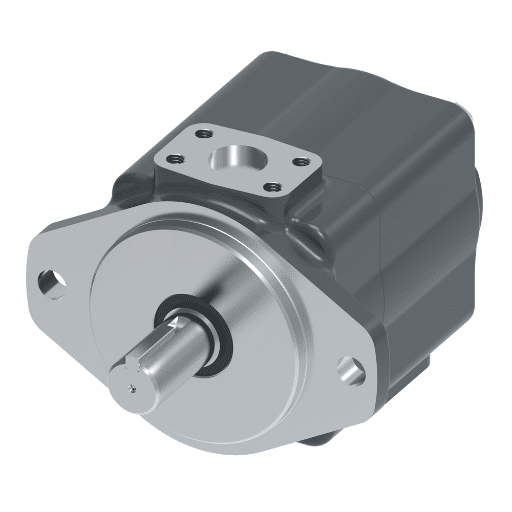

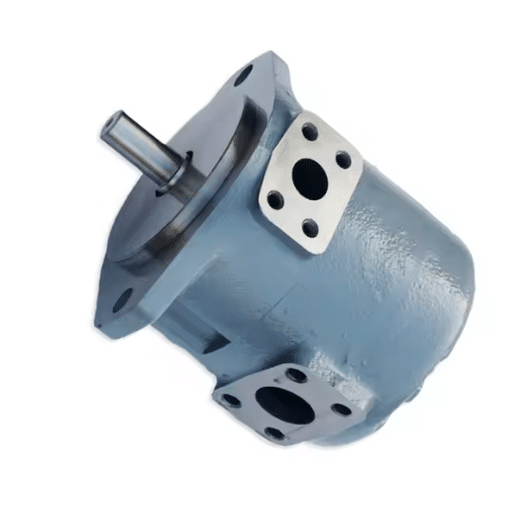

Various industrial applications employ hydraulic pumps to facilitate movement of fluids within hydraulic systems through conversion of mechanical energy to hydraulic energy. They are however prone to various challenges that affect their operation like any other mechanical system which may lead to lower performance and efficiency. This manual provides in-depth analysis on the most common problems with hydraulic pumps explaining detailed fixes for technicians and engineers who can therefore be able to diagnose and correct these issues efficiently. Users, following a procedural model, shall improve their knowledge on how dynamic the hydraulic system is thus increasing dependability during operation for minimal downtime in industry. Either pressure discrepancies, fluid leakage or inconsistency in performance this complete resource acts as an authoritative reference tool to ensure that integrity of the hydraulics pump systems is maintained.

What Are the Hydraulic Pump Common Failures?

- Cavitation: This occurs characteristically when there is low inlet pressure, which causes the hydraulic fluid to form vapor bubbles. They then implode, severely damaging the pump parts and reducing their performance.

- Contamination: If dirt, moisture, or debris gets into hydraulic fluid, it can cause pump components to wear, block, and increase friction, resulting in failure. Therefore, consistent fluid analysis and filtration are important for minimizing this exposure.

- Mechanical Wear and Tear: Components like seals, bearings and vanes among others deteriorate over time due to regular operational stresses. To avoid such wear that leads to leaking fluids, lower efficiency, and eventual breakdown of pumps if regularly maintained.

Common Causes of Hydraulic Pump Issues

Common issues with hydraulic pumps often arise from a number of factors that may affect system operation considerably. One common reason is poor maintenance practices where not conducting regular check-ups or changing fluids cause contamination and mechanical deterioration, increasing risks of cavitation and decreasing efficiency. Similarly, incorrect installation or alignment may occur whereby undue stress on components makes them fail before time arises due to that particular pump’s issue concerning this matter. Moreover, choosing the wrong type of hydraulic fluid can have a detrimental effect by either making them too viscous or poorly lubricating, which ultimately negatively impacts their life span but also affects their overall functioning capability at any given time. Finally, operating under extreme conditions; such as high temperatures or pressure beyond the pump’s design limits can lead to accelerated wear out leading to catastrophic failures later on (Jia et al., n.p). These issues must be systematically addressed if hydraulic pump systems are going to last longer, particularly for the most demanding operating conditions.

Signs of Pump Failure

- Unusual Noises: Grinding sounds during pumping may indicate mechanical problems such as worn-out bearings or misalignment

- Vibration: Too much vibration may denote misalignment, cavitation, and other mechanical faults that, if ignored, can lead to further damage.

