinstalled after cleaning and adjustment. Double-check all connections. - 7

Testing the Engine: Start the engine and listen for its response. A good idle and immediate throttle response should be a given. If difficulties persist, further diagnostic testing may be required.

Follow these steps together with the latest expert-based guidance from reliable automotive sources in order for the throttle valve to function properly, therefore leading to optimization of fuel efficiency, reduction in emissions, and smoothness in driving.

Frequently Asked Questions (FAQ)

Q: What is a carburetor throttle valve?

A: A carburetor throttle valve is a different name for a mechanism in the carburetor that controls the volume of air flowing into the engine. It controls the flow of fuel by adjusting the intake of air, which is necessary for the smooth running of an engine.

Q: How does the throttle valve work with engine power?

A: The carburetor throttle valve governs the air and fuel mixture that makes a higher output: When the throttle is all the way open (WOT), more air flows into the engine; more fuel is also flowed in along with this air, resulting in increased power output. When the throttle is at some position other than full opening, a loss of power output is observed in general.

Q: What are some symptoms for a throttle position sensor that is malfunctioning?

A: Symptoms caused by a faulty throttle positioning sensor are an erratic engine, poor performance, or sometimes improper air-fuel mixture. At any decrease in engine response or irregular idling speed, you should test the throttle position sensor for the carburetor throttle valve.

Q: How do you install a carburetor throttle valve?

A: First, one must remove the carburetor off the engine. Now select the proper bore size for the valve. Align the throttle shaft with the control lever and tighten it down. Correct installation is important to prevent any air leaks and to allow the valve to operate efficiently.

Q: What maintenance is required for the carburetor throttle valve?

A: The regular upkeep council of the carburetor throttle valve includes cleaning to remove any trash, dirt, or buildup, checking for wear on the shaft and seal, making sure the idle air control is working properly to furnish a smooth idle, and maintain top performance along with poor engine performance.

Q: How does manifold vacuum relate to the throttle valve?

A: The manifold vacuum occurs inside the intake manifold when the throttle valve is not opened completely. This vacuum facilitates by sucking the fuel into the engines. When the throttle is too wide open, the vacuum will be too less, which will result in the improper fuel mixture and poor engine performance.

Q: What should I do if I’m experiencing issues with my carburetor throttle valve?

A: If you are having trouble, first check the throttle position sensor and the idle setting of the throttle valve. Look out for any air leaks through the carburetor, and for debris. If you’ve followed all this and the issue still persists, maybe ask for further advice or diagnostic help to track the problem down and ensure the correct operation of the carburetor.

Q: What effect does the solenoid have upon the carburetor throttle valve?

A: Normally, a solenoid in a carburetor throttle valve is applied to open and close the throttle mechanism electronically. It helps make sure the throttle responds smoothly and accurately to the driver’s input, ensuring smoother acceleration and better fuel mileage.

Q: How can I tell if my carburetor throttle valve is too wide open?

A: If the carburetor throttle valve sits too far open, erratic engine behavior may be observed. Also, excessive fuel consumption or diminished engine efficiency are some of the symptoms of an improperly set throttle valve. Monitoring the throttle position sensor readings will be helpful to ascertain that the valve is not functioning within the desired range.