Hydraulic pumps are at the very heart of every industrial and mechanical system, converting mechanical energy into hydraulic energy to power machines and equipment. Given their vast applications across industries such as construction, manufacturing, and agriculture, one has to understand the types of hydraulic pumps to be able to make educated decisions regarding system design, efficiency, and maintenance. This guide will dive into the major types of hydraulic pumps, how they work, and where they find their applications. Engineers, technicians, or even a layperson interested in expanding their technical know-how will find this complete resource useful in learning how to achieve the best hydraulic system performance and reliability.

Introduction to Hydraulic Pumps

The Importance of Hydraulic Pumps in Industrial Systems

Hydraulic pumps are an integral part of industrial systems, being generally considered the prime source of power for the conversion of mechanical power into hydraulic energy. In such a conversion process, transmission of force is accomplished through fluid, unhindered by any kind of force; hydraulics are ideally suited for precise manipulation and movement of machinery and equipment. Being capable of delivering more or less constant power over a wide range of applications, they thus cannot be done without some sectors, such as manufacturing, construction, or agriculture.

The force transfer through hydraulic pumps is mostly efficient with minimal losses, which is one of the advantages of hydraulic pumps. In contrast to other power transmission methods, hydraulic systems could employ very high pressures for useful work, thus useful in tasks of applying large forces. Thus, in conditioned presses and heavy machinery, the hydraulic pumps give forces to carry out tasks that could either be inefficient or impractical mechanically.

Hydraulic pumps are also used to enhance system reliability and performance, and vary flow and pressure according to demand to supply the speed and accuracy necessary in modern-day automation and control systems. The proper choice, handling, and upkeep of hydraulic pumps shorten the downtime for the systems, extend their life, and guarantee safety at work sites. Because of their versatility and ability to adjust to different operational requirements, the pump proves to be a worthy companion in the advancement of industrial processes.

Overview of Fluid Power Technology

With fluid power technology, whether liquid or gaseous, it is used to transmit power in industrial and mechanical systems of all kinds. This field primarily extends into two domains: hydraulics, which uses liquids such as oil or water, and pneumatics, which uses compressed air or other gases. Both systems ensure the efficient transfer of energy and exact control over mechanical operations; therefore, it is very crucial in industries like manufacturing, construction, or aerospace.

Key Advantages of Fluid Power Systems:

- High power-to-weight ratios

- Smaller system sizes

- Flexibility in speed, force, or direction control

- Integration capability with higher-control systems

In any fluid power system, reliability and efficiency hinge on several factors, from the quality of its components to the design of the system itself and the maintenance being done regularly. Having proper filtration, selecting fluids aptly, and monitoring the system appropriately minimizes wear and reduces downtime. Material science and digital controls have cooperated to provide intelligent, energy-conserving fluid power systems that can diagnose themselves and carry out predictive maintenance. Fluid power, which continues to evolve and innovate, is now a very important contributor to contemporary engineering and industrial prosperity.

How Hydraulic Pumps Function

Hydraulic pumps are machines that are constructed to convert mechanical energy into hydraulic energy by transmitting fluids to generate flow. With the energy carried through the hydraulic system, performing work is possible; for example, lifting, pushing, or moving some machine components. Mainly, the function of the hydraulic pump is the ability to maintain flow and pressure, and minimize losses in energy.

Usually, something drives hydraulic pumps. Most common drives include an electric motor or internal combustion engine. The pump causes a vacuum to exist on the inlet side so that the fluid can enter from the reservoir. It then applies pressure to the fluid and discharges it into the hydraulic system through the outlet. Hydraulic pumps include gear pumps, vane pumps, and piston pumps. Each type of pump would be chosen for an application depending on flow rate, pressure requirements, and efficiency.

Initially, the fluid quality, the temperature of the system, and scheduled maintenance must be observed and maintained to avoid languid performances must be avoided in implementation. These can also include internal wear contamination of the fluids, thereby reducing efficiency; hence, the use of a proper filtration system becomes necessary. Furthermore, choosing the appropriate pump type for the application stands as a major requirement to ensure operational performance, reliability, and life span of a hydraulic system. As such, adhering to the above-stated principles should remain firmly in place to make the hydraulic pumps key constituents in widespread moves across industrial and engineering domains.

