The global three rotor screw pump market is at the forefront of industrial innovation, driving efficiency and reliability in fluid handling systems across various sectors. As industries like oil and gas, chemical processing, and power generation expand, the demand for advanced pump technologies has surged. This article dives deep into the trends shaping the market, the factors fueling its impressive growth, and the innovations that are setting the stage for the future. Whether you are a stakeholder, engineer, or industry enthusiast, this comprehensive analysis will provide valuable insights into the evolving dynamics of the three rotor screw pump market.

What are Three Rotor Screw Pumps and How Do They Work?

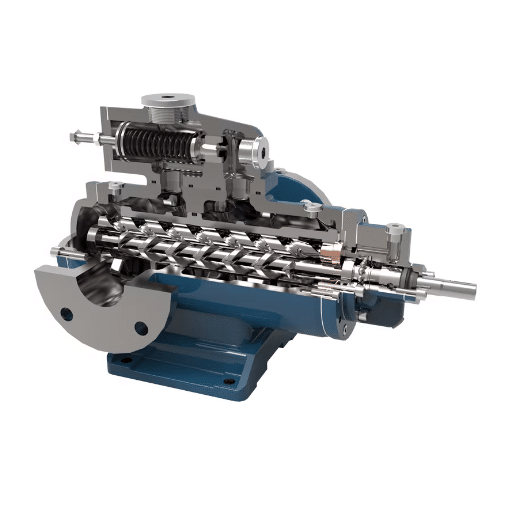

Understanding the Basics of Screw Pumps

Positive displacement pumps try to move a fluid with precision and efficiency, and one of many names for such devices is three rotor screw pumps, and sometimes triple screw pumps. The pumps consist of intermeshing screw pairs: one for driving and two for driven. These screws rotate in a cylindrical chamber machined with very close tolerance so that the forming cavities transport fluid smoothly from the suction side to the discharge side of the pump with hardly any pulsation, which makes them very reliable for handling viscous or sensitive liquids.

The basic principle behind the working of a three rotor screw pump is the axial flow principle. When the driving screw rotates, it, in turn, drives the driven screws that, together with the pump casing, establish a continuous seal. Such a movement pushes the liquid forward along the screw axes without turbulence or shearing, thus ensuring steady flow with very high volumetric efficiency. These pumps have great versatility, as, on the industrial scale, they withstand a large range of pressures, viscosities, and temperatures.

Three rotor screw pumps are widely found and used in many industrial fields such as oil and gas, chemical processing, and marine operation. These would facilitate the transfer of lubricating oils, fuels, hydraulic fluids, or any medium that is non-corrosive and non-abrasive. Their quiet operation, as well as their ability to maintain reliability even at high-pressure conditions, have helped these pumps become a major part of systems requiring precision fluid control. High efficiency, long life, and advancements in hydraulic systems are what make them indispensable in modern fluid handling technology.

The Role of Rotors in Screw Pump Efficiency

The rotors intersect the scope of operational efficiency and system reliability within these pumps with different constructions. These make sure that there exists a uniform shear flow as the fluid is moved axially along the pump. Minimal turbulence and minimal pulsation make it very efficient in pumping sensitive or viscous liquids with rotors kept meshing properly. To maintain the best volumetric efficiency for the pump and reduce energy losses during operation, the rotor should be properly designed and aligned.

The better selectivity of materials and machining improves rotor functioning and life. Best on-site materials, like corrosion-resistant alloys, enable the rotor to withstand very harsh working conditions, which include thermal power and high pressures. Also, they are machined to fairly tight tolerances to minimize any wear between the rotor and the pump casing, thereby prolonging the system’s life. Regular maintenance, coupled with properly manufactured rotors, keeps operational failures to a minimum.

The geometry and surface finishing of screws ripeners will affect the efficiency of the screw pump. Advanced rotor designs like variable pitch or multi-lobe rotors aid in pumping efficiency by reducing internal leakage and providing smoother flow profiles. A smooth surface finish of the rotor components also diminishes friction losses, thus enhancing mechanical efficiency. These factors place emphasis on the vital role the rotor plays in guaranteeing constant performance and electricity savings of screw pumps in a multitude of industrial applications.

Applications in the Oil and Gas Industry

Due to their ability to work with different viscosities in fluids and different rates of flow, these pumps find application in the oil and gas domain under various severe conditions. They are useful for transferring crude oil, natural gas liquids, and related hydrocarbons even while mixed with solids or gases being entrained. Maintaining steady flow devoid of pulsation is, therefore, an essential feature of screw pumps to allow smooth transportation and processing operations, especially in upstream and midstream sectors.

