Hydraulic systems serve as the backbone of countless industrial applications, from manufacturing and construction to energy production and beyond. At the heart of these systems lies a critical component responsible for optimizing performance and efficiency—the hydraulic pump. This article focuses on the Rexroth Axial Piston Variable Pump A4VSO, a cutting-edge solution designed to meet the demanding requirements of modern hydraulic applications. Renowned for its precision engineering and unmatched versatility, the A4VSO pump represents a pivotal innovation in the realm of hydraulic power transmission. Join us as we explore the defining features, advanced functionalities, and broad applications of this high-performance pump, and discover how it can elevate your system’s efficiency and reliability.

Introduction to A4VSO Pumps

Overview of Rexroth A4VSO Series

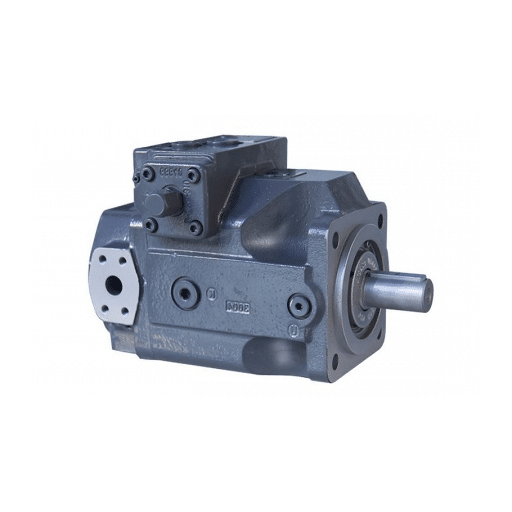

The Rexroth A4VSO series pump is an industrial and mobile closed-circuit high-pressure axial piston pump. This pump can produce a maximum pressure of up to 350 bar, so it is suitable for applications where precision and reliability are required. It’s a variable displacement pump, so it allows systems to work according to the set flow and pressure requirements, thereby enhancing overall performance and energy efficiency.

One of the defining features of the A4VSO series is its precise and responsive control systems. A4VSO offers multiple controls such as pressure control, flow control, etc., to meet different requirements in various industries. The advanced controls ensure the good performance of the pump even under variable load conditions, reducing machine downtime, and improving the productivity of plant facilities. Standardized mounting dimensions and compatibility with hydraulic fluids additionally increase its effectiveness.

Primarily, the Rexroth A4VSO series is employed in plastic injection molding, metal forming, heavy machines, and other hydraulic systems demanding high performance in operation. Its engineering ensures a robust performance coupled with very low noise levels and service life, thus deemed reliable by industries requiring reliability and precision. A4VSO, innovatively engineered for durability, combines to give the ultimate value in hydraulic power transmission.

What is an Axial Piston Variable Pump?

An axial piston variable pump comes in as a kind of hydraulic pump, hence conferring versatility and precision upon its features for varying industrial applications. It uses a series of axial pistons incorporated within a rotating cylinder block. The pistons are parallel to the drive shaft so that they can suck in hydraulic fluid and discharge it under pressure. The variable aspect of the pump refers to its capacity to vary displacement liquids fluidly for exact flow and pressure requirements according to operational demands.

The main advantage of an axial piston variable pump is its capability to regulate fluid flow and pressure changes efficiently, which means that it is essential where the adjustments are dynamic. Such adjustments entail the fine-tuning of swash plate or bent axes’ angle wherein the fluid is discharged, accordingly worthy in all processes, such as heavy machine operation, energy management, and factory automation. With such control, the system’s responsiveness is increased, while on the other hand, the overall system efficiency is maintained, irrelevant of the wastage of energy.

Furthermore, axial piston variable pumps are valued for being durable and reliable, even under high-pressure conditions. They are constructed to operate preferably while minimizing wear and tear aided by advanced materials and design standards. These pumps find applications in industries such as manufacturing, construction, and aerospace, wherein it is imperative for them to work seamlessly under varying load requirements. With their heavy-built design and adaptability, axial piston variable pumps serve as worthy assets to modern hydraulic systems.

