Cavitation in hydraulic pumps is an important issue that may affect the performance and life span of hydraulic systems. Be it in industrial machinery, construction equipment, or marine applications, understanding cavitation becomes vital in maintaining the efficiency of operations and avoiding repair expenses. This article goes deep into the causes, symptoms, and prevention of hydraulic pump cavitation. With reference to methodologies and practical aspects, we intend to equip you with the knowledge required to diagnose and remedy this prevalent problem before it culminates in irreparable damage. If you have discovered an unfamiliar noise or unexpected system performance with unusual pressure variations, read on as we explain how to keep your hydraulic systems from cavitation and ensure smooth operation.

Causes of Cavitation in Hydraulic Pumps

Fluid Contamination and Its Effects

The contamination of fluid is one of the causes of hydraulic pump cavitation, leading to system deterioration and thus being a cause of performance. Contaminants, dirt, debris, and air bubbles entered hydraulic fluid through worn seals, improper maintenance, or refilling procedure practices. Once foreign particles find their way into the system, they hinder the fluid’s ability to maintain proper pressure and lubrication; hence, cavitation sets in, and finally, those very internal parts get battered.

Critical Consequences of Contamination:

- Erosion of pump bodies due to high-pressure collapse of air or vapor bubbles

- Pitting action on metal surfaces progressively decreases performance

- Abnormal changes in viscosity and flow properties

- Irregular pressure distribution causes higher stress on components

In view of these few critical consequences of the contaminant, let’s look at the erosion of the pump bodies due to high-pressure collapse of air or vapor bubbles. This erosion occurs as a pitting action on metal surfaces, which progressively decreases the performance and structural integrity of the pump. Moreover, contaminants make abnormal changes in vithe scosity and flow properties of the fluid that remain uneven in pressure distribution. This irregular pressure causes higher stress on bearings, seals, and other important components of the pump, thereby increasing the rate of wear and posing the possibility of failure.

The way to fight fluid contamination is by preventive procedures during maintenance. These include using high-quality filters that may trap even fine particles, regularly checking for inconsistencies in fluid reservoirs and seals that could let contaminants in, and handling fluids in a proper way. Keeping hydraulic fluids clean is an important step in preventing cavitation and ensuring the dependability and best performance of hydraulic pumps. A proactive approach against contamination will allow operators to extend the service life of their systems, hence reducing costly downtime needed for repair.

Improper Pressure Settings

In a hydraulic system, pressure is one of the common variables used to explain malfunctions and inefficiencies of equipment. A hydraulic system needs accurate pressure calibration to produce the desired effect. The higher the set pressure, the more force the components, such as seals, hoses, and valves, have to suffer from. Seals and hoses can even wear out faster or fail catastrophically. Conversely, if the pressure setting is less than sufficient force, it will reduce its usefulness and can stall the system.

Pressure Management Best Practices:

- Monitor system using calibrated pressure gauges

- Make adjustments only by competent personnel using approved methods

- Install automatic pressure regulators for real-time feedback

- Maintain strict adherence to the manufacturer’s specifications

Maintaining a system under accurate pressures requires the monitoring of the system and strict adherence to the manufacturer’s specifications. Operators should check system pressures using pressure gauges that have been calibrated, with adjustments being made only by competent personnel using approved methods. With modern systems, automatic pressure regulators can be installed to maintain accuracy and provide real-time feedback. Such monitoring of pressure levels ensures that they remain within the allowed limits so as not to shorten the life of componentry and, in turn, improve the reliability of the whole system.

Improper pressures seriously affect services when maintenance and inspection are not adequately performed. It is useful to review system performance logs to detect pressure aberrations, and these irregularities, measured by operators, should be dealt with immediately, as they could otherwise prove to be unsafe. Operators should also be trained to recognize warning signs of an abnormal nature-such as noises or temperature fluctuations-which could indicate that a system is not safe. Thus, with good pressure management procedure in place, operators will ensure that machinery will give a longer life and optimum performance, foregoing costly repairs.

Design Flaws in Hydraulic Systems

Being anything less than perfect or downright miscalculated in hydraulic-system design can cause inefficiencies, along with performance issues, and lead to outright system failure. One of the most common design errors is the incorrect sizing of system components. Pumps, valves, or reservoirs coming undersized result in improper flow rates, undue heat generation, and fast wear of components. The crucial thing here is to ensure that all components are well-sized to withstand operational pressures and flow requirements to keep the system efficient and workable.

