Salon chairs are one of the most essential pieces of equipment in any salon, supporting both the client’s comfort and the stylist’s workflow. However, over time, the hydraulic pumps that enable height adjustments can wear out or malfunction, leading to unnecessary frustration and potential disruptions in daily operations. This guide is designed to help salon owners and professionals understand how to effectively address such issues by using a hydraulic pump repair kit. Whether you’re looking to save costs on replacements or extend the life of your equipment, this comprehensive resource will equip you with the knowledge and tools needed to restore your salon chair’s functionality with ease.

Understanding Hydraulic Pumps in Salon Chairs

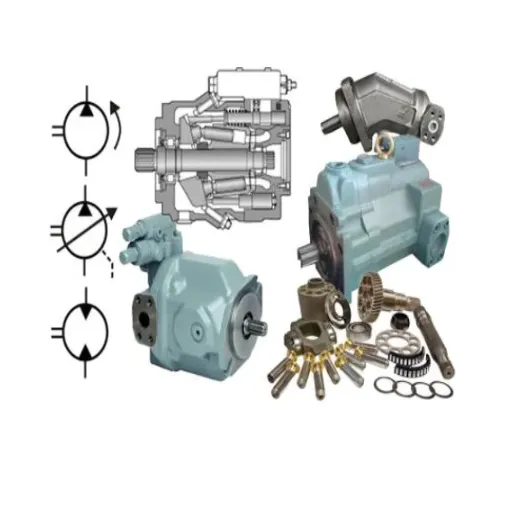

What is a Hydraulic Pump?

A hydraulic pump is primarily used in salon chairs. It enables the smooth adjustment of chair heights to best accommodate the clients and stylists. It converts mechanical energy into hydraulic energy, using the pressure of the fluid to carry out the vertical movements. This system commands seamless operation and precision for the height adjustments; hence, it can be used comfortably and ergonomically.

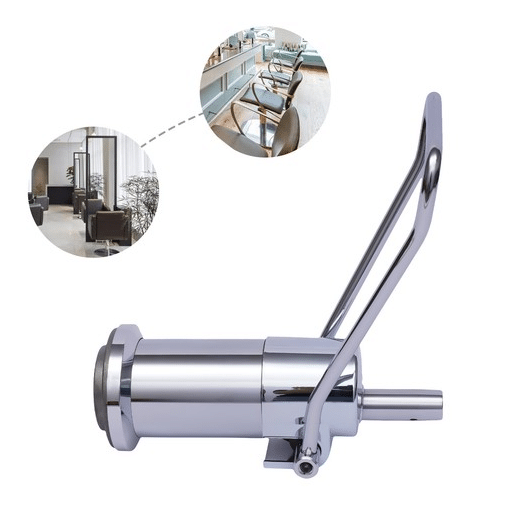

Basically, hydraulic pumps consist of a cylinder-and-piston combination connected to a reservoir filled with hydraulic fluid. When the foot pedal is pressed, its pressure builds in the pump cylinder, forcing the hydraulic fluid to push the piston upwards, thereby raising the chair. To set the chair down, the fluid is merely released back into the reservoir with a controlled descent. Thanks to such simple yet highly effective functioning, hydraulic pumps are an excellent fit for use in salon equipment.

Variability in the durability and efficiency of a hydraulic pump comes about via the quality of its parts, alongside maintenance thereof and proper utilization. Cleaning, inspections for leaks, and ensuring the hydraulic fluid remains free from contamination are some basic practices in maintaining its performance. Repairing minor defects, such as a worn or unserviceable seal or loss of fluid, can restore hydraulic performance and avoid expensive refurbishments or replacements to the longer life of the hydraulic pump, thus making it a highly valuable asset within any salon environment.

