The throttle valve carburetor is an essential component in many internal combustion engines, playing the role of controlling airflow and fuel mixture so as to maximize the performance of the engine. Although mechanically simple, this device goes a long way in affecting crucial parameters like fuel efficiency, power output, and engine responsiveness. What does a throttle valve carburetor really do? Anyone looking to fine-tune performance or diagnose a possible issue must be familiar with it. We will therefore explore in detail how throttle valve carburetors operate, their effect on engine dynamics, and why their maintenance is key to peak-performance realization.

Introduction to Throttle Valves in Carburetors

Overview of Carburetor Functionality

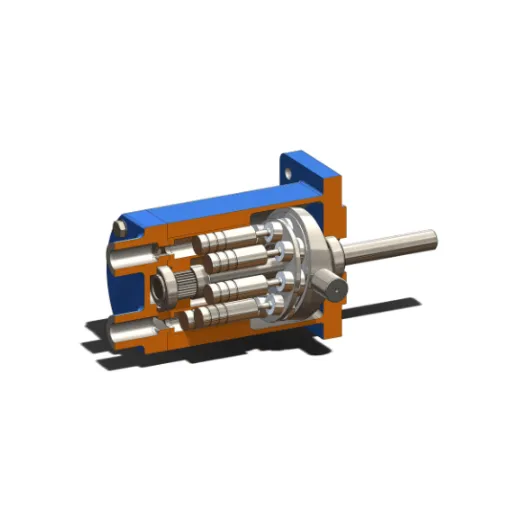

Carburetors act as the intermediaries between the fuel supply and the engine-venturing to create a perfect air-fuel mixture for efficient combustion. At their basic level, they regulate the air-fuel ratio entering the engine cylinders according to demands of operation: idle, acceleration, and cruising at high speed. Considering the various parameters of engine operation, such as speed and load, environmental conditions also exert their sway in this adjustment.

Here, fuel is introduced into the air stream as it enters through the venturi of the carburetor; this venturi is just a narrow passage where air pressure is lowered. The pressure difference draws fuel into the air stream from the float bowl in a manner calculated precisely by the jets and throttle valve position of the carburetor. In turn, the throttle valve acts to restrict the amount of air-fuel mixture entering the combustion chamber depending on how far the opening is, which changes as the accelerator pedal is moved, facilitating smoothly between differing power demands.

An accurate air-fuel ratio must be maintained for proper engine operation; imbalances may act as inefficiencies leading to incomplete combustion, poorer power output, or more emissions. Regular inspections, adjustments to the carburetor components such as the throttle valve, fuel jets, and float system are important to let the engine operate within its designed performance parameters, besides offering fuel economy and environmental compliance.

The Role of the Throttle Valve

The throttle valve is one of the important systems in regulating air intake into an internal combustion engine, which in turn affects engine performance, fuel consumption, and emission levels. Located between the air cleaner and intake manifold, the throttle valve varies all air entering into the engine, thus being the main factor determining the volume of fuel being intermixed with the air for combustion. Valving of these mechanisms depends on the throttle handle or pedal, with the operator determining whether to be increased or decreased in power output from the engine.

Five Essential Facts About Throttle Valve Function:

- Airflow Regulation: Air entering the combustion space is regulated by the throttle valve. It controls air intake so that the engine gets a proper air-fuel ratio throughout all load conditions.

- Effect on Power Output: Power is given to the engine depending upon the degree of opening of the throttle valve. More power is generated when more air and fuel mix inside the engine, whereas less power is generated when less air and fuel mix inside the engine.

- Effect At Idle Speed: The throttle valve is almost closed at the idle position, but some air is allowed to bypass the almost closed throttle valve via the idle air control system, thus enabling the engine to operate smoothly at low speeds.

- Contribution to Fuel Economy: Proper calibration of the throttle valve results in efficient burning by keeping the air-fuel mixture at optimal proportions, thereby giving better mileage and lesser pollutant emissions.

- Compatibility with Modern Systems: Most modern engines use an electronic throttle control (ETC) system, whereby the valve position is adjusted by a sensor or an actuator rather than by direct mechanical linkage. It allows quicker response, less wear and tear, and more accurate control of airflow.