Another important use of screw pumps in the oil and gas segment is multiphase pumping, where mixtures of oil, gas, water, and solids are transported directly from production wells to processing plants. Because they can handle this complicated fluid mixture without phase separation, screw pumps reduce infrastructure costs and ease the handling of offshore and onshore operations. Their rugged construction and resistance to wear ensure the reliability and longevity of the pump, even in highly abrasive and corrosive environments.

Furthermore, screw pumps have a grand use in chemical injection processes, which are critical for well integrity and optimized extraction. They supply controlled, precisely metered flows of inhibitors, corrosion preventatives, and other chemicals into production systems. The ability of screw pumps to maintain low flow rates with high accuracy lends further application flexibility. All in all, screw pumps, being versatile, ensures robustness and, by being operationally efficient, find application in several oil and gas activities, helping in cost and performance optimization.

Why are Screw Pumps Preferred in Oil and Gas Segments?

Handling High-Viscosity Fluids

The screw-type pump is one among all varieties suitable for high-viscosity fluids, a major demand in the oil and gas sector. Through the conventional design where the intermeshed screws rotate within a sealed cavity, an almost uniform and smooth flow is generated. This Type of pump imparts very low turbulence and shear, thus making them especially efficient for the transfer of viscous substances like heavy crude, lubricant, and other thick industrial substances. On the other hand, these pumps tend to provide constant throughput irrespective of viscosity variation; therefore, they deliver reliable performance in almost all working environments.

One of the core advantages of the screw pump for handling high-viscosity fluids is that it is self-priming. Therefore, these pumps are efficient in maintaining low inlet pressure within the system, in energy consumption, and in preventing cavitation. Moreover, since the internal velocities of such pumps are quite low during operation, it imparts minimum wear of the equipment, thus affording the equipment a long life condition that is of utmost importance on offshore platforms or refineries, which are high-demand service areas. Reduced downtime and maintenance costs due to the preferring the installation of screw pumps make them an inexpensive option for industries where time, cost, and efficiency matter.

Screw pumps provide a choice with better efficiency and minimal mechanical wear when coupled with monitoring technologies like IoT-enabled sensors. It gives operators the facility to control the set points of both the fluid properties and the pump performance with precision, even as they fluctuate. Such capability in handling very high-viscosity fluids with the best efficiency, less mechanical wear, along with the advanced capability of monitoring is why screw pumps are preferred in the oil and gas industry in critical applications.

Advantages Over Centrifugal Pumps

The screw pump has many distinctive advantages over the centrifugal pump; hence, in specific applications, especially those involving challenging fluids and demanding operating conditions, screw pumps are superior. Below are the primary advantages:

- Able to Handle High-Viscosity Fluids: These pumps handle high-viscosity fluids, which range from heavy crude oil to polymeric solutions. In contrast, centrifugal pumps face problems of low efficiency and increased wear in the presence of such fluids, screw pumps maintain their efficiency with negligible mechanical stress. For instance, screw pumps can pump fluids with a viscosity above 1,000 cSt without too much energy loss.

- Constant Flow Rates, Regardless of Pressure Variations: Being pressure-dependent, centrifugal pumps operate opposite to screw pumps that maintain a constant volume flow rate, regardless of changes in system pressure. This characteristic allows them to be very trustworthy where fluid delivery must remain consistent under highly critical processes, predominantly satisfactorily retaining constant flow rates even under pressures of 10 bar.

- Less Mechanical Wear, Longer Life: The rotor of a screw pump, which is properly lubricated, runs without contacting its casing. Consequently, friction and wear are virtually absent. This condition shortens downtime for maintenance, with service intervals sometimes exceeding 10,000 hours is in contrast to centrifugal pumps and contributes to the lower costs of ownership.

- Better Efficiency in Handling Multiphasic Fluids: Screw pumps transfer emulsion-type multiphasic fluids or gas-liquid mixtures efficiently due to their rugged design concept suitable for complex fluid composition. Centrifugal pumps often fail in such situations due to problems such as cavitation or separation.

- Lower Noise and Vibration Levels: Smoother operation and fluid flow at laminar levels optimize screw pumps for producing less noise and vibration compared to centrifugal types. Typically, screw pumps produce sound level readings that are 10-15 dB lower, thus, are applied best in environments sensitive to noise, such as urban installations or enclosed installations.