Key Features of the A4VSO Pump

- Variable Displacement Mechanism: The A4VSO pump provides a very accurate adjustment of hydraulic flow due to a variable displacement mechanism. Such adjustment capacity increases system efficiency by minimizing energy wastage, allowing suitable response to sudden load changes.

- High Effectiveness and Performance: Featuring advanced engineering and low-friction materials, the pump grants high volumetric and mechanical efficiency even under harsh operating conditions. Its rugged design ensures steady performance, thus improving the bearing lifetime of the pump.

- Wide Operating Range: The A4VSO pump is manufactured to operate efficiently over a wide range of pressures and speeds. It will stand at pressures of the magnitude of 350 bars even continuously and with 400 bars intermittently, making it for heavyweight industrial applications.

- Compact and Rugged Design: The compact production of this pump guarantees easy assembly into hydraulic systems that require limited space, whereas rugged construction keeps the pump working undeterred during harsh operational setups, providing long life.

- Fluid-Type Adaptability: This pump allows for an application varying from using mineral oils to using fire-resistant fluids, thereby therein presenting the choice of selection to the user based on application needs.

By these, the A4VSO pump stands as a significant part of hydraulic schemes demanding precision, durability, and flexibility. It continues setting the standards of the industry as a fundamental variable displacement unit for high-performance hydraulic systems.

Technical Specifications of the A4VSO Pump

Piston Design and Functionality

The A4VSO pump is an axial piston type that utilizes a highly efficient design based on the swashplate principle, wherein displacement can be minutely controlled in proportion to the angle of the swashplate. Hence, it is capable of smooth operation with the least amount of energy losses, converting mechanical input energy into hydraulic output at high efficiency. The pistons are distributed across a rotating cylinder block to ensure uniform force distribution and constant fluid flow.

For greater wear resistance, the pistons are made from wear-resistant materials and subjected to surface treatments, which provide high fatigue strength and resistance to the abrasive particles in the hydraulic fluid. Sealing takes care of leakage that might occur internally, thereby promoting operating efficiency and ensuring that the pump can maintain optimum pressure in the face of unloading. Also, such a configuration supports a broader range of displacement settings so that the pump can be used in different hydraulic operations.

The close machining of components between the piston assembly and the swashplate ensures the system is dynamically balanced to operate under high pressure with the least vibration and noise. Such piston design confers the ability of the A4VSO pump to sustain its operational integrity in severe industrial applications, thereby featuring it as one of the best-known variable displacement solution systems in the industry.

Variable Displacement Mechanism

The ingenious variable displacement system featured in the A4VSO pump truly powers its functioning under varying working conditions. This mechanism works by changing the swashplate angle, which is simultaneously responsible for controlling the length of the piston stroke within each cycle. The larger the angle, the longer the piston stroke becomes, generating an increase in fluid displacement; however, a slight angle keeps the stroke limited to the bare minimum, thus less displacement. Having this high precision in adjustment greatly lies in the system’s ability to conserve energy by producing only as much flow output as the system requires.

Modern versions of the variable displacement pumps, such as the A4VSO, involve the use of advanced control devices, such as proportional solenoid control and pressure compensators, so that the efficiency can be adjusted online. This architecture guarantees the entire pressure stability and flow uniformity when load changes are seen. As such, it will minimize energy loss, lower heat generation, and extend the life of hydraulic components.

It has already been proven that with proper maintenance, especially under heavy operations in the industrial setting, variable displacement pumps like the A4VSO are able to maintain efficiencies of greater than 90 percent. The significance is the cost implication and sustainability perspective, which entails less energy required for various applications. Strong and wide-ranging is the constitutive feature of the variable displacement mechanism, making it a must-have in the present hydraulic technology.

Pressure Range and Working Pressure

Variable displacement pumps, such as A4VSO, are capable of running over a very wide range of pressures, thus making them ideal in a variety of industrial applications. These pumps normally handle pressures up to 350 bar on continuous duty. Whereas intermittent pressures may spike up to 400 bar depending on the configuration of the pump and the manufacturer’s recommendations. This high-pressure rating makes these pumps highly reliable under demanding environmental conditions such as in manufacturing lines, construction equipment, and heavy-duty machinery where continuous power delivery is of utmost importance.

