Hydraulic systems are the backbone of countless industries, powering heavy machinery and enabling precision operations across sectors such as construction, manufacturing, and agriculture. At the heart of these systems lies the Rexroth hydraulic piston pump, a critical component renowned for its reliability and efficiency. However, like any sophisticated piece of engineering, these pumps are not immune to wear, malfunctions, or operational inefficiencies. This guide is designed to help you identify, diagnose, and resolve common issues that may arise with Rexroth hydraulic piston pumps. Whether you’re a seasoned technician or a maintenance specialist, this troubleshooting roadmap will equip you with the insights and technical know-how to keep your systems running at peak performance.

Understanding Rexroth Hydraulic Pumps

Overview of Piston Pumps

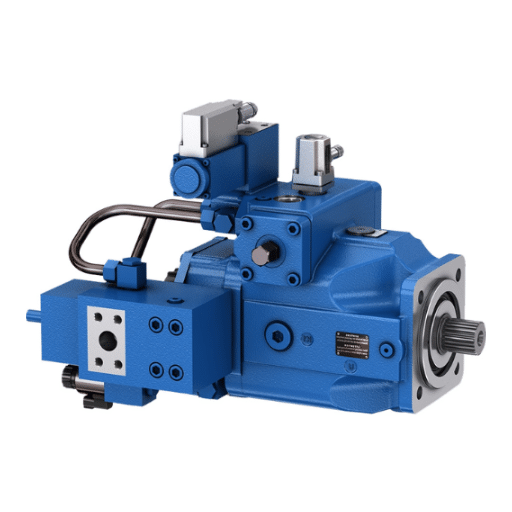

Being hydraulic piston pumps, Rexroth hydraulic piston pumps serve as essential components in hydraulic systems, which impart an exact and steady amount of flow of fluid with variable pressure. Their functioning is based on the principle of reciprocating motion, where pistons undergo variable motion in cylindrical chambers to transfer hydraulic fluid. This ensures great efficiency, so they find applications where accuracy, durability, and high performance are desired.

In hydraulic systems, we mainly have two types of piston pumps: axial piston pumps and radial piston pumps. Axial piston pumps have pistons lined up with one another and are used in systems that require variable flow rates and pressures. A radial piston pump, contrarily, arranges the pistons radially around a rotor in order to handle higher pressure. Recognition of this difference, therefore, aids in knowing which pump arrangement fits best for a particular working need.

Rexroth piston pumps stand for their reliability and accuracy; however, like all mechanical parts, they require regular maintenance to prevent wearing down into fluid loss and to ensure optimal functionality. These pumps may operate till they face any malfunction-causing internal leakage and cavitation, or contamination, but these can be controlled and minimized with regular servicing as recommended by the manufacturer and quality hydraulic fluids. By ensuring component integrity, operators are hence able to increase the operating lifespan of the pump, thereby leading to more efficient functioning of the system concerned.

Components of Rexroth Hydraulic Systems

Rexroth hydraulic systems contain several crucial components working together to achieve smooth and precise operation. The main component is the hydraulic pump, which takes mechanical energy and transfers it to the fluid during pressurization. This pump is the heart of any hydraulic system as it produces flow at a given pressure with which power is transmitted to different types of hydraulic actuators.

Another important component is the hydraulic actuator, which includes cylinders and motors. An actuator is meant to perform a particular job by converting hydraulic energy back into mechanical energy. Cylinders generate linear motion when it comes to lifting or pressing, while motors generate rotational motion required for driving a piece of machinery or equipment.

Further components include control valves and other associated accessories, precisely controlling the direction, pressure, and flow of hydraulic fluid within the system. These valves guarantee smooth and precise motion control. Accumulators, filters, and reservoirs are also essential; the accumulator is responsible for storing excess hydraulic energy for later use, whereas the filter cleans the fluid by purifying it from contamination, and the reservoirs act as volumetric stores and providers of hydraulic fluid for the system. By working in unison, all these ensure the consistent reliability, durability, and efficiency of Rexroth hydraulic systems.