Common Design Errors:

- Incorrect Component Sizing: Undersized pumps, valves, or reservoirs

- Poor Line Routing: Sharp bends, excessive hose lengths, poor support

- Inadequate Filtration: Missing or insufficient filtration systems

- Poor Layout Planning: Components too close together, limiting maintenance access

Hydraulic line routing errors could be at an equal level of common occurrence. Sharp bends, excessive hose lengths, or poorly supported lines cause pressure drops, energy consumption rises, and the hose is degraded faster. Components that are too close to each other can then curb the ease of maintenance and cause parts to overheat due to poor airflow. Proper thought should go into the hydraulic layout to circumvent missable setbacks.

Filtration is expensive and constitutes a big design oversight. Particles of contaminants such as dirt, water, and metal debris will invade the fluid and compromise its integrity, thereby impairing the life and performance of system components. Some of these contaminations can be prevented by implementing high-efficiency filters and strict cleanliness standards during system assembly. Correcting these commonly found design errors at the early design stage will also greatly improve the reliability and efficiency of the hydraulic system.

Recognizing Symptoms of Hydraulic Pump Cavitation

Unusual Noises and Vibrations

Hydraulic pump cavitation is accompanied by very peculiar sounds, sometimes referred to as a “gravel” or “bubbling” noise, happening when vapor bubbles in the hydraulic fluid collapse while going through the pump. Thus, apart from being an auditory nuisance, they also serve as important warnings that indicate cavitation inside the system. These noises and vibrations emanating from collapsing vapor bubbles impose significant mechanical stress on the internal components of the pump, such as the impeller, housing, and bearings. If not settled promptly, the continuous stresses would lead to surface pitting and degradation of the material until complete failure.

Typical Causes of These Symptoms:

- Restricted fluid flow due to clogged filters

- Undersized lines and excessive suction piping lengths

- Low pressure at the pump inlet

- Poor system design allows aeration

- Running a hydraulic system at low temperatures increases fluid viscosity

Typically, the causes behind these symptoms can be restricted fluid flow, low pressure at the inlet of the pump, or bad system design that entertains the possibility of aeration to occur in the hydraulic fluid. Restricted fluid flow can be due to clogged filters, undersized lines, and excessive lengths of suction piping. Another important consideration is that running a hydraulic system at low temperatures can cause fluid viscosity to increase, thereby promoting cavitation. Maintenance, along with continuous inspection of system components, must therefore be enforced to detect and correct these faults before they escalate into costly system failures.

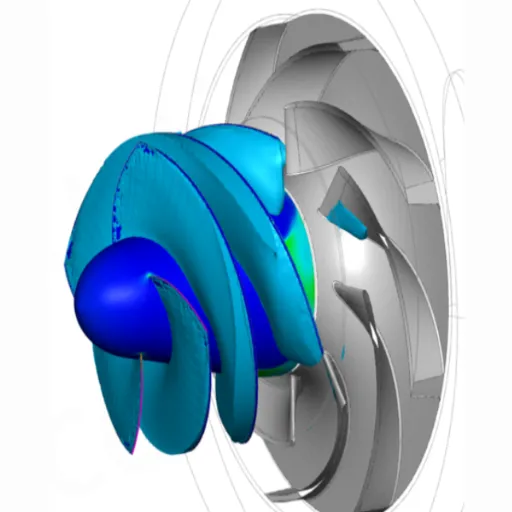

Cavitation-related atypical noises and vibrations can be prevented by engineers making certain that the proper inlet conditions are satisfied for the pump. Examples are an appropriate suction line diameter, fewer bends and restrictions, and viscosities that should be as per the company’s recommendations. CFD software should furthermore be implemented in the design phase to model fluid behavior under different operating conditions so that adjustments can be made in advance whenever these conditions appear likely to cause cavitation. A combination of advanced diagnostics and predictive maintenance could ensure longer life and greater productivity of the system.