Such advantages produce strong reasons for the common acceptance of the screw pump among industries for demanding, efficient, and sturdy pumping applications.

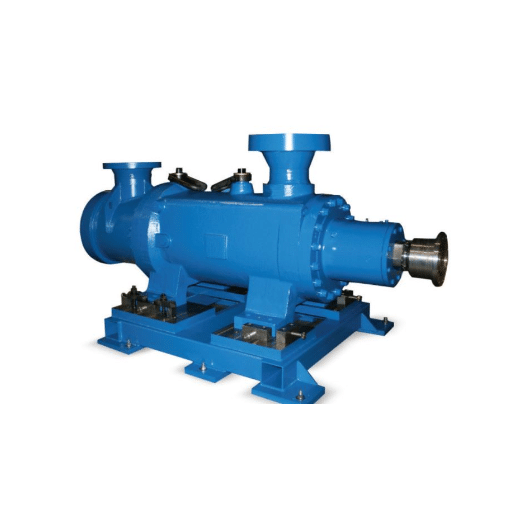

Operational Efficiency in Oil Pipeline Transport

Operational efficiency in oil pipeline transport consists of ensuring the reliable and cost-effective movement of petroleum products over huge distances. One of the foremost metrics of efficiency in pipeline transport involves optimizing flow rate and pressure management to minimize energy consumption while achieving the highest throughput. Advanced monitoring systems equipped with sensors and automated control technologies allow for the real-time observation of anomalies such as pressure drops or flow inconsistencies. This greatly reduces the possibility of leakages, downtime, or environmental hazards.

The application of drag-reducing agents (DRAs) has further improved efficiencies in oil pipeline operations. DRAs consist of chemicals that alter the turbulent flow occurring within the pipeline, carrying the liquids in a laminar streamline, thus spending less energy. It is proven that with the use of DRAs, flow rates can be increased by 15–40%, which saves a huge volume of dollars in the long run.

Material advances in pipeline manufacture have also acted to increase the life of the infrastructure and reduce maintenance requirements, corrosion-resistant alloys and coatings being an example. Predictive maintenance combined with machine learning algorithms allows operating companies to schedule repairs before failure occurs, reducing operational interruptions.

These developments in pipeline transport technology stand at the confluence of mechanical engineering, materials science, and data-driven analytics, further enabling the oil and gas industry to answer the world’s rising energy needs without compromising on safety, sustainability, or cost efficacy.

How is the Screw Pump Market Evolving Globally?

Key Market Participants and Their Strategies

Highly competitive is the global screw pump market with key players adopting strategies like technological innovation, product diversification, and geographical expansion to garner market share. These creations are for meeting up with higher demands for sturdy performances in wastewater treatment, oil and gas, and food processing industries.

Aside from this, mergers, acquisitions, and partnerships are intensifying market consolidation, which enables companies to increase their global presence and assist in the expansion of their technology portfolio. For instance, recent engagements were being made by manufacturers and digital solution providers to embed advanced monitoring systems into the design of screw pumps, enabling operational insight in real time and predictive maintenance.

Moreover, the establishment of pumps with lower energy consumption and support for sustainable operation is a new advancement wherein players are adjusting amid ever-changing regulatory environments and environmental standards. Corrosion-resistant materials and IoT-enabled reforms present the most noticeable trends altering the market landscape. Concurrently, many companies provide after-sales services, including tailor-made maintenance programs for end users to secure maximum equipment efficiency and management of life cycle costs.

Impact of Increasing Industrial Applications

Pumping systems install innovative methods and economies into an enterprise, placing the pumps at the epicenter of demand in various industries. Prominent adoption of pumps rises in both classical and new applications as numerous industries, including pump technology, scale with greater operational requirements. The following are the five major fields wherein the industrial applications exert considerable influence:

- Oil and Gas Industry: The sector of oil and gas industry remains one of the utmost consumers of high-grade pump facilities in upstream, midstream, and downstream processes. Improved submersible and centrifugal pumps are widely used for crude oil extraction, pipeline transfer, and refining operations. Recent data show the global demand for pumps in this sector is forecast to grow at a CAGR of 4.3% till the year 2030.

- Chemical Processing: In chemical manufacturing, industry pumps are involved in handling aggressive, viscous, and corrosive substances with precision. The integration of chemical-resistant materials and seal-less designs has relegated leakage to the past and given them greater operational reliability. Market reports put chemical processes as consuming 18% of operational machinery expenditures.