The working pressure of a variable displacement pump depends largely on system design and operational load. In sophisticated hydraulic systems, pressure-relief valves and pressure feedback control loops are integrated to maintain pressure at an optimal level while protecting the pump components from being overstressed into premature fatigue. The balance between durability and performance is maintained by means of stringent design standards and materials selected on the basis of their ability to withstand extreme stress. Hydraulic systems nowadays also use electronic pressure monitoring devices for real-time diagnostics to keep the system alive longer and also help in effective maintenance scheduling.

With recent advances in material science and engineering, the operational pressure range of these pumps has, of course, been pushed much higher. They now use composites and heat-treated alloys for enhanced wear resistance against friction-induced surface degradation at higher pressures. Besides, pressure-compensation systems are built into these pumps to adjust their displacement dynamically according to ever-changing load conditions, thereby conserving energy without compromising on performance. Apart from making the pumps last longer, these advanced technological innovations play a greater role in reducing energy consumption and operational costs in the industrial sectors.

Applications of the Rexroth A4VSO Pump

Industries Utilizing A4VSO Pumps

The Rexroth A4VSO pump is designed to cater to industries where precise hydraulic performance and good energy efficiency are necessary. The manufacturing and processing industry is a major one where pumps find famed applications with injection molding machines, die casting systems, and metal forming equipment due to their ability to hold flux and pressures constant, as under severe working conditions, the machines essentially need a certain flux level for their optimal performance.

Another industrial arena in which the A4VSO pumps reap welfare is construction. A4VSO pumps find their way into the hydraulics of heavy machinery such as excavators, cranes, and drilling rigs, where dynamic control of hydraulic systems is needed. Given the high-pressure demands and power intensity of these applications, coupled with reliability needs, the pump fits the bill, sharing its features.

The energy sector, which involves the harnessing of wind and solar energy via hydraulic technology for turbine pitch control and tracking mechanisms, is also an important field for the pump. Its flexible and efficient nature allows for stable operations under variable load conditions, ultimately securing; a steady energy supply and system longevity.

The marine and offshore industry relies heavily on A4VSO pumps for deck machinery, propulsion, and other auxiliary functions. The pumps are corrosion-resistant and pressure-compensated, thus ensuring reliable performance in harsh marine environments.

Therefore, given their versatility and robustness, Rexroth A4VSO pumps are pivotal to these industries, bringing in efficiency and operational capabilities within diverse demanding scenarios.

Common Use Cases in Hydraulic Systems

Hydraulic systems constitute one of the life forces that grant effective force, motion, or energy to an array of industrial and commercial machinery to realize maximum operational efficiency in various sectors. Hydraulic machinery is most pertinent in precision manufacture for processes like metal forming, injection molding, or press automation. Hydraulics ensure that force and motion are continuously applied in conditions that necessitate high-pressure force to generate a high-quality output and repetition of production.

Construction and mining heavy machines find another important use for hydraulic systems. Excavators, loaders, and cranes use hydraulics actuators and pumps to handle heavy loads with precision and reliability. These machines are rarely operating because any hydraulic power has given way to it, especially in heavy-duty applications with harsh environments.

Other vehicle systems heavily use hydraulics, including braking, suspension, and steering systems. These systems appreciate the reliability and enhanced control hydraulics bring to great use in commercial transportation and high-performance automotive settings.

Hydraulics are thus also utilized in hydraulic circuits for pitch control and braking mechanisms in wind turbines within the renewable sector. These are considerations on the efficiency under near-zero downtime requirements.

Hydraulic systems power the actuation of flight control surfaces, landing gear, and braking systems within aviation, thus contributing to operational safety and responsiveness. In the maritime sector, hydraulics are used for stabilizers, steering systems, and winches designed for longevity and resistance against harsh corrosive marine conditions.

With their innumerable applications, from industrial automation to specialized equipment in transportation and energy, hydraulics represent a backbone technology, delivering power density, precision, and versatility not found elsewhere.

