Working Principle of Triplex Plunger Pumps

How Triplex Plunger Pumps Operate

Triplex plunger pumps work by using a simple yet effective mechanical action to pressurize fluid. The pump has three plungers (or pistons) driven mechanically by a synchronous movement. The plungers come into reciprocating motion inside their cylinders to perform suction and discharge cycles.

The Operating Cycle:

- Suction Phase: The plunger withdraws, creating a vacuum in the chamber which draws the fluid inside through the inlet valve

- Discharge Phase: The forward motion of the plunger pressurizes the fluid, forcing it out through the discharge valve

- Continuous Operation: The staggering of the strokes of the three plungers ensures one plunger is in the suction stage while the other two are at different positions of discharge

This overlapping movement reduces pulsations and increases smooth functioning. High-quality seals are provided in such pumps to eliminate leakages, increasing reliability in adverse working conditions.

Mechanics Behind High-Pressure Functionality

High-pressure pumps convert rotational energy into hydraulic energy through a precise combination of design and materials. The system maintains a consistent flow in adverse conditions through several key mechanisms:

- Material Selection: Stainless steel or special alloys resist wear, corrosion, and abrasion

- Precision Engineering: Tight tolerances and strict clearances prevent leakage

- Advanced Sealing: Gaskets, O-rings, and mechanical seals maintain constant pressure

- Control Systems: Modern systems regulate flow and pressure for safety and efficiency

- Cooling & Lubrication: Systems reduce friction and improve equipment life expectancy

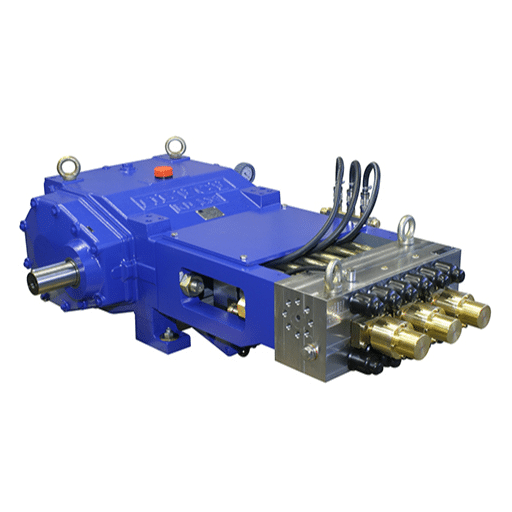

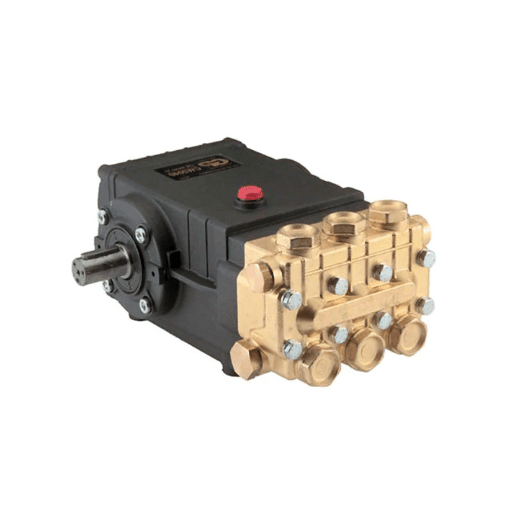

Components of a Triplex Plunger Pump

A triplex plunger pump comprises several key components that work cooperatively to ensure efficient and dependable high-pressure fluid transfer:

| Component | Function | Key Features |

|---|---|---|

| Power End | Converts motor/engine energy to linear motion | Crankshaft, connecting rods, bearings for synchronized operation |

| Fluid End | Generates high-pressure fluid flow | Contains plungers, valves, and sealing mechanisms |

| Plunger Assembly | Creates fluid displacement movements | Made from corrosion-resistant materials (stainless steel/ceramic) |

| Valve Configuration | Controls fluid flow direction | Suction and discharge valves with quick, precise operation |

| Sealing Mechanisms | Maintains pressure and prevents leakage | Packings and O-rings resistant to temperature and chemical damage |

Applications of Triplex Plunger Pumps

Oil and Gas Industry Utilization

Triplex plunger pumps serve integral functions in the oil and gas domain, where operational reliability under extreme pressure is essential:

- Hydraulic Fracturing: High-pressure output to crack rock formations for oil and gas extraction

- Pipeline Pigging: Ensuring efficient flow by dislodging clogs and maintaining pipeline integrity

- Chemical Injection: Precise application of inhibitors, anticorrosive agents, and specialized chemicals

- Versatile Applications: Suitable for upstream, midstream, and downstream operations

Chemical Processing Applications

Chemical processing requires advanced pump technologies for precision, reliability, and safety in extreme conditions:

| Application Type | Fluid Handled | Special Requirements |

|---|---|---|

| Acid and Caustic Handling | Sulfuric acid, sodium hydroxide | PTFE or Hastelloy construction for chemical resistance |

| Polymer Production | High viscosity materials (polyethylene, polypropylene) | Precision flow rate control for product uniformity |

| Solvent Transfer | Acetone, toluene | Explosion-proof construction and leak-proof sealing |

| Heat Transfer Fluids | Dowtherm and similar fluids | Extreme temperature reliability |

| Slurry Handling | Abrasive materials for catalyst manufacture | Wear-resistant lining and sealing technologies |

Manufacturing and Water Jetting Scenarios

In manufacturing and water jetting operations, pumps must deliver durability, precision, and extreme pressure capability:

- Manufacturing Applications:

- Precise fluid transfer

- Coolant circulation

- Chemical and abrasive treatment

- Water Jetting Applications:

- Ultra high-pressure cutting

- Surface cleaning

- Material shaping with precision

Technology Integration: Modern systems incorporate IoT-enabled sensors for real-time monitoring of flow rates, pressures, and component wear, enabling dynamic adjustments and predictive maintenance.

