Hydraulic systems represent the backbone of modern mechanical operations, powering everything from industrial machinery to heavy construction equipment. Central to their functionality are hydraulic pumps, among which vane pumps, specifically triple vane pumps, play a critical role. This article takes a deep dive into triple vane pumps—an advanced and efficient variation of the vane pump design—and explores their operating principles, construction, and applications. Whether you’re an engineer, technician, or industry professional, this guide will equip you with the technical insights needed to understand how triple vane pumps contribute to optimizing hydraulic system performance.

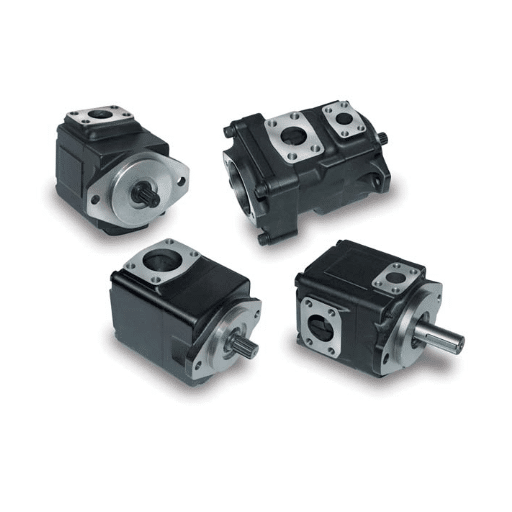

Types of Vane Pumps

Overview of the Three Types of Vane Pumps

Vane pumps may generally be classified into single, double, and triple types, depending on their design and application. Each type is characterized by different features, allowing them to be used across different hydraulic systems and performance criteria.

- Single Vane Pumps: Single vane pumps feature a very simple design where the rotor, having adjustable vanes, rotates within the cavity. They are easy to manufacture and thus well suited for low- to medium-pressure applications, which do not require high performance. Apart from being used in automotive transmissions and other light machinery, they could have thousands of other applications.

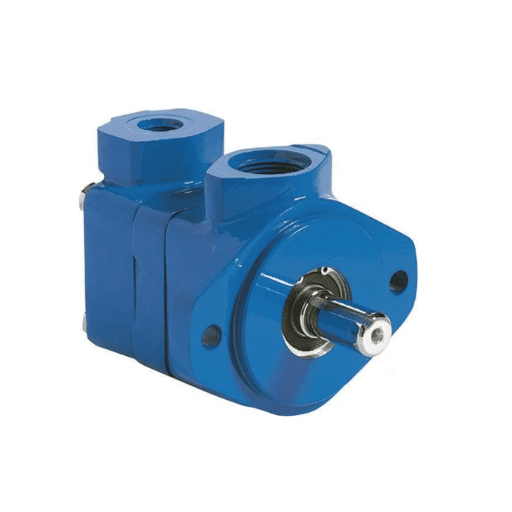

- Double Vane Pumps: Though the double vane pumps have two pumping chambers within one unit, they manage to provide higher flow rates and efficiencies than the single vane ones. Their relative compactness and capability of handling at medium pressure levels make them candidates of choice when both space and performance are important characteristics that apply to industrial machinery and mobile hydraulics.

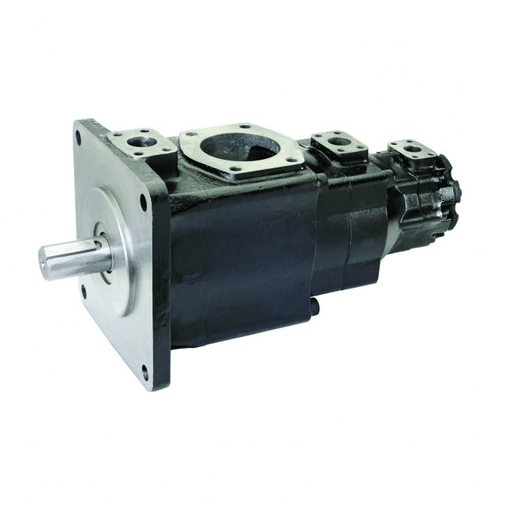

- Triple Vane Pumps: The triple vane pumps are the most evolved. Because of the three pumping chambers, they retain high volumetric efficiencies while giving very smooth operation and good noise control at relatively high-pressure levels. These pumps work superbly where design demands high precision and dependability, such as aerospace systems, high-performance industrial equipment, and advanced fluid power applications.

