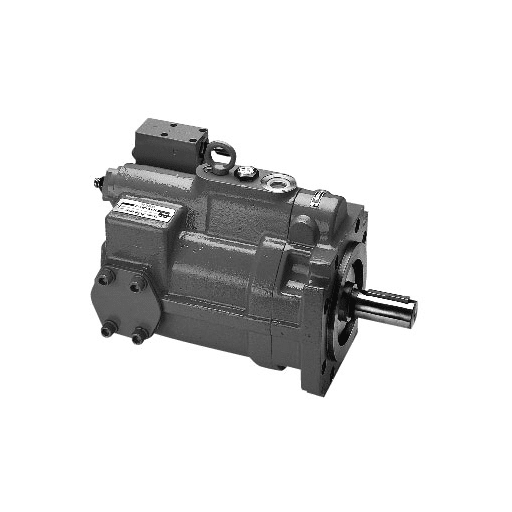

The Nachi Piston Pump stands as a vital component in modern hydraulic systems, renowned for its efficiency, reliability, and advanced engineering. Whether you’re an engineer, a technician, or simply someone researching high-performance hydraulic solutions, understanding how this pump operates and its wide-ranging applications is essential. This guide aims to provide a detailed examination of the Nachi Piston Pump, covering its design, functionality, key features, and benefits. By the end of this article, you’ll have a clear insight into why this pump is a trusted choice in industries ranging from manufacturing to construction. Join us as we uncover everything there is to know about the Nachi Piston Pump and its pivotal role in optimizing hydraulic performance.

What is a piston pump?

Getting into the Mechanics Behind Piston Pumps

Piston pumps work on the principle of positive displacement, wherein a piston moves within a cylinder to pressurize and transfer hydraulic fluid. This method starts with mechanical energy being transformed into hydraulic energy by the rotation of the pump’s drive shaft, thus creating a differential head. The engine’s cam/crank mechanism drives the piston’s stroke in two phases: suction and compression. During the suction phase, the hydraulic fluid is drawn from the reservoir into the pump chamber. Simultaneously, during the compression phase, the fluid is dispensed through an outlet port, thus elevating the pace and pressure to a constant level.

Axial and radial types are applied for optimizing efficiency and performance in modern piston pumps, such as the Nachi Piston Pump. The axial piston pump places the pistons in parallel with the drive shaft, utilizing swash plates in many cases for varying the flow rates. In contrast, radial piston pumps have pistons set perpendicularly to the drive shaft, granting them very high-pressure capabilities. Both designs maintain very accurate fluid control with minimal energy loss and adaptability to different industrial applications.

Improvements in piston pump technology also paved the way for the implementation of wear-resistant materials, optimized internal geometries, and advanced sealing methods. Such advancements improve the pump’s durability, reduce its maintenance requirements, and thereby guarantee fine performance even under adverse conditions. The piston pumps have become an essential component of hydraulic systems within numerous industries under stricter operational demands.

Notable Features about Piston Pumps

There are several key aspects associated with these systems that make them highly efficient in their operation within various industrial sectors, especially those involving hydraulics, as explained below:

Firstly, they have a High-Efficiency rating, usually between 85% and 95%, depending on specific design factors and the operation mode. It is normally because of a high degree of sealing that fluid leakage is reduced and, therefore, helps in the optimal energy transfer.

Secondly, it is capable of handling fluids of different viscosities, suggesting a multipurpose usage involving oil, among other highly viscous liquids. The piston’s diameter and length can be customized, thereby leading to adjustable displacement volumes that are typically within the ranges from 0.1 up to 1000 gallons per minute (GPM).

Moreover, piston pumps can generate high pressures, often exceeding 5000 psi, making them ideal for applications that require forceful fluid movement. Flow stability may be significantly enhanced through the use of a multi-piston arrangement that minimizes pulsations, which should be avoided in processes such as those needing uniform fluid flow.

Finally, a design flexible enough to include alternatives like variable speed drives or electronic controls allows flow modulation concerning pressure, meeting specific requirements put upon different hydraulic systems.

