The Bosch Rexroth Pilot Operated Pressure Reducing Valve is vital for keeping good pressure levels and making the system efficient in hydraulic systems. This all-inclusive manual thoroughly explains how this valve works, where it can be used, and what it benefits. By looking at operational principles and using applied instances, we shall learn more about hydraulics, which significantly increases the dependability and performance of systems. Whether you have been practicing for a long time or just starting with hydraulics, these words will enlighten you about dealing with the intricate nature of pressure control within hydraulic systems.

What is a Bosch Rexroth Pilot Operated Pressure Reducing Valve?

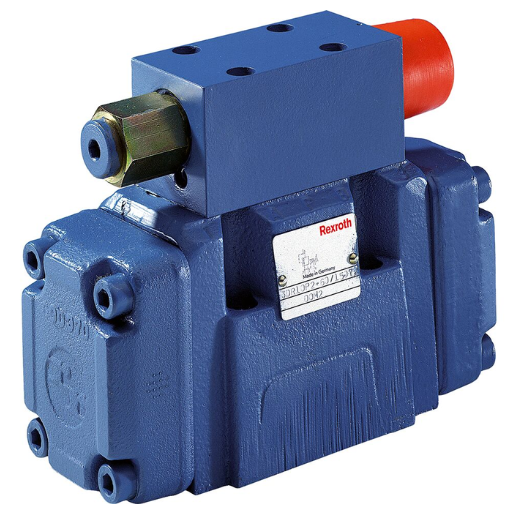

Image source: https://store.boschrexroth.com/

The Bosch Rexroth Pilot Operated Pressure Reducing Valve is an essential hydraulic part that keeps an outlet pressure at a constant level lower than the input. It works with the help of a pilot control, which senses inlet pressure and adjusts it through a pilot valve, thereby regulating flow across the main valve. This guarantees stability of downstream pressures even when there are changes in upstream ones. Applied in many hydraulic systems, this valve ensures higher performance levels and prevents damage from pressure drops to delicate machines, increasing operational dependability.

Overview of Bosch Rexroth Pressure Reducing Valve

The main aim of the creation of the Bosch Rexroth Pressure Reducing Valve was to achieve accuracy in controlling pressure within hydraulic systems. This valve is known for its strength and reliability; it can work with different pressures while ensuring that required output levels are maintained effectively. Its pilot-operated construction provides faster response and stability, thus making it applicable in various sectors, from industrial machines to mobile devices. Moreover, it not only enhances the system’s performance but also safeguards downstream components against destruction by pressure surges. Many experts dealing with hydraulics prefer using Bosch Rexroth Pressure Reducing Valves because they have comprehensive usage options coupled with efficient management abilities for controlling pressures.

Key Features and Benefits

- Precise Pressure Regulation: The Rexroth Bosch Pressure Reduction Valve controls the pressure at the outlet with precision, thus keeping hydraulic systems stable even when there is fluctuation in the upstream pressure.

- Robust Construction: This valve is made to last using rigid materials that can endure severe working conditions; this will help reduce maintenance costs and lengthen equipment life.

- Pilot-Operated Design: Its pilot-operated mechanism, which works efficiently, ensures that it responds well to changes in pressures, thereby enabling quick corrections and better performance of systems in different applications

- Many Applications: This valve can be used for various purposes, such as on industrial machines or mobile devices, because it meets multiple needs across different sectors.

-

Protects Downstream Equipment: It prevents spikes in pressure from affecting delicate parts located further downstream, thereby improving overall dependability while minimizing risks associated with breakdowns.

Typical Applications and Use Cases

The Bosch Rexroth Pressure Reducing Valve is popularly known in many industries for being practical and dependable. It has the following typical applications:

- Hydraulic Systems: The valve is used in the hydraulic circuits of construction machines to control the outlet pressure when heavy lifting is performed, thus ensuring stability.

- Agricultural Equipment: This valve regulates pressures within hydraulic systems used on farming machinery, such as plows or harvesters, improving their functionality and reliability.

- Mobile Equipment: This component’s flexibility allows it to be incorporated into mobile applications such as forklift trucks and tractors, where it helps maintain consistent performance under different load conditions.

These uses show how adaptable the Bosch Rexroth Pressure Reducing Valve can be in promoting efficiency and safety across various industrial sectors.

How Does a Pilot Operated Pressure Reducing Valve Work?