Common Applications of Axial Piston Pumps

An axial piston pump is used wherever high efficiency, accurate control, and reliability are needed. These pumps generally form part of heavy machinery operating under construction, such as excavators, loaders, or cranes. Regardless of extreme working conditions, the pumps are supposed to assure the delivery of hydraulic power sufficient for complex operations such as lifting, digging, and material handling.

The other application is found in the manufacturing sector, where axial piston pumps power industrial presses and injection molding machines. These machines require accurate pressure and flow control to achieve the proper working conditions in stamping, molding, and metal-forming processes. The pumps’ robust construction and versatility make them well-suited for performing such rigorous operations.

These pumps in the energy sector are heavily employed, particularly in wind turbines and oil and gas exploration equipment. They facilitate crucial hydraulic operations such as pitch control in turbines and high-pressure drilling operations. The ability to withstand the most trying of environments renders them exceptionally valuable for guaranteeing operational efficiency and safety in these industries.

Troubleshooting Hydraulic Pump Issues

Identifying Symptoms of Pump Failure

Hydraulic pump failures may present various symptoms, each hinting at a different problem within the system. One chief symptom is an abnormal noise-whining, rattling, or knocking induced from cavitation, aeration, or wear of internal components. Cavitation may occur when air or vapor bubbles form in the hydraulic fluid or an insufficient fluid level is maintained, or the fluid insects at the inlet or is contaminated with impurities. Aeration, meanwhile, mostly arises from air entering the system through ill-sealed connections or damaged hoses, thus lowering the efficiency and the lifetime of the pump.

Another alarming symptom affecting system performance and demanding immediate attention is a decline in the pressure or flow rates. This could indicate excessive internal leakage by worn-out seals, valve damage, or low oil viscosity. Direct effect from low-pressure output is suffered by a pump in performing important tasks, like holding pitch control systems in turbines or applying forces accurately in drilling operations. Pressure gauges can and should be monitored regularly, allowing early detection of abnormalities and thus averting failure.

Contamination of hydraulic fluid proves to be another major factor contributing to pump failure. Contaminants, either metal particles or water, or debris, can cause erosion of internal elements, reduction in fluid quality, and, consequently, undermine the integrity of the system. Bad fluid maintenance, disregarding filter replacements, for instance, or ignoring stipulated recommended service intervals-worsens the contamination risk. Prevention of hydraulic pump failure starts with regular inspection for fluid clarity combined with maintenance criteria. Immediate identification of these symptoms, followed by continuous preventive maintenance, will promote lasting and efficient hydraulic systems, maintaining them even in challenging environments.

Step-by-Step Troubleshooting Guide

- Identify the Symptoms: Initially, all observable symptoms of failure in the hydraulic systems are documented. These symptoms may include abnormal sound generation, erratic operational speeds, fluid leakage, or even the system overheating. Hence, identifying the symptoms correctly will assist in narrowing down the root cause.

- Check Hydraulic Fluid Levels and Condition: Look into the hydraulic reservoir to confirm that the fluid levels comply with the standards of the manufacturer. Simultaneously, check the quality of the fluid. Contamination, change of color, or aeration are some of the factors that can affect system performance and highlight an existing problem.

- Inspect Hydraulic Filters: Remove hydraulic filters and check for clogging or saturation by debris that might reduce fluid flow through cavitation or stress the pump. Replace with a new filter when it is clogged or saturated, always following recommended service intervals.

- Examine the Pump and Associated Components: The hydraulic pump should be inspected for signs of wear, leaks, and damage to seals and gaskets. Damages to shafts, misalignment, damaged bearings, and excessive internal clearances may also be contributory factors that should be addressed.

- Test System Pressure: At key testing points, use a pressure gauge to measure system pressure. Compare these pressures with the values given in the manufacturer’s specifications of operation. Pressure out of the acceptable range may be a sign of pump malfunction, a leak in the system, or an obstruction within the system.

- Inspect Hoses and Connections: Go about a thorough inspection of all the hydraulic hoses and fittings, checking for visible damage, wear, or loose fittings. An aged hose may lead to fluid leakage and irregular system functioning. Immediately replace a faulty component.