Each of these vane pump designs satisfies a cardinal need for specific applications, and offers a nice solution to competing demands on hydraulic performance, and engineers have to select that which gives the best compromise in their systems in efficiency, life, and cost.

Comparative Analysis of Vane Pump Types

The primary types of vane pumps include Single Vane Pumps, Double Vane Pumps, and Triple Vane Pumps. Each type offers its own set of advantages concerning efficiency, handling pressure, and application versatility.

|

Aspect |

Single Vane |

Double Vane |

Triple Vane |

|---|---|---|---|

|

Performance |

Moderate |

High |

Very High |

|

Pressure Cap. |

1500 psi |

2000 psi |

2500 psi |

|

Flow Range |

5-150 GPM |

10-200 GPM |

10-200 GPM |

|

Sound Level |

Loud |

Moderate |

Quiet |

|

Lifespan |

Moderate |

High |

Very High |

|

Upkeep |

Low |

Moderate |

Low |

|

Usage |

Basic |

Industrial |

Precision |

|

Expense |

Low |

Moderate |

High |

Choosing the Right Vane Pump Type

Selecting the appropriate vane pump type requires a careful evaluation of system operational requirements, pressure demands, fluid viscosity, and flow rate expectations. Fixed displacement pumps are used when applications require constant flow and pressure, such as in lubrication systems or basic hydraulic circuits. On the other hand, variable displacement vane pumps add operational flexibility and energy efficiency and are used for complex systems where load conditions vary.

When selecting the optimal vane pump type, it is advisable to consider the environmental and operational conditions that the system will undergo. High-pressure systems or those with potentially abrasive fluids would probably be best served by heavy-duty vane pumps with enhancements for durability. Still, they must also be conversant with old energy consumption goals for the system, as variable displacement pumps aim to reduce any unnecessary energy loss incurred whenever working under varying conditions.

Apart from performance considerations, a vane pump choice should be cost-related. A pump of fixed displacement generally costs less to acquire and maintain, rendering it less expensive for simpler system applications. The price of a variable displacement vane pump is worthwhile, however, when it comes to advanced hydraulic systems where accuracy, efficiency, and adaptability are of paramount importance. Selecting a pump by system requirements and operational concerns should yield reliable and efficient performance from the accompanying engineers.

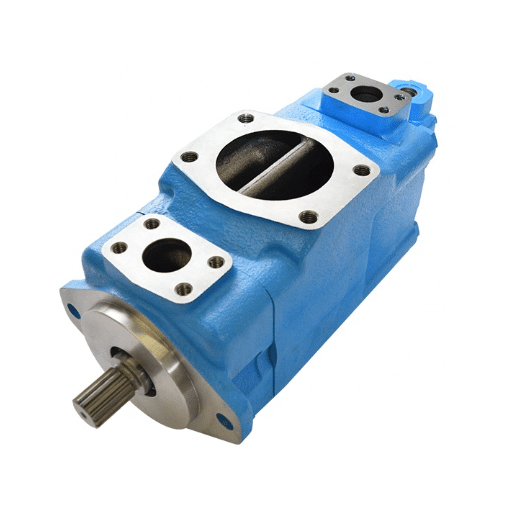

Benefits of Using Triple Vane Pumps

Efficiency in Hydraulic Systems

Triple vane pumps are vital in improving the efficiency of hydraulic systems for accurate fluid delivery under fluctuating load conditions. The design in turn reduces internal leakage and allows for more consistent volumetric output, thereby minimizing energy losses of a conventional hydraulic pump. These pumps find greater applicability in high-reliability systems with slight allowable variances in pressure or flow rate.

Advancements in manufacturing sciences have in turn improved the performance of triple vane pumps. Modern triple vane pumps often incorporate advanced material coatings aimed at reducing wear and increasing durability, and improved rotor designs for significantly lower noise during operation. With all the improvements combined, industrial application data and case studies show up to a 15-20% increase in efficiency.

Triple-vane pumps further save energy by considering system dynamics and ensuring motor power matches the demands of the operation. Such consideration lowers energy consumption and reduces the heat within the system, which also increases the service life of components. Due to such considerations, triple-vane pumps contribute to a cost-effective and green solution to the industrial debate on energy-efficient hydraulic technology.

Advantages Over Other Pump Types

- Energy Efficiency: Because of the ability of V.P.s to continuously match power output with system demands, power input varies constantly, thereby rendering these pumps energy inefficient. Research has found that the energy savings can be as much as 30% over the traditional, fixed-displacement type of pumps.

