Hydraulic axial piston pumps play a critical role in modern industrial and mobile applications, offering unmatched efficiency and reliability in the transmission of hydraulic power. These intricate machines are highly valued for their ability to maintain consistent pressure and deliver precise control in systems where durability and performance are non-negotiable. But what exactly makes these pumps so effective, and how do their designs contribute to their functionality? This article dives deep into the engineering principles, core components, and working mechanisms of axial piston pumps. Whether you are a seasoned engineer or just entering the field of hydraulics, this technical guide will provide a detailed, authoritative exploration of one of the most indispensable components of hydraulic systems.

What is an Axial Piston Pump and How Does it Work?

Principles of Axial Piston Pump Operation

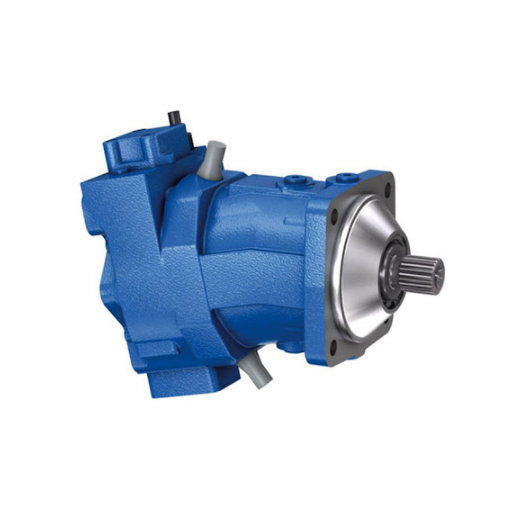

An axial piston pump is a machine that works on the principle of reciprocating motion to generate hydraulic power. It consists of several pistons that lie parallel to the axis of rotation, inside a cylinder block. Movement of the pistons, either by an inclined swash plate or a bent axis, controls the stroke length of each piston and hence controls the volume of fluid displaced. This design gives the axial piston pumps the ability to accurately control the flow of fluid in a hydraulic system, making them very suitable for high-pressure applications.

Converting mechanical energy into hydraulic energy is the fundamental act dictating the working capability. As the pump shaft rotates, the inclined swashplate imparts a reciprocation motion to the pistons within their bores. In the suction phase, the backward movement of the piston causes a vacuum in the cylinder that draws hydraulic fluid through the inlet port. The compression stroke is, however, just the opposite, whereby the piston pushes the fluid out via the outlet port. It is this cycle repeated continuously that delivers an uninterrupted and efficient flow of pressurized fluid.

A variable displacement application would be an appropriate one for axial piston pumps since the swashplate angle can be varied, allowing for variation in flow rate and pressure. Its design allows for high speed, high volumetric efficiency, and can accommodate different hydraulic fluids. They find application in industrial machinery, mobile equipment, and aerospace hydraulic systems where reliability and precision are indispensable.

Components of a Hydraulic Axial Piston Pump

A hydraulic axial piston pump is made up of several critical components, each of which works cohesively to ensure efficient and precise operation. Said components include the cylinder block, pistons, swashplate, valve plate, and drive shaft. Together, the elements change mechanical energy into hydraulic energy while maintaining a continuous flow of hydraulic fluid under pressure.

The cylinder block holds the pistons in extremely fine bores and rotates with the drive shaft. Pistons reciprocate in split bores, caused by the movement of the swashplate. The displacement of the pump is governed by the angle of the swashplate: the larger this angle, the greater will be the flow rate of hydraulic fluid. The valve plate separates the suction and discharge ports, controlling the flow of fluid so that smooth, uninterrupted operation can take place.

The drive shaft is what defines the mechanical input for the pump; it takes energy from the motor or engine. Bearings and seals form other components that serve to support the pump’s efficiency and life by reducing friction and preventing leakage of fluid. All these are what make an axial piston pump capable of high efficiency, durability, and precision in diverse applications.

Role of the Swash Plate in Pump Operation

The swash plate is a crucial element for the axial piston pump, controlling piston movement and fluid flow. The stroke length of the pistons inside their respective cylinders depends on the angular position of the swash plate. By varying the angle of the swash plate, the fluid displacement can be varied, thus controlling the flow rate very precisely in hydraulic circuits. An axial piston pump is best suited for variable displacement applications.