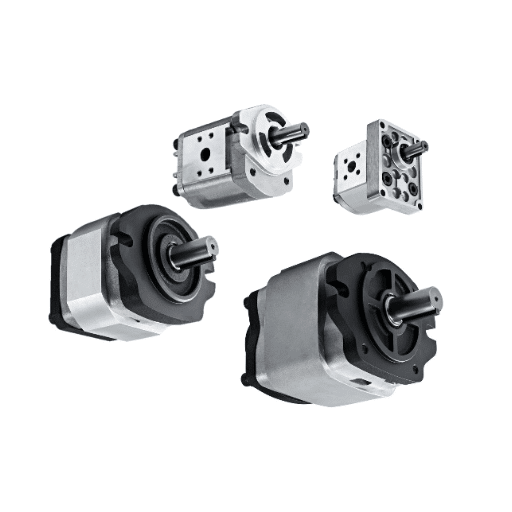

Different Types of Hydraulic Pumps

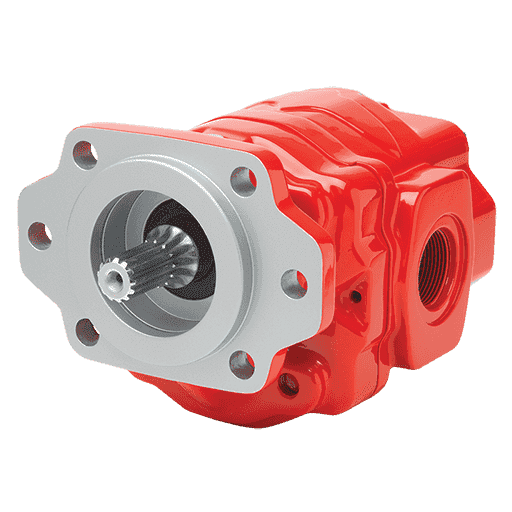

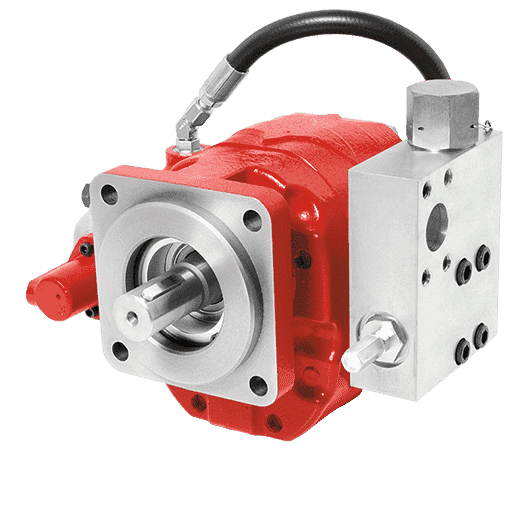

Gear Pumps: Characteristics and Functionality

Gear pumps belong to the positive-displacement family of pumps that leverage two interlocking gears to move fluids with acute precision and efficiency. It is so well constructed and simple in design that it finds application across industries, including automotive, manufacturing, and oil and gas. The operation of a gear pump involves the action of two gears; thus, a drive gear rotates in one direction, while the other gear, known as the idler, rotates the other way, creating a vacuum at the inlet. The fluid is then rapidly sucked into the outlet under high pressure through the fluid drawn around the outside of the gear casing.

External Gear Pumps

Consists of two gears of the same size, preferred for higher-pressure applications.

Internal Gear Pumps

Small driving gear inside a larger driven gear, suitable for fluids of higher viscosity.

The salient features of gear pumps are their capacity to pump viscous liquids, to operate at relatively higher pressures, and to deliver a very steady, non-pulsating flow. Design selection depends on the application at hand: external gear pumps are preferred for higher pressure applications, whereas internal gear pumps are suitably used for fluids of higher viscosity.