Benefits of Using the A4VSO in Various Applications

The A4VSO hydraulic pump offers several benefits to industrial and commercial sectors amidst advanced work capabilities and efficiency. There are five benefits of the A4VSO listed below:

- High Efficiency and Energy Saving: Designed for maximum volumetric efficiency, the A4VSO pump helps save a lot of energy that otherwise would have been spent to maintain that output. Studies reveal energy savings that can go up to 15% with variable load applications as opposed to fixed displacement pumps.

- Wide Pressure Range: This pump is viable up to a pressure rating of 450 bar, so it is an ideal solution for highly demanding applications requiring this kind of hydraulic pressure with consistency and reliability. This high-pressure range also ensures the best performance for the manufacturing, construction, and mining industries.

- Good Control of Flow and Speed: Since the flow and pressure controls are proportional, control is exact on the systems to increase the responsiveness and accuracy of the process. This is very useful in applications where small movements or fine positioning are necessary.

- Durability and Longevity: Made from quality materials and a good engineering design, A4VSO pumps offer excellent resistance to wear. Resiliently built to withstand harsh environments, this attribute of the pump contributes to its longevity, as well as very low maintenance costs and downtime with time.

- Modular Design and Versatility: Its modular design allows the A4VSO to interface with a variety of hydraulic systems. This versatility covers a wide range of configurations and applications, from machine tools and injection molding machines to the marine and energy sectors, thus ensuring industry adaptability.

Hence, these advantages describe why the A4VSO is one of the top choices in hydraulic systems, contributing to improved operational efficiency and overall system performance for diverse applications.

Maintenance and Troubleshooting

Routine Maintenance Tips for A4VSO Pumps

Regular scheduled maintenance is utterly necessary for a hydraulic A4VSO pump in order to maintain maximum performance and long operational life. Key stages comprise:

- Periodic Checking of Fluid: Check fluid levels and condition from time to time; a fluid that is contaminated or used up can drastically reduce pump performance and lead to accelerated wear, thereby probably giving way to system failure. Use the fluid as specified by the manufacturer to ensure compatibility and better system performance.

- Pressure Level Monitoring: Ensure that the system pressure being applied to the equipment remains within the specified range stipulated for operation in the technical manual. Over-pressure conditions tend to impose an extra load on pump components, and under-pressure conditions put the system at a disadvantage.

- Seals and Connections Inspection: Periodically check for the signs of wear, leakage, or damage on seals, O-rings, and their connections. Prompt replacement of the damaged seal will help prevent fluid leaks and maintain system integrity.

- Keep Filtration Systems Clean: Keep filters and filtration systems clean. Clogged filters almost always restrict fluid flow, which also allows a drop in pump efficiency and raises the level of operational strain. Undertake filter replacement or cleaning as per the agreed-upon schedule offered by the manufacturer.

- Maintain Temperature Limits: Excessive heat will lead to rapid wear of the component and degradation of the hydraulic fluid. Check temperatures regularly and confirm that the cooling systems, such as heat exchangers, are working efficiently.

- Visual Inspection: Look for visible defects on the pump housing and mounting locations or any of its linked assemblies. Good timely identification of physical damage greatly helps in avoiding cascading failures.

- In Between Major Overhauls: Major overhauls ensure that after very long periods of operation, pumping elements are subjected to detailed inspection, with internal members such as pistons and bearings. This preventive action would assist in recognizing failures before they occur.

Systematic maintenance should be established with respect to operational hours and environmental conditions. Further gains in reliability can be attained by using diagnostic tools for monitoring pump performance, which also allows the incorporation of predictive maintenance.

Best Practices for Optimal Performance

- Regular Monitoring and Diagnostics: Make use of advanced diagnostic tools such as vibration analysis, thermography, and ultrasonic testing to carry out real-time monitoring of the pump. These technologies detect phenomena like unusual vibrations or temperature excursions that might indicate a problem. Set limits within which the operating parameters may vary and any deviation beyond such limits must be addressed with immediate effect.