Being vital in air manipulation, the throttle valve is indispensable for smooth engine operation, wherein balance is struck amidst performance, environment, and economy. If not kept up and calibrated regularly, the valve will lead to inefficiencies during operation or may even bring about engine problems.

Throttle Bodies vs Carburetors

Throttle bodies electronically control air intake, while carburetors mechanically mix air and fuel.

| Aspect | Throttle Body | Carburetor |

|---|---|---|

| Regulation | Electronic | Manual |

| Fuel Delivery | Injection | Mechanical |

| Adjustment | Automatic | Manual |

| Precision | High | Low |

| Upkeep | Minimal | Frequent |

| Startup | Easy | Challenging |

| Performance | Quick | Slower |

| Customization | Flexible | Limited |

| Expense | Higher | Lower |

| Application | Modern | Vintage |

Throttle Valve Impact on Engine Responsiveness and Fuel Efficiency

Understanding Engine Responsiveness

Simply put, engine responsiveness defines how quickly and efficiently an engine responds to throttle inputs, with this much being a prime determinant of the performance and drivability of a vehicle. This response time is greatly influenced by the decision and operation of the throttle valve. The throttle valve, be it electronically controlled or mechanically maintained, regulates the amount of air that enters the combustion chamber of an engine. With ETC systems in place, modern engines now adjust quickly and precisely, hence the greatest potential for greater response.

The air-fuel charge-delivery rate directly affects engine torque and acceleration. Therefore, the particularly most important mechanism in the perfect functioning is the configuration of the throttle valve. Research shows a considerable difference in how an ETC control scheme responds to instantaneous driver input over a mechanical control system, the difference being higher in rapid acceleration and load change cases. Moreover, with the advent of advanced sensor technology, an ETC integrates with air and fuel delivery systems to ensure that combustion air-fuel mixing is performed for maximum combustion efficiency; thus, the better fuel economy.

Performance Insight: The newest age of throttle bodies aims to combine performance with sustainability. By integrating machine learning algorithms and into real-time analytics into the modern ETC systems, manufacturers increase predictive qualities of response while diminishing fuel wastage and emissions. Studies proclaim that such an advancement enhances the transient response up to 20%, confirming engine responsiveness still remains the strong point of technological progress for the internal combustion engine.

Fuel Efficiency Considerations

Energy efficiency is a great desideratum in automotive engineering, even more so as industries undertake environmental regulations and consumer preferences. Modern ICEs promise thermal efficiency and are now adopting direct injection, turbocharging, and variable valve timing technologies. With new methods of ignition-say, controlled auto-ignition or homogeneous charge compression ignition or HCCI-the burning of fuel is accomplished at minimal energy loss to realize MPG improvement.

Indeed, this drawing of hybrid power systems combining internal combustion and electric motors not only improves fuel economy but also lays an answer to environmentally friendly transportation. Regenerative braking systems capture kinetic energy and convert it for electrical energy charging the battery, which is then used for propulsion. Consequently, during low-speed urban driving conditions, vehicles use less fuel. Data shows that such hybridization of powertrains can increase fuel efficiency by 30% on the average, compared to a conventional ICE powertrain, with a simultaneous reduction in greenhouse gas emissions.

Moreover, trend-setting connected vehicle technologies and predictive eco-driving have great potential for optimizing fuel efficiency in reality. Using advanced telematics systems and machine learning algorithms, these vehicles can watch for driving habits and terrain conditions and then suggest and/or automatically adjust settings for fuel-efficient driving. For instance, predictive cruise control may adjust the acceleration and braking input to consider road curvature or traffic pattern to save fuel and also conserve wear and tear on the vehicle. This double-edged sword exemplifies the next big thing, where major emphasis will be on utilizing innovative technology to negotiate performance, efficiency, and environmental responsibilities.