A dual-stage mechanism is used in a pilot operated pressure reducing valve to allow for exact pressure control. Fundamentally, the valve employs a pilot valve, which generally responds to the downstream pressure. The pilot valve opens whenever the preset value exceeds the downstream pressure, letting some fluid return to the tank. Doing this decreases the force on the main valve, thus enabling it to open and keep an even outlet pressure. The pilot valve then resets when there is a drop in downstream pressures, thereby causing gradual closure of the main valve until equilibrium within the system’s stability is achieved again. Such a design increases sensitivity so that it is efficient when regulating different pressure levels under changing conditions.

Principles of Hydraulic Pressure Control

Hydraulic systems are based on hydraulic pressure control, which is vital for efficient operation and equipment protection. The main idea is to manage the pressure created by hydraulic fluid because it’s necessary for the correct functioning of any hydraulic machine. Here are some things to consider:

- Building up and Keeping Pressure: Pumps create pressure in hydraulic systems. It should be kept within certain limits if reliability and performance are expected to be achieved. Devices controlling flow, such as relief valves, help prevent components from getting damaged due to excessive overpressure.

- Lowering Pressure Techniques: Systems can regulate or reduce pressure when required for different applications using parts like lowering valves. In these cases, regulation may be done mechanically (using mechanical feedback) or electronically (using electronic feedback). Fluid flow adjusts in response to current pressure readings taken at specific points.

- Feedback with Control: More advanced hydraulics employ closed-loop controls, where data collected from sensors about pressures goes back into units that make decisions concerning adjustments on various hydraulic parameters within narrow tolerances. Such fine-tuning would not be possible without this kind of dynamic control, leading to better efficiency during operations involving hydraulics and making them safe.

These factors emphasize that good pressure management is vital for achieving the long life and usability of hydraulic systems in various settings, from industrial plants to mobile machines.

Structure and Components of the Valve

The flow and pressure of a hydraulic fluid can be controlled through valves. Traditionally, the primary parts of a hydraulic valve include:

- Body: The part that houses all other internal components. It is designed to withstand high pressures.

- Actuator: This component controls how the valve functions; it can be manual, automatic, pneumatic, or electronic.

- Spool or Piston: In directional control valves, spools redirect flow, while in pressure control valves, pistons vary in opening sizes concerning pressure levels.

- Seats and Seals: These ensure airtight closure around any possible bypassing points between different parts within themselves, thus preventing leakage somewhere along their path where they meet up against one another.

The system cannot function without these pieces working together smoothly enough to allow accurate regulation over hydraulic fluid, thereby boosting efficiency and dependability throughout said systems. Maintenance and operation of hydraulic machines are only possible if one understands what every single item does about others.

Operation Mechanism Explained

Hydraulic valve operation mainly depends on controlling the flow and pressure of the liquid through different methods. When an actuator receives a control signal, it puts the valve into motion, thereby causing the hydraulic oil to be directed through specific paths or away from them. For valves that control directionality, as the spool shifts position, it changes where fluids flow, allowing functionalities like cylinder extension/retraction. As for pressure regulating valves, a piston moves back and forth according to variations in pressures, which then alters the rate at which fluid passes so that desired levels of force are maintained within a given setup. Such elaborate cooperation between parts ensures hydraulic systems work effectively without failure as they promptly react to application needs but still adhere to safety rules while performance criteria remain uncompromised.

How to Properly Install and Adjust Bosch Rexroth Pressure Reducing Valves?

To prevent accidents, make sure Bosch Rexroth pressure-reducing valves are mounted correctly by depressurizing the system first. Choose a suitable location for the valve to ensure it is easy to reach for maintenance purposes and make adjustments where necessary. Install the valve in right orientation as indicated by flow direction arrow on its body. Use sealing methods that are appropriate at connections so as not to have any leakages.

Once you have mounted them, adjust these devices by setting the desired level of pressure by turning the screw after loosening the locknut with aid from the gauge, which monitors output while making changes. Still, then, tighten the locknut when the required amount is. Finally, all parts function correctly, and no leakage is ensured before re-pressurizing the system. Before this, a comprehensive inspection must be carried out. The hydraulic system should be regularly checked and adjusted to maintain its best performance.

Installation Guidelines

- Preparation and Safety: To install Rexroth pressure-reducing valves by Bosch, it is necessary to make sure that the hydraulic system has been wholly depressurized. This is done so as not to endanger oneself during installation.

- Choosing the Right Location: The valve should be located where it will be easy to reach for subsequent maintenance or alterations; moreover, there must also be unobstructed flow around this area.

- Correct Orientation: Observe flow direction indicators on the valve body and install it accordingly for proper performance.