- Judge Control Valves for Blockages: Disassemble the control valves and verify that they are not blocked by dirt or contaminants; clean or replace them as necessary. A bad valve can block the fluid flow, reducing the efficiency of the system’s performance.

- Test Actuators or Cylinders: Assess actuators or hydraulic cylinders for leak tightness and extend and retract mechanically. Usually, seal breakdown or internal damage in these components would affect the working of the system as a whole.

- Re-Test the System: After troubleshooting and remedy, properly reassemble the components and carry out a thorough operational test on the whole system, ensuring all the pressure, flow rate, and temperature fall within the specified limits.

- Document and Align with Maintenance Schedule: Record all details about the findings during troubleshooting and all repairs, replacements, and components performed. Use this information to adjust to or synchronize with the preventive maintenance program for the hydraulic system, thus ensuring optimized performance and preventing future failures.

These systematic steps, when applied meticulously, will increase the reliability and efficiency of hydraulic systems while reducing downtime in working environments.

Common Causes of Pump Malfunctions

Pump malfunctions in hydraulic systems can arise from several underlying factors, many going hand-in-hand with operational wear, environmental situation, and maintenance. Some of the leading ones are listed below:

- Cavitation: Cavitation happens when vapor bubbles are generated in the fluid, usually due to a pressure drop at the inlet of the pump. When these vapor bubbles collapse, they impart damage to the internal components, which may include impellers or seals and lead to performance reduction and life shortening; thus, such a problem is usually precipitated by improper fluid levels, poor system layout configurations, or the presence of restrictions along the supply line of the fluid.

- Hydraulic Fluid Contaminants: Solid particles, water, or air entrained in the hydraulic fluid cause abrasive wear, corrosion, and reduced lubrication effectiveness. These contaminants are often introduced into the system during maintenance, through worn or degraded seals, or through improper filtration, and they quicken the degradation process of the pump components.

- Overheating: High operating temperature results in reduced viscosity, which leads to poor lubrication and increased wear of pump components. Causes of overheating are an inefficient cooling system, long-term overloading, and above-grade operating pressure.

- Incorrect Fluid Use: Using an unsuitable hydraulic fluid in a particular system can cause a drop in pump performance. The choice of hydraulic fluid should consider viscosity, thermal stability, and chemical compatibility to preserve the life of system components.

- Seal and Bearing Failures: Defective or worn-out seals cause leakage, and bearing failures affect the alignment and rotation of the pump shafts. Usually, these problems can set in because of high operating pressures, misalignment, or excessive mechanical stresses.

- Misalignment and Installation Errors: An incorrectly installed pump or a pump that is misaligned with its drive motor or any other component will be unevenly loaded and vibrate. This vibration, as it continues over time, will cause accelerated wear and fatigue of both the pump and associated components.

By pinpointing and then rectifying these prevailing common causes, maintenance teams can greatly enhance the life and performance of hydraulic pumps. Thus, the implementation of preventive measures like frequent inspections, adequate fluid handling, and following set manufacturer guidelines will certainly act as a shield against operational downtimes and expensive maintenance.

Addressing Cavitation in Hydraulic Pumps

Understanding Cavitation and Its Effects

Cavitation occurs in the case of hydraulic pumps when vapor bubbles form in the liquid due to localized low-pressure zones with pressures below the vapor pressure of the liquid. These vapor bubbles collapse energetically on their way to the high-pressure region inside the pump, dissipating energy, which in turn is used to damage the internal components grossly. Cavitation damage occurs immediately and detracts from hydraulic system performance, reliability, and working life.

- Erosion of Internal Components: The collapsing vapor bubbles generate shock waves under high pressure that erode the surfaces of impellers, vanes, or valves. Pitting develops along with the erosion and material degradation, and weakening of the integrity of the critical components.

- Reduced Pump Efficiency: There is a fair degree of fluid interchange going on between the pump and the cavitation. The chaotic fluid flow within the pump leads to vibrations, thus lowering the pump’s efficiency concerning volumetric and general standards. Hence, the output flow rate is lowered, as is the operational performance.