⚠️ Important Considerations

Gear pumps are very precise and reliable in their operation, and yet some disadvantages apply. The absence of a seal between the gears allows fluid to slip back into the inlet chamber, thereby reducing volumetric efficiency under high pressure. Also, wear is a severe concern over time with abrasive or contaminated fluids; hence, regular maintenance and installation of proper filtration systems are very much needed.

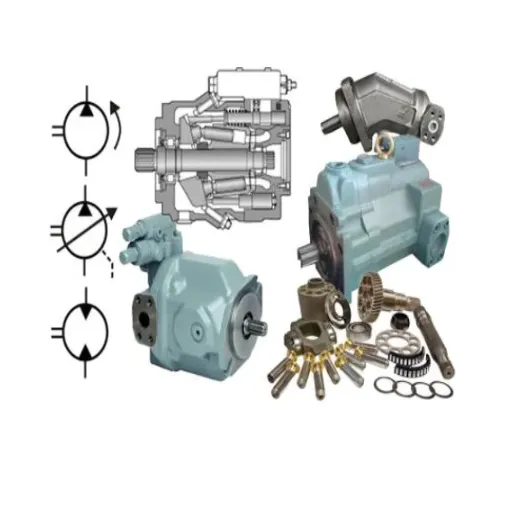

Piston Pumps: Mechanisms and Applications

Piston pumps have the reputation of being highly efficient, versatile hydraulic components built to provide a constant flow at high working pressures. In this reciprocating system, pressure differences are exerted by pistons or plungers that reciprocate within cylinders to achieve fluid movement. Following this operating method of differential fluid pressure makes them more exact in their application and, therefore, capable of treating low and high-viscosity fluids in harsh environments.

High-Performance Capabilities

- Capability to reach high pressures, generally above 10,000 psi

- Fewer pulsations ensure a steady and exact working performance

- Increased durability when exposed to harsh conditions

- Available in axial and radial configurations

Further improvements in materials and designs have increased the durability of such pumps when exposed to harsh conditions like temperature variations or abrasive fluids. Axial and radial piston pumps are configured with certain interchanges so that they can be applied in systems from automotive applications right up to aerospace hydraulics, manufacturing, and oil and gas production.

Piston pumps require routine maintenance, including inspection of piston bearing wear and scratches; sealing conditions; proper lubrication; and other preventive maintenance for sustained best operational performance. Modern control technologies like electronic proportional valves are used to increase operational efficiency and responsiveness. Piston pumps thus remain a cornerstone in advanced hydraulic and fluid management systems serving multiple fields.

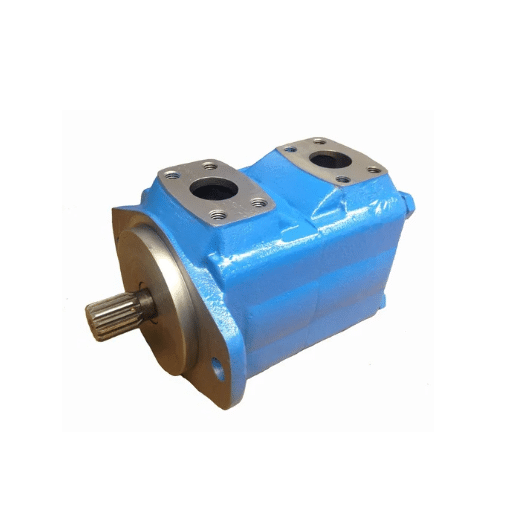

Vane Pumps: Unique Features and Uses

Vane pumps are considered a positive displacement pump renowned for their dependable working, efficacy, and versatility in a spectrum of application areas. Motion of vanes consists of sliding from/to a rotor that keeps a tight seal with the pump casing to deliver fluid with a fixed volume. Hence, they are more suitable for systems in which a constant flow rate with minimal pulsation is required.