When the swash plate angle is steep, pistons make longer strokes of fluid displacement per revolution. In contrast, decreasing the swash plate angle reduces piston stroke length and overall output. This variable feature is useful where wide operating ranges with very accurate flow control are required, among other areas such as industrial machinery, automotive systems, and aerospace technologies.

The choice of materials and manufacturing methods affects the product life and performance of the swash plate. Various coatings and surface treatments are applied for wear resistance and to maintain mechanical integrity under high-pressure applications. The swash plate acts with the pistons in determining the efficiency and reliability of the entire pump assembly, thus making it a crucial part of axial piston pump design.

How Does the Displacement Mechanism in a Hydraulic Axial Piston Pump Function?

Understanding Variable Displacement

The variable displacement feature in a hydraulic axial piston pump means that the fluid output can be altered by adjusting the swash plate angle and, thus, changing the stroke length of the pistons in the cylinder block: this adjustability allows the pump to be optimized for varying demands of the system. By varying flow rate and pressure, variable displacement pumps conserve energy and limit heat generation that is otherwise unnecessary in a fixed displacement pump.

The swash plate probably can tilt at angles that form the fundamental principle of this mechanism. At full tilt, pistons complete their maximum stroke, with maximum fluid displacement being produced. When the swash plate angle is lessened, it reduces the stroke length and the output volume. Very often, in modern hydraulic systems, servo controls actuate the swash plate with precision to provide fine control of displacement in response to real-time needs of the system.

In engineering terms, the benefits of variable displacement pumps include less energy consumption, reduced wear and tear on equipment, and improved adaptability in variable fluid power systems. Field data and research consistently show that the variable displacement system cuts down operation costs as much as 30% in the industrial and mobile hydraulic systems. This level of efficiency makes variable displacement pumps indispensable in construction, manufacturing, aerospace, and a range of other industries where great importance is given to dynamic system performance.

Impact of Piston Stroke on Pump Performance

The length of the piston stroke is a critical parameter that dictates the ultimate yield, efficiency, and performance of a variable displacement pump in a hydraulic system. The stroke further determines the volume of displacement that gives room to pressure and flow rate set by the pump. Leading into a detailed study of piston stroke impact, one can list the following important considerations:

- Displacement Volume Variability: With each cycle, the piston stroke fixes the volume of displacement. When the stroke length is increased, the pump capacity to cope with higher demands of flow proportionally increases; hence, it functions well for an application that calls for a higher fluid delivery. Shorter strokes, on the other hand, cut down on displacement capacity, making it more efficient in terms of energy consumption, where less flow is required.

- Energy Efficiency: Maintaining proper piston stroke adjustment allows the operator to control energy consumption. Field tests disclosed that systems with variable piston stroke design can reduce energy losses by 20%, especially under varying load conditions.

- Pressure Control and Stability: Better accuracy in stroke adjustment will improve the pressure control within the system. It has been reported that pressure variations are 15% less in adaptive piston stroke systems than in fixed strokes, thus providing pressure stability under varying operational loads.

- Wear and Durability: Longer piston strokes accelerate wear and tear to components, especially under severe service conditions. It has, however, been shown that optimally adjusting the stroke lengths according to the operating conditions can improve the life expectancy of pumps by 25%, substantially reducing the associated maintenance expenses.

- Effect on Noise and Vibration of a System: The vibrations of the pump are also affected by the stroke length. Studies show that the forced piston stroke significantly reduced vibration energy, downsizing noise by an average of 10 dB in compliant systems. Improvement of this allows for comfortable working conditions and minimizes mechanical stress on the system.

These factors related to the overall performance show the importance of the piston stroke and stroke length tuning in the optimization of hydraulic systems. With the stroke regulation mechanism, engineers can guarantee the highest possible operational efficiency, the lowest maintenance, and the best system reliability.

Adjusting the Angle of the Swash Plate

Since adjusting the swash plate angle controls the output of hydraulic pumps or motors in axial-piston mechanisms, changing its tilt will correspondingly change the displacement of the pistons in the cylinder block and thereby control the flow and pressure of the hydraulic fluid. Increasing the swash plate angle will increase the piston stroke and, thus, volumetric output, whereas a decrease in the angle leads to a decrease in displacement and, hence, flow output.