- Water and Wastewater Management: Industrial growth means greater importance is given to water treatment and the conservation of water resources. Pumps find application in filtration, desalination, and wastewater recycling systems. Now, IoT-enabled monitoring solutions allow real-time optimization of pump performance that reduces up to 15-20% of the secondary energy consumption in modern treatment plants.

- Power Generation: Seen from the requirement of strong pump systems that work for heat transfer, cooling arrangements, and fuel handling, power generation, both renewable and conventional, would find ample scope. In nuclear and thermal plants, for instance, the functioning of enormous feedwater and boiler circulation pumps for large temperature differences is considerable. Energy-efficient motor technological innovations have thus improved power plant efficiencies by 12%.

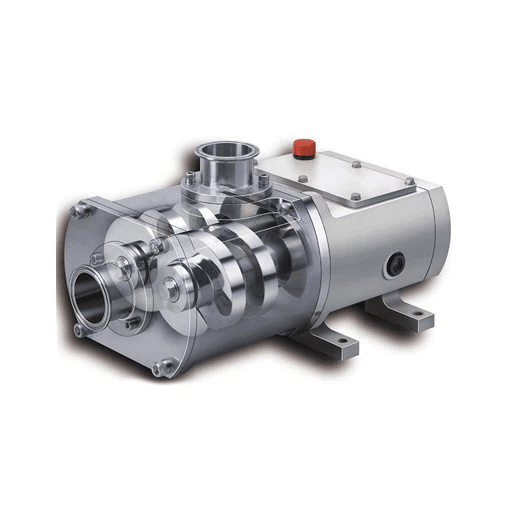

- Pharmaceutical and Biotechnology: Pharmaceutical technology and applied fields generally use sanitary pumps so that contaminated and hygienic standards are observed during drug production and fluid transfer processes. Hygienic pumps designed to enable clean-in-place (CIP) systems ensure fast production cycles while ensuring compliance with regulations. Market analysis also shows that this specialized pump sector has seen an increase in demand by about 6.8% per annum in the recent past.

These applications highlight how industrial productivity depends heavily on pumps while also fostering sustainability and operational efficiency.

What Factors Drive the Growth of the Screw Pump Market?

Technological Advancements in Pump Technologies

Screw pump market growth is fueled by a major driving force: the incessant development of pump technology. From the material employed in construction through to processes and designs, considerable advances have been passed upon the reliability, life, and efficiency of the screw pump. Initially, the selection of corrosion-resistant materials in conjunction with the design of advanced sealing techniques made it possible to transport highly viscous and abrasive fluids with minimal wear and tear in several industries. These levels of innovation keep screw pumps in line with the increasingly stringent operational and environmental standards demanded by contemporary applications.

Automation and smart technologies, meanwhile, positively impact screw pump performance in industrial applications. Intelligent sensors, IoT-enabled monitoring and control systems, and data-driven algorithms perform real-time diagnosis and optimize operating parameters. This basically reduces downtime through mechanical failures, enhances energy efficiency, and thus saves money while making operations eco-friendly. Such systems equipped with predictive maintenance also give the equipment a longer life while minimizing the number of times replacements or repairs are needed.

I believe that the changes towards more energy-efficient systems have, for the most part, contributed to the bulk of R&D efforts in this field. Due to concerns about global energy consumption and the imposition of stricter environmental regulations, manufacturers have taken steps towards original designs like multi-phase screw pumps that optimize fluid handling with the least energy input required. In effect, this balance of efficiency, versatility, and sustainability is a major factor in the route toward the market, catering to the varying needs of several industries from oil and gas to food processing. Generally, based on the above technology, screw pumps are a vital functional element of any modern industrial operation.

Rising Demand for Water and Wastewater Treatment

Increasing urbanization, industrial ventures expanding globally, and environmental regulations imposing restrictions on the water and wastewater treatment sector see growth. Screw pumps in these industries are especially apt due to unmatched flexibility in varying flow rates and viscosities. Due to these pumps, modern wastewater treatment plants have been able to transport raw sewage, sludge, and treated water smoothly even under adverse conditions.

According to industry estimates, the global wastewater-treatment market is set to breach $400 billion by 2030, supported by efforts to combat water shortage and pollution. These days, more advanced types of screw pumps are designed for higher resistance to wear, with high precision engineering that offer a longer operational life and lower maintenance costs, both prominent requirements in infrastructure maintenance.