Throttle Valve Configurations in Motorcycles vs. Cars

Motorcycles mostly use an individual throttle body for each cylinder, while in normal-four-wheelers, a single throttle body is used for all cylinders.

| Aspect | Motorcycles | Cars |

|---|---|---|

| Type | Individual bodies | Single body |

| Control | Mechanical/Electronic | Electronic |

| Response | High precision | Moderate precision |

| Usage | High-performance | General-purpose |

| Maintenance | Complex | Simpler |

| Cost | Higher | Lower |

| Fuel Mix | Per cylinder | Shared |

| Efficiency | Optimized | Balanced |

| Application | Sport bikes | Passenger cars |

Common Problems with Throttle Valves

Identifying Sticking Throttle Valves

If the throttle valve sticks, it becomes one of the prime incidents affecting the performance and efficiency of the engine. This trouble generally develops when carbon deposits, dirt, or oil residues settle down on the throttle plate or its enclosing housing. With time, such contamination will restrict the valve from its free movement causing irregular air intake and, more importantly, thwarting the process of efficient combustion. Now drivers can look out for symptoms like reduced response from the throttle, irregular idling, sudden acceleration, and low speed stalling.

A sticking throttle valve needs a methodical approach to its diagnosis. Step one involves simply observing for dirt or grime existent around the butterfly valve of the throttle body. Scanning for codes with an OBD2 scanner would bring up codes such as P2111 (Throttle Actuator Control System Stuck Open) or P2112 (Throttle Actuator Control System Stuck Closed), which are related to throttle problems. Also, unusual fuel consumption or unexpected RPM changes might point toward the throttle being irregular. Controlled tests of throttle valve systems have shown that even microdeposits on the valve surface are able to influence the airflow parameters to some extent, reminding the technicians of the level of precision involved for handling these systems correctly.

The presence of an electronic throttle control (ETC) unit in today’s automotive systems only highlights the necessity of maintaining a thorough cleaning regimen and a fully functional throttle valve. The cleaning process can be completed by using products like aerosol throttle body cleaners that dissolve carbon deposits, and this restores the valve’s proper movement under ideal conditions. However, in the extreme cases where mechanical wear is detected or an actuator fails, it is better to tear it all down and replace the damaged parts. Regular preventive maintenance, such as cleaning the air intake at regular intervals and assuring that the filter material remains clean, would drastically reduce throttle sticking problems and increase the general lifespan of the throttle assembly.

Improper Adjustment Issues

Incorrect setting of either the throttle position sensor (TPS) or the throttle linkage, if at all, may cause major performance problems on the vehicle-often in all the opposite ways. The TPS may misinterpret the position of being opened, thus causing the engine to run erratically-Hesitation on acceleration, murmuring at idle, or reduced fuel economy. With too tight throttle linkage, on the other hand, the plate may be restricted from moving through an adequate range of motion.

Besides any other concerns, the TPS requires fine calibration, normally through the use of diagnostics that measure sensor output voltage against a set range at either a closed or fully open throttle position. Also, the throttle linkage must be examined and tested for proper tensile strength, thus allowing free operation of the throttle plate. It is considered that improper application and adjustment of the components can augment fuel consumption by 15% and lead to premature wear of other related systems.

With the observance of regular inspection schedules and standards as specified by the manufacturer through an adjustment procedure, the risk can be significantly reduced, thus assuring operational stability in the short term as well as system reliability in the long term.

Symptoms of Throttle Valve Failure

Warning Signs to Watch For:

- Reduced Engine Power: Noticeable decrease in acceleration and overall performance

- Erratic Idling: RPMs fluctuating due to disrupted air-fuel mixture

- Check Engine Light: Often triggered by fault codes from the Electronic Throttle Control system

- Increased Fuel Consumption: Resulting from improper airflow calibration

- Delayed Throttle Response: Stalling during gear changes or quick deceleration

- Carbon Buildup: Leading to additional intake system problems

Symptoms of throttle valve failure can present themselves in many ways directly affecting engine performance and the vehicle’s drivability. One such symptom may be a reduction in engine power or acceleration. This is because the throttle valve essentially controls air intake. Other symptoms may be erratic idling, where RPMs may fluctuate because a misaligned or malfunctioning valve disrupts the air-fuel mixture. Another common symptom involves the “Check Engine” light turning on, many times due to fault codes from the Electronic Throttle Control (ETC) system.