In many modern hydraulic applications, the angle of the swash plate is determined through electronic control mechanisms, which allow precise adjustments. These mechanisms usually use proportional solenoid valves or servo-driven actuators with means to dynamically respond to changing load conditions. For instance, with variable displacement pumps, feedback sensors along with electronic control units (ECUs) monitor system performance, such as flow demand and pressure, continuously to maintain the orientation of the swash plate in real-time. This real-time operation reduces energy consumption and maximizes efficiency while lessening thermal load on the system.

Energy savings as much as 30% have been reported from variable displacement pumps utilizing dynamic swash plate control as compared to fixed displacement systems under similar functioning conditions. Moreover, advances in wear-resistant materials and lubrication have further enhanced swash plate and auxiliary component durability, providing stable and reliable performance in heavy-load environments for the long term.

Harnessing the ultimate control through swash plate design, engineers have been able to withstand the challenging applications of modern-day hydraulics while guaranteeing their proper functioning throughout an array of industries, from construction and manufacturing to aerospace and green energy.

What Are the Key Benefits of Using Hydraulic Axial Piston Pumps?

Efficiency in Hydraulic Systems

In my opinion, axial piston pump efficiency ranks among its defining properties. These pumps are engineered to transfer power primarily into hydraulic energy with minimum loss so that the power can be utilized within the system efficiently. High volumetric efficiency coupled with mechanical efficiency demands low energy consumption and consequently results in reduced operating costs and improved performance of the system.

The other critical feature lies in the ability to meet varying demands of pressure and flow. The swash plate is essentially a mechanism controlling fluid displacement in precise terms so as to ensure optimum energy utilization. The ability to maintain system stability despite fluctuating load conditions helps eliminate unnecessary energy loss, thereby improving energy efficiency.

Furthermore, building a better and even more advanced axial piston pump enhances durability, assures system reliability, and when less attention is paid to breakdowns, there are fewer maintenance requirements. Its robust design, coupled with innovations in wear-resistant materials and advanced sealing technology, reduces losses due to inefficiency caused by wear of components. These are thus factors enabling hydraulic axial piston pumps to become indispensable for jetting out high-efficiency performance in paramount applications.

Applications in Heavy Hydraulic Equipment

Whenever one needs sustained performance at high pressure, axial hydraulic piston-type pumps find application in all kinds of heavy hydraulic equipment. Here are the five applications that highlight the essential role of axial piston pumps:

- Excavators: Axial piston pumps give the fine hydraulic power needed to control the heavy arms and buckets of excavators. With flow rates of 100 to 350 l/min and pressure surpassing 400 bar, the axial piston pump helps to make smooth and efficient operation of excavation in fairly heavy work.

- Cranes: Used in mobile cranes and tower cranes, these pumps lift and maneuver loads particularly accurately. The hydraulic powers are so finely controlled via the proportional control mechanism that they can safely handle all variations in load.

- Bulldozers: Bulldozers use axial piston pumps to control the blade-lift and tilt functions, with high efficiency of the pump design ensuring stability and responsiveness, qualities necessary in earth-moving activities that require control under stiff working conditions.

- Agricultural Machinery: They provide hydraulic power for plowing, sowing, and harvesting tasks at working pressures usually ranging from 250 to 500 bar, with the plants being productive due to a normal power supply for complex machinery.

- Mining Machines: Axial piston pumps serve in the hydraulic circuits of mining drills and trucks to aid in the extraction and transportation of materials. Their very rugged construction renders them capable of standing up to extreme pressures, temperature variations, and abrasive environments.

The use of hydraulic axial piston pumps in these applications indicates their optimization for higher operational efficiency, minimizing downtime, and satisfying demanding performance standards of the heavy industries.

Durability and Reliability of Axial Piston Pumps

Designed to provide utmost durability and reliability, axial piston pumps operate under the most adverse conditions available. Their ruggedness allows them to withstand prolonged exposures to unusual pressure levels, commonly exceeding 6,000 psi under industrial systems. Resistance to wear from abrasive particles present in hydraulic fluid is made possible through enhanced surface treatment and hardening of components within the pumps.

