Hydraulic systems play a crucial role in a wide range of industrial and mobile applications, and among the key components driving these systems are hydraulic pumps. Muncie hydraulic pumps, known for their reliability and efficiency, represent a pinnacle of engineering excellence. This blog delves into the diverse applications and benefits of Muncie hydraulic pumps, highlighting their importance in optimizing performance across various industries. From construction machinery to agricultural equipment, these pumps are integral to enhancing operational throughput and minimizing downtime. As we explore their features and capabilities, you will gain insights into how Muncie hydraulic pumps can be leveraged to achieve superior results in your specific field.

What is a Muncie Hydraulic Pump?

Basics of Muncie Pumps

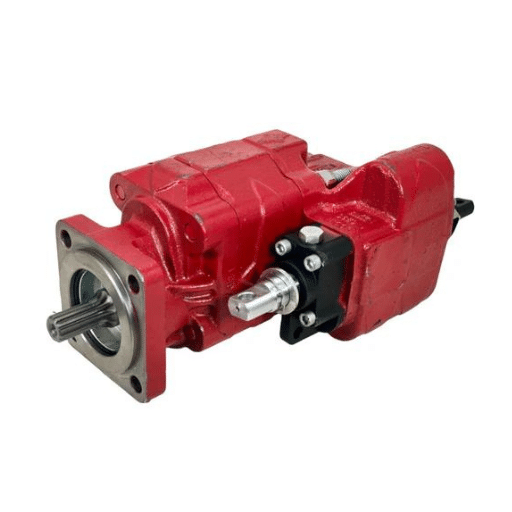

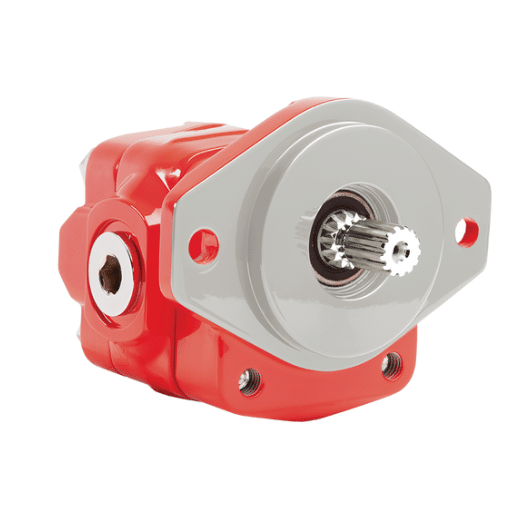

The path taken by Muncie hydraulic pumpsis a mechanical engineering pump that is intended for converting the power of motion into hydraulic power. In other words, Muncie Pump is very simple in making and is seemingly easy in use – it simply functions by means of the principles of displacing fluids to endorse or generate flow in order to pass on power in the form of pressurized fluids. Generally labelled and described in terms of stability and accuracy of Muncie pumps, they meet the wider line of provisions extending in essence from the gear to vane or piston pump types Muncie P. This added features regarding these contractors enable them to enhance the standards and operations of pumps hence using the Munc applicants is quality. In industries that use Muncie hydraulic pumps, it is possible to reduce energy expenses, enhance reliability of work in the works and increase longer actively working lifespan.

How Does a Hydraulic Pump Work?

A hydraulic pump functions by transforming mechanical energy into hydraulic energy via the motion of fluid displacement for the movement of machinery and energy within a hydraulic system in engineering works. The cycle commences with the suction when the hose of the pump is placed in a tank full of liquid, and the liquid is pulled by the piping from the reserve. The internal arrangement of the pump, which can be to include the use of gears, pistons or vanes, tends to compress the fluid thereby increasing the speed and force of the fluid. The hydraulic fluid under pressure is transferred into the hydraulic cylinders or motors to perform useful work such as lifting, thrusting, or turning machines parts. Through continuous delivery of the compressed liquid, the head or body of the pump is engaged in the pump and allows the system to function without hindrance.