Common Issues with Hydraulic Pumps

Hydraulic pumps play an irreplaceable role in the efficient operation of a system and can suffer from many common trouble signs. One sign is fluid leakage, arising due to failing seals, dented or cracked hoses, and beyond-the-book fitments. Leaks decrease the efficiency of the pumps and increase operating costs, and could also cause contamination to adjacent equipment. Such an issue could be dealt with effectively if, from time to time, seals and connections are inspected and any damaged parts are replaced.

Overheating is one more problem commonly faced and can be due to high-pressure loads or insufficient fluid in the system, along with restricted flow. Overheating could cause degradation of hydraulic fluid-and in those cases, it ceases to be really effective for lubrication or the very means by which a pump should operate optimally. To solve such matters, make sure to keep the hydraulic fluid level adequate and specified for that particular pump. In addition, filters should be cleaned regularly so that the flow remains free, helping the heat to dissipate.

The third common problem is cavitation, resulting from the entraining of atmospheric air into the system and forming air bubbles that collapse under pressure. This action damages the internal components, instantly reduces efficiency, and causes excessive noise. Cavitation prevention lies in keeping the fluid levels exact, ensuring that the suction line operates correctly, and getting rid of the air enterprising in the system. Following regular maintenance checks by the manufacturer’s recommendations can hugely diminish the frequency of this problem and aid in maintaining the pump’s assurance of reliability and longevity.

Causes of Hydraulic Pump Failure

Hydraulic pump failure could arise from several conditions, such as contamination, lack of proper maintenance, or system misalignment. Dirt or debris entering the hydraulic fluid may cause severe damage to the internal components; wear and corrosion may set in, with reduced efficiency as a whole. Clean hydraulic fluid should, therefore, be used, and stringent filtration should be practiced.

Improper maintenance easily results in pump failures. If one neglects maintenance of the pump, common problems may arise, including worn-out seals, improper lubrication, excessive heating, etc. Following a strict maintenance schedule with checks for leaks and monitoring of fluid temperatures will, therefore, prevent these common problems and extend the pump life.

The next cause of failure is system misalignment, which may include an improper installation or poor alignment of components. Misalignment applies uneven forces to the pump shaft and bearings and causes premature wear and failure. Avoidance can be ensured by strictly following the manufacturer’s instructions during installation and by regularly verifying the proper alignment of all system components during maintenance. Applying these interventions to the four causes significantly diminishes the risk of hydraulic pump failures and optimizes system performance.

Identifying Problems with Salon Chair Hydraulic Pumps

Symptoms of a Failing Hydraulic Pump

Diagnosing issues in a faulty hydraulic pump in a salon chair is crucial for achieving optimum operation and longevity of the equipment. The most common symptoms of failure in hydraulic pumps include irregular height adjusting, wherein the chair will not remain in the chosen position or slowly lose height with weight applied. This usually hints at internal oil leakage or dewetting of seals.

Other warning signals include an unusual noise, such as grinding, whining, or hissing, that hints toward internal damage of components, cavitation, or air presence in the fluid. Further warnings could be that, while operating, the pump should require very much force, and it is extremely resistant to opposition, which indicates that there may be a blockage in the fluid or damage to some mechanisms. Operators may notice fluid spurting on the pump’s exterior, which means that there are ruptured seals or loose fittings in the hydraulics. It is counterproductive to hydraulic pressure.

Staying vigilant about these symptoms and following a maintenance schedule can help salon technicians avoid expensive repairs and cut down on equipment downtime. The best course of action is to ensure high-quality and clean hydraulic fluid while promptly replacing any worn-out parts to preserve hydraulic pump longevity and reliability.

How to Diagnose Hydraulic Pump Issues

The repair procedure first involves spotting and diagnosing hydraulic pump faults. Pressure and flow checks should be carried out first and foremost, since those greatly affect hydraulic system functionalities. Therefore, pressure and flow readings can confirm possibilities or invalidate them. A falling pressure value would, for instance, indicate an internal leakage or perhaps worn components. The noises produced are usually unusual-these may be whining or knocking sounds from the pump due to cavitation, air contamination, or bad bearings.

