Hydraulic and gear pumps play a pivotal role in powering modern industrial and mobile applications, serving as the backbone of countless machines and systems across industries. Among the leading manufacturers in this domain, Parker Hannifin stands out as a trusted name, known for its innovative engineering and reliable performance. This guide dives deep into the world of Parker pumps, providing an in-depth exploration of their hydraulic and gear pump technologies. Whether you are a technician, engineer, or decision-maker in need of precise and efficient pump solutions, this article will equip you with the knowledge to understand their functionality, features, and practical applications.

Overview of Parker Pumps

Introduction to Parker Pumps

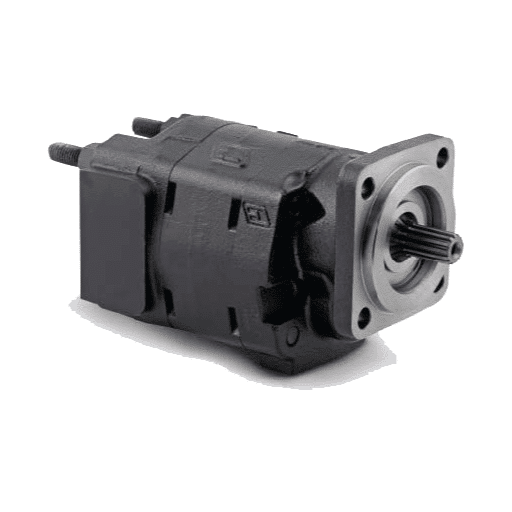

Parker pumps are high-performance fluid power systems intended for use in hydraulic and pneumatic actions involved in various industrial applications. These pumps are designed for an efficient fluid management system, wherein mechanical energy is efficiently converted into hydraulic energy for use in machinery. High on durability and consistency, Parker pumps are used where operations demand exact pressures and flow rates, rendering these pumps popular in manufacturing, construction, and energy sectors.