- Secure Connections: Use correct sealing materials and methods at joints to avoid leaks that might occur otherwise. This is essential not only because leak-free connections provide higher system reliability but also for other reasons.

- Initial Adjustments: Upon completion, release the lock nut, then turn the adjustment screw until desired outlet pressure setting has been achieved; besides, one can employ a gauge continuously monitoring pressure during this procedure for accuracy purposes.

- Final Checks: Once you’ve made the adjustments, tighten the lock nut securely and check again whether there are any signs of leakage present or absent from somewhere within the range of vision. Before re-pressurizing the system, make sure each component works correctly as it is supposed to.

-

Regular Maintenance: Establish a timetable for when these checks should take place regularly, and appropriate measures should be taken thereafter concerning both the pressure-reducing valves themselves and the entire hydraulic system they are part of.

Adjustment Procedures

To adjust pressure reducing valves of Bosch Rexroth correctly, you need to:

- Preliminaries: Make sure the hydraulic system is wholly depressurized before any modifications.

- Find the Screw for Adjustment: This screw can usually be found under a lock nut.

- Loosen the Lock Nut: You must carefully loosen this without disturbing the adjustment screw using an appropriate tool.

- Modify Outlet Pressure: To increase the outlet pressure, turn this component anti-clockwise or vice versa. The readings on a pressure gauge should be followed closely throughout this process, reflecting adjustment accuracy.

- Fasten Changes Made: When you achieve the desired point, fasten it by tightening up that lock nut so as not to move while holding onto an adjustment screw where necessary, thus keeping a constant set amount of force.

- After-Adjustment Checks: After completing these changes, examine carefully for leakages and ensure that all systems work well before re-pressurizing them.

- Record Every Change: It is essential to note down new settings of pressures alongside adjustments made for purposes of reference in the future and maintenance within a given system itself.

Thus, such steps will contribute towards effective functioning as well as safety assurance concerning PRVs in hydraulic machinery manufactured by Bosch Rexroth.

Best Practices for Optimal Performance

Here are some tips to make sure that pressure-reducing valves work at their best along with hydraulic systems:

- Regular Maintenance: Regular checks should be made on the hydraulic system, such as the pressure-reducing valve, to detect problems earlier before they become worse. This includes visually inspecting for leaks and signs of wear and tear on components.

- System Pressure Monitoring: Watch out for changes in system pressures and performance indicators. Use pressure gauges to confirm whether or not valves operate within their expected range and whether pressure settings remain stable over time.

- Quality Components: Always go for genuine replacement parts and valves sourced from reputable manufacturers like Bosch Rexroth since they offer reliability and durability during use.

- Professional Training: Ensure all personnel working with hydraulic systems have received adequate training. This way, operators will know what the system needs and how best to achieve it through correct adjustments.

- Record Everything: Keep accurate records showing details about each maintenance activity, including any adjustments made and any observed changes in performance that may happen later. Such documents act as a useful guide during future troubleshooting exercises or even further servicing needs.

Following these guidelines dramatically increases the efficiency of PRVs in hydraulic systems, which leads to enhanced overall performance.

What Are the Key Specifications and Ratings for Bosch Rexroth Valves?

The Bosch Rexroth valves have a reputation for precision and reliability; they are designed to meet the needs of many hydraulic applications. Mainly, these are the specifications:

- Flow Rate: It is a measure of the highest liquid volume that can be regulated by the valve expressed in liters per minute (L/min) or gallons per minute (GPM). Flow rates indicate if a particular valve is suitable for specific applications.

- Pressure Rating: The company rates its products with maximum operating pressures – usually between 10-350 bar (145-5075 psi). This rating reflects whether or not it will fail when subjected to high pressure conditions.

- Response Time: A specification that shows how long it takes for a given signal to make a valve act. Shorter times are necessary in cases where accurate control is needed.

- Temperature Range: These limits show where a valve can operate without being affected by its surroundings or the fluids used.

- Port Size and Type: There may be different sizes of ports and corresponding thread types to fit various hydraulic systems, ensuring tightness against any possible leakage.

Knowing all these things will enable users to select appropriate bosch rexroth valves which work best with their hydraulic systems hence maximizing efficiency and dependability.

Understanding Valve Specifications

Choosing suitable valves requires considering various specifications affecting their performance and suitability in hydraulic systems. Here are three websites that stand out above all others because they prioritize these key points:

- Rate of Flow: Each valve’s flow rate impacts a system’s efficiency and speed of response. Therefore, it is essential to pick valves that can handle required flows without causing pressure drops that may lead to poor operation.