- Excessive Noise and Vibration: Vapor bubble implosions lead to noises and vibrations that may damage bearings, seals, and supporting systems for pumps, until unchecked, vibrations are spread to linked machinery, amplifying their wear and tear.

- Elevated Operating Temperatures: Positions of elevated heat build-up are typical of cavitation brought upon by turbulence generated by fluid flow alongside friction found in the pump. Prolonged high temperature exposure causes hydraulic fluid degradation, wherein it loses both its lubricating ability and its cooling ability of its own.

- Shortened Equipment Lifespan: Persistent cavitation vehemently accelerates wear of components, resulting in frequent breakdowns and costly repairs; hence, prolonged exposure to its harmful effects takes a heavy toll on the working life of a hydraulic pump.

Studying cavitation involves talking about its causes, including inlet pressure being too low, blocked or restrictive inlet lines, or incorrect use of hydraulic fluid. Adhering to design best practices and preventive measures can assist in alleviating those effects that would otherwise prove detrimental to the integrity of hydraulic systems as time goes on.

Preventing Cavitation in Rexroth Systems

For cavitation-prevention purposes in Rexroth systems, I concentrate my attention on the system design and proper maintenance. From inlet pressure standpoints and potential causes of cavitation, the important thing is to ensure the pressure recommended therein. Inadequate pressure at the pump inlet causes those vapor bubbles to come into formation, and it is one of the major causes leading to cavitation. I always look out for blockages or excessive restrictions inside inlet lines, as these increase pressure drops and the occurrence of cavitation.

Equally important is the correct evaluation of the hydraulic fluid to be used in the system. I insist on using hydraulic fluids as per the manufacturer’s recommendation, and keep in mind the viscosity and operating temperature range of the fluid. Fluid with the wrong viscosity can create irregular flow conditions that can induce cavitation with time. I conduct periodic fluid analyses to detect any possible contamination or degradation of fluids, so that replacement can be ensured, consequently reducing any possible system failure due to cavitation.

In addition, I keep lining up with system monitoring apparatus that can alert me of early-stage cavitation by detecting aberrations in noise or vibrations of the pump. Together with an organized maintenance plan, such detection easily puts potential problems into remedy before their plights are too far advanced. My application of such detailed measures grants the Rexroth hydraulic systems that I work with their efficiency alongside structural integrity for a long duration.

Repairing Cavitation Damage

Repairing cavitation damage in hydraulic systems is a methodical and precise process to restore the system’s functionality to maximum levels and prevent further damage. At the very least, the process begins with a thorough inspection to judge the magnitude of the damage. Most often, surface damage such as pitting or erosion on pump elements is treated by machining or polishing the areas affected to restore surface smoothness and remove all imperfections. In cases where the damage is much more serious, replacement of the components may be necessary to ensure the system’s reliability.

Advanced composite materials and surface treatments offer an advantageous technique for strengthening the repaired components with an improved resistance to further cavitation. Also, upgrading the pump materials to cavitation-resistant ones, such as hard steel or certain coatings, can help improve longevity. During this stage, however, care should be taken in reassembly and alignment to prevent the introduction of operational inefficiencies and misalignments that may cause cave formation to recur.

Further to prevent cavitation, recalibration of the system may be needed, with adjustments to the system’s operational parameters, e.g., fluid pressure, flow rates, and inlet conditions. Anti-cavitation methods, such as proper fluid viscosity and good reservoir level, should also be implemented to enhance the system’s performance. In combination with preventive maintenance, such methods serve to greatly improve the life expectancy and efficiency of hydraulic systems.

Valves and Hydraulic System Performance

Role of Relief Valves in Hydraulic Systems

Relief valves represent an important system in ensuring the safety and efficiency of hydraulics by controlling pressure build-up within the system. They are designed to far exceed pressure limits, which can cause system failure, damage to equipment, and combined hazards. When the pressure goes above preset limits, it will cause the relief valve to open, and the flow of fluid is either diverted or released to ensure that the hydraulic system works within permissible operational limits. Below are five important roles and detailed functions of relief valves in the hydraulic system:

- Over-Pressure Protection: When pressure exceeds the maximum allowable limits in the hydraulic circuit, the relief valve releases hydraulic fluid to prevent over-pressurization that may cause structural damage or failure to components such as pumps, actuators, and pipes.