The Role of Piston Pumps in Hydraulic Systems

Essential Functions in Various Applications

The Nachi Piston Pump has been engineered with precision to ensure hydraulic performance throughout a wide range of industrial applications. Basically, the function implies the transfer of fluid efficiently at different pressures against loads. This is possible through the sophisticated axial piston design, which ensures no variation in flow rates and limits energy loss during operation. The pump in manufacturing industries is used for powering hydraulic presses and injection molding machines in instances where precision and duration of application are paramount.

Additionally, in construction, due to its solid build and ability to generate high pressures, this pump is crucial for heavy machinery such as excavators and cranes, which require reliable hydraulic power with no interruptions. The variable displacement feature further improves the adaptiveness of the pump by regulating output flow to meet operational requirements efficiently, thereby saving energy.

Furthermore, it is an ideal option for any installation where space-saving and quiet operations are essential, thanks to its compact size and minimal noise emission. Resultantly, the blend of versatility, durability, and engineering makes Nachi Piston Pumps a product that can endure the rigors of today’s industrial applications, delivering excellent performance with very little downtime.

Enhancing System Efficiency with Piston Pumps

Piston pumps are crucial to the working of a high-pressure hydraulic system in industrial applications. This ability to generate very high-pressure outputs with a set flow rate results from the power of the internal components’ pistons that compress and move fluid inside a cylinder as it rotates with the shaft. This high-pressure performance, therefore, is most suited for scenarios where there is a need for pressure control, e.g., heavy lifting machinery, manufacturing systems, and aerospace technologies.

Another noteworthy feature of piston pumps is their volumetric efficiency, which is mostly above 90% and allows for the least energy loss during operation. In addition, the implementation of new materials and innovative coatings into recent designs of piston pumps has also contributed to working against wear, thereby giving them longer operating lives even while situated in harsh environments. They develop this further with variability in displacement, meaning the system itself can be adjusted as to fluid flow or pressure strengths to the arrangement it searches in real-time relative to the work placed upon it, thereby saving on a lot of energy.

Recent developments in sensor technology and digital monitoring techniques have been integrated with piston pumps for best performance. With the ability to integrate real-time diagnostics and predictive maintenance alerts, deviations may be detected early to maximize system uptime and avoid expensive unplanned maintenance. These smart features, along with their traditional attributes, will keep piston pumps in demand for industries striving for reliability, precision, and energy efficiency.

Exploring the Applications of Piston Pumps

Industrial Uses of Piston Pumps

Because of their high-pressure generation capability of fluid transfer with high efficiency, piston pumps have high and extreme usage in many industries. Accessing pressure through a temporary up and down movement, piston pumps exert a stroke against the liquid being pumped, providing a certain rate of flow from the pump inlet to the pump outlet despite varying pressures during work conditions. It can be poured on any kind of liquid that comprises viscous-liquid slurry, abrasive, or corrosive on the surface to cause extreme wear and tear.

Hydraulic systems are among the prime applications for piston pumps in industries like manufacturing, construction, and automotive. Piston pumps establish the hydrostatic pressure required to operate machinery, tools, and heavy equipment efficiently. Piston pumps are also found in large quantities in the oil and gas sectors, where the extraction and refining of crude oil require high pressure and very precise flow control.

Chemical processing industries benefit from piston pumps for metering, dosing, and transferring chemicals with precision. Their materials of construction, such as stainless steel, resist chemical corrosion, ensuring operational reliability and long life. In addition, the food and beverage sector relies on piston pumps for hygienic liquid transfers-tightening the legal requirements for the sanitary nature of their operational systems with syrups, oils, and the like. This highlights their corollary indispensability in modern industrial operations.

Specialized Applications in Heavy Machinery

Piston pumps are widely used by industries to be a staple in heavy machinery due to their ability to withstand high-pressure environments and offer precise fluid metering. Specialized design allows them to be efficient in handling the severe operating conditions that processes require. Presented below is a detailed list of five specialized applications of piston pumps in the heavy machinery sector:

- Hydraulic Excavators: Piston pumps constitute part of the hydraulic systems of excavators. They produce the necessary hydraulic pressure to control the movements of the boom, arm, and bucket, which amounts to efficient operations. Independently, all completions are ready and willing to work at pressures exceeding 5,000 psi to hold heavy loads with exactness.