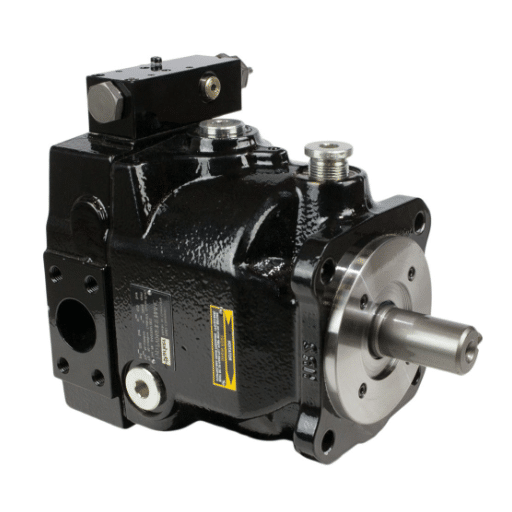

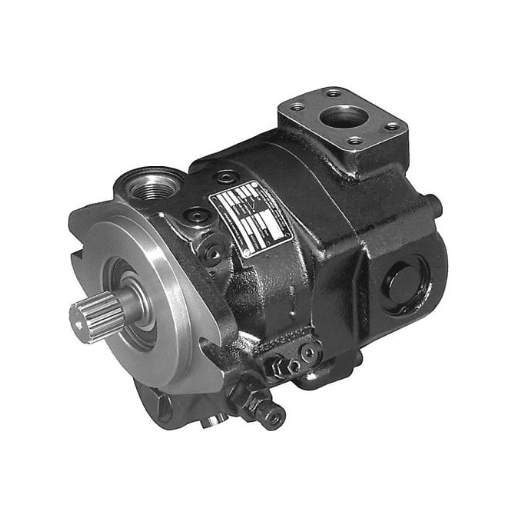

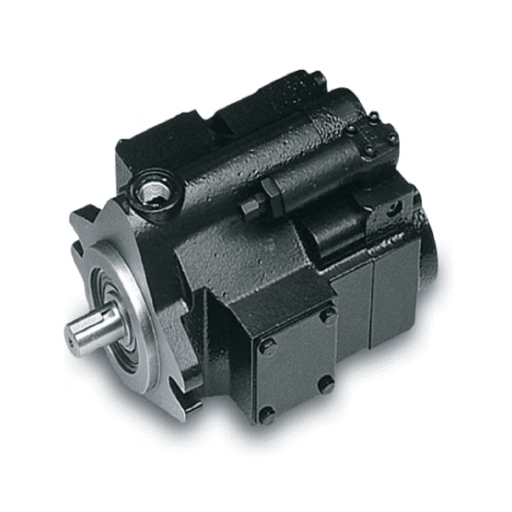

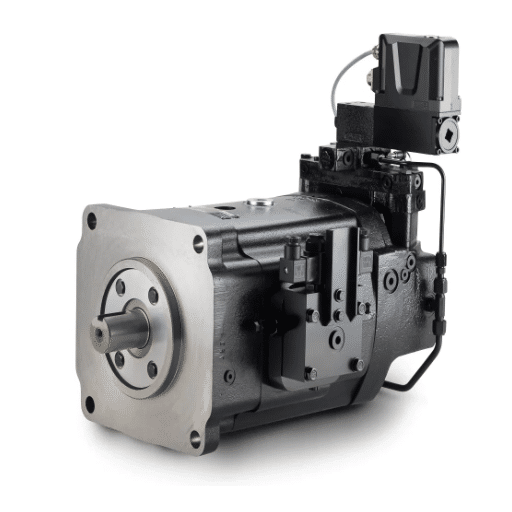

The types of pumps offered by Parker include hydraulic pumps as well as gear pumps, each optimized toward its own set of operational conditions. Hydraulic pumps work in systems where there is control of force and motion, generally in machinery and equipment used in aerospace, agriculture, and material handling. Gear pumps are proficient in the handling of viscous fluids under pressure and are found in oil and chemical processes. The Parker product range thereby assures operational solutions to the needs of any industry, including energy savings and prolonged reliability.

In other words, besides operational efficiency and cost-effectiveness, Parker pumps are important. With such engineering and materials that minimize the use of energy and demand the least maintenance, these pumps do so well in reducing all other operational costs. Their modular, adaptable design is a consideration for taking in different systems. These are the factors accentuating the desirability of Parker pumps in optimizing industrial processes while staying dependable and responsible towards the environment.

Types of Parker Pumps: Hydraulic and Gear

The Parker line of hydraulic pumps was created to provide maximum performance and efficiency in fluid power applications. These pumps operate by converting mechanical power into hydraulic power by way of liquid within the system. They are generally used in sectors like construction, manufacturing, or agricultural operations where steady flows of fluid with high-pressure are imperative. Since a Parker hydraulic pump is built durably, advanced engineering allows controlling it with precision to the degree that energy losses are diminished.

Parker gear pumps are another mostly used choice for applications that require high-speed power transfers reliably. These pumps transfer fluid using meshing gears, making them suitable for systems where simplicity and reliability are basic. They find their applications in lubrication systems, automotive applications, or anything that needs steady, low-maintenance operations. They have a small footprint and are very efficient, thus becoming a solution that can fit in most markets.

Both hydraulic and gear pumps are built with the philosophy of best-in-quality and innovation ingrained in them by Parker. Modular configurations and a wide variety of compatible materials keep these pumps adaptable to the specific operational needs of the end-users. Moreover, Parker has always been in favor of sustainability and energy efficiency, and therefore, ensures their pumps are at par with modern environmental standards without compromising on exceptional application performance.

Key Features of Parker Pumps

- High Performance and Efficiency: Parker pumps are considered the most efficient in their operations due to their optimal utilization of power; hence, low energy cost occurs. A combination of advanced fluid technology and precision engineering assures excellent hydraulic performance in diverse applications.

- Customizable Design Options: Pumps are designed by a modular approach whereby they can be configured by the user to meet particular application requirements. This flexible design extends to the choice of materials, shaft configurations, or mounting options.

- Durability and Longevity: Manufactured with corrosion-resistant alloys and high-strength components and designed under rigid quality norms, Parker pumps may work for a lifetime under demanding conditions cast upon them.

- Sustainability Focus: Environmental sustainability first governs Parker’s design philosophy. In tune with the highest sustainability and regulatory norms, the pumps are designed for low emissions and environmental impact.