- Accurate Control: The advanced control systems provide precision adjustments to flow and pressure. This minimized misapplication of fluids and environmental enhancement of system function makes it more apt where sensitivity is paramount, such as in the field of robotics or aerospace technologies.

- Less Heat: By outputting just enough power for the task at hand, these pumps also generate less heat in comparison to fixed displacement pumps. Less heat translates to less thermal stress, subsequently improving the life of hydraulic oils and other system components, thus creating a more maintenance-friendly system with lesser downtime.

- Smaller and Lighter: A variable displacement pump, more often than not, is just a simple design; hence, it takes less space with respect to weight, an added design advantage for mobile machinery and compact industrial systems.

- Lower Operational Costs: Increases in energy savings, reduction in wear and tear, and low maintenance requirements of these pumps have also contributed to lowered operational costs over the life of the equipment. Field data has shown that costs were as much as 20% lower when applied to industrial systems.

Cost-Effectiveness and Reliability

Cost-effectiveness and reliability have always been the major factors favoring the adoption of modern industrial systems, especially in operationally efficiency-oriented contexts. Good design and new technologies applied to systems, e.g., pump systems, drastically improved their service life and performance capabilities. High-end systems, for instance, use corrosion-resistant materials with high strength such as stainless steel alloys or polymer composites while operating under adverse conditions. These improvements extend service life, making replacement less necessary, thus minimizing downtime and guaranteeing reliability in challenging environments.

Energy efficiency, too, greatly influences being cost-effective and has become the prime concern in industrial engineering design. Utilizing the best design technologies like variable-speed drives (VSDs) and advanced hydraulics could curtail energy costs by up to 30-50%, as industry statistics reveal. Additionally, predictive maintenance systems that rely on IoT (Internet of Things) and remote monitoring capabilities permit the detection of performance degradation before it grows. This cuts down on repair expenses and unplanned halts, allowing workflows to be smoothly saved at the cost of dropping lifecycle expenses.

Often tested equipment will unquestionably underperform under extreme environmental variables, such as extreme temperature variations and high pressures. Hence, such abilities make modern industrial systems not only a wise choice for any enterprise seriously interested in cost efficiency but also for one that must sustain competitor advantages through continuous operational stability.

Applications of Triple Vane Pumps

Industries Utilizing Triple Vane Pumps

Triple vane pumps have become a must-have in numerous industries, providing precise and reliable service with a high level of efficiency. One of their uses is in the manufacturing sector, where hydraulic systems are powered and facilitated for machinery and automation. The nature of their operation allows constant flows to be maintained under varying operating pressures-the very specification set by assembly lines and high-volume manufacturing plants.

Oil and gas is yet another important industry in which applications for triple vane pumps arise, transfer of fluids, injection operations, and hydraulic fracturing all require these pumps because of their robust construction and ability to work under very high pressures. In this highly demanding environment, their capacity to contain viscous or abrasive fluids increases their utility.

Also, the automotive industry uses triple vane pumps in hydraulic systems within the vehicle, such as in steering and braking, where consistency of performance and longevity are of utmost importance. Aerospace applications similarly benefit from precise fluid handling for hydraulic actuation, which ensures safety and accuracy in aircraft operation.

The design of the triple vane pump is also well suited for chemical and pharmaceutical processes, where a controlled flow rate is a necessity for complex processes, including chemical reaction control and sterile fluid transfer. Maintaining consistent and leakproof procedures is the first contribution of these pumps toward assuring process integrity.

Lastly, the food and beverage industry employs triple vane pumps in processes that require stringent hygienic standards, such as the transfer of syrups, sauces, and dairy products. Their ability to carry out clean-in-place processes and avoid contaminating the product puts the industry in direct compliance with regulatory standards.

Continuous improvements and innovations make triple vane pumps the backbone of industrial processes and enable them to aptly address the varied needs of these sectors concerning technical precision and operational excellence.

Specific Use Cases and Examples

Considered an important category among triple vane pumps due to their precision finish and better working reliability, these pumps find application in drug industries to pump delicate and viscous materials such as liquid pharmaceuticals and cosmetic creams under sterile conditions, with strict control of volumetric delivery. In the food industry, triple vane pumps find application in the hygienic transfer of various viscous substances, including honey, chocolate syrup, and yogurt, thus maintaining their quality all through.