Advantages of Triplex Plunger Pumps

Efficiency Compared to Diaphragm Pumps

Triplex plunger pumps demonstrate superior efficiency over diaphragm pumps in multiple applications:

- Energy Efficiency: Direct-action mechanism with minimal energy loss

- Pressure Handling: Superior performance at increased pressures with low energy consumption

- Flow Consistency: Exact flow rate delivery even at medium to high pressures

- Volumetric Efficiency: Up to 90% efficiency maintained under extreme conditions

Reliability in Extreme Conditions

Operational performance data clearly demonstrate the advantages of triplex plunger pumps:

- Designed for high pressures and variable temperatures

- Maintains up to 90% volumetric efficiency in adverse conditions

- Superior performance compared to diaphragm pumps in harsh environments

- Robust materials resist abrasion and mechanical wear

Durability Over Other Pump Types

Triplex plunger pumps offer unparalleled durability through robust design and operational efficiency:

| Pump Type | Durability Factor | Triplex Advantage |

|---|---|---|

| Centrifugal Pumps | Prone to erosion in abrasive applications | A positive displacement mechanism provides steady pressure |

| Diaphragm Pumps | Limited performance in harsh conditions | Superior longevity with ceramic plungers and corrosion-resistant alloys |

| Gear Pumps | Performance degradation over time | Thousands of operational hours with minimal performance loss |

Maintenance Tips for Triplex Plunger Pumps

Routine Inspections and Best Practices

Maintenance is crucial for obtaining optimum performance and longevity:

- Component Inspection: Regularly check plungers, seals, valves, and bearings for damage

- Alignment Verification: Ensure proper alignment with the drive system to prevent vibrations

- Lubrication System: Maintain working order to minimize friction and enhance reliability

- Performance Monitoring: Track pressure and flow rate during operations

- Preventive Replacement: Maintain strict schedules for consumables like seals and packing

Proper Lubrication Techniques

Lubrication plays a vital role in smooth and dependable operation:

- Lubricant Selection: Use manufacturer-specified viscosity and thermal stability requirements

- Synthetic Oils: Recommended for resistance to oxidation and high-temperature performance

- Level Monitoring: Regular oil level checks with in-line filtration systems

- Condition Monitoring: Advanced sensors provide real-time lubricant quality feedback

- Precision Delivery: Proper lubrication programs ensure even oil distribution

Technological Advancements in Triplex Plunger Pump Design

Innovations in Materials and Construction

Modern materials and construction techniques have revolutionized pump performance:

- Advanced Materials: High-strength stainless steel and ceramics for critical components

- 3D Printing: Optimized internal geometries for improved fluid dynamics

- Advanced Coatings: Reduced friction and enhanced chemical resistance

- Precision Manufacturing: CAD and FEA ensure structural integrity

Automation Integration in Pump Systems

Automation has transformed operational capabilities:

- Control Systems: Advanced PLCs and SCADA systems for real-time monitoring

- Predictive Maintenance: Sensor data analysis prevents failures before they occur

- Adaptive Control: Variable Frequency Drives (VFDs) optimize efficiency

- IoT Integration: Remote monitoring and control via cloud platforms

Energy Efficiency Developments

Latest developments focus on reducing operational costs and environmental impact:

- AI and machine learning for predictive energy analysis

- Advanced energy storage technologies

- Smart controls and sensor integration

- Sustainable energy architecture development

Frequently Asked Questions (FAQ)

A: A triplex plunger pump is a type of positive displacement pump that utilizes three plungers to move fluid. This design allows for a continuous flow of fluid, making it suitable for various applications including industrial cleaning, oil extraction, and water jetting.

A: The triplex plunger pump operates by using three reciprocating plungers that move within a cylinder. As the plungers move back and forth, they create a vacuum that draws fluid into the pump and then expels it under high pressure. This mechanism ensures a steady and reliable flow.

A: Solid ceramic plungers offer several advantages in triplex plunger pumps, including increased durability and resistance to wear and corrosion. This material can withstand high-pressure environments and abrasive fluids, extending the lifespan of the pump and reducing maintenance costs.

A: Triplex plunger pumps are ideal for applications that require high pressure and consistent flow, such as hydroblasting, pressure washing, and chemical injection. They are widely used in industries such as oil and gas, manufacturing, and construction.

A: While triplex plunger pumps are primarily designed for low to medium viscosity fluids, they can handle certain viscous fluids if properly configured. However, it is essential to consult the manufacturer’s specifications to ensure optimal performance and avoid damage.

A: Regular maintenance for a triplex plunger pump includes checking and replacing seals, inspecting plungers for wear, and ensuring proper lubrication. It is also important to monitor fluid levels and pressure to maintain efficiency and prevent breakdowns.

A: Selecting the right triplex plunger pump requires considering factors such as the required flow rate, pressure, fluid type, and application specifics. Consulting with a pump specialist can help identify the most suitable model based on these parameters.

A: Common issues with triplex plunger pumps include leaks, reduced flow rates, and wear on the plungers. These problems can often be traced back to inadequate maintenance, incorrect installation, or using the pump outside of its specified limits.

Conclusion: Triplex plunger pumps represent a pinnacle of engineering excellence in high-pressure fluid handling applications. Their robust design, operational efficiency, and technological advancements make them indispensable in industries requiring reliable, high-performance pumping solutions. With proper maintenance and understanding of their capabilities, these pumps deliver exceptional value and performance in the most demanding industrial environments.