- Wide Application Range: Parker pumps cater to a variety of industries on a single level, including aerospace, agriculture, automotive, construction, and factory manufacturing. Their versatility is designed for other applications that satisfactorily encompass hydraulic, pneumatic, or electromechanical solutions.

- Advanced Control Options: Parker pumps use state-of-the-art electronic controls for precise flow and pressure control, integrating IoT-enabled monitoring features and allowing predictive maintenance to ease downtime.

- Stringent Testing and Quality Assurance: Each pump is rigorously tested within controlled environments, achieving performance metrics that meet or exceed industry standards. Through active quality control, Parker ensures that all products are reliable and high performing.

Combining the newest technology with customizable options and energy-efficient solutions, Parker pumps are versatile and future-proof hydraulic solutions to complex industrial challenges.

Benefits of Using Parker Pumps

Efficiency and Performance Advantages

- Energy-Efficiency Enhanced: Parker pumps are specialized to maximize energy usage, costs being reduced by up to 15% over a conventional pump. These improvements are achieved with hydraulic designs and energy-saving mechanisms that minimize power losses.

- Heavy Flows: They are capable of having high flow rates up to 500 GPM (gallons per minute), thus ensuring very rapid and reliable operation under conditions of high demand. This is good for applications that require rapid and constant performance.

- Control with Precision: Serving with modern variable displacement technology, this pump allows very precise flow and pressure regulation, so as to cut down on waste and increase the overall system accuracy. Its responsiveness enhances system reliability and operational safety.

- Durable Construction: Parker pumps are built of corrosion-resistant materials to withstand harsh environments and prolonged usage, thus reducing maintenance requirements and extending product life. Tests indicate up to 20% life extension against standard pumps.

- Quiet Operation: Noise-reduction technology and advanced sound-dampening systems keep Parker pumps operating at low noise levels of 68 dB, making them a perfect choice in locations where noise levels are to be kept low, such as an indoor facility or residential area.

Durability and Longevity in Applications

Parker pumps are well crafted for great durability and longevity in different applications of a demanding nature. The use of quality materials in the construction of these pumps, such as corrosion-resistant stainless steel and wear-resistant polymers, ensures that they retain their highest performing standards in the fiercest kind of industrial environment. Advanced sealing technology also separates the pumps from wear and tear by decreasing friction and providing good lubrication, which increases the frequency of repairs and replacements during the lifecycle. These factors prolong the life of the pumps while also lowering expenses for the users.

One of the features of distinction that sets apart Parker pumps is their ability to operate under high pressures and temperatures without any compromise in respective parameters. They have been tested multiple times, subjected to simulation under so-called extreme environmental conditions, to prove sustainability and reliability. For example, hydraulic systems have a pressure of more than 4,000 psi and a temperature beyond 200°F (93°C) during the operation. Parker pumps deliver in meeting and much more than these expectations. This makes them a good fit for industries where equipment reliability is of utmost importance, such as oil and gas, chemical processing, and heavy machinery.

Parker also goes above and beyond in assessing the health and status of their pumps through the implementation of cutting-edge predictive technologies, such as real-time monitoring systems and digital twin simulation models, which track and analyze wear patterns and formulate recommendations to avoid potential failure. The integration of IoT-enabled sensors within pumps allows users to track critical performance metrics like flow rates, pressure levels, and vibration signals, ensuring smooth system operation. Not only does this greatly lessen the unexpected downtime from damages, noises, and interruptions to system operation, but it also keeps things running smoothly and efficiently, hence making Parker pumps an extremely reliable and sustainable solution for industries that require dependable equipment for the very long term.

Applications of Parker Pumps Across Industries

Parker Pumps in Manufacturing

By making processes more viable and faster, Parker pumps play an essential part in granting enhanced productivity and reliability to manufacturers. Parker pumps find applications in handling various industrial fluids, requiring high pressure and high performance, especially in metal forming, plastic injection molding, or precision machining. Highly advanced with variable displacement capability and energy-efficient motors, Parker pumps help manufacturers to optimize energy consumption and maintain consistent performance at the same time. Additionally, the design also helps in cutting down management costs and promotes contemporary sustainability measures, given that there are now pressing environmental concerns within manufacturing operations.