Vane pumps can be used to pump liquids such as solvents that have a thin consistency and oils that are heavy. Furthermore, they are self-priming and can fit into spatially restricted areas, which makes them further suitable for installations where being mobile is paramount. The most recent coating and material technologies have led to the enhancement of the life of vane pumps, reducing the wear due to abrasive fluids on the pump surface, thus lengthening the service time.

Modern Advancements

Modern vane pumps, which are also designed for low energy consumption, incorporate automated control systems that adjust flow and pressure according to the system requirements on a real-time basis. These features have made these pumps especially valuable in places where automotive lubrication systems, industrial manufacturing, and fuel transfer operations are involved.

Working Principles of Hydraulic Pumps

Converting Mechanical Energy into Hydraulic Energy

A hydraulic pump converts mechanical energy released by an engine or motor into hydraulic energy in terms of fluid flow and pressure. In this process, a prime mover (for example, an electric motor or internal combustion engine) drives the pump mechanism. The mechanical action within the pump in effect produces a vacuum at the pump inlet, such that the fluid gets sucked into the pump chamber-lifting it from the reservoir. Simultaneously, the motion of the pump forces the fluid from the outlet side into a pressurized system.

Its efficiency depends on the design and specifications of the pump, and things such as displacement, pressure capability, and flow rate. Positive displacement pumps, like gear, vane, or piston pumps, can control the fluid very precisely by displacing an exact amount of fluid per rotation. More advanced designs could also have variable displacement features that allow the flow rate to be adjusted in real time based on actual demand for maximum energy efficiency and system performance.

Another great factor on the side of all hydraulic pump materials and construction is the duration under high pressure. In modern times, hydraulic pumps usually employ better seals, wear-resistant coatings, and highly precise manufacturing of components to reduce energy losses and increase uplift life. Extant data suggest that material innovations along with digital controls are making hydraulic pumps more reliable and output-efficient, which is important for high-performance industrial and mobile applications.

Step-by-Step Insights into Pump Operation

1

Fluid Intake and Cavitation Prevention

During the first stage of operation, the pump draws the fluid from the reservoir into the inlet port. Well-designed systems with carefully controlled inlet pressure ensure that cavitation does not occur, in which vapor bubbles are produced and collapsed, with the power to crush pump components. Air-release valves and good piping layout can help prevent problems from being created.

2

Compression and Energy Transfer

The fluid enters the pumping chamber, where the state of energy of the fluid is increased. Depending on the nature of the pump-i.e., it may be centrifugal, axial, or positive displacement-this energy transfer can be one of rotational momentum (impellers in centrifugal pumps) or direct volumetric displacement (gears, pistons, or vanes). Since then, modern computational fluid dynamics (CFD) models have been developed and used to guarantee the utmost optimization of pressure distribution with minimized energy loss at this stage.

3

Sealing and Leakage Control

A strong sealing mechanism is installed inside the pumping mechanism to prevent internal and external leakage. Mechanical seals, along with dynamic sealing technologies, have now been enhanced with composite materials and self-lubricating surfaces in order to increase the efficiency and life of the pumps, even at extreme temperatures and pressures.

4

Discharge and Efficiency Optimization

Once being raised under pressure, the fluid leaves the pump through its outlet port, moving to the point of use. To fill real-time flow demands, modern pump systems use variable speed drives (VSDs) and digital monitoring tools for exact discharge pressure, while avoiding needless electricity consumption. Performance of an adaptive mechanism is optimized under variable operational conditions.

5

System Monitoring and Predictive Maintenance

In advanced pumping systems, IoT sensors can monitor parameters like pressure, temperature, vibration, and flow rate in real time. This data is analyzed through predictive maintenance algorithms to forecast the failure of these systems, thus allowing timely interventions to avoid downtime and increase service life. Studies show that maintenance efficiencies are increased by 25–30% through this digital path.