Look around all hydraulic connections and components that may be showing signs of wear, fluid leaks, damaged seals, or cracked hoses. An operating temperature measurement of the hydraulic system may also reveal some useful information, as an abnormally high temperature reading could be due to an overworking pump, wrong fluid viscosity, or restricted flow within the system.

A flow test that uses a flow meter will reveal how much fluid is flowing through the pumps at any particular moment, thus helping determine if the pumps are exhibiting flow rates within the specified range for them. Any significant deviation from the flow indicates that either there are damaged gears, vanes, or pistons. Complementing these tests are hydraulic fluid cleanliness tests to detect particulate contamination that may shorten the life of pump components.

Efficient application and recording of diagnoses build a better basis for any salon technician or mechanic to pinpoint hydro-pump failure causes efficiently, thus improving system reliability and reducing downtime.

Importance of Prompt Repairs

Fixing hydraulic systems should be done immediately with the purpose of ensuring operational efficiency, minimal downtime, and, above all, the avoidance of possible catastrophic failure. Hydraulic pumps, being a core element of industrial and automotive systems, have to function with precision. Late repair merely intensifies the problem or issues with secondary damage, exacerbated by contamination, pressure irregularities, or localized overheating, etc. In contrast, a bad hydraulic pump might supply pressure erratically, thereby undermining the performance and safety of the system, creating potential stoppages of production or an unsafe working environment.

On the other hand, timely repairs will also help contain costs for equipment maintenance. On-topic issues, when dealt with, whether micro-cracking in the seal, vane wear, or bearing degradation, will cost only a fraction of the price compared to the total system failure. Further, running a failing component causes collateral damage, which means that a couple of parts need replacements or repairs, possibly ultimately triggering a system overhaul. Such interventions, triggered by early inspections and maintenance schedules, will give the operator the edge in extending the life and cost of the hydraulic components.

Prompt repairs in additional ways protect you from liability to meet the regulatory standards and ensure optimum system efficiency. Many industries are cited from stringent operational guidelines departure caused by equipment malfunction or failure, will be punishable will compromise quality control, or may lead to suspension of operations. Such quick moves will restore the integrity of the system and achieve maximum energy efficiency as the operator will be able to avoid pressure losses, fluid leaks, or unnecessary power consumption. Cases solved on time mean that the operators will save a few pennies at the cost of reinforced safety standards, operational reliability, and sustainable development of a facility.

Step-by-Step Guide to Repairing Hydraulic Pumps

Tools and Materials Needed

To ensure a successful repair of hydraulic pumps, gather the correct tools and materials beforehand. The following are suggested items:

- Precision Wrenches and Torque Tools: Disassembly and reassembly of parts have to be done accurately so as not to damage the pump housing or internal components. Torque tools must be within the allowable limits as specified by the system.

- Seal Kit: Quality seal kits with O-rings, gaskets, and other sealing material compatible with the fluid being used in the pump are indispensable to avoid leakage and to maintain the system’s integrity.

- Cleaning Materials: These would include industrial degreaser, lint-free wipes, and solvent-resistant brushes for cleaning all parts from contaminants that could affect performance.

- Digital Calipers and Micrometers: These measuring tools are essential to measure the wear and tolerance of internal components to verify whether the parts meet operational limits.

- Hydraulic Oil and Filter: Unsure that the substitute oil conforms to system specifications, and always use new and clean filters to block any debris from entering the repaired system.

- Diagnostic Instruments: Flow meters, pressure gauges, and thermal-imaging instruments help test a pump’s functioning after repairand delivery to ensure efficient operation.

- Safety Gear: Put on the measure gloves, safety goggles, and any other recommended personal protective equipment to safeguard from pressurized fluid and sharp components throughout the entire repair.