Additionally, with automation and IoT-enabled technologies integrated into the screw pump systems, the system can be monitored and optimized almost in real-time, reducing energy costs and thus increasing process reliability. These are some of the few innovations critical to meeting the demands for adherence to sustainability and stricter regulations, creating a favorable impact on the growing application of screw pumps for water and wastewater treatment.

Challenges and Opportunities in the Chemical Processing Sector

The chemical processing sector confronts a unique set of challenges in view of the shifting nature of regulatory frameworks, ever-increasing operational costs, and the global trend toward sustainable development. In the words of environmental regulations, adverse emissions and wastes have to be controlled, enabling cleaner technologies to be deployed in chemical processes, with the processes retaining their efficiency and competitiveness. This induces additional investments in advanced equipment like energy-efficient pumps, corrosion-resistant materials, and state-of-the-art filtration systems, which strain budgets and reduce profitability.

Conversely, there lie ample opportunities that offset the challenges. Increasing global demand for specialty chemicals, bioplastics, and other high-value chemical products provides scope for growth and innovation. Moreover, new digital technologies, such as predictive maintenance and advanced data analytics, can help optimize asset performance, reduce downtime, and extend equipment life. Industry 4.0 adoption based on automation and interconnection will be a turning point toward further development of chemical processing from the viewpoint of operational accuracy and scalability.

Hence, the key must lie in innovation, regulation compliance, and technology integration toward sustainability and profitability to grow through the circumstanced and fluid chemical processing environment.

How Do Screw Pumps Compare with Other Pump Types?

Comparing Screw Pumps with Gear Pumps

Under these considerations, screw pumps handle high-viscosity, smooth, and pulsation-free flow, making them quiet. Conversely, gear pumps serve applications with high pressure yet low viscosity and with a simple design and low first cost.

|

Aspect |

Screw Pumps |

Gear Pumps |

|---|---|---|

|

Flow Type |

Smooth, steady |

Pulsating |

|

Fluid Type |

High-viscosity |

Low/medium-viscosity |

|

Sound Level |

Quiet |

Loud |

|

Performance |

Highly efficient |

Moderately efficient |

|

Investment |

Higher upfront |

Lower upfront |

|

Upkeep |

Infrequent |

Frequent |

|

Pressure Range |

Moderate |

High |

|

Use Cases |

Thick fluids |

High-pressure needs |

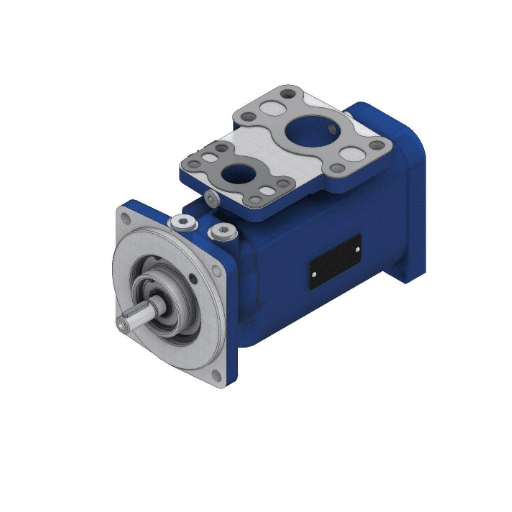

The Competitive Edge of Positive Displacement Pumps

The wide array of applications assigned to positive displacement pumps can be attributed to their precise operational mechanism and flexibility to detect the output fluid. In contrast with dynamic pumps, positive displacement pumps are designed to deliver a constant volumetric flow rate regardless of the discharge pressure, similar to chemical dosing or high viscosity fluid transfer, or even in the careful handling of sensitive materials.

An admirable feature of these pumps is that they work through all viscosities, from thin, water-like fluids to thick, highly viscous slurries, without losing efficiency. This is indeed valuable in the chemical processing and oil-and-gas industries, wherein fluid properties differ greatly. On the downside, positive displacement pumps generate higher pressures at a lower power input than centrifugal pumps, thus assisting better operational efficiency at a lesser cost.

Through the engineering of precision complicated screw pumps and other multi-stage types, the technical development in the field of positive displacement pumps has now facilitated their application even in the harshest operating environment. Modern-day pumps are fitted with intelligent monitoring systems capable of collecting operational data on a real-time basis and enabling predictive maintenance. IoT-enabled functions may help operators identify signs of wear and tear early on, thereby addressing the issues before complete failure occurs, minimizing downtime, and maximizing productivity.