Key Features of Muncie Hydraulic Pumps

- High Efficiency: A given Muncie hydraulic pump is manufactured wusingoutstanding design techniques, areducing power waste and enhancingthe functioning of the complete system.

- Durability and Reliability: Muncie pumps are famous for their durability and performance even in highly demanding conditions. They are manufactured from heavy-duty materials and advanced technology.

- Versatility: HHigh-performanceMuncie hydraulic pumps for sale offer piston, vane ,and gear pump configurations , which allows designersto meet the needs of many industries in dheir systems.

- Space-Saving Configuration: Iuncie ppumps’ innovative designsare complemented by their small size ,which allows these products to be effortlessly implemented into txisting systems, thus enabling space maximization without losing efficiency.

- Low Maintenance: These pumps are built with the end user in mind, incorporating several characteristics that will ease maintenance tasks in order to decrease idle time and disruption of operations.

What Applications Use Muncie Hydraulic Pumps?

Industry Applications

Muncie hydraulic pumps are very useful in the trucking industry as they facilitate a number of operations. For example, these pumps are used in dump trucks to engage the hydraulic rams that tilt the truck bed to empty its contents efficiently. Moreover, they find application in tow trucks for actuating winches and booms, thereby efficiently lifting and moving the cars to be towed. The pumps are also found in Muncie hydraulic systems in waste collection vehicles and are utilized for the compression and the dumping of the wastes. Most of all their characteristics are optimized for trouble free operation in these pumps.

Hydraulic Pumps Used in Dump Trucks

Muncie hydraulic pumps are important in dump trucks as they power the hydraulics that raises and lowers the truck bed. Such an efficient power source quickens the unloading process of construction materials which is very vital for mining and building works. The pumps’ design includes rugged materials which may be used in heavy duty operations without failure of the pump. These compact pumps make it possible to integrate with other hydraulic equipment already installed on the truck, without sacrificing outflow power. With their unmatched performance, Muncie hydraulic pumps offer a reliable component in enhancing dump trucks’ operational efficiency.

How Muncie Pumps Help in Subduing/Icing of the Roads

Muncie hydraulic pumps, which happen to be located in the trucks, are essential for ice control, because they provide the energy for the different spreaders and sprayers which help in spreading the de-icing materials like salt and brine on the road surfaces. The pumps offer the power and flow that is required in applying the materials evenly so that it becomes difficult for ice to buildup which improves the road usage during the winter season. Because of their solid structure, they are less likely to suffer intensive wear-and-tear even in the coldest conditions and thus, cities are assured of these pumps for ice control regardless of the weather. Muncie hydraulic pumps have so much efficacy that the de-icing tasks performed using them are cheap and also lessen the chances of causing a hazard to the environment.

How to Choose the Right Muncie Hydraulic Pump?

Important Considerations When Choosing a Pump

Sometimes, you need to consider a number of important aspects in order to achieve optimal performance through a Muncie hydraulic pump. Primarily, you must determine the pump size based on the flow rate and pressure requirements of the rolling mill auxiliary hydraulic system and its sub-systems. That is, you need to ensure that the pump specifications and the operational requirements coincide in order to allow all operational situations without rendering the case useless or ingesting too much risks. Secondly, think about the mounting methods as well as the size of the pump in order to ensure its proper integration with the layout of the equipment. Thirdly, take note of the general conditions within which the pump will work such as temperature and exposure to dirt in order to specify the kind of material and sealing the pump will require. Furthermore, consider the maintenance effectiveness and the degree of availability of spare parts for the pump in order to ensure reliability and durability. By considering these particular points, you are assured of selecting a Muncie hydraulic pump that is efficient and provides a long service period for your applications.

GPM Requirements for Your Application

In order to understand the gallons per minute (GPM) requirement for hotwork, start with the estimation of total hydraulic fluid flow that is required for all the components of the system, actuators and motors included. Estimate how much flow is needed to maintain the required performance and efficiency at peak system load. Differentiate the specific application needs considering aspects like speed, force, and time factors associated with the operations. Also include the two losses due to heat sinks in hose fittings and hoses not internal to the cylinder portion of the system. It is important to describe this to avoid under rating or over ratting the GPM of the pump and center line actuated to obtain the required flows efficiently without waste of power. Considering these aspects, you will be able to assist the best GPM rating for the system.