- Manufacturer Repair Manual: This is the most important document for any equipment to follow along with specific instructions, torque values, and installation details that have been given by the manufacturer of the equipment.

- Hydraulic Bench or Workstation: Well-stabilized hydro-bench or workstation ensures that the components are handled securely without risk of damage or contamination.

Having these tools and materials ready speeds up the process, reduces downtime, and guarantees that after maintenance, the pump is able to perform within its engineered specifications.

Replacing or Repairing Hydraulic Components

When replacing or repairing hydraulic components, it’s very important to keep everything super-precise and work according to standard operating procedures to uphold the integrity and the functioning of the system. Usually, a complete diagnostic inspection takes place first, looking for failing points with, say, a worn seal, damaged valves, or compromised hoses. Now that the fault is confirmed, the components should be replaced or fixed with parts approved by the manufacturers of the systems to ensure perfect compatibility and performance.

Hydraulic system disassembly has to adhere to very detailed guidelines so that all fittings, connections, and internal components are properly documented and handled to allow guarantees against contamination. Clean working conditions should be maintained at all times, because even a few fine particulates can compromise the system’s performance or thrust it toward early failure.

In addition, the hydraulic fluids should be inspected and, if not found to be in optimum viscosity and contamination levels, replaced, as these could have a direct bearing on system performance. Upon completion of the repair, the hydraulic system should be subjected to pressure testing and functional verification under controlled conditions to ensure compliance with operational standards. Replacements or repairs thus, can be effectively accomplished by proper procedures and accurate technical data, consequently extending the service life of the equipment and reducing unnecessary downtime.

Reassembling and Testing the Chair

The chair must always be reassembled after maintenance according to the manufacturer’s assembly guidelines to maintain its integrity and functionality. After this, the good practice is to ensure that the components are clean, have no defects, and are properly aligned. Fasten bolts and screws with a torque wrench to conform to the specified torque. Under-tightening could compromise stability; over-tightening might cause strain in the components.

Once reassembled, the chair will go through tests that will certify its safety conditions and performance. The first test will be a load test to certify deformation or failure under maximum weight capacity. The cycle test will be carried out on any mechanical or hydraulic mechanism to ensure it moves properly under operational conditions and withstands durability under repeated use.

Functional verifications should be carried out with tilting lock, reclining, and ergonomic adjustment, such as height, lumbar support. By combining precise reassembly and strict testing, the performance validation of the chair is realized, minimizing either the risk of customer dissatisfaction or premature failures, according to accepted safety standards.

Choosing the Right Salon Chair Hydraulic Pump Repair Kit

Key Features to Look For

While choosing a salon chair hydraulic pump repair kit, ensure you check for compatibility, durability, and ease of installation. Compatibility is the first consideration, as if the kit does not properly fit the hydraulic pump, it will not work appropriately or may even cause operational issues. Search for kits with universal components or kits explicitly specified for your chair brand and model.

Durability, especially for certain components such as seals, pistons, and springs, is another must-have characteristic. So, contemplate good materials, like industrial-grade rubber or corrosion-resistant metals from the set’s manufacturer, to guarantee a long life for the repair kit. Also, products that fulfill internationally recognized standards of manufacturing processes provide further guarantees of reliability.

Ease of installation speeds up the repair process. If there are parts pre-lubricated or with additional tools and clear instructions, the effort for maintenance will be minimal, and downtime will be greatly reduced. Furthermore, check that the kit contains all parts needed for the repair; otherwise, missing parts could result in an incomplete repair and cause further problems.

Balancing Quality and Affordability

Depending on the particular industry where one evaluates certain products or services, striking a balance between quality and affordability becomes of great importance, especially where factors like reliability and performance are absolute. Having high-quality components or materials should imply, at least in theory, a product that has a longer lifespan, requires less upkeep, and is cheaper in the long run. However, the purchase must be such that the price premium is justified by the quality given. Modern manufacturing processes and top-quality raw materials might improve product performance, but those improvements must be able to accommodate their added price with actual benefits.