Increased fuel consumption is yet another symptom, stemming from improper airflow calibration. This creates an imbalance in the mixture and a mismanaged combustion procedure. The driver may witness that the throttle response is delayed or even got stalled upon gear changes or a quick deceleration process. From an intermediate level, if the throttle valve issues are left unattended, then it can lead to excessive carbon buildup and deposits in the intake system, setting the stage for other problems.

Such symptoms require being addressed promptly through diagnostic tools and following the manufacturer’s recommended procedures for testing and replacement. Early treatment helps in the performance of the vehicle so that further damage to associated engine parts can be curbed due to extensive cost.

Troubleshooting Throttle Valve Issues

Step-by-Step Troubleshooting Guide

- Inspect for Diagnostic Trouble Codes (DTCs): Start by attaching an OBD-II scanner to the vehicle so as to read stored diagnostic trouble codes. Common DTCs relating to throttle valve problems include P2101, P2119, or P0120, which indicate malfunctions of the throttle actuators or position sensor faults.

- Perform a Visual Inspection: Visual inspection of the throttle body will reveal if it is contaminated or has carbon deposits or is damaged. Heavy deposits will hamper airflow and throttle plate operation and will cause vehicle performance issues. Moreover, inspect electrical connections for corrosion or wear and tear that could hamper signal transmission.

- Make an Evaluation of Throttle Position Sensor (TPS) Operation: Using a multimeter or oscilloscope, check the voltage range on the throttle position sensor during operation. It should normally read between 0.5V (closed throttle) and 4.5V (wide-open throttle). Any measurement outside this spectrum is the sign of a defective sensor that must be replaced.

- Ensure Throttle Actuator Operation: Activate the throttle actuator using a bi-directional scan tool so that the motor opens and closes the throttle plate. Hear for any abnormal noise or irregular movement upon operation, which may indicate internal actuator failure.

- Test Intake Airflow System: Check that there are no obstructions in the intake manifold, air filter, or other associated components. Impaired air flow to the throttle body can be detrimental to engine performance and cause symptoms similar to throttle valve issues.

- Calibrate or Relearn the Throttle Body: Calibration of throttle body becomes crucial once physical and mechanical issues have been addressed. A scan tool that supports throttle relearn procedures must be used, and during the process, the manufacturer’s instructions must be followed for resetting the throttle position memory so that the engine will be able to perform at its optimum.

- Check System Behavior after the Repair: Once the DTCs have been cleared after fixing the problems, a test drive under normal operating conditions should be done. During this, live data should be monitored from the scan tool to verify that such as throttle position and airflow are consistent with normal values.

Following these comprehensive procedures, technicians can identify and resolve throttle body problems in an orderly fashion so that engine performance and reliability can be reinstated while minimizing the unnecessary exchange of components.

Tools Needed for Diagnosis

In diagnosing throttle body problems, genuinely, an array of specialized tools and accurate diagnostic equipment plays crucial roles. An in-depth and full evaluation demands the following tools:

Essential Diagnostic Tools:

- OBD-II Scan Tool: Read and clear DTCs, monitor live data

- Digital Multimeter (DMM): Measure electrical parameters

- Throttle Body Cleaner: Remove carbon deposits

Advanced Equipment:

- Automotive Diagnostic Oscilloscope: Detailed waveform analysis

- Vacuum Gauge/Smoke Machine: Detect vacuum leaks

- Service Manual/Wiring Diagram: Reference materials

Technicians, with the use of this tool, can certainly isolate faults with accuracy, know the true nature of the problem faced by the throttle body, and have a guarantee that the right repair procedures are implemented. Utilizing other available technology alongside an oscilloscope guarantees that any intermittent electrical or mechanical faults will be identified and therefore lessen chances from a misdiagnosis or undue part replacements.

When to Seek Professional Help

To me, when to ask for professional help with throttle body matters depends on how complex one thinks the problem is and, most importantly, if the kind of equipment they have on-site can really help them. Lacking a diagnostic tool that can be an oscilloscope may render most troubleshooting a guessing game that potentially leads to unnecessary delays or even damages. An untrained person, hence, can’t tell if the fault is in the electrical system, the throttle body, or some other section above ground. That, in most cases, is the best time to call in a service professional with the right equipment and expertise.