Displacement Methods: Variable vs. Fixed

Hydraulic pumps based on displacement could either be Variable Displacement, where the flow is adjustable, or Fixed Displacement, where the flow remains fixed.

| Key Point | Variable | Fixed |

|---|---|---|

| Flow | Adjustable | Constant |

| Efficiency | High | Moderate |

| Control | Precise | Simple |

| Applications | Versatile | Specific |

| Cost | Higher | Lower |

| Maintenance | Complex | Simple |

| Power Use | Optimized | Fixed |

| Flexibility | High | Low |

Advantages and Disadvantages of Each Type

Efficiency and Performance Comparisons

In evaluating the efficiency and performance of variable displacement systems compared to fixed displacement systems, a few factors stand out in importance. Variable displacement systems are better in efficient because they can vary flow rates according to demand. Flow or pressure was the exact avenue for energy wastage, so by adjusting displacement dynamically, these systems can maximize the use of the power generated. This feature makes these systems suitable for the hydraulic machinery in which precision control is required under changing load conditions, or in advanced manufacturing setups.

✅ Variable Displacement Systems

- 30-50% energy savings in variable load applications

- Precise control under changing conditions

- Optimal power utilization

⚖️ Fixed Displacement Systems

- Simple, reliable operation

- Lower initial cost

- Consistent performance in stable applications

From the opposite viewpoint, fixed displacement systems are simpler by design, emphasizing steady and constant flow. However, while their simplicity tends to result in a lower up-front purchase cost and less maintenance, it conversely translates into less efficient energy consumption when demands fluctuate. These systems are meant to be used in applications where the operating parameters are expected to remain consistent under all conditions, such as in simple pumping systems or hydraulic presses with fixed requirements.

To taste some numbers, studies report variable displacement systems being able to save energy by as much as 30-50% in applications where loads are varied. Conversely, fixed displacement systems, while reliable, do have a hard time using energy optimally with time whenever demand ceases to remain constant. These trade-offs are worth analyzing on a case-by-case basis when making the choice of system design.

Durability and Maintenance Considerations

Durability and maintenance become big factors with respect to long-term performance and cost-effectiveness of hydraulic systems. Variable displacement systems, being fluctuation-dependent, tend to bear more complex mechanisms, on account of adjustable swash-plates or electronically controlled actuators. Such components, technically, may have to undergo calibration and monitoring regularly to keep performance at its best and to prevent different mechanisms from premature wear. Preventing failures and enhancing operational life retain maintenance, with routine inspection and fluid analysis as some of the activities involved.

🔧 Maintenance Requirements

Variable Systems:

- Regular calibration needed

- Electronic component monitoring

- Complex mechanism inspection

Fixed Systems:

- Simple routine maintenance

- Fewer moving parts

- Basic fluid monitoring

Oppositely, having a simpler design and fewer moving parts, fixed displacement types often exhibit superior longevity when in steady-state applications. Simplicity brings forth lesser maintenance, as fewer components can get misaligned or fail. On the other hand, it should be ensured that the excessive heat buildup, as one of the preconditions or contamination of fluid due to negligence, does not hamper long-term system performance. The use of good hydraulic fluids, proper filtration, and maintenance according to manufacturer recommendations are the most important ways to care for either system.

Based on operational efficiency, the system to be selected could also consider maintenance ease, projected life costs, and application dynamics.

Cost Analysis of Different Hydraulic Pump Types

Cost implications of different types of hydraulic pumps are assessed depending on the initial capital and expenditure made in installments over time operations. Fixed displacement pumps or gear pumps undergo simpler design and manufacturing processes and are thus usually cheap. The application requires a fixed flow rate and comparatively low pressure ranges, so that maintenance becomes simple and cheap.

On the other side of the coin, because of their elaborate structures and the precision required in their making, variable displacement pumps such as the axial piston kind entail more initial costs. However, they tend to be very efficient with respect to the energy used during operation, especially in those systems that require a variable flow rate. For those industries whose operations necessitate ample flexibility and energy savings, this efficiency translates into a big cost offset throughout the life of the pump. Further technological developments have ensured superior longevity and performance reliability of variable pumps, further supporting their purchasing feasibility.