When it comes to affordability, one goes beyond the initial purchase price into the life-cycle cost of the product. This life-cycle cost includes not only the costs of maintenance but also those for repair and downtime. For example, it can initially look like a cheap answer that will fail more often, thereby increasing future costs. On the other hand, a more expensive solution comes with features that make it cheaper overall, such as resistance to wear and tear, modular design for easy replacements, and perhaps an extended warranty. Such factors ought to be totally assessed by the decision-makers through detailed cost-benefit analyses in making a choice appropriate to both operational and financial goals.

In addition, economic viability often sits on market and technology trends that constitute generic price dynamics. Price can come down for options formerly expensive with advances in production against shortage of alternative materials or increased competition, without infringing upon quality. Businesses and consumers can make such purchases or negotiate for the best value by dint of keeping abreast of such developments. Moreover, they could seek to dispense with any bias in procurement strategies towards either affordability or quality with the help of data-driven tools and insights like predictive analytics. Essentially, the balance between these attributes ensures efficient appropriation of resources as well as presents competitive advantages and long-term sustainability.

Maintaining Salon Chairs for Longevity

Regular Inspections and Maintenance Routines

For salon chairs to work well, they require adequate care and a systematic process involving checks and complete maintenance. Start by checking weekly to ascertain if wear and tear can be spotted: upholstery cracks, loose screws, problems with the hydraulic system, etc. All surfaces should be cleaned with a non-abrasive cleaner to prevent dirt from accumulating and wearing out the material further.

Check the hydraulic pump mechanism carefully to see if it is still ok, meaning that the fluid level is enough and could not have any leaks through the seals, causing either loss of function or less efficiency. Grease the reclining mechanism and hinges once a month to reduce friction and prolong life. Always use manufacturer-recommended products and respect the maximum load capacity to avoid stressing structural components. Proactive replacements of parts worn to the point of jeopardizing functionality, reduce downtime, and reinforce the professional image of the salon.

With a good inspection regime combined with prompt attention to issues, a salon can effectively extend the service life of its chairs while ensuring the safety and comfort of clients.

Cleaning Practices for Salon Furniture

A systematic cleaning technique based on efficacy and conservation of materials is essential to keep salon furniture in impeccable condition. First, check the manufacturer’s instructions for recommended cleaners and methods, as the materials provided-whether consisting of leather, vinyl, or wood-may require specific care to keep them from deterioration. For leather surfaces, wipe them gently with a damp microfiber cloth and treat with a pH-balanced leather cleaner to keep it supple; while for vinyl upholstery, nonabrasive cleaners free of alcohol should be used to prevent cracking or discoloration.

Disinfect surfaces that come in frequent contact with customers, such as armrests or headrests, for hygiene and to prevent the transmission of germs. Use disinfectants approved by the EPA, which are meant to be used in professional salons while following local health regulations. Take care to avoid over-saturation, as this can cause degradation of materials or corrosion of internal components.

Dust wooden finishes frequently with a soft dry cloth, and occasionally polish with wood-safe polish to prevent wear or moisture damage. Do not use excessive water or harsh chemicals, as these might result in warping or discoloration. In addition, apply a daily cleaning regimen, which involves vacuuming hair and debris from crevices and ensuring that hydraulic bases and mechanisms do not accumulate buildup.

A stringent cleaning regimen and maintenance protocols will keep salon furniture beautiful and functional, ultimately offering clients a welcoming and professional setting. If their cleanliness is consistently assessed and maintained, these critical items would be able to serve for an extended period.

Preventive Measures to Extend Equipment Life

Implementing preventive maintenance protocols extends the operating life of equipment and maintains optimal performance standards. Hence, a major strategy is to schedule conceptual inspection of wear: any indications of wear in the field must be detected beforehand and corrected so as to avoid catastrophic failures. This procedure entails inspecting for loose fittings, lubrication of all the moving parts, and replacement of consumables such as filters or seals based upon the recommended service period indicated in the manufacturer’s instructions.