Decreased Performance Metrics

Many cases of decreased performance in fluid systems can be attributed to a number of factors, such as poor design, the gradual degradation of materials, and perhaps even mismanagement in operational terms. One major sign of the system not performing well is that there should be a sudden drop in flow rates, which may also mean blocked lines due to incorrect pump sizing or misconfiguration of hose fittings. Another way in which these impairments show up can be simple wear and tear, that is, the deterioration of valves, gaskets, seals, and so forth, culminating in further downstream inefficiency in carrying out the desired throughput. Determining the exact reason for poor performance is aided by performing tests and observations for changes in pressure gradients and temperature variations throughout the system.

Performance Impact Factors:

- Cavitation and Fluid Turbulence: Irregular fluid paths cause an increase in energy consumption.

- Temperature Fluctuations: High temperatures reduce viscosity and cause seal leakage

- Contamination: Particulate matter eroding internal components

- Poor Maintenance: Improper scheduling affects performance parameters

Another big consideration in having a decreased performance metric is cavitation and fluid turbulence in the system. Whatever irregularities in the fluid path turbulence may be caused due to sudden geometric changes in pipe geometry, a disruption in fluid dynamics results in higher-energy consumption or uneven pressure distributions. Cavitation, for instance, is the worst case when vapor bubbles form and collapse violently with a cause being local pressure drops. Hence, system stability and system efficiency are affected, and, physically, there is an impact on system components that damages them and reduces their life, and hence promotes maintenance. Accurate CFD modeling during the design phase can help eliminate risk factors associated with flow path optimization and system configurations.

Besides, other factors, such as temperature fluctuations, contamination of working fluids, and improper scheduling of preventive maintenance work against desired performance parameters. For example, high fluid temperatures can bring down viscosity, which in turn causes leakage around the seals, thus reducing hydraulic efficiency. Particulate contaminants in the fluid might erode internal components and hamper fine fluid mechanics. Those issues would be reduced by thorough and continuous system diagnostics, lately supported by predictive maintenance, such that a problem is pinpointed and addressed before its adverse effect cascades through the system. An integrated approach to monitoring, maintenance, and system design is instrumental in improving and maintaining the key performance indicators throughout the service life of fluid systems.

Physical Damage to the Pump Components

Physical damage to pump components can result from several operational and environmental conditions, each posing a threat to impaired performance or system failure. Cavitation is the foremost cause of pump erosion. Cavitation takes place when vapor bubbles are created inside the pump due to low pressure and subsequently collapse with considerable force. This process erodes impeller surfaces and causes them to degrade structurally with time. Another matter of concern is abrasive wear, and that is largely sustained by particulate matter or debris in the fluid stream, which acts almost like sandpaper, weighing against the internal components and accelerating deterioration.

Studies have indicated that misalignment during installation and thermal expansion when subjected to operating loads heavily contribute to mechanical stress in high-capacity systems. This stress may cause housing cracks, shaft misalignment, or seal failure. Also, a lack of lubrication or corrosive fluids may deteriorate the components on the microscopic scale, thus compromising the overall integrity of the pump.

Advanced Diagnostic Solutions:

- Real-time monitoring via vibration analysis

- Thermographic imaging for temperature monitoring

- Flow measurements for performance tracking

- Predictive maintenance scheduling based on data analysis

The first generation of procedures aimed at solving the problem emphasized the real-time monitoring of pumps via vibration analysis, thermographic imaging, and flow measurements. It is this generation of advanced diagnostics that allowed for the early detection of unusual events and helped predict maintenance. Combining the information-based approach with solid design considerations allows these maintenance schedules to be tied to system downtime to sustain original design life for critical components of the pump.

Effects of Cavitation on Hydraulic Pumps

Wear and Tear on Pump Parts

Cavitation is a major concern in hydraulic pumps because of damage caused to internal components. This phenomenon occurs when vapor bubbles are created in regions of low pressure inside the pump, after which they are carried to areas of higher pressure and swiftly collapse. Due to such an implosion, these bubbles generate very powerful and localized forces and cause damage by way of pitting and erosion mainly over the surfaces of impellers, vanes, and housing walls. With greater passage of time, such damages deteriorate even further deteriorate the surface integrity and fluid flow efficiency further while increasing the levels of operational noise and vibration.

A way to measure the level of cavitation affecting the hydraulic pumps is material highways and efficiency decrease over time. Research has established that short, intense events of cavitation can create microcracks that become areas of stress concentration and propagate under cyclic loading, thereby resulting in premature component failure. While materials like hardened steel or composites that are highly resistant to cavitation can be used to counteract the damaging effects, however, even specialized materials tend to show signs of deterioration when placed in a continuous cavitation environment.