💰 Total Cost of Ownership Factors

- Initial Purchase Price: Equipment and installation costs

- Energy Consumption: Operational efficiency over time

- Maintenance Costs: Regular servicing and repairs

- Downtime Costs: Production losses during maintenance

- Warranty Coverage: Protection against defects

Cost factors for the pump include materials in terms of quality, warranty packages available on purchase, compatibility with the system requirements, and more. A thorough analysis that factors in the price of life includes energy consumption, maintenance, and possible downtime, ensuring that the hydraulic pump chosen fits away from technical consideration and economic operational costs.

Common Applications of Hydraulic Pumps

Industry Applications: Construction and Agriculture

In construction and agricultural industries, hydraulic pumps find application to impart huge power in small, efficient systems. Here are five common applications these sectors comprise to indicate their function and utility:

🚜 Excavators and Backhoes

Hydraulic pumps and their induced movements of excavator booms, arms, and buckets provide the graft needed to excavate, lift, or move materials. These pumps place an important mandate on accurate control of heavy loads, necessary under construction conditions.

🌾 Tractors and Harvesters

Tractors and harvesters use these hydraulics to operate their attachments-plows, balers, and seed planters, to name a few. The hydraulic systems serve to reduce time and energy in operationally intensive agricultural practices, thereby providing ease of transferability amongst different types of equipment.

🏗️ Cranes and Loaders

The hydraulic pumps of cranes and loaders help in heavy lifting and the smooth transfer of materials at construction sites. Their reliability and efficiency are essential for handling complex projects within strict time frames.

💧 Sprayers and Irrigation Systems

Agricultural sprayers and irrigation systems employ hydraulic pumps to dispense water, fertilizer, and pesticides over vast areas. These pumps seek to maintain steady output in order to increase crop yields and lessen manual intervention.

🏗️ Concrete Pumping Equipment

Construction sites rely heavily upon hydraulic concrete pumps for the conduction of pouring concrete into difficult locations. These systems reduce project delays and enhance structural integrity by the placement of materials in an evenly dispersed manner.

All applications serve as testimony to the flexible, durable, and tremendously valuable nature of hydraulic pumps in easing operations within construction and farming industries.

Automotive Uses of Hydraulic Pumps

In the technical domain, hydraulic pumps constitute essential apparatuses to actuate systems requiring great force with fine control. That is to say, during the operation of power steering, the pumps deliver high pressure, enabling smooth and easy steering. It converts mechanical energy into hydraulic energy, and the systems allow the driver to cause minimal physical input for keeping the vehicle in control, mostly in big vehicles or at slower speeds.

🚗 Power Steering Systems

Deliver high pressure for smooth, easy steering with minimal driver input, especially crucial for larger vehicles and low-speed maneuvering.

🛑 Braking Systems

Essential for heavy-duty and commercial vehicles, transmitting driver force efficiently to brake calipers for consistent performance.

Hydraulic pumps are also necessary for braking systems, particularly in heavy-duty and commercial vehicles. A hydraulic braking system imposes pressure through hydraulic fluid to transmit the driver’s force with great efficiency to the brake calipers. To further elaborate, it ensures that braking remains the same in any operating condition, irrespective of terrain, hence providing maximum safety.

In this case, hydraulics are extended to the vehicle suspension systems. Particularly so with more advanced setups called active or hydraulic suspension systems. Such systems change with road conditions for the best ride comfort and handling, where hydraulic pumps are employed to change the suspension stiffness. The versatility they provide makes hydraulic pumps indispensable in traditional automotive engineering and modern innovations toward increasingly capable, reliable, and efficient vehicles.

Manufacturing and Production Systems

In short, manufacturing and production systems encompass all processes and methodologies that convert raw materials into finished goods. In modern production systems, all parameters considered for efficiency, precision, and scalability are subjected to advanced technology comprising automation, robotics, and data-driven analytics. These are to design and develop systems that interface with production and work order flow to minimize waste and ensure product quality every time.

🏭 Industry 4.0 Integration

One peculiar occurrence in manufacturing sits under the application of Industry 4.0 principles that utilize IoT, Machine Learning, and real-time data exchange across manufacturing networks. Predictive maintenance based on IoT sensors, for example, can forecast failures in machinery and equipment before their occurrence, thereby minimizing downtime and related cost.