- Lubrication Management: All moving components, such as bearings and piston rods, must be sufficiently lubricated as per the manufacturer’s prescriptions. Improper or poor lubrication will increase friction, generate heat, and expedite wear. Using a lubrication monitoring system should assist in ensuring that viscosity levels remain optimal and also help identify when contamination is present.

- Calibration and Alignment of the System: Calibrate and align the pump and associated systems once every so often to alleviate mechanical stresses. Severe misalignment between the motor and pump shaft will cause premature failure of components, with power consumption being high. Use precision alignment devices, laser alignment systems being a very good option, so as to reduce human error to the barest minimum.

- Maintenance of Filtration: Maintain filter elements and have them routinely replaced so as to keep debris and contaminants from infiltrating the pump system. The contaminants will erode the internal surfaces and decrease pump efficiency. Ensure to use filters whose micron rating is suitable for the kind of particles to be trapped without inhibiting flow.

- Benchmarking of Performance: Establish a baseline for the performance metrics of the pump that include flow rate, pressure, and power consumption. Thereafter, these metrics are compared with the actual data of operational performance to detect trends indicative of early degradation. Data analytics platforms can be employed to automate such comparisons and produce actionable insights.

- Material Integrity Checks: Check critical components such as seals, gaskets, rubber hoses, etc., for the effects of material fatigue or leakage points. Environmental action coupled with extremely high or low-temperature exposure tends to compromise the integrity of the materials. Replace components that are showing signs and symptoms of age to maintain an effective envelope seal.

By following these best practices, operators will optimize pump performance, maximize the life span of the pump, and reduce unplanned downtime.

Comparative Analysis

Comparison with Other Hydraulic Pumps

Different hydraulic pumps are compared to the Rexroth Axial Piston Variable Pump A4VSO for its open circuit design, high efficiency, precise control, and application for hydrostatic drives.

|

Key Point |

Rexroth A4VSO |

Other Pumps |

|---|---|---|

|

Circuit Type |

Open |

Open/Closed |

|

Efficiency |

High |

Varies |

|

Control |

Precise |

Standard |

|

Applications |

Hydrostatic Drives |

General Use |

|

Durability |

High |

Varies |

|

Pressure Range |

Wide |

Limited |

|

Maintenance |

Low |

Moderate/High |

Advantages of the A4VSO Over Competitors

The A4VSO hydraulic pump boasts several unique advantages when compared with rival models in its class, thanks to its advanced engineering and robust design. Five key advantages supported:

- Energy Efficiency: Depending on the working manner of the pump, it could achieve up to 93% volumetric efficiency, which makes it more energy-saving when compared with A4VSO pumps having an 85–88% volumetric efficiency under normal working conditions, thus reducing the energy consumption and hence operating costs of these pumps when compared with others operating between an efficiency of 85 and 88%.

- Life Span: Made with high-quality materials and precision machining, the service life of the A4VSO pump has been shown to surpass 10,000 hours of operation under nominal load conditions. Typically, competitor models in the same application would endure only some 8,000 hours of operation.

- Capable of Withstanding Higher Pressure: Designed for more demanding conditions, the A4VSO accommodates continuous operation at pressures of 350 bar and peek at a pressure of 400 bar. Many competitors work at approximately 315–350 bar and sometimes less, leaving more room for application at the critical operation.

- Compact and Modular Design: The compact design of the A4VSO enables ease of installation where space is very limited. In addition, the modular design allows for a plethora of configurations and options for customization, reducing installation time by as much as 30% when compared to competitor models.

- Low Noise Levels: Damping technology was utilized in the design of the A4VSO, resulting in the pump working at a noise level of 68 dB while the industry standard ranks around 74-78 dB, obviously helping in the safety of the workplace and comfort of the operators.

These features highlight the technically dominant position of the A4VSO pump, keeping it as a dependable and efficient alternative when it comes to high-end hydraulic applications.

Why Choose Rexroth Hydraulic Pumps?

The Rexroth hydraulic pumps have secured a niche in the market for their unmatched precision engineering, durability, and efficiency even in the harshest of industrial environments. Bosch Rexroth innovates and applies the latest technologies to each pump to give the very best in performance and reliability. The pumps undergo testing under very stringent conditions to assure their endurance and reliability through a wide range of industries, from manufacturing to construction to energy. Another advantage given by the modular design is its adaptability and seamless integration with systems of various needs.