Mitigation Strategies:

- Provide proper pump inlet conditions

- Ensure correct fluid viscosity

- Minimize suction lift

- Avoid sudden changes in fluid velocity

- Use advanced CFD tools for design analysis

- Implement specialized cavitation-resistant materials

To reduce wear-and-tear problems, designers and system operators are advised to provide proper pump inlet conditions by ensuring correct fluid viscosity, minimal suction lift, and absence of sudden changes in fluid velocity. Using advanced computational fluid dynamics (CFD) tools during the analysis phase will enable the simulation of cavitation zones, allowing design corrections to be made before manufacturing. When combined with improvements in material properties and precise operational control, the damaging effects of cavitation-induced wear on components of a hydraulic pump can be greatly lessened, thus extending the lifespan of the equipment and reducing maintenance costs.

Reduced Efficiency and Performance

When allowed to continue affecting processes, cavitation functions to hamper the hydrostatic pump’s efficiency and the depreciation of performance over time. This would reduce the volumetric efficiency of the pump, since the cavities are interruptions for the fluid flow. A collapse of these cavities would cause localized damage to the component surfaces and also generate noise and vibration, which are additional signs of efficiency losses. For instance, this turbulence distorts the velocity profile of the fluid flow, hence increasing the rate of turbulence energy dissipation and consequently decreasing the rate of mechanical energy conversion from input to output.

Research Findings:

Tests with axial-piston pumps show a 20% or lower loss in volumetric efficiency under cavitation-prone operating settings. The inefficiency is normally associated with conditions such as low inlet pressures, high rotational speeds, and high fluid temperatures.

Tests with axial-piston pumps show a 20% or lower loss in volumetric efficiency under cavitation-prone operating settings. The inefficiency is normally associated with such conditions as low inlet pressures, high rotational speeds, and high fluid temperatures. In such cases, the vaporization of fluid is encouraged, thereby increasing the chance for cavitation inception and so making preventive measures all the more important. An engineer can compare these results with respect to typical operational criteria to identify an early decline in performance and schedule the maintenance accordingly.

The loss in efficiency can be mitigated if advanced diagnostics, such as vibration analysis and acoustic emission monitoring, detect the cavitation signatures in real-time. Using these diagnostic tools together with predictive maintenance algorithms can precipitate timely corrections by the operators before significant damage occurs. In addition to design optimizations like improved inlet geometries and sophisticated impeller coatings to resist shear-induced vaporization, the chances of cavitation formation can be considerably reduced. By investigating the soluble causes of inefficiencies in performance, the combined operational potentials of hydraulic pumps would stay within an acceptable range when subjected to severe working conditions.

Increased Maintenance Costs

Cavitation occurrence and other mechanical inefficiencies in hydraulic systems result in significantly increased maintenance costs. Such costs are, on one hand, actually incurred for repairs and component replacements, and on the other hand, output loss and reduced operational efficiency are considered indirect costs. Outlined here are five major facets that contribute to increasing the maintenance cost:

Major Cost Contributing Factors

1. Frequent Component Replacement

Cavitation and extreme wear increase wear in parts such as impellers, seals, and bearings, requiring more frequent replacement. Studies indicate average component life decreased by as much as 40% in cavitation-prone systems.

2. Energy Losses

Losses due to mechanical wear and disruptions in fluid flow cause higher energy demand, directly increasing operational costs through extra energy consumption.

3. Unscheduled Downtime

Sudden system faults can halt production, with unplanned downtime estimated to cost industrial facilities an average of $260,000 per hour.

4. Repair Labor Costs

More maintenance demands mean more man-hours of technicians and engineers. Complex internal pump repairs require specialized labor, adding significant costs.

5. Auxiliary Equipment Damage

Chronic cavitation can inflict collateral damage to connected equipment from pipelines to control valves, creating a cascading effect requiring extensive system-wide maintenance.

Rectifying these with preventive maintenance strategies, improved system design, and continuous monitoring will help to keep costs down and prolong the equipment’s service life.