Moreover, lean manufacturing methods focusing on waste minimization and maximization of productivity have been popularly adopted to couple sustainability with production efficiency. Additive manufacturing developments, including 3D printing, are making production systems more and more flexible by allowing the creation of complex geometries and supporting fast prototyping. These innovations together present a tremendous change from the standpoint of intelligent and fully automated manufacturing ecosystems in meeting the present needs.

Frequently Asked Questions (FAQ)

❓ What are the main types of hydraulic pumps?

Answer: The different types of hydraulic pumps include gear pumps, piston pumps, and vane pumps. They all function differently and are tailored for various applications. Gear pumps are selected for their simplicity and efficiency; piston pumps are capable of operating at high pressures and can be variable displacement; vane pumps can be used in various hydraulic applications where the flow has to be kept constant.

❓ How does a hydraulic gear pump operate?

Answer: Hydraulic gear pumps operate by using two gears. The meshing gears rotate and create a cavity into which hydraulic fluid is drawn by the suction created at the pump inlet. As the gears rotate, the fluid is transported around the circumference of the gears to the outlet side. In terms of principle, they are positive displacement as they give a fixed volume of fluid per rotation, thus, are suitable for applying pressure to hydraulic systems. They are usually found in applications like industrial machinery and mobile equipment.

❓ What is the difference between fixed and variable displacement piston pumps?

Answer: A fixed displacement piston pump always produces a flow of hydraulic fluid of fixed volume regardless of the pressure in the system. On the other hand, a variable displacement piston pump can adjust the volume of flow as requested by the system. Because of this capability, a variable displacement pump operates efficiently at varying loads, making it suitable for applications that require pressure compensation and dynamic flow control.

❓ What do clutch pumps do, and where are they applied?

Answer: Clutch pumps are hydraulic pumps that work by engaging and disengaging fluid flow according to the demand of the operation. They find applications in dump trucks or other types of mobile equipment, where power from a hydraulic system is required on an on-demand basis. Clutch pumps help reduce fuel consumption because the hydraulic drive is allowed to run only when necessary.

❓ What is the significance or importance of the operating pressure in hydraulic pumps?

Answer: The operating pressure of a hydraulic pump is very important since it can affect the performance efficiency of the hydraulic system. Each type of hydraulic pump has a maximum pressure rating, which is the amount of pressure it can safely handle. When the pressure rating is exceeded, the pump may cease to function, or it could damage other components within the hydraulic system.

❓ How do axial piston pumps serve hydraulic applications differently?

Answer: Axial piston pumps are preferred for hydraulic applications due to their ability to operate at high operating pressures and provide variable displacement. Hence, being able to change displacements under different operational load conditions makes them well-suited for applications in industrial machinery, hydraulic power units, and other demanding environments.

❓ What is the role of control valves in a hydraulic pump system?

Answer: Control valves regulate the flow and pressure of hydraulic fluid in pump systems and direct the oil flow to various elements within offices, consisting of hydraulic power units, depending on the conditions of the hydraulic units, to obtain optimum performance. By regulating the flow, the valves ensure that the desired working conditions and performances are maintained in a wide range of hydraulic applications, such as computer-controlled machine tools and injection molding.

❓ Can you explain the function of vanes mounted in vane pumps?

Answer: Inside vane pumps are spring-loaded vanes that are fitted on a rotor rotating in a pump housing. As the rotor revolves, the vanes move in and out of the rotor slots, creating a set of cavities that intake and expel hydraulic fluid. This mechanism allows vane pumps to deliver a smooth positive flow, suitable for numerous hydraulic applications.

❓ What are the advantages of using hydraulic power units in hydraulic systems?

Answer: The hydraulic system contains hydraulic power units that provide hydraulic fluid, pressure, and flow to actuate different hydraulic devices. These power units are designed in simple, efficient ways, often with built-in pressure relief valves and other features to ensure safe operation. The power units enhance the system’s operating capability and reliability, and hence are very much needed in mobile and industrial applications.