In several manufacturing applications, Parker pumps are noted for their exquisite control and precision. These pumps, with their extended hydraulic and electronic controls for precision in flow rate adjustment and pressure control, are required anywhere where fine tolerances or process control are placed on a high degree of repeatability in output quality. In the field of automotive manufacturing, some stages of die-casting and stamping rely on Parker pumps, whereby slight deviations in hydraulic pressure could substantially affect the quality of the end product. By controlling pressure and flow with unfailing precision, Parker pumps ensure that manufacturers can produce highly consistent changes with the least wastage.

The design of Parker pumps also enables them to endure the rigors of a demanding manufacturing environment with advanced materials and sealing technology. This ensures that they have durability and have a long working life, thereby curbing maintenance cycles and possible downtime. Moreover, these pumps can be interfaced with condition monitoring systems for predictive maintenance, allowing manufacturers to deal with impending failures before they escalate. This reduces unplanned interruptions, improves operational modifications, and ensures that manufacturing facilities are capable of maintaining high productivity levels in function for extended periods.

Parker Pumps in Oil and Gas

Parker pumps are crucial to the oil and gas industries in an environment where operational reliability, efficiency, and safety are of utmost importance. These pumps are designed to endure extreme pressures, temperatures, and corrosive conditions present in upstream, midstream, and downstream processes. By the use of advanced materials and precision machining, the company has ensured that the pumps are durable and can perform well even in severe conditions, for instance, offshore platforms or desert-type rigs.

These pumps enjoy the reputation of versatility across various applications in the oil and gas sectors. These hydraulic pumps are used by drilling operators to provide precision control and high power output to drive the drilling equipment. These chemical injection pumps deliver additives and inhibitors accurately to maximize production flow and inhibit corrosion of the pipelines. Parker high-pressure pumps are installed in wellhead control panels, hydraulic fracturing, and pressure testing so widely that they comply with the industry’s most stringent standards.

Real-time diagnostics and condition monitoring provided by Parker’s IoT-enabled technology continue to further the operational enhancements. Maintenance can evolve into a predictive practice using this data, thus lessening random incidences of downtime and improving safety protocols. With proven ruggedness, avant-grade features, and customized solutions, Parker pumps cater to the ever-demanding challenges of the oil and gas industry and, at the same time, boost operational efficiencies and cost-effectiveness.

Parker Pumps in Construction

The construction sector utilizes Parker pumps to build efficiency and reliability in a few applications. These pumps with their modern hydraulic systems are designed to meet harsh environments and, thus, they provide excellent performance even under the most trying conditions. On the contrary, the reliability guarantees that excavators, bulldozers, and cranes that need heavy-duty pump capacity for their operation do not function through optimum power till failure.

The other characteristic that places Parker pumps among the very energy-efficient is that a design of precision and advanced flow control methods is utilized. By decreasing hydraulic losses and optimizing power consumption, these systems lower the cost of operations and reduce the environmental impact. Besides, the flexible configurations of Parker pumps allow smooth integration with newer construction machinery, thus offering compatibility with newer technologies like automation and telematics. IoT connectivity enables real-time monitoring and diagnostics to ensure an operator precedes a maintenance action, minimizing downtime and life extension of critical assets.

The construction arena asks for solutions that, aside from merely performing, comply with stringent safety and environmental regulations. Parker pumps adhere to all of those demanding standards, granting leak-proof operations and environmentally safe measures that lessen the hazards of hydraulic fluid contamination. With the advantage of innovation in design and strong working materials, Parker pumps stand equipped to address all demands from residential development to large-scale infrastructure construction requiring marketing and detail.

Maintenance Tips for Parker Pumps

Routine Maintenance Practices

Proper maintenance of Parker pumps guarantees that the pumps will deliver the best performance, will have a longer operational life, and will be spared from unexpected downtimes. A systematic approach to routine maintenance would require inspection of all components regularly. Check for wear and tear, corrosion, and leakage in essential parts such as seals, gaskets, and connections. It is, therefore, necessary to clean the exterior surfaces to avoid the accumulation of dirt or debris, which can hinder the working of the pump. It is also important to take care that proper alignment is maintained and that bolts and fittings are tightened enough to ensure stability in operation, yet not too much as to cause distortion.