Preventing Cavitation in Hydraulic Systems

Proper System Design and Configuration

Cavitation is prevented in hydraulic systems with the implementation of a well-engineered design on the system. This starts by ensuring the right selection of pumps and hydraulic lines, and a fluid reservoir, depending upon the working of the system. To avoid a low-pressure zone at the pump inlet, which usually leads to cavitation, appropriate NPSH margins must be maintained. Inefficient restrictions or sharp bends that can cause turbulence in hydraulic lines should be eliminated.

Cavitation risk prevention further requires the appropriate selection of fluid viscosity. The fluids should be able to withstand the operating temperatures of the system so that they maintain the desired flow rate at varied temperatures. CFD simulations may also be scheduled during the design phase to allow engineers to identify areas prone to stressing within the system and then preemptively resolve them.

Modern Prevention Technologies:

- Real-time flow rate, pressure, and temperature sensors

- Automated controls for continuous system adjustment

- Early warning systems for cavitation onset

- Integrated diagnostics and sensing technologies

Embedding modern diagnostics and sensing technologies into system configurations can also aid in preventing cavitation. Sensors having the capability of monitoring real-time flow rates, pressure variations, and temperatures offer early warning signals of cavitation onset. In tandem with automated controls, these systems will prevent damage to the hydraulic components by continuously readjusting settings to ensure stable operation.

Regular Maintenance Practices

Regular preventive maintenance guarantees the durability and functional operation of hydraulic systems, particularly in environments threatening to occurrences like cavitation. This consists mainly of periodic inspections of the pump internals, including impellers, seals, and bearings, to determine any potential wear and tear or loss that could affect performance. From there, and in close alignment with manufacturers’ lubrication schedules, appropriate lubrication is given to lessen frictional losses and onward heat generation.

Key Maintenance Areas:

- Hydraulic Fluid Management: Regular fluid changes and contamination monitoring

- Advanced Filtration: High-efficiency systems with contamination level testing

- Sensor Calibration: Regular calibration of diagnostic devices

- Performance Monitoring: Pressure and temperature threshold maintenance

Given the importance of maintaining the hydraulic fluid, it is also pertinent that it be changed as and when required. Consider that contaminants, as well as degraded oil properties, can contribute to cavitation by lessening and resolving the system’s ability to maintain consistent pressure and flow. Advanced filtration systems coupled with extensive testing for fluid viscosity and contamination levels could lead to immediate maintenance feedback.

Another important aspect entails the regular calibration of sensing and diagnostic devices. Sensor accuracy ensures that the pressure and temperature are within their respective specified thresholds, thereby avoiding conditions leading to ultimate cavitation. In turn, all these maintenance activities underpin a comprehensive approach that ensures safety on systems and non-emergency interruptions of downtime.

Utilizing Advanced Monitoring Tools

An advanced monitoring tool, being key to guaranteeing the best system performance and curtailing any possibility of an unexpected operational disruption, these tools allow one to monitor the slight variation in pressure, flow rate, or temperature in real-time, which can be used to alert to any abnormalities or nonconformity in their respective areas. Once such warning signs are noted, they can be used in predictive maintenance activities initiated through irregular operation patterns so that those patterns do not become mechanical failures. The advanced maintenance activities reduce downtime and increase system reliability.

Advanced Monitoring Benefits:

- Machine learning algorithms for trend analysis

- Predictive maintenance scheduling based on historical data

- Operational optimization through data analytics

- Precise equipment wear rate predictions

- Reduced operational expenditure and performance lag prevention

I perceive that from the perspective of operational insight, these tools carry some benefits. With an end-to-end setup of machine learning algorithms and data analytics in the monitoring system, we become capable of accessing trends, predicting future occurrences of operational issues, and achieving operational optimization. An illustration of this would be: the historical data could predict wear rates of equipment, and maintenance activities would then be scheduled very precisely. This sense of precision would cut down on operational expenditure, as well as deter an unlooked-for performance lag, which would be the sole cause of critical degradation in the equipment.

Being agreeable to me, there is, in fact, a degree of emphasis to be placed on the scalability and compatibility of the tools during installation. There is significant importance in ensuring that these systems can smoothly fit into the operational workflows and infrastructure. A modular approach to design allows upgrades along the way as new technologies are introduced to keep the system adaptive and mature. From this perspective, I see that focusing on these aspects may give organizations a chance to use their advanced monitoring tools to weed out problems in their systems and guarantee long-term operational resilience as well.