Differences Between Series Hydraulic and Series Gear Pumps

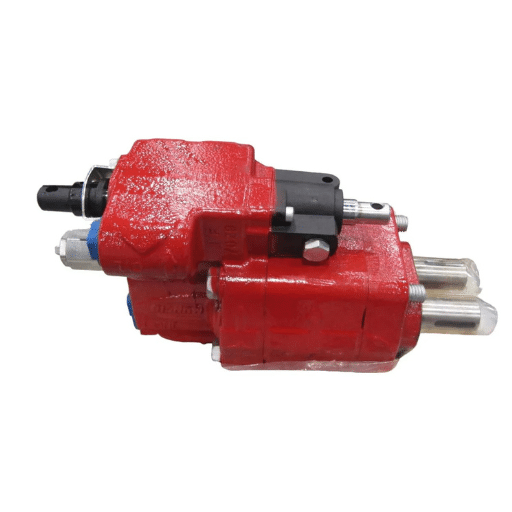

In general series hydraulic pumps, it is mostly for high pressure variety and for complex applications. This is because these types of pumps are characterized with several arrangements like piston or vane types in order to cater for different fluid movements. These pumps are well known to have moving vanes and are by large used in various systems due to their variable displacement options which enhances manageable flow rate and pressure ideal for systems that requires versatility.

Conversely, the series gear pumps are simple and dependable within the scopes of their designs. They employ rotating gears that displace a fluid and are typically employed where the emphasis is on the flow being as small or as large as possible and there is no need of inversion. Most and primarily gear pumps are fixed displacement in nature meaning that the quantity of liquid flow obtainable at a given speed is constant which is why they are used in systems which do not require much attention towards the control systems. They are relatively inexpensive, reliable and easy to repair, however do not have the capacity to tolerate drastic changes in pressure loads as well as their hydraulic counterparts. It is possible to achieve optimal performance and durability of the systems by selecting the correct type of pumps depending on the working conditions.

What are the Key Components of Muncie Hydraulic Systems?

Hydraulic Elements in Muncie System – An Overview

Muncie hydraulic systems commonly to several basic elements which usually go along hand in hand to guarantee proper functioning and performance. One of these components is the hydraulic pump which is the power source transforming the mechanical energy into hydraulic energy. Constructed for good and dependable output in various operations, Muncie’s pumps are made to award completeness. Another component that is a must in the system is hydraulic motors, which convert hydraulic energy back to mechanical energy for use. Enabling precise engagement of the machinery are the control valves which are mounted with the motors, the hydraulic pump and required pressure valves to control the inflow and outflow of the hydraulic fluid. There are also reservoirs for the storage of the hydraulic fluid and filters to keep the hydraulic fluid clean and free from any dirt that may damage the system. In general, these components are designed to be, efficient operationally, effective and especially strong and reliable in respect to a variety of hydraulic uses.

Power Take-Off (PTO) Definition And Practical Significance

The Power Take-Off (PTO) is an important device in any hydraulic system, more so in machinery such as a truck or tractor where there is a need to transform the power of the engine into that of hydraulics. It permits the use of the engine of the vehicle for operating the auxiliary hydraulic implement. It is worth mentioning that the PTO systems are purposeful and robust, making it possible to supply and detach the power smoothly without damaging the engine of the vehicle or the auxiliary equipment. This modification allows the mounting of various attachments and implements, thus increasing the application of the vehicle. Moreover, correct operation and selection of the PTO is the key aspect for appropriate use of the system which in turn affects the performance and lifetime in hydraulic based systems.