Additional thought should be given towards professional assistance in the case of a fault with complicated components or systems with which you are unfamiliar. Intermittent faults, wiring harnesses being defective, or the latest kind of electronic controls can be the hardest ones to isolate without application of an advanced skill level. An accredited technician will use a series of advanced diagnostic workflows to ensure the particular nature of the problem will be accurately pinpointed and fixed as efficiently as one could. The calibre of their experience can additionally mitigate further risks or diminish the chances of a recurrent problem.

Finally, precise time requirements occur to justify the need for an expert when repairs warrant a special calibrating or reprogramming tool. For instance, after having provided service on or replaced a throttle body, recalibrating might be in order for the synchronization between it and the engine control unit (ECU). Should one’s software and knowledge not be proficient, even the simplest repair might lead to functionality or performance problems. Retaining the assistance of a qualified technician will best ensure that any repairs and adjustments are made according to the manufacturer’s specifications for safety and reliability.

Maintenance Best Practices for Throttle Valves

Cleaning Techniques

Proper cleaning of throttle valves is critical for ensuring optimal engine performance and efficiency. Given enough time to settle, carbon deposits and other particulates can cling to the inside surfaces of a throttle body, thereby disrupting the formation of an air-fuel mixture ratio. This results in drivability issues such as stalling, rough idling, or less acceleration. One must disconnect the battery first to prevent any electrical interference hazards. Carefully removing or accessing the throttle body (depending on the vehicle design) is necessary to clean it thoroughly while avoiding any damage to the sensitive components.

⚠️ Safety Precautions:

- Always disconnect the battery before beginning work

- Use only specialized throttle body cleaners

- Avoid abrasive materials like steel brushes

- Handle the throttle position sensor with care

- Allow components to dry completely before reassembly

When the throttle body can be accessed properly, one should use a special throttle body cleaner. This is specially formulated to attack the carbon deposits, without damaging the surface or interfering with any coatings on the throttle valve. Deposits should be gently wiped out using soft and non-abrasive materials like a microfiber cloth or a nylon brush. Never use hard scrubbing implements like steel brushes or abrasive pads, as such treatment may scratch the throttle plate or its housing so that it will not seal correctly or give accurate readings on airflow. Care should also be taken not to dislodge the throttle position sensor (TPS), often integrated into modern designs, which is critical for accurate engine calibration.

Ensure that nothing is left over inside the throttle body and that no cleaner remains within it after cleaning, since some chemicals may affect the working of nearby sensors or even be sucked into the intake manifold. They recommend letting the components dry thoroughly before installation. After installing, recalibration is sometimes needed in order for the throttle valve to operate within the manufacturer’s preset parameters. Advanced diagnostic equipment would then clear any fault codes and check for irregularities with engine performance that came about due to the cleaning process. Applying these thorough cleaning procedures will maintain the integrity of the throttle body and ensure that the vehicle performs at an optimum level.

Inspection Tips for Long-term Reliability

Preserving long-term reliability of a throttle body begins with periodic inspections and an obligation to understand the operating conditions of this unit. Start keeping track of the external appearance to check for carbon buildup, dirt, or corrosion, as these can clog the airflow channel. Cleaning with special tools such as throttle body cleaners can cure the problem quickly without damaging sensitive components. Inspect the linkage of the throttle and other actuator mechanisms and look for any physical obstacles or wear hindering smooth operation.

Next, move advanced diagnostic tools to check the readings for the throttle-position sensor (TPS). These tools check on the ability of the sensor to correctly communicate the throttle plate angle to the engine control unit (ECU). Intermittent or erratic readings mean that some problem can exist in the line of sensor, wiring, or even throttle plate alignment. Calibration should also be checked at regular intervals as recommended by the manufacturer, so that the throttle body remains within specification for optimum fuel delivery and air intake.

Also, consider any other systems integral to the throttle body operation, such as the air intake and fuel delivery systems. Look out for vacuum leaks in any intake hoses, as this will upset the air-fuel ratio, and the IAC valve must be checked for blockage or malfunction. Thorough inspection schedules, in addition to cleaning and diagnostic testing, will very much enhance the life of the throttle body. Through a methodical, evidence-based maintenance approach, both workshop technicians and vehicle owners can keep the component in working order for years to come while contributing to engine performance and efficiency.