Therefore, the same reliability that produces consistent performance throughout great operational cycles is what also allows these machines to stand the test of time. Such are precision-engineered with tight tolerances between piston and cylinder assemblies to reduce internal leakage, thus retaining efficiency while preserving the risk of component failure. Real-time monitoring systems are now incorporated into new axial piston pumps, where performance is tracked in real time, allowing the operator to quickly notice any abnormality before it grows into a severe problem. This sort of maintenance-by-exception allows for reduced downtime and increased equipment life, thereby providing a measurable long-term benefit to industries like construction, mining, and manufacturing.

Moreover, today, axial piston pumps mostly feature modular drives, allowing repairs and component replacement in situ. This ensures minimal disruption to operations, further reinforcing their status as the reliable choice for high-performance hydraulic systems.

What Are Common Issues and How to Prevent Pump Failure?

Signs of Pump Failure to Watch For

Early signs of pump failure must be recognized to retain the hydraulic system’s efficiency and save on expensive downtime costs. Strange noises coming from the pump rank among the most prominent indicators. These sounds could be knocking, whining, or even cavitation- air being trapped or inadequate lubrication, or excessive wear of the internal components. Such sounds should prompt the inspector to take immediate action; if untreated, they will escalate into damage and ultimately failure.

Another very important sign will be a performance drop, noticed by reduced flow rate, erratic pressure, or slow operation. Usually, internal leakage, worn-down seals, or contamination within the hydraulic fluids will have a bearing on these symptoms. Several performance tests and system output monitoring done continuously will give early indications of any inefficiency being noticed, leaving operators with time to correct the issue before it worsens.

Another big red flag for pump failure is overheating. Excessive heat can be generated because of the breakdown of fluid viscosity, clogged filters, or pumping beyond the bounds of its design. An overheated system will not do any favor to the pump functionality, but also puts the very integrity of the machinery at stake. Preventive-keeping with oil analysis, filtration, maintenance, and drilling into system load balancing, will help keep these hazards aside and further extend pump service life.

Regular Maintenance Tips for Hydraulic Axial Piston Pumps

The best pump maintenance schedule will allow these hydraulic axial piston pumps to perform at their optimum level, minimize downtime, and increase service life. Below are specific and authoritative examples of pumps for maintenance:

- Fluid Quality and Contamination Monitoring: Clean oil is a key to the hydraulic system working efficiently. Run tests on oil once in a while to determine levels of contamination, moisture, or degradation. Should any fluid be depleted of additives or undergo viscosity changes, it is imperative to replace it. Use only high-quality filters and strictly follow the recommended filtration period to minimize the risk of debris damaging the interior of the pump assembly.

- Wear Component Checkups from Time to Time: Components such as pistons and swash plates, as well as bearings, should be examined for extensive wear, scoring, or misalignment. Defective components should be replaced immediately to prevent further damage to the pump and other machines. In the long run, this guarantees system reliability.

- Review Operating Conditions: Load and pressure levels should be evaluated frequently to verify that they remain within those specified in the permitted design of the pump. Such overload or pressure spikes could cause the pump to wear prematurely and finally fail. Pressure gauges and diagnostic tools should be used to keep operating parameters in a stable range.

- Undertake Adequate Cooling of the System: One fruitful cause of hydraulic-pump failure is overheating; ensure that the heat exchangers and cooling systems perform adequately. Clean any clogging of the cooling fins so that the system runs within the recognized working temperature, usually between 120°F and 140°F, to avoid thermal distress to the pump.

- Leak Check and Fitting Tightening: Check regularly for leakage of seals, hoses, and connections. When hydraulic fluid leaks, efficiency suffers; it also becomes an environmental hazard. Tighten fittings that need this and replace seals that are degrading to keep the system intact.

- Schedule an Overhaul: A major overhaul, as per pump manufacturer recommendations on working hours, should be scheduled with a vengeance. The major overhaul, cleaning, inspection, and replacement ensure that all critical parts retain the highest possible efficiency.

Created into a routine, integrating these practices in an industry can yield high potential in extended operating life, with the downside of reduced unplanned downtime. The manufacturer’s recommendation and possible use of modern tool kits and equipment for real-time monitoring should form the core of any given maintenance program.