- Construction Cranes: High-pressure piston pumps are needed for driving hydraulic cranes to lift and lower heavy materials with precision. By constantly ensuring the maintenance of pressure even when there are different load conditions on the lifting system, they are a valuable contributor to the highest performance of heavy-lifting systems.

- Agricultural Tractors: Pistons are used in the advanced agricultural equipment, particularly tractors, for hydraulics needed to operate plows, seed drills, and other implements. The working system depends on piston pumps to hold pressures in the range of 2,000-3,500 psi.

- Mining Equipment: For the underground mining applications like drilling rigs and loaders, piston pumps are needed to provide hydraulic pressure for heavy-duty operations. Under abrasive conditions, a piston-type pump will not only work but also serve well, even under severe climatic stresses.

- Industrial Presses: In many heavy industrial presses, including metal forming and forging, piston pumps are employed in the hydraulic system. They enable the rapid application of force, often over 10,000 psi, used to change the shape of metal workpieces with precision.

Each domain emphasizes the heavy reliance that heavy machinery places on durability, efficiency, and precision of piston pumps, thus truly standing as the backbone of modern industrial activity.

Versatility in Different Hydraulic Systems

Piston pumps are essential components of a large family of hydraulic systems; in fact, their adaptability spans a broad range of industrial and commercial applications. Being able to generate pressures as high as 40,000 psi makes these pumps useful wherever exact force and control are of the essence in operations. Axial piston pumps are usually employed in systems of closed-loop hydraulics that need a ubiquitous power generation, e.g., compactors, excavators, and other heavy construction equipment. The radial piston kinds, on the other hand, fit open-loop hydraulic designs also because they retain efficiency with varying load and flow demand from a system.

Piston pumps hold the most prominent advantage in being able to operate with all sorts of fluids disadvantage that does not plague some other kinds of pumps-and this includes water, oil-based hydraulic fluids, and a dozen synthetic substitutes. This functionality thus ushers them into sensitive environments and industries where conventional fluids cannot be used, for example, marine applications and systems that necessitate a biodegradable fluid. Another enhancement in modern piston pumps comes from minimizing internal leakage, a design factor that directly increases volumetric efficiency and ultimately aids in the reliability of the whole system.

The employment of modern materials and fine engineering practices has further enhanced the flexibility of piston pumps in hydraulic systems. For instance, ceramic-coated pistons and corrosion-resistant materials are now more and more frequently being used to resist harsh environments and increase longevity. Similarly, from the standpoints of smart technologies, integrated sensors, and electronic controls promote the real-time monitoring of performance and predictive maintenance, with the effect of reduced downtime and optimized efficiency. Since this versatility emphasizes the focal importance of piston pumps in modernizing hydraulic systems, they have proved capable of addressing industrial concerns of the present time while pushing boundaries on innovation and efficiency.

Why Choose Nachi Piston Pumps?

Advantages Of Nachi Technology

Nachi Technology is famous for its cutting-edge innovations and engineering solutions that affect productivity, reliability, and precision across all industries. Alignment with data and insights follows with five key advantages of Nachi Technology:

- High-Precision Manufacturing: With precision CNC machining techniques and robotic automation, Nachi Technology has achieved manufacturing tolerances that meet the needs of extremely fine applications, providing service for aerospace and medical equipment requiring precision with accuracy of tolerance up to ±0.001 mm.

- Energy Saving: The products and systems designed by Nachi achieve optimum energy consumption. Reports prove that factories with servo motors and hydraulic systems of Nachi gained 30% less in energy consumption, thus saving cost and being environmentally friendly.

- Extended Equipment Life: Employing strong materials along with proprietary coating technologies, Nachi ensures its instruments and components are capable of withstanding much wear and tear. Nachi bearings, for instance, last a full 45% longer than other bearing types in the market, consequently bringing down downtime and maintenance costs.

- Integrated Automation Solutions: Nachi’s automation technologies integrate robotics and AI-powered systems for streamlining production lines, thereby enhancing operational efficiency by 40% and improving production quality from the standpoint of automotive and electronics manufacturing.

- Global Support and Customization: Backed by an ever-growing global technical support network, Nachi provides solutions tailored for diverse client needs. These customizations enable industries to embrace technology that adapts seamlessly to their operational requirements, causing an improvement of up to 20% in performance metrics, according to client case studies.