Actionable Maintenance Tips for Hydraulic Pump Professionals

Routine Inspection Guidelines

If one wants to have hydraulic pumps working efficiently and reliably, that person must undergo structured routine checks continuously. There must be an initial visual inspection of all hydraulic components, which includes hoses and fittings, for any signs of wear, cracks, leaks, or even corrosion. All connections must be checked to verify any dents that might have occurred from impact and to ensure that no fluid has dribbled from them. Checking fluid levels is a must, and hydraulic oil must not deviate from its recommended specifications lest the pump undergo cavitation or have a poor output performance.

Essential Inspection Checklist

✓ Visual Components

- Hoses and fittings

- Signs of wear, cracks, leaks

- Corrosion evidence

- Connection integrity

✓ Fluid Analysis

- Fluid level verification

- Hydraulic oil specifications

- Cleanliness particle count

- Contamination assessment

✓ System Monitoring

- Pressure value checks

- Operating temperature levels

- Warning indicators

- Unusual system noises

Measure the hydraulic fluid cleanliness in terms of particle count, thus preventing a failure caused by contamination. Next up are the pressure values, which must be checked against the manufacturer’s specifications so that the system always works within the intended range. Operating temperature levels should also be watched; any deviation might be an indication of issues with efficiency, straight from the source or in the equipment itself. Lastly, carry out an appraisal of warning indicators or strange system noises since, very often, they mean an immediate mechanical problem requiring attention.

Upholding dearly the prescriptive measures will keep downtime to a minimum, thus making the pumps last longer and ensuring a much more reliable system.

Fluid Quality and Testing Recommendations

Ensuring satisfactory fluid quality is one of the necessary steps to guarantee efficient and reliable system performance. Poor fluid quality results in accelerated wear, decreased efficiency of the system, and failure in the extreme case. Therefore, regular fluid testing must be undertaken to keep an eye on factors such as viscosity, pH, contamination, particulate or microbial, and water content. Any deviation in such will provide not only warnings about the deterioration of the fluid but also alert to the occurrence of some other problem in the system so that actions can be taken to prevent further damage.

| Testing Parameter | Importance | Impact if Neglected |

|---|---|---|

| Viscosity | Governs lubrication and hydraulic characteristics | Poor flow characteristics, inadequate lubrication |

| pH Level | Indicates acidic/alkaline state | Corrosion of internal system components |

| Particulate Contamination | Prevents wear particle accumulation | Component wear, system damage |

| Water Content | Prevents cavitation and emulsification | Severe fluid degradation, cavitation issues |

Viscosity flows as one of the main aspects of fluid health, as it directly governs the lubrication and hydraulic characteristics of the system. In an ideal setting, the viscosity should be measured regularly to ensure that the fluid has its designed flow characteristics under operating conditions. pH level testing is also necessary to verify the acidic or alkaline state of the fluid, since it can cause corrosion on the inner parts of the system if imbalanced. Detecting and correcting this situation at the early stages will considerably help in prolonging the system’s lifespan, thereby preventing costly repairs.

Particulate contamination is yet another factor that must be assessed while conducting routine fluid analysis. Particulates can enter the system externally or internally as wear particles from the system components. With the help of an advanced filtration system and regular fluid sampling, one can identify and mitigate contamination. Equally important is being on the lookout for water ingress, which severely degrades the quality of fluids and consequently can create cavitation or emulsification problems. Employing the latest test techniques and complying with industrial standards for advanced fluid quality will ensure operational efficiency and cost savings from prolonged uptime and minimal wear-related failures.

When to Seek Professional Assistance

When abnormalities are detected through fluid analysis, which are difficult to diagnose or solve at the company’s facility, one should consider professional assistance. Cases of persistent contamination, sudden unexplained fluid degradation, or a sudden unexplained drop in equipment performance must have the root cause correctly analyzed by an expert. Specialists, armed with the best diagnostic equipment and experience in the field, are capable of performing a full-scale study, including chemical analysis, particle counting, and more advanced spectroscopic studies, to uncover any issue that might otherwise avert being unnoticed.