Preventing Pressure Rises and Controlling Pump Pressure from Exceeding Limits

Keeping a constant pressure in the hydraulic systems is what determines the safe and efficient operation of an axial piston pump. Pressure rises above the maximum permissible limit for component failure or complete breakdown. Pressure relief valves rated for the system’s working capacity must be provided to avoid such incidents. Such devices should be tested on a regular basis for proper response and working in different load conditions.

Pressure in the system can be monitored using advanced instrumentation equipped with real-time sensors that detect any anomaly and send alarm conditions to the operator when the pressure reaches certain set limits. Such systems have to log operational data against pressure, gaining insight into pressure trends so that decisions or servicing can be done beforehand. Operators must be trained in this respect to ensure that they can identify an excursion and take immediate action.

Pressure spikes, therefore, lead to maintenance with an integrated pressure regulating device, real-time monitoring, and observance of the manufacturer’s recommendations for the hydraulic system.

How Does Load-Sensing and Pressure-Limiting Control Work in Axial Piston Pumps?

Understanding Load-Sensing Mechanisms

Load-sensing systems in axial piston pumps are meant for hydraulic system efficiency variation by adjusting the pump output automatically depending on the system demand. Basically, the control system ensures that the pressure and flow needs of the actuators of the circuit are being measured. This is done through a feedback loop wherein the load-sensing valve measures the pressure drop across an orifice or certain other hydraulic element. The Appointed difference in pressure or delta pressure lets the pump adjust its displacement to deliver a flow corresponding to exactly what is needed to perform the desired operation, thereby eliminating unnecessary loss of energy or heat.

Modern load-sensing systems work primarily through a compensator that is linked to the pump control mechanism. When any change in operational demand is observed, the compensator will change the angle of the pump swashplate, thus modifying the stroke of the pistons and changing the fluid flow, providing just enough pressure to do well. Among other load-sensing benefits, energy-saving is the most crucial, realized further through the reduction of wear between system components and the adaptation to workloads varying in terms of overload character.

With recent developments in sensor technology and the advent of digital integration, the precision and reliability of load-sensing systems have been advanced to a much higher level. Real-time data monitoring and predictive analytics allow operators to draw actionable insights from performance trends that set them on proactive maintenance pathways for reduced downtime. These enhancements, along with basic load-sensing principles, place load-sensing systems at the convenient end of utilization in construction, agriculture, and industrial hydraulics, where efficiency and reliability are of utmost importance.

The Role of Pressure Differential Across the Flow Control

Pressure differentials across a flow control valve have a marked influence on the behavior of fluid flow rates and system stability. Before and after passing through the valve, the pressure difference maintains exactly the desired flow characteristics, which is critical in various hydraulic and pneumatic systems. Proper working pressure differentials, which means getting it just right for the situation, can optimally serve operations, saving energy, and supporting smoother durability of components. Some of the effects that majorly influence system performance are explained below:

- Flow Rate Accuracy: A constant pressure differential produces flow rate consistency and predictability, which is an integral consideration in systems that demand precision, such as injection molding or CNC machines.

- Energy Efficiency: Keeping the pressure differential in check could reduce energy losses since it limits throttling and turbulence that may arise inside the valve; hence, one big contributor to energy consumption in hydraulic circuits.

- Temperature Stability: Maintaining an appropriate pressure differential is a controlling factor in the heat generated due to energy dissipation. Excess energy dissipation resulting from incorrect flow control could cause overheating, thereby reducing system efficiency.

- Minimized Cavitation: Design to control cavitation, i.e., its vapor bubble formation inside the fluid, by adopting an adequate pressure differential to avoid damage to the inner valve components; hence increases system life.

- System Responsiveness: Properly maintained pressure differential gives the system the ability to respond quickly and smoothly to changes in item load or operational demand, enhancing dynamic performance and reliability.

High system performance, reduced wearing of members, and greatly improved reliability and efficiency can be achieved by combining the art and science of pressure differential.

Benefits of Load-Sensing and Pressure-Limiting Control

The introduction of load-sensing and pressure-limiting controls is a key innovation in hydraulic systems, bringing with it a host of advanced benefits for operational efficiency and system longevity. The primary advantages comprise:

- Energy Efficiency: These systems vary flow and pressure by demand, significantly cutting energy consumption and wasting a little less. Secondly, modern hydraulic systems can improve energy efficiency by as much as 30% through the use of load-sensing technology, thereby greatly contributing to sustainable development.