Another special case of interest is found in chemical processing, where triple vane pumps are used to convey corrosive or abrasive fluids. Materials of construction consist primarily of chemically resistant alloys or coatings that enable the pumps to operate in such hostile environments, thus affording the pumps good durability and process stability. Furthermore, in petroleum and lubricants applications, they find excellent use in the precision handling of fuels, oils, and additives while at the same time satisfying strict compliance criteria for competent safety and efficiency.

Recent studies have shown that these specialized pumps are now integrated into automated bottling lines at beverage production plants. Whenever tasked with pumping thick syrups or flavor concentrates, triple vane pumps would generate better flow precision than alternative pump technologies, and less maintenance. Another working example would be in dairy production lines, where triple vane pumps assist in pasteurization processes by providing consistent and sanitary flow rates that are critical to product quality.

These examples demonstrate not only the versatility of triple vane pumps but also their ability to answer sector-specific demands while maintaining the integrity of their performance-based regulation. They are considered a superior asset in modern industries due to their precision, reliability, and adherence to industry standards.

Future Trends in Application

The future for triple vane pumps lies in technological innovation and changing use patterns. Five key trends are helping shape their application. They include:

- Integration with IoT for Predictive Maintenance: The IoT-inclusive triple vane pumps are allowing predictive maintenance. Equipped with sensors, the pumps measure critical parameters on the spot, such as flow rate, pressure, and operating temperature. Recent industry data suggest that predictive maintenance strategies can reduce downtime by as much as 30%, thus contributing to better system efficiency.

- Energy-efficient operations: Being energy efficient has been given serious consideration in designing triple-vane pumps. With better motor technology and hydraulic component design, energy consumption is reduced by 15-20% so as to maintain energy conservation targets and the regulating standards of the world.

- Durability by use of advanced materials: Advanced composite materials are increasing the life span of triple-vane pumps. These materials ensure that there is less wear and chemical corrosion in harsh conditions so that the pumps will be able to achieve high performance, be it for chemical processing or seawater applications.

- Changes to fit renewable energy systems: Triple vane pumps are entering the renewable energy application field, especially hydroelectric and geothermal plants. They deliver precision fluid transfer so these pumps are often utilized in efficiently controlled transfer systems. Market projections foresee an annual growth of 10% in demand for pumps in connection with renewable energy installation activities.

- Customization through Modular Design: Modularity in design forms another trend: Customers are allowed to tweak the pumps to meet their exact requirements. This thus supports use in multiple ways and leads to minimal replacement expenditures, since modular components enable maintenance and replacement of parts by 25% faster compared to conventional designs.

These trends are a reflection of the ongoing evolution that triple vane pumps go through to meet the challenges of modern industries, thereby positioning the industry at the forefront of fluid handling innovations.

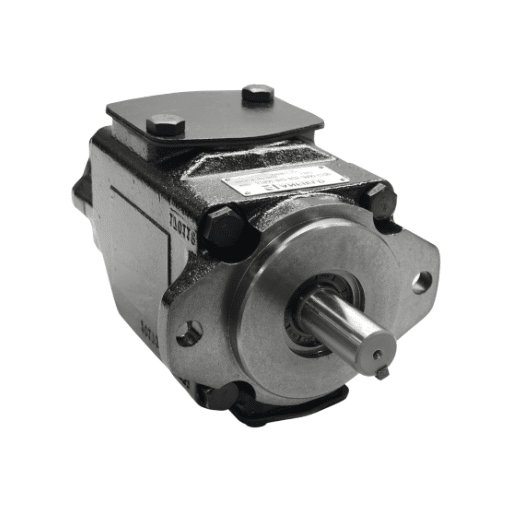

Maintenance Practices for Triple Vane Pumps

Essential Maintenance Tips

With proper maintenance, a triple-vane pump system will provide excellent performance for a long time. Of utmost importance are the inspections that must be performed on the vanes and seals; if these parts incur wear or damage, the efficiency of the pump is immediately affected. Ensuring through proper selection of fluids that the viscosity falls within the range specified by the manufacturer will help reduce stress on mechanisms and thus minimize premature wear. Operating conditions are important as well; thus during pumping operations, on-site checking of temperature and pressure shall help flag early indications of trouble such as cavitation or overloading.