- System Stability: Through the maintenance of constant pressure within the hydraulic circuit, such valves prevent random fluctuations or surges that destabilize system operation and compromise the accuracy of hydraulic components.

- Energy Efficiency: In managing pressure levels appropriately, relief valves mitigate energy losses that would have been incurred due to overpressure, thus contributing to the hydraulic system’s efficiency.

- Thermal Expansion Compensation: Relief valves compensate for the thermal expansion of the hydraulic fluid. Upon heating and expansion of fluid, there is an increased pressure; in such a case, relief valves come into operation to get rid of excess pressure, avoiding any damage or interruption in operation.

- Emergency Response and Safety: Relief valves act as emergency elements diverting flow to prevent disastrous system failures or safety catastrophes in unusual situations like blockage or a fault in operation.

By performing the above functions, relief valves remain indispensable in sustaining resilience, functionality, and service life in hydraulic systems.

Maintaining Valve Functionality

To achieve an ideal operation and maximize the life of all relief valves, there should be but one maintenance organization with a combination of maintenance strategies consisting of safety, conditional, and corrective types. Preventive maintenance may imply scheduled inspections to find out if wear and tear have affected the sealing surfaces, seals, springs, or even diaphragms and to replace these components before final failure. Prediction can incorporate the use of certain non-destructive techniques or condition-monitoring tools with the control of operational such as pressure at the threshold, time of response, or leakages, etc. For example, hydrostatic pressure testing is employed to check whether a pressure relief valve can function correctly against a controlled pressure.

The manufacturer sets operating limits, and further calibration guarantees that the valve opens and closes in response to a setpoint. Modern minute diagnostic tools allow real-time assessment of valve health while also pinpointing some common failure modes among valves, such as internal corrosion and fatigue. Having a documented maintenance schedule together with logging data of maintenance actions performed and valve performance is considered best practice to address recurring issues and mitigate sudden operational failures.

Checking fluid cleanliness on an ongoing basis would be equally critical, for any contamination accelerates wear or causes clogging. Such factors as temperature fluctuations should be constantly monitored in the installation environment, or some exposure to aggressive chemicals may require material considerations or insulation measures.

Following this approach helps operators limit downtime, hazards, and increases the lifetime of the relief valve, contributing to a very competitive hydraulic system. Documenting and analyzing data will allow further improvements across maintenance planning and system design.

Optimizing Pump Performance and Longevity

Effective Lubrication Techniques

Proper lubrication ensures adequate performance and extends the life of a pump. Selection of a lubricant every time begins with a thorough study of the operating conditions of the pump: load, temperature, pressure, and the environment. For example, given that any scenario may include high temperatures, synthetics or specially prepared lubricants may be created that resist thermal breakdown and maintain their viscosity.

Equally important is the proper application of the lubricant at regular intervals. One should use an automatic lubricating system to dispense the amount of lubricant warranted, thus preventing the gravest issues that equipment undergoes, either too much or too little lubrication. Best pumping practices must include such things as a maintenance schedule for lubrication intervals determined by all observed operating conditions, contaminants prevented from entering the system by utilizing such things as sealed bearings, filtration, and regular testing for moisture and particulate contamination in lubricant samples.

There is a growing trend for using advanced monitoring instruments for real-time assessment of lubrication performance. Infrared thermography or ultrasonic analysis would be appropriate for this purpose. Tools such as these allow an operator to recognize abnormal conditions, such as excessive friction or heat production, well before these can cause a significant mechanical failure. Incorporating such best practices must bring about enhanced reliability, reduced maintenance costs, and extended efficiency of pumps within the hydraulic systems.