Professional Intervention Indicators:

- Complex Contamination Issues: Persistent contamination despite mitigation efforts

- Unexplained Performance Drops: Sudden equipment performance decline

- Advanced Problems: Water ingress, emulsification, or unchecked cavitation

- Compliance Requirements: Industry standards and regulatory compliance needs

If water ingress, emulsification, or cavitation have been left unchecked and all mitigation measures have been exhausted, it is a must to obtain expert advice. These problems become dangerously exacerbated with time, culminating in serious mechanical damage, leading to a loss in system reliability or a complete failure of equipment. These specialists recommend suitable interventions such as installing desiccant breathers, improving filters, or improving dehydration processes using vacuum dehydration units (VDUs). The solutions are specifically designed to handle complicated contamination situations to optimize the operation of fluid systems.

In the end, somewhat regular and professionally conducted audits of fluid systems have become necessary for the systems to maintain compliance with changing industry standards and regulations. Industry standards such as ISO 4406 for the fluid cleanliness codes would change as new research and newer technologies come into being. Accordingly, duly qualified professionals will check whether or not a system complies with the codes and standards and take proactive measures if necessary to improve performance and reduce risks. With such an embracing approach consisting of professional insight, implemented at the operational plan level through to day-to-day maintenance, operators can thereby extend the life of the fluids and the equipment with a necessarily minimal level of downtime and consequent maximum operational efficiency.

Frequently Asked Questions (FAQ)

Q: What is hydraulic pump cavitation?

Cavitation in a hydraulic pump is an event during which the pressure inside the hydraulic pump drops below the vapor pressure of the hydraulic fluid, resulting in the creation of vapor bubbles. These bubbles, upon reaching a higher pressure zone within the hydraulic circuit, implode and generate shock waves, thus posing damage and loud noise, further causing the failure of the pump.

Q: What generally causes cavitation in hydraulic pumps?

Several factors cause cavitation in hydraulic pumps. Among them are an insufficient supply of flow, turbulence at the inlet of a pump, and a clogged suction strainer. Besides, a dirty hydraulic oil filter and the wrong viscosity of hydraulic fluid will also contribute to the occurrence of cavitation.

Q: How can cavitation affect the performance of hydraulic motors?

Cavitation will have severe effects on a hydraulic motor because it produces vibrations, reduces its efficiency, and leads to increased abrasion of pump seals and other components. This causes severe damage to the pump over time, so the earlier cavitation is noticed, the earlier action can be taken to correct it.

Q: What are the symptoms of cavitation in a hydraulic pump?

The symptoms of cavitation in a hydraulic pump are the pump making a strange noise, pressure fluctuations occurring at the inlet of the pump, and a drop in flow at the outlet of the pump between 5 and 10%. Furthermore, if some metallic debris appears in the hydraulic fluid, this may be an indicator that cavitation has damaged the pump.

Q: How does one prevent cavitation in hydraulic systems?

In order to prevent cavitation, the hydraulic pump inlet should be designed very carefully, and the supply hose should be checked for any blockage. Ensuring that hydraulic fluid has the correct viscosity, plus the reservoir-to-pump levels are retained at the proper setting, are also good measures against cavitation.

Q: What is the leading cause of hydraulic pump failure related to cavitation?

A hydraulic pump failure related to cavitation most often arises due to possible improper supply flow to and inlet conditions of the pump. Whenever the pressure at the pump inlet goes beyond a low limit, cavitation conditions set in, causing massive pump damage and pump failure.

Q: How does turbulence at the pump inlet contribute to cavitation?

Turbulence at the pump inlet can disrupt the smooth flow of hydraulic fluid, causing fluctuations in pressure that may drop below the vapor pressure. This creates an environment where cavitation can occur, resulting in the formation of cavitation bubbles and potential damage to the hydraulic pump.

Q: What do fittings do to prevent cavitation in hydraulic pumps?

Properly chosen fittings, such as a flange-type fitting at the pump and ball valves, are used to maintain consistent pressure and flow into the hydraulic circuit side. Also, they have to be free of any obstruction to prevent cavitation and other associated problems.

Q: Will flushing the whole hydraulic system sort out some of these cavitation problems?

Yes, flushing the entire hydraulic system removes contamination and metallic debris, thus improving the overall conditions of the hydraulic fluid. Once restored in terms of flow and pressure, it reduces the chances of cavitation occurrence and creates better performance for the hydraulic pump.

Key Takeaways

Understanding and preventing hydraulic pump cavitation is essential for maintaining system efficiency, reducing maintenance costs, and extending equipment life. Regular monitoring, proper system design, and proactive maintenance are your best defenses against this costly problem.