The lubrication of the pumps is a concern that needs to be addressed when concerning the life of the pump. Using the recommended lubrication oil grade and respecting the replacement intervals will help reduce friction and prolong the life of the components. Cleaning or replacing filters promptly is necessary so that cleanliness standards are maintained and contaminants do not have the opportunity to enter the system and cause abrasive wear or obstruction.

Vibration analysis and thermal imaging are more advanced approaches to diagnosing pump performance issues and detecting anomalies before they escalate into severe failures. Keeping maintenance logbooks will ensure that the history of all operational problems and maintenance frequencies is well documented, thus allowing for predictive maintenance and unexpected downtime reduction. Following these recommendations will guarantee that operators can always count on triple vane pump systems operating at their best efficiency and reliability level.

When to Seek Professional Help

Occasions arise when even a well-maintained system if operated otherwise correctly, calls for professional intervention. Performance inconsistencies in a triple-vane pump system would be a case in point. These might show in abnormal pressure fluctuations, unusual vibrations, or unexplained efficiency losses despite the system undergoing standard maintenance. Any sudden leakage, excessive operating noise, and unusual component wear may serve as symptoms of an underlying cause that may not be recognized or solved without certain equipment or expertise.

The professionals use advanced diagnostic tools to find hidden defects within the system, including ultrasonic testing and thermal imaging. With their knowledge, they can identify and solve problems precisely, preventing the failure of the system on a larger scale. Additionally, the certified technicians can source manufacturer-specific parts so that repairs can be made following OEM standards. Working with them ensures restoring the system to the highest performance standard and extending its lifetime.

With a goal of higher efficiency, operators might use periodic professional consultation as a means of being updated on any upgrades of their system or a new technology that could come into play, further enhancing system performance and meeting contemporary standards.

Innovations and Trends in Hydraulic Systems

Emerging Technologies in Vane Pumps

In the hydraulic vane pump realm, significant changes are occurring due to the incessant search for improved efficiencies, durability, and sustainability. The incorporation of smart technology into pump systems is one trend. Smart vane pumps now employ sensors and IoT (Internet of Things) connectivity to facilitate real-time monitoring of actual parameters such as pressure, flow rate, and temperature, allowing operators to detect anomalies early, schedule predictive maintenance, and optimize performance to minimize downtime.

Further, advanced materials and coatings provide some very innovative solutions. Manufacturers are now employing wear-resistant composites and surface treatments such as diamond-like carbon coatings to increase the resistance of vane components under very severe operating conditions. These materials reduce friction and wear, thus increasing pump life and reliability.

Additional designs of vane pumps also work toward improving energy efficiency, with newer designs having variable displacement mechanisms able to accurately control hydraulic flow to lubricate energy use where fluctuating load demands exist. When coupled with advanced control systems, these pumps almost meet stringent requirements for efficiency while maintaining low operational costs.

Lastly, sustainable manufacturing stands as one more important development promoting the technology, as most vane pump systems are now developed with eco-acceptable hydraulic fluids and include components that can be recycled or replaced with ease to reduce their environmental impact. In essence, these developments are allowing vane pumps to show an ecological conscience whilst facing the ever-growing industrial needs.

Impact of Industry Standards on Pump Design

In modern companies that design, fabricate, and install pump systems, industrial standards find relevance for various functioning considerations of the vane pump. Standards set forth are necessary for specifying for performance, safety, and efficiency of all pumps, on account of which pumps are expected to meet the particular requirements depending upon their varied applications. For example, if pumps comply with standards laid out under ISO or ANSI, they can efficiently operate under all sorts of working conditions and also remain compatible with all other components, styles, and designs. If these did not exist, product quality and safety levels would greatly fluctuate and would lead to inefficiencies in operations and to further risk to safety.

From a design perspective, the incorporation of some features and technologies becomes necessary to comply with industry standards. The standards often dictate the materials to be used, tolerances, target energy efficiency levels, and operational limits to stress that these pumps must endure in a demanding environment with reasonably little maintenance accounting for their lifespan. Energy efficiency standards, for example, require manufacturers to minimize energy consumption to stimulate further developments in motor efficiency and control.

In my opinion, these industry regulations have helped enforce a greater degree of uniformity and reliability within the industry of pumps. It has forced manufacturers, myself included, to consider quality and sustainability on a whole new level rather than just trying to satisfy customer concerns. When we adhere to the standards, we can be sure that pump systems are safe, energy-efficient, and environmentally conscious-an aspect that has gained significant importance in today’s industrial world.