Examining the Function of the Output Shaft

The output shaft has a lot of importance in hydraulic systems as it allows the torque produced from the PTO to be transferred to several machines and tools. This is important in transferring rotational force into useful work that activates some auxiliary components. It is also crucial that the output shaft is installed properly and interlocked to facilitate energy transfer without mechanical failures. Furthermore, care for the output shaft is also very important to reduce wear and enhance the performance of various systems in the hydraulic system. Changes in the productive instructions for the routine include objectives that may help to avoid more arrests to the action than the part can work properly and extend its temperature in severe conditions.

How to Install a Muncie Hydraulic Pump?

Common Mistakes to Avoid During Installation

When installing a Muncie hydraulic pump, I ensure to carefully avoid a few common mistakes to guarantee optimal performance. First, I make sure that all parts are clean and free of any debris before starting the installation, as this prevents contamination and mechanical issues. Additionally, I double-check that all components, such as hoses and fittings, are compatible with the pump specifications to avoid leaks and connection problems. Another key point is adhering to the recommended torque settings for bolts to prevent overtightening, which might cause damage to components. Lastly, I take care to properly prime the pump to avoid any air entrapment, which could lead to inefficient operation or pump failure.

Best Practices for Mounting and Sealing

When mounting a Muncie hydraulic pump, I ensure the surface is clean and flat to provide a solid foundation, reducing the risk of vibration and misalignment. I use high-quality mounting bolts and secure them evenly to avoid stress on the pump casing. For sealing, I select appropriate seals and gaskets that are compatible with hydraulic fluids to prevent leaks. I inspect all sealing surfaces for uneven wear or damage that could compromise the integrity of the seal. Applying sealant sparingly and as the manufacturer recommends helps to ensure a tight fit without excess that could contaminate the system. By following these steps, I ensure a durable and leak-free installation.

Reference sources

- Muncie PH1-05-02-BPBL Hydraulic Pump: This source provides detailed specifications about the Muncie PH1-05-02-BPBL hydraulic pump, including its high-pressure capability and application versatility. You can find more information here.

- Gear Pumps by Muncie Power: This page offers insights into the PH Series gear pumps, highlighting their all-cast iron construction and various displacement options. Check it out here.

- Muncie PL Series Hydraulic Gear Pump PL12702BPBB: This source details the features of the Muncie PL Series hydraulic gear pump, including its flow rate and mounting specifications. More details are available here.

These sources should help validate the feasibility and technical aspects of Muncie hydraulic pumps for your readers.

Frequently Asked Questions (FAQs)

Q: What role does the motor play in the workings of a Muncie hydraulic pump?

A: The motor dpumpsand supplies the pump with its RPM (rotations per minute), which in rturnplays a great role in determining the flow rates and operation of the whole hydraulic system . Somemodels even ooffer17 GPM at 1000 RPM.

Q: What task is carried out by the valve of a Muncie Hydraulic system?

A: The valve in a Muncie hydraulic system directs the effective hydraulic liquid pump to activate the hydraulic cylinders and allow motion to be executed without unnecessary resistance.

Q: Do I have to forgo the benefits of a Muncie hydraulic pump on automatic transmissions?

A: Yes, automatic transmissions are compatible with Muncie hydraulic pumps , particularly in situations where a clutch shift is needed when the power is takenoff the gear.

Q: What is the solution in case my Muncie hydraulic pump manual is poorly performing?

A: If you encounter problems with the Muncie hydraulic pump, you should begin troubleshooting by examining the fluid levels, checking for leaks, and visual inspecting the fittings. If the above doesn’t help, supplementary actions may involve referring to the part number or the manufacturer’s information and advice.

Q: From what materials are Muncie hydraulic pumps processed?

A: Molded with Cast Iron materials, Muncie hydraulic pumps are strong and long-lasting in many hydraulic applications.

Q: What are the advantages of Muncie hydraulic gear products?

A: EMuncie hydraulic gear products offer efficiency reliability, and versatility . Theyoffer a great degree of play to a single vein, which covers a vast number of needs within the range of hydraulic system installations. They are made to fit in hheavy-stressingconditions of trucks and attachments.