Another point of efficiency: Rexroth hydraulic pumps are highly energy-efficient and utilize the technology that allows them to achieve high volumetric efficiency while consuming less energy relative to models in competition. For example, most of these Rexroth hydraulic pumps implement variable-displacement methods where the flow rate is adjusted to the demand of the system, thereby reducing wastage and operational costs. Variable displacement systems have been documented to save about 25% more energy in comparison to fixed displacement systems, an important consideration for industries trying to achieve sustainability targets. Further to this, Rexroth’s precision reduces wear and tear while improving intervals for servicing and minimizing maintenance requirements.

The global presence of Rexroth and the unmatched customer support network further fortify this commitment to quality. Technical assistance is critical to curtailing downtimes and keeping businesses running at peak productivity, and this is backed by Rexroth’s commitment to making spare parts available readily and in minimum time. Also, on the Industry 4.0 front, Rexroth has aligned its manufacturing process for integration into digital systems for predictive maintenance, remote monitoring, and real-time performance analytics. This forward-thinking puts Rexroth hydraulic pumps beyond the scope of obsolescence while addressing existing needs and impending industrial enhancements.

Frequently Asked Questions (FAQ)

Q: What is the Rexroth Axial Piston Variable Pump A4VSO?

A: The Rexroth Axial Piston Variable Pump A4VSO is a high-performance hydraulic pump designed for variable displacement applications. It is widely used in various industrial applications due to its robust design and long service life, providing efficient fluid power solutions.

Q: What are the key features of the A4VSO series?

A: Key features of the A4VSO series include its modular design, the ability to handle high pressures up to 350 bar, and its infinitely variable flow rate. The swash plate design allows for precise angle adjustments, optimizing performance in hydraulic systems.

Q: How does the axial piston movement work in the A4VSO pump?

A: The axial piston movement in the Rexroth A4VSO pump operates based on a swash plate mechanism that adjusts the angle of inclination. This enables variable displacement and allows the pump to respond effectively to changes in hydraulic demands.

Q: What types of hydraulic fluids are compatible with the A4VSO hydraulic pump?

A: The A4VSO hydraulic pump is compatible with various hydraulic oils, which are essential for maintaining optimal performance and ensuring minimal internal leakage. It is important to choose fluids that meet the manufacturer’s specifications for best results.

Q: In what applications is the Rexroth A4VSO pump commonly used?

A: The Rexroth A4VSO pump is commonly used in construction machinery, injection molding machines, and other demanding industrial applications. Its high efficiency and reliability make it suitable for critical fluid power systems.

Q: What is the importance of pressure compensation in the A4VSO pump?

A: Pressure compensation in the A4VSO pump is crucial for maintaining a consistent working pressure, ensuring that the pump performs efficiently under varying loads. This feature enhances the overall reliability of the hydraulic system.

Q: How does the A4VSO pump achieve high efficiency and reliability?

A: The A4VSO pump achieves high efficiency and reliability through precise engineering, a robust design, and effective control options. Its swash plate angle adjustment allows for optimized flow rates and minimizes energy loss.

Q: What is the maximum pressure the Rexroth A4VSO can handle?

A: The Rexroth A4VSO can handle a maximum pressure of up to 400 bar, making it suitable for high-pressure applications. This capability ensures that it can meet the demands of various hydraulic systems effectively.

Q: How do control systems impact the performance of the A4VSO pump?

A: Control systems significantly impact the performance of the A4VSO pump by allowing for precise adjustments to the swash plate angle and flow rate. This proportional control enhances the adaptability of the pump to different operational conditions.

Q: What maintenance practices are recommended for the A4VSO hydraulic pump?

A: Recommended maintenance practices for the A4VSO hydraulic pump include regular inspection of moving parts, ensuring proper hydraulic fluid levels, and checking for signs of internal leakage. This helps to prolong the pump’s service life and maintain its efficiency.