Future Directions for Triple Vane Pump Development

With the future triple vane pump evolutionary cycle, the driver would be material science, energy efficiency, and the intelligent integration of such pumps into industrial systems. An important arena for innovation would lie in the realm of highly technical composites and alloy,s worthy of giving better pump life and hence reduced maintenance requirements. So, materials offering better corrosion resistance combined with superior wear properties would be considered critical in harsh chemical or mining environments.

Efficiency improvement comes first, focusing on lower energy consumption while maintaining performance consistency. It could come through hydraulic improvements to reduce internal leakage and optimize fluid dynamics under various operating pressures. The use of a variable frequency drive is also becoming a factor in itself to reduce power waste further by adapting to the system demand in real time.

The next pivotal development lies in the integration of smart sensors with IoT-enabled systems. They can provide real-time monitoring of pump performance metrics, including flow rate, temperature, and vibration levels. This data is used by algorithms to predict maintenance activities and prevent failures while maximizing operational uptime. This will ripen even more when coated with machine learning models that adapt on a continuous basis to improvements, ensuring that the pump remains in peak condition throughout its life cycle.

Environmental concerns have limited the design choices to comply with stricter emission and disposal legislations. Ranging from bio-compatible hydraulic fluids to designs that optimize component recycling at end-of-life stages, the triple vane pumps are venturing out into the realm of sustainable engineering practices. By concerted efforts, the next generation of pumps will truly address the growing needs of various industries with increased efficiency, reliability, and ecological acceptability.

Frequently Asked Questions (FAQ)

Q: What are triple-vane pumps, and how do they work?

A: Triple vane pumps are a type of positive displacement pump that utilizes three vanes mounted on a rotating shaft. As the shaft rotates, the vanes slide in and out of the rotor, creating chambers that trap and move fluid through the pump. This design is particularly efficient for transferring low-pressure fluids, making them suitable for a variety of applications.

Q: What are the advantages of using balanced vane pumps?

A: Balanced vane pumps are designed to reduce the hydraulic forces acting on the vanes, leading to lower wear and tear. This design allows for smoother operation and increased longevity, making them a popular choice for applications involving vacuum and low-pressure conditions. The balanced design helps maintain efficiency and performance over time.

Q: How do unbalanced vane pumps differ from balanced vane pumps?

A: Unbalanced vane pumps do not have the same design considerations as balanced vane pumps, which can lead to greater wear on the vanes due to uneven hydraulic forces. While unbalanced designs may be simpler and less expensive, they may not perform as well under varying pressure conditions, making balanced vane pumps the preferred choice for many users.

Q: In what applications are triple-vane pumps commonly used?

A: Triple vane pumps are commonly used in a range of industries, including chemical processing, food and beverage, and oil and gas. Their ability to handle diverse fluids and maintain low-pressure operation makes them ideal for applications that require reliable performance under varying conditions.

Q: What is the role of the ring in a triple-vane pump?

A: The ring in a triple-vane pump serves as a guide for the vanes and helps maintain their position as they rotate. This ensures that the vanes can efficiently create and collapse the chambers necessary for fluid movement. Proper ring design is crucial for optimal pump performance and longevity.

Q: Can triple-vane pumps be used in vacuum applications?

A: Yes, triple-vane pumps are suitable for vacuum applications due to their design, which allows for efficient fluid movement even at low pressures. Their ability to operate effectively in vacuum conditions makes them an excellent choice for various industrial processes that require vacuum transfer.

Q: What factors should be considered when mounting triple-vane pumps?

A: When mounting triple-vane pumps, it is essential to consider factors such as alignment, vibration, and accessibility for maintenance. Proper mounting ensures that the pump operates efficiently and reduces the risk of mechanical failure. Additionally, ensuring that the pump is positioned correctly can help maintain optimal performance and extend its lifespan.

Q: What types of fluids can be handled by triple-vane pumps?

A: Triple vane pumps can handle a diverse range of fluids, including viscous liquids, slurries, and even some gases. Their versatile design allows them to be used in various industries, making them a reliable choice for many applications that require the movement of different types of materials.

Q: How does centrifugal force play a role in the operation of triple-vane pumps?

A: While triple vane pumps primarily function through positive displacement, centrifugal force can play a role in their operation, especially in larger systems where fluid dynamics come into play. Proper design and understanding of the interplay between centrifugal force and the pump’s mechanics can enhance performance and efficiency in fluid transfer applications.