Caring for Throttle Valves in Internal Combustion Engines

The proper care of throttle valves of internal combustion engines requires an understanding of issues that can hamper performance. Such problems generally include carbon formation, ETC malfunctions, and mechanical wear. Carbon deposits, which form from incomplete combustion of fuel, find their way around the throttle plate and bore, restricting airflow and causing engine mis-operation. Regular cleaning of the throttle mechanism using special cleaners for the throttle bodies prevents its buildup by renewing the internal surfaces to a considerable extent.

ETC systems, being sensor and actuator-based, require extra attention. A failure of the TPS, wiring harness, or ETC motor assembly can result in improper valve operation. Having the diagnostics enhancement from an onboard scan tool would really help in preventing action being taken from time to time when irregular sensor readings or fault codes are observed.

Besides that, mechanical wear addressing shall include intermittent inspections for return springs if they are degraded, and for housing components if wornout. Keeping the valve lubricated, and thereby replacing its constituent parts when necessary, will ensure the valve’s smooth operation and prevent sudden failure. When these diagnostic and maintenance procedures are implemented together with modern diagnostic equipment, greater reliability, and long-term performance of throttle valves may be assured across a wider range of operating conditions.

Frequently Asked Questions (FAQ)

Q: What is a throttle valve carburetor?

A: A throttle valve carburetor is an engine component key to the carbureted engines that controls how much air-fuel mixture enters the engine. It has a throttle valve that may open and close to regulate the flow of air so that the engine runs at optimum performance and efficiency.

Q: How does the throttle valve affect fuel flow within the carburetor?

A: The throttle valve acts primarily to control the fuel flow by regulating the amount of air entering the carburetor. More air rushing into the carburetor also allows more fuel to mix with air through the throttle, maximizing combustion in an engine that can then deliver a greater level of performance.

Q: What kind of maintenance is required for a throttle valve carburetor?

A: Clean and maintain the throttle valve carburetor from time to time so that the throttle works smoothly. Look out for debris that might have gotten into the throttle shaft, examine the throttle cable for signs of wear, and ensure that the valve moves freely without being obstructed.

Q: How can a bad throttle valve affect engine performance?

A: An improper throttle valve operation can hamper an engine’s performance by disrupting the airflow and fuel mixture. Symptoms might show in rough idling, stalling, or difficulty in acceleration since either not enough air might be going into the carburetor or that it is being detected wrongly.

Q: Can a throttle valve carburetor be used for diesel engines?

A: While primarily used in gasoline engines, it is possible that some diesel engines may use the same concept to control air intake. However, fuel injection systems are almost always used by diesel engines to carry out fuel delivery rather than carburetors.

Q: What is the relationship between throttle position and fuel injection?

A: The throttle position influences fuel injection in carbureted or fuel injection systems. The greater the throttle opening, the more air is admitted there, calling for the increased injection of fuel to maintain the correct air-fuel ratio for combustion.

Q: How do multiple carburetors and throttle valves work?

A: In multi-carburetor setups, each throttle valve regulates the air-fuel mixture on its own for a specific cylinder or pair of cylinders. This can boost performance by ensuring the proper atomization and distribution of fuel throughout the engine.

Q: What is the function of the throttle pedal in a carbureted engine?

A: The throttle pedal in carbureted engines is directly connected to the throttle cable controlling the throttle valve. When the driver presses the pedal, the valve opens more and allows more air to flow into the engine, which increases fuel flow for acceleration.

Q: How to troubleshoot a partly closed throttle valve?

A: Checking the throttle cable for obstructions or damage should be your first step if you are to troubleshoot a partly closed throttle valve. Check that the linkage is free-moving. Inspect the valve for dirt or debris that could be impeding its operation. If the valve is stuck, it might need cleaning or swapping out to restore proper airflow.

Q: What is the importance of manifold vacuum with regard to the operation of the throttle valve?

A: The manifold vacuum is highly important in the operation of the throttle valve as it is used to indicate the air-consuming capacity of the engine. When the manifold vacuum is high, it means the throttle valve is being held partially closed, which means it will constrict the air intake capacity of the engine and thus affect both its performance and efficiency.