- System Longevity: Pressure-limiting controls prevent the occurrence of excessive pressure and reduce the wear of critical components. This method helps reduce maintenance costs and extends machine life by lowering the possibility of overpressure.

- Heat Dissipation: Load-sensing systems chop excess flow and pressure, which is essentially the major source of heat generation in any hydraulic system. Less heat results in better system performance and less thermal degradation of hydraulic fluids, thus keeping the system working efficiently.

- Machine Accuracy: By adjusting to variations in load, the systems improve the accuracy and responsiveness of the machinery. Such ability comes in handy in applications that require fine control, like construction equipment, manufacturing machines, and agriculturally oriented vehicles.

- System Integration: Advanced load-sensing and pressure-limiting systems integrate with the electronic control units (ECUs), thus rendering them compatible with the modern-day machine operation protocols. This integration enables monitoring and optimization in real time for enhancing predictive maintenance and overall throughput.

All things considered, these advantages go some way to suggesting why load-sensing and pressure-limiting control technologies should be embedded within modern hydraulic systems. Such technologies help reduce operational costs while boosting energy efficiency and machine life, which are all activities aligned with the global call to improve industrial sustainability and productivity.

Frequently Asked Questions (FAQ)

Q: What is an axial piston pump, and how does it function?

A: An axial piston pump is a type of hydraulic pump that uses a series of pistons arranged in a circular pattern within a cylinder block. The pistons move parallel to the pump shaft, which allows for the conversion of mechanical energy from a prime mover rotating the pump into hydraulic energy. The interaction between an axial-piston pump and a typical hydraulic motor enables the transfer of fluid under pressure to perform work.

Q: How does the displacement of the pump affect its operation?

A: The displacement of the pump refers to the volume of fluid moved by the pump per revolution. It directly impacts the pump output, meaning a higher displacement results in greater hydraulic flow and power. Adjusting the displacement of the pump allows for control over the flow rate and pressure, which is crucial for adapting to different load conditions.

Q: What roles do pump control and pump control uses play in hydraulic systems?

A: Pump control is essential for managing the operation of the pump and ensuring it meets the desired performance criteria. Pump control uses include regulating flow rate, pressure, and pump output to match system demands. This function of the pump control ensures efficiency and prevents damage due to overload or excessive pressure.

Q: What is the significance of set pressure and maximum pressure in an axial piston pump?

A: Set pressure refers to the predetermined pressure level at which the pump is designed to operate efficiently. Maximum pressure is the highest pressure the pump can handle safely. These parameters are crucial for maintaining the pump’s integrity and preventing failures when the pressure reaches critical levels.

Q: How does the load-sensing function of the pump work?

A: The load-sensing function of the pump adjusts the pump output automatically based on the load requirements. This feature helps in maintaining optimal performance by varying the flow and pressure to meet the system’s needs, thereby improving efficiency and reducing energy consumption.

Q: Why are axial piston pumps used in various industries?

A: Axial piston pumps are used in various industries due to their efficiency, variable displacement capabilities, and high-pressure operation. They are suitable for applications requiring precise control over flow and pressure, such as in construction equipment, manufacturing machinery, and aerospace systems.

Q: How does the pump shaft influence the performance of an axial piston pump?

A: The pump shaft is responsible for transmitting mechanical energy from the prime mover to the pistons. Its alignment and rotation speed directly influence the pump’s efficiency and output. A well-maintained pump shaft ensures smooth operation and optimal performance of the pump.

Q: What happens at the bottom of the piston chamber in an axial piston pump?

A: At the bottom of the piston chamber, the pistons retract, creating a low pressure that allows fluid to be drawn into the chamber. As the pistons move upward, the fluid is compressed and directed towards the ports of the pump model, generating the high-pressure output necessary for hydraulic operations.

Q: What factors determine the decision to increase or decrease the displacement of the pump?

A: Decisions to increase or decrease the displacement of the pump are based on system demands and efficiency requirements. Increasing the displacement results in higher flow and pressure, while decreasing it reduces the pump output, saving energy when full capacity is not needed.