At the same time, being able to meet very stringent industry regulations in pharmaceutical and food manufacturing makes positive displacement pumps a trusted solution. Closed-loop systems assure minimum contamination risk, very much assisting the growing demand for sustainable and environmentally safe solutions. This ability to comply with regulations, combined with robustness and versatility, truly cements these pumps as an important asset in varied industrial applications.

Applications of Three Screw Pumps in Various Industries

Three screw pumps- thanks to the hard and durable design, top-grade efficiency capabilities, and therapeutic ability to handle all sorts of fluids under harsh working environments- serve almost all industries. Below are the five prime industries serviced by these pumps, along with the related advantages:

- Petroleum and Gas: In petroleum and gas, three-screw pumps perform a range of functions, including pumping crude oils, refined petroleum products, and lubricants. The major advantage is that they can adequately manage highly viscous fluids and facilitate processes in which almost absolute flow control is of paramount importance. Residual pressure in lines and excellent output performance at extreme temperature and pressure conditions might as well be described as major functions the pumps perform in both upstream and downstream operations.

- Chemical Processing: These pumps come in handy in transferring aggressive and high-viscosity chemicals such as resins and polymers while maintaining a smooth, pulsation-free flow. Their corrosion-resistant materials and low-shear design make them perfect for the treatment of delicate fluids, which require gentle handling to maintain their properties during processing.

- Marine Industry: These pumps find application in various marine usages-financing fuel injection, engine lubrication, and ballast water treatment. Their lightweight, coupled with reliability, gives them an advantage in the constrained shipboard environment. They can also handle high-viscosity and low-viscosity fluids.

- Power Generation Industry: In power plants, three screw pumps are used for pumping fluid fuel oil, lubricants, and any other bodily fluids required for the working of the turbine and generator. These pumps provide high-efficiency flow, so they ensure the exact delivery of fluids needed promptly while also reducing downtime caused by maintenance or failure from operation.

- Food and Beverages: In this industry, three screw pumps transport edible oils, syrup, and other viscous liquid ingredients. Its hygienic design helps ensure compliance with strict regulatory standards, a must in operations where product purity and contamination prevention are paramount.

The flexibility of the three screw pumps emphasizes their strategic importance in the efficient yet controlled transfer of fluids over a wide variety of operational environments. With advanced design, they can still stand tall even in the most demanding operational conditions and hence producing an impact on the upliftment of the productivity and sustainability goals of these industries.

Frequently Asked Questions (FAQ)

Q: How does viscosity affect the performance of three rotor screw pumps?

A: Viscosity plays a crucial role in the performance of three rotor screw pumps as these pumps are often used to handle a range of fluids with varying viscosities, ensuring efficient and low-maintenance operations even in demanding applications.

Q: Which industries primarily use three rotor screw pumps?

A: Three rotor screw pumps are often used in industries such as oil, food and beverage, and wastewater management due to their ability to handle demanding conditions and a wide range of fluid viscosities.

Q: What are the key competitors in the global screw pump market?

A: Some of the key competitors in the global market include companies like Netzsch, Alfa Laval, and Colfax, which hold strong market positions due to their innovative solutions and extensive industry experience.

Q: Why are three rotor screw pumps preferred over twin screw pumps in certain applications?

A: Three rotor screw pumps offer advantages such as higher efficiency and the ability to handle a wider range of fluids compared to twin screw pumps, making them suitable for demanding applications and conditions.

Q: How are timing gears important in the operation of three rotor screw pumps?

A: Timing gears are crucial for synchronizing the movement of the rotors in three rotor screw pumps, ensuring a smooth and efficient transfer of fluids through the pumping chamber.

Q: How does the global push towards sustainability impact the screw pump market?

A: The global push towards sustainability is positively impacting the screw pump market by increasing demand for energy-efficient and low-maintenance pumping solutions that are capable of handling a wide range of industrial applications.

Q: What role does monitoring and predictive maintenance play in the future of the screw pump market?

A: Monitoring and predictive maintenance are becoming increasingly important in the screw pump market as they help in reducing downtime, extending the lifespan of equipment, and optimizing performance in demanding conditions.

Q: How is the demand for crude oil affecting the screw pump market?

A: The demand for crude oil significantly influences the screw pump market as these pumps are often used to transport crude oil efficiently, thereby driving market growth and innovation in pump technologies.