Furthermore, using equipment within its specified load and capacity limits eliminates unnecessary exertion on the equipment and potential prospects of early breakage. For example, pressure for hydraulic systems shouldn’t go above rated levels since any stress would take its toll on system fatigue and leakage. Cleaning equipment is yet another crucial consideration, since dust and debris could harm sensitive parts like bearings, electrical contacts, and cooling systems.

Further, the advent of modern data-driven solutions opens further possibilities for predictive maintenance. Through monitoring usage data and operational data via sensors and software, operators are warned of obstacles to their efficiency or potential trouble situations. As a direct consequence, this approach can greatly decrease downtime since remedial action can be taken ahead of time. For instance, in vibration analysis for rotating machinery, misalignment or imbalance can be forecasted before it progresses to major damage.

Training is also important in enhancing equipment life. Well-trained and well-informed personnel have fewer chances of misuse. Consequently, thorough inspection, operational limits, technology, and skilled operation constitute a well-abided formula for preserving equipment life cycle from suddenly incurred costly repairs or replacements.

Frequently Asked Questions (FAQ)

Q: What is a salon chair hydraulic pump repair kit?

A: A salon chair hydraulic pump repair kit is a collection of replacement parts designed to fix or maintain the hydraulic system of salon chairs, barber chairs, and styling chairs. These kits typically include essential components such as hydraulic cylinders, gas lifts, and seals that ensure the chair operates smoothly and allows for effortless height adjustments.

Q: How do I know if my salon chair needs a hydraulic pump repair?

A: Common signs that your salon chair needs a hydraulic pump repair include instability, the chair getting stuck at certain heights, or the inability to adjust the chair height at all. If you notice any signs of leaks or if the chair does not operate smoothly, it may be time to consider replacing the hydraulic pump or other chair parts.

Q: Can I replace the hydraulic pump myself?

A: Yes, replacing the hydraulic pump can often be done as a DIY project if you have basic tools like a Phillips screwdriver and a few mechanical skills. However, if you are unsure, it’s advisable to seek expert advice or professional repair services, especially for heavy-duty salon chairs.

Q: What parts are included in a salon chair hydraulic pump repair kit?

A: A typical salon chair hydraulic pump repair kit may include a standard hydraulic pump, hydraulic baseplate, hydraulic cylinder, seals, and sometimes additional chair parts that may need to be replaced to ensure the chair functions properly. Always check the product description to ensure all necessary components are included.

Q: How do I adjust the height of my salon chair after a hydraulic pump repair?

A: After replacing or repairing the hydraulic pump, you can adjust the height of your salon chair by using the lever located under the seat. Pulling the lever will engage the hydraulic system, allowing you to position the chair at your desired height. Ensure the chair’s gas lift is functioning properly to achieve smooth operation.

Q: What should I do if my chair pump is leaking?

A: If you notice signs of leaks from your chair pump, it’s crucial to address the issue promptly. Inspect the hydraulic lines and seals for damage. Often, replacing the hydraulic cylinder or other components in the repair kit will resolve the issue. If the problem persists, consider professional repair services.

Q: How can I ensure my salon chair lasts longer?

A: To extend the lifespan of your salon chair, perform regular maintenance checks on chair parts, including the hydraulic pump. Ensure that the chair operates smoothly and adjust the chair height carefully to prevent stress on the hydraulic system. Using the chair for its intended purpose and avoiding excessive weight can also help maintain its condition.

Q: What are the benefits of using a hydraulic chair in a hair salon?

A: Hydraulic chairs offer several benefits in a hair salon setting, including effortless height adjustments, stability, and comfort for both the stylist and client. They are designed to swivel easily, allowing stylists to groom clients efficiently without requiring them to move excessively, enhancing the overall salon experience.