Focusing on innovation, efficiency, and solutions put forth for the customer, Nachi Technology continues to uphold new standards across industries that demand precision and reliability.

Quality And Reliability Of Nachi Products

The Nachi brand is associated with quality products known for their reliability, a reputation that has been built on extensive testing and compliance with international standards. Such is the case since various factors, such as the choice of materials used in their manufacture, have contributed to the long life and high performance characteristics of these items. These include:

- Manufacturing Standards: Nachi’s quality systems are accredited by ISO 9001, which ensures consistent quality control across all its product lines and justifies its claim that it is continually improving while keeping its customers satisfied.

- Endurance Testing: For this kind of test, a wide range of hydraulic parts undergo this procedure for endurance simulation purposes, providing a viable answer to durability with an average estimated life span quoted at above 10 thousand hours in continuous working conditions.

- Performance Metrics: The pumps can operate efficiently under maximum pressures of up to 4000 psi while maintaining a constant flow rate, contributing towards optimal functionality within any given hydraulics system.

- Quality Control Measures: Advanced manufacturing techniques ensure reliability by detecting and correcting any potential defects before production phases are complete; thus, strict dimensional accuracy and functional testing are carried out on them during inspection.

These indicators manifest Nachi’s commitment towards creating world-class brands that meet buyers’ demands within various industries.

Efficiency And Performance Of Nachi Piston Pumps

The pumps of Nachi must have been designed to meet the demand to operate efficiently on a reliable basis within diligent applications. A feature that stands out is the extreme precision in component design that stands to lose hardly loses any energy and ensures the utmost hydraulic output. Built with wear-resistant materials, capable of obstructing the transfer of scratches from dust particles into the working surfaces of pump parts, these pumps could work long hours without stopping for maintenance.

Maintaining the optimized volumetric efficiency, the Nachi piston pumps can operate at high pressures whilst maintaining excellent precision and control. Dynamic capacity adjustments and control factors contribute to the smooth transition of the pumps when reacting to changing load conditions, offering great operational flexibility; for instance, variable displacement mechanisms ensure that energy loss is kept at a minimum by having the hydraulic output matched to the specific requirement of a task.

Application data from many working sites shows that these pumps operate very often above the 90% efficiency rating, establishing them as one of the top leaders for hydraulic systems. In addition to this, their sturdy structure and noiseless features provide an edge in applications in fields such as construction, manufacturing, and heavy equipment operations. In factory settings combined with cutting-edge technologies and stringent testing standards, Nachi piston pumps prove to be a foregone choice for professionals demanding the finest hydraulic solutions.

Proper Use and Maintenance of Nachi Piston Pumps

Best Practices for Operating Piston Pumps

In order for piston pumps to perform efficiently and reliably, it is important that specific detailed best practices are followed. First is maintenance: seals, valves, and lubrication systems require periodic inspection, and care must be taken to ensure that any wear is not allowed to infringe upon the efficient working of the pump. Next is handling of the pump; this must always be within the limits of pressure and temperature for which it was specified. Anything beyond this can cause a premature failure of parts.

Prime it properly to prevent cavitation, so the cavitation never reduces the flow rate, compromising internal components along the way. Use should be made of clean fluids, without any contaminants, and those by the stipulated requirements of the pump, as any abrasions introduced due to contaminants would hurt life. Tracking system performance through operational data such as flow rates, discharge pressure, and energy consumption allows much insight into the condition of the pump and hence gives an alert to symptoms that the pump is showing.

If all these best practices are followed meticulously, the operator will go a long way in ensuring that piston pumps become more reliable, safe, and serve long in respect of almost all applications.

Routine Maintenance and Care Tips

The key to sustaining piston pump performance for the long haul lies in proper maintenance and care. One way to achieve this is to schedule inspections so that one can detect wear and tear before it culminates in failure. This includes assessing seals and gaskets, as well as other components likely to degrade. Lubricating moving parts prevents friction and overheating, so the use of oils recommended by manufacturers is highly encouraged.