Lubrication is yet another pivotal process in maintaining the life of the pump. Over a given period, enough time could have elapsed so that the lubrication could degrade due to the environment or the mere passage of time, thus increasing the friction and wear in the internal components. Oil changes or lubrication replenishment should be carried out as per the recommended interval. Using only compatible high-quality hydraulic fluid that meets OEM specifications whenever replenishing hydraulic fluid in Parker pumps would be best. Also, keep monitoring the fluid levels and contamination in them, as any such events could be severely detrimental to pump performance and functionality.

Finally, performance testing on a regular basis can help identify early-stage problems before they develop into significant malfunctions. Employ diagnostic measuring instruments for flow rates, pressure, and temperature. These readings enable assessment of the pump’s performance and determine whether calibration or repair is needed. Keep detailed records of maintenance operations, including the dates and types of inspections, repairs, and replacements. Such records prove useful for troubleshooting and increasing operational reliability over time. Hence, with these practices in conjunction with modern technology and following manufacturer guidelines, Parker pumps can offer superior performance even under the hardest operating conditions.

Common Troubleshooting Techniques

Effective troubleshooting of Parker pumps requires a step-by-step approach for appraising potential problems, combining precise inspection with data analysis. Conduct a complete visual inspection of the pump and the associated componentry, noticing anything unusual that inspires doubt over wear-and-tear, leakage, loose joints, or any odd sounds emanating from operation. Also, take measurements for the presence of corrosion or contamination in the hydraulic oil, given that all may affect the efficiency and performance.

Then check to see whether the values of the system, such as pressure, flow, and temperature, are as they are supposed to be according to the manufacturer’s specifications. This way, precise measurement values can be obtained, which would help identify any irregularities. Equipped with state-of-the-art sensor systems or condition monitoring software, one can work with diagnostics in the form of real-time data and predictive analytics rather than reactive approaches.

In cases of erratic operation or sudden dips in performance, one has to look into the internals of the pump. With the air in the fluid or lack of fluid being the two most common causes, cavitation will typically present itself as a sudden drop in efficiency or noise. Also, make sure that the pump’s driving motor voltage and current are within expected limits; otherwise, electrical issues might disturb its operation.

Maintenance records can be particularly helpful in finding repeat issues or parts that seem to fail too often. From here, you can narrow down the fundamental causes and make informed decisions on whether a repair or a replacement is most appropriate. By combining the procedural methodologies with modern advances in diagnostic technology and basing the course of action on best practices, operators achieve a reliable performance of pumps for the long term.

Maximizing Lifespan and Performance

The transition from industrial pumps to equipment is based on inertia and preventive care to keep up with maximizing lifespan and efficiency. Preventive maintenance comprises scheduled inspections, routine servicing, and the deployment of a host of diagnostic tools to ensure that potential problems are discovered ahead of actual failures. Lubrication analysis, filter changes, seal inspections, monitoring operational parameters such as flow rates and pressure, and so forth, rank among the common procedures. Research shows that vibration analysis and ultrasonic monitoring are best at early recognition of bearing wear and shaft misalignment, which are two primary contributors to downtime.

Besides that, predictive maintenance is being introduced with IoT-enabled sensors and advanced analytics to support more data-driven decision making. These technologies assist in gathering performance metrics in real-time and accurately identifying and tracking deterioration trends. For example, it has been proven through studies that this can reduce maintenance costs by as much as 30% while increasing equipment uptime by almost 25%.

Through smooth integration, the two sets of maintenance approaches can help operators make systems more durable and efficient. This will ensure optimal performance through the maintenance of risks associated with sudden breakdowns, thus ensuring increased reliability on the operational front and cost-efficiency.

Recent Trends in Pump Technology

Sustainability Initiatives in Pump Design

Sustainability would appear to have been at the heart of modern pump design in a continuum of development that operates on technical and environmental considerations. Here, several initiatives aim at making energy-efficient pumps that consume the least power with no compromise on performance. With newer materials, optimized hydraulics, and variable frequency drives, manufacturers strategized their energy consumption to develop competitive pumping systems. The energy-efficient approach leads to greater carbon footprint reductions toward underlining broader sustainability initiatives.