Monitoring Coupling and Motor Performance

Monitoring coupling and motor performance properly ensures smooth operation of hydraulic systems. Misalignment in couplings-could be angular, parallel, or axial, could lead to wear, vibration, and losses in energy. Laser alignment tools give operators precise measurements necessary to correct even the smallest misalignment accurately. Torque monitoring sensors can be mounted in couplings to monitor torque levels, and any deviation from the set values may be taken as an indicator of early motor or component failure.

With regards to motors, certain key performance indicators are to be monitored with measurement over time, namely power consumption, temperature stability, and vibration patterns. Advanced condition monitoring systems, adopting vibration analysis and thermal imaging, provide early warning that bearings may be wearing, rotors becoming imbalanced, or electrical faults may occur before such problems become system failures. By correlating real-time sensor data with historical performance information, predictive analytics modeling may gauge the likelihood of overhead failures so that such occurrences can be mitigated with preemptive actions.

Such monitoring procedures, when implemented as part of an asset management program, will maximize the reliability of the system, extend component life, and offer enhanced energy efficiency. It is, therefore, an option that every organization should consider implementing to satisfy current operations while minimizing unanticipated downtime and maintenance costs.

Frequently Asked Questions (FAQ)

Q: What are the common symptoms indicating issues with a Rexroth hydraulic piston pump?

A: Common symptoms of problems with a Rexroth hydraulic piston pump include unusual noises, reduced pressure output, overheating, fluid leaks, and erratic operation. These issues often prompt Rexroth hydraulic piston pump troubleshooting to identify underlying causes.

Q: How can I identify the source of a leak in my Rexroth hydraulic piston pump?

A: To identify the source of a leak in a Rexroth hydraulic piston pump, inspect the pump housing, seals, and connections for signs of wear or damage. During Rexroth hydraulic piston pump troubleshooting, using dye or a leak detection solution can help pinpoint the exact location of the leak.

Q: What maintenance practices can prevent issues with Rexroth hydraulic piston pumps?

A: Regular maintenance practices, such as checking fluid levels, replacing filters, inspecting hoses and connections, and ensuring proper lubrication, can prevent issues with Rexroth hydraulic piston pumps. Consistent monitoring is crucial for effective Rexroth hydraulic piston pump troubleshooting.

Q: What should I do if my Rexroth hydraulic piston pump is overheating?

A: If your Rexroth hydraulic piston pump is overheating, first check the hydraulic fluid level and quality. Ensure that the cooling system is functioning properly and that there are no blockages. Addressing these factors can often resolve overheating issues during Rexroth hydraulic piston pump troubleshooting.

Q: How can I test the pressure output of my Rexroth hydraulic piston pump?

A: To test the pressure output of a Rexroth hydraulic piston pump, use a pressure gauge connected to the pump’s outlet. Monitor the readings while the pump is in operation. If the pressure is below specifications, further Rexroth hydraulic piston pump troubleshooting may be necessary to determine the cause.

Q: What are the signs of worn-out components in a Rexroth hydraulic piston pump?

A: Signs of worn-out components in a Rexroth hydraulic piston pump include decreased efficiency, increased noise levels, vibrations, and erratic performance. Regular inspections can help detect these issues early and facilitate effective Rexroth hydraulic piston pump troubleshooting.

Q: How often should I perform Rexroth hydraulic piston pump troubleshooting?

A: Rexroth hydraulic piston pump troubleshooting should be performed regularly, ideally during scheduled maintenance checks or immediately when symptoms arise. Regular assessments help maintain optimal performance and extend the lifespan of the pump.

Q: Can I repair my Rexroth hydraulic piston pump myself?

A: While minor issues may be repairable by someone with basic mechanical skills, significant problems with a Rexroth hydraulic piston pump should be addressed by a qualified technician. Professional assistance ensures proper troubleshooting and repairs to maintain pump efficiency and safety.

Q: What tools are needed for Rexroth hydraulic piston pump troubleshooting?

A: Essential tools for Rexroth hydraulic piston pump troubleshooting include pressure gauges, wrenches, screwdrivers, leak detection solutions, and multimeters. Having the right tools on hand facilitates effective diagnosis and repair of pump-related issues.