If contaminants find their way into the system, they tend to cause premature failure. Hence, equipping the system with filters that offer high levels of filtration capability can help. Routine filter replacements also guard against such damage. Setting operating parameters within acceptable ranges, such as pressure and temperature, reduces undue stress on the pump. Ensuring compatibility of fluids used in the system according to equipment manual specifications also works towards efficient operation.

Keeping detailed records on maintenance activities such as remedial and predictive works, component replacement, and measuring performance fosters trend analysis. Operators achieve reduced downtime, enhanced productivity, and considerably more consistent performance through the adoption of such methods.

Troubleshooting and Extending Pump Lifespan

Effective troubleshooting is an integral part of sustaining a pump’s performance and its operational lifespan. While cavitation, overheating, or abnormal vibrations are common problems, these conditions are usually caused by improper flow, wear of the internal components, or alignment issues. Operators should be familiar with indicators, such as erratic discharge pressure, abnormal noise, or operating temperature, as these warning signs can mitigate further damage if addressed promptly.

To ensure longevity, first, operate the pump within its rated capacity range. Being overloaded or operating at one end of its capacity range stresses the system unnecessarily. If lubricating is due, use the lubricant recommended in the manual to reduce friction and wear of the moving parts. Keeping the filters and seals clean will allow fewer contaminants inside the pump, which otherwise is almost always a cause for premature failure.

Adopting cutting-edge innovations in condition monitoring technology can certainly prove to be an asset in troubleshooting and life extension. Vibration analysis, thermal imaging, and flow rate sensors provide real-time records that help in identifying potential issues, allowing for timely interventions. Predictive maintenance software feeds on historical data and is capable of precisely predicting when the equipment will need maintenance. These software packages not only enhance maintenance results but also minimize functional downtime and repair costs.

Proactive maintenance combined with advanced diagnostics will promote reliability and efficiency across pumping systems, thus reducing their ownership costs.

Frequently Asked Questions (FAQ)

Q: What is a nachi piston pump?

A: A nachi piston pump is a type of hydraulic pump that utilizes a piston mechanism to generate flow and pressure within hydraulic systems. This pump is designed for high efficiency and stable operation, making it a popular choice in various industrial applications.

Q: How does a variable volume piston pump work?

A: A variable volume piston pump, such as the Nachi piston pump, operates by adjusting the displacement of the pistons to control the flow rate and pressure. This mechanism allows for energy-saving operation by ensuring that power is used effectively by the load requirements.

Q: What are the advantages of using NACHI Hydraulics?

A: The advantages of using NACHI hydraulics include high efficiency, precision engineering, and a world-class design that enhances the performance of hydraulic power systems. These pumps are also known for their durability and low maintenance requirements.

Q: Can Nachi piston pumps help reduce hydraulic costs?

A: Yes, nachi piston pumps can help reduce hydraulic costs by providing an energy-saving solution that conserves energy during operation. Their efficient design minimizes excess discharge and improves overall system performance, leading to lower operational expenses.

Q: What types of applications are suitable for nachi piston pumps?

A: Nachi piston pumps are suitable for a wide range of applications, including manufacturing, construction, and agricultural machinery. Their ability to handle varying pressure levels and flow rates makes them versatile for different hydraulic systems.

Q: How do Nachi piston pumps ensure stable flow and pressure?

A: Nachi piston pumps ensure stable flow and pressure through their innovative design, which includes a semi-circular barrel swash plate that receives pressure on its surface. This mechanism allows for precise control of the discharge volume, contributing to reliable system performance.

Q: What is the typical pressure range for NACHI piston pumps?

A: The typical pressure range for NACHI piston pumps can vary, but they are designed to operate efficiently at pressures often exceeding 3000 psi. This high-pressure capability makes them suitable for demanding hydraulic applications.

Q: What maintenance is required for NACHI piston pumps?

A: Maintenance for nachi piston pumps generally involves regular inspections, checking fluid levels, and ensuring that all components are in good working condition. Keeping the pump clean and addressing any signs of wear can help prolong its lifespan and maintain optimal performance.

Q: How do Nachi piston pumps contribute to energy efficiency?

A: Nachi piston pumps contribute to energy efficiency by utilizing a design that minimizes energy losses during operation. Their ability to adjust displacement allows for effective use of power corresponding to the load, which conserves energy and reduces operational costs.