Another well-known theme is to produce pumps using recycled or other environmentally friendly materials. Parts made from recycled metals, polymers, or composites reduce the depletion of natural resources and lessen negative environmental impact during production. Also, manufacturers are increasingly shifting focus to designs that facilitate maintenance, repair, and recycling at the end of the product life cycle. This pro-circular economy approach will give new life to expensive components, thereby greatly diminishing waste in the long run.

Digitalization will be the paramount enabler of sustainable pump operations. With the Industrial Internet of Things (IIoT) being embraced, pumps may be monitored in real time, and predictive maintenance may be carried out, thereby guaranteeing that pumps are operating at maximum efficiency and unnecessary resources are never consumed. Such systems also provide precise performance data for operators who can then make decisions that support sustainability targets. With the gamut of innovations, the pump sector is heading toward a future that balances environmental concern with operational excellence.

Energy-Efficient Solutions in Parker Pumps

Parker pumps have always been leaders in energy-efficient technology while focusing on sustainability without sacrificing performance. These pumps use advanced hydraulic systems and precision engineering to limit their requirement of energy requirements. It is worth noting the use of VFDs, where variable frequency drives govern pump speed with power consumption perfectly adjusted to the set demands of the system in real-time. The pump is thus put to work only when required, and it saves energy, while the uneconomical operation can shorten the life of the equipment.

State-of-the-art materials and designs employed by Parker promote good fluid flow with as few frictional losses as possible, thereby enhancing overall pump efficiency. Using CFD modeling in the design phase allows the company to smooth out the flow path and ensure optimum operation under differing conditions. For continuous-duty or heavy-demand applications, they provide energy-saving, multi-stage pumps through better load sharing and reduction in downtime for maintenance.

Studies have shown that the proper integration of Parker energy-efficient pumping solutions into an industrial or commercial system can yield energy savings of up to 30% over conventional pump designs for their target applications. Such innovations align with ISO 50001 and other global energy efficiency measures as well as comply with the basis of international regulations for environmental protection, thus validating Parker’s position at the front line for the sustainable solution to fluid handling.

Frequently Asked Questions (FAQ)

Q: What is a Parker Pump?

A: A Parker Pump is a type of hydraulic pump manufactured by Parker Hannifin, designed to provide efficient fluid movement in various applications. These pumps are known for their reliability and performance in systems that require high pressure and precise control.

Q: What series of Parker Pumps are available?

A: Parker offers several series of pumps, including the P1/PD series, PGP series, and the PVP series. Each series is tailored for specific applications, ensuring optimal performance and compatibility with different hydraulic systems.

Q: How does a Parker Pump piston work?

A: The piston in a Parker Pump operates by moving back and forth within a cylinder. This motion creates a pressure differential that draws fluid into the pump and then forces it out under high pressure, making it essential for hydraulic systems.

Q: What are the common troubles associated with Parker Pumps?

A: Common troubles with Parker Pumps can include leaks, unusual noises, and decreased performance. These issues may arise from worn components, improper installation, or lack of maintenance, and should be addressed promptly to avoid system failure.

Q: How do I order replacement parts for my Parker Pump?

A: To order replacement parts for your Parker Pump, you can visit the official Parker Hannifin website or contact a local distributor. It’s important to have the specific model and series information available to ensure you receive the correct components.

Q: What role does a valve play in a Parker Pump system?

A: A valve in a Parker Pump system regulates the flow of hydraulic fluid, directing it to various components as needed. This ensures that the system operates efficiently and safely, preventing pressure build-up and potential damage.

Q: Can a Parker Pump be used in an engine application?

A: Yes, Parker Pumps can be used in engine applications, particularly in hydraulic systems that require lubrication or cooling. Their reliability and efficiency make them suitable for various engine-related tasks.

Q: How can I troubleshoot my Parker Pump?

A: To troubleshoot your Parker Pump, start by checking for leaks and unusual noises. Inspect the hydraulic fluid levels and ensure the pump is correctly installed. If issues persist, consult the user manual or contact a professional for assistance.

Q: What maintenance is required for a Parker Pump?

A: Regular maintenance for a Parker Pump includes checking fluid levels, inspecting for leaks, and replacing worn components as needed. Following the manufacturer’s guidelines will help ensure the pump’s longevity and optimal performance.