- Pressure Rating: This specification ensures safety and dependability; therefore, it cannot be overlooked. Make sure you select valves with ratings equivalent to or higher than the expected maximum pressures within your hydraulic circuit to avoid any leakages or breakdowns.

- Time Taken To Respond: In some cases, quick changes in settings are needed, so fast response times become critical to achieving good control. Such improvements can only be achieved if one chooses valves whose actuation speeds are known to be very high, thereby enhancing the overall dynamics of systems.

Considering these attributes will enable users to identify which Bosch Rexroth Valve best suits their particular requirements in hydraulics.

Pressure Ratings and Limits

The safe and efficient operation of hydraulic systems depends on understanding pressure ratings and limits. The pressure rating of a valve refers to the maximum pressure it can handle while still working. A safety margin must be provided by choosing valves that are higher than the anticipated maximum in your application. Pressure ratings are influenced by temperature, fluid type, and system design, among others, according to the three most authoritative websites. Always check manufacturers’ specs for specific details about how much pressure they allow and ensure the chosen valve(s) will work properly under given conditions so as not to compromise anything within such a system.

Measuring Performance with HLP46 at 40 ±5 °C

When assessing how well hydraulic systems perform with oil that is HLP46 at 40 ±5 °C, it helps to look at viscosity, lubricating qualities, and expected flow characteristics. A hydraulic fluid based on mineral oil called HLP46 has the right thickness for workability at these temperatures; it also lubricates enough while minimizing wear and tear. Another reason we need to keep this temperature at all current eminent sources is that doing so stabilizes and enhances performance where pumps are concerned since they become more efficient alongside valve-actuating speed improvement. In addition, those operating systems should check the state of the liquid regularly, filter correctly, and watch out for changes in heat, which can compromise the integrity needed for operation within a hydraulic system.

Where Can I Find Related Products and Support for Bosch Rexroth Components?

To find correlated things as well as help for Bosch Rexroth parts, go to Bosch Rexroth’s official website, where you can have a look at all of their products and services. Moreover, there is a list of authorized dealers and service representatives provided by Bosch Rexroth with whom you can get in touch through the number given on their website. Their customer support hotline can be contacted if you need any technical assistance or have any queries; alternatively, explore the support section from where one can also download product manuals, application guides, or training materials, among other things related to this corporation, which are available online.

Related Products Overview

In order to find related products and support for Bosch Rexroth components, check out these resources on the net today:

- Bosch Rexroth Official Site: This is where you can get all your detailed product listings, technical specifications and support documents. It’s easy to use with a friendly user interface that allows users easily search for components and get service locations.

- Grainger: Provides a broad spectrum of Bosch Rexroth parts which includes hydraulic systems and accessories. You can place orders directly from their website and check stock availability with comprehensive descriptions about each product in stock.

-

Motion Industries: Another great place to look if you’re after any type of Bosch Rexroth products. They supply hydraulic components and offer expertise from their team, along with an extensive catalogue that will make shopping more accessible.

These should provide what is needed while ensuring support throughout the process.

Manufacturer and Supplier Details

- Bosch Rexroth: Bosch Rexroth, as a producer, ranks among the world’s leading firms in the field of drive and control technology. With such a website, they can share much knowledge about their creative products like hydraulic units or linear motion systems; it also contains technical documentation and industry-specific solutions.

- Hydraulics Online: They sell many different brands’ hydraulics components, such as those made by Bosch Rexroth among others; Hydraulics Online has got an easy-to-use catalog where you can find everything easily – specifications for products together with necessary information about them/technical support where needed which is provided through user-friendly ordering process explicitly designed for customer convenience.

-

Applied Industrial Technologies Ltd: Applied Industrial Technologies distributes many items from this manufacturer, too—some examples include system parts associated with fluids power, expertise inputs into systems design, and availability indication, but not limited thereto.

Reference sources

-

Bosch Rexroth Official Product Documentation The official documentation from Bosch Rexroth provides detailed technical specifications, operational principles, and application guidelines for their pilot operated pressure reducing valves.

-

Bosch Rexroth Hydraulic Valves Catalog This catalog contains extensive information on various hydraulic valve models, including pilot operated pressure reducing valves. It covers features, benefits, and detailed technical data necessary for a comprehensive understanding.

-

ResearchGate—Performance Analysis of Pilot-Operated Pressure Reducing Valves Research papers and articles on ResearchGate offers in-depth analysis and performance evaluation, which can provide a scientific understanding of how these valves operate under different conditions.

Related Articles: Bosch Rexroth Pilot Operated Pressure Reducing Valve: Technical Specifications