- Decrease in Performance: A significant drop in flow rate or pressure usually suggests a blockage, internal wear out and insufficient levels of fluid thus necessitating immediate attention.

- Fluid Leaks: Seal failure or component wear may be indicated by pump leaks or leaks around fittings, which could compromise the system’s integrity.

- Overheating: Inadequate lubrication, excessive friction or fluid viscosity issues can result in continuous overheating causing it to become permanently damaged when left unattended.

Preventative Measures for Pump Failures

- Regular Maintenance and Inspection: Regularly check the condition of pumps and their components through inspections, such as looking for signs of wear, corrosion, and uneven wearing patterns, as these could suggest something is wrong elsewhere (Engerman et al., n.p).

- Proper Installation: The pump should be installed according to the manufacturer’s specifications by aligning it properly, ensuring proper support, orienting it correctly so as not to cause cavitation due to air entrapment.

- Fluid Management: Analyze hydraulic fluid regularly to ensure that it meets necessary specifications and requirements; replace it as recommended, and keep an eye on contamination and degradation that can result in lubrication failures.

- Environmental Control: When installing pumps, extreme conditions such as temperature fluctuations and contaminants must be considered; proper housing and shielding will greatly improve their reliability.

- Training and Best Practices: People should know how far they can go with hydraulics, thus establishing performance indicators for constant watch over them by simply going back to monitoring protocols that alert people whenever there are dangers while at work (Duong et al., n.p). Following best practices while operating helps minimize undue stress on the pump.

How to Diagnose Cavitation in Hydraulic Systems?

The first step in diagnosing cavitation in hydraulic systems is to identify specific indications of it. Indeed, common symptoms include an apparent drop in the pressure at the pump inlet, increased noise levels characterized as grinding or rattling sounds, and pump performance fluctuations. This is where measurement tools such as pressure gauges and flow meters come into play, giving accurate information about operating conditions.

During visual inspection, looking for pitting or erosion on the pump’s impeller and housing can confirm whether cavitation has occurred. A hand-held infrared thermometer can also be used to measure temperature changes that may occur during a cavitation event. For more advanced diagnostics, techniques like ultrasonics or vibration analysis can reveal acoustic signatures connected with cavitation; these help spot potential problems before irreversible damage occurs.

Symptoms of Cavitation

Signs of cavitation manifest themselves through a range of observable factors that could affect the functioning of hydraulic systems. Among them, we have:

- Unusual Noise: An increase in noise, often described as grinding or rhythmic thumping sounds. This denotes disturbed fluid flow and bursting steam bubbles within a pump.

- Performance Fluctuations: Abnormal performance characteristics such as pulsating flow patterns (surges and drops), shifting pressure readings, etc.

- Vibration: Increased system vibrations due to unbalanced forces from collapsing bubbles that eventually cause structural failures over time.

- Erosion or Pitting: Through visual examination, one may observe erosion/pitting on internal parts including impellers and housings which result from liquid jetting impact caused by vapor bubble explosions.

- Heat Generation: Cavitation events are characterized by higher operating temperatures due to energy losses associated with them, which increase wearing rates on system parts while making them less efficient.

Causes of Pump Cavitations

Pump cavitations are mainly caused by several interrelated factors that affect the fluid dynamics within a system. First, insufficient inlet pressure which is usually due to either excessive suction lift or low levels of reservoir can lead to vapor bubble formation if the pressure drops below the fluid’s vapour pressure. Second, pump selection errors or operational mismatches like operating at high flow rates /using pumps meant for different fluids intensify cavitation risks. Furthermore, system pressure changes may inadvertently result in cavitation when there are obstructions upstream or valve problems. Lastly, temperature rises within the fluid caused by ambient conditions, and friction losses reduce its density, further contributing to vapor pressure fluctuations followed by cavitation. These causes are important in addressing cavitations and ensuring your water pump performs according to expectations.

Steps to Fix Cavitation and Repair Your Hydraulic Pump

- Identify Symptoms: Start by checking for signs of cavitation by listening (e.g., unusual sounds) and watching (e.g., physical damage). Then, monitor other performance indicators like flow rate and pressure.

- Assess Operating Conditions: Evaluate the pump’s operating environment, including suction conditions, fluid temperature, and viscosity. Ensure that there is adequate inlet pressure and confirm if the pump is set up according to its design specifications, as it needs calibration accordingly.

- Correct Inlet Conditions: Whenever a weak inlet pressure is noted, consider reducing the suction lift, raising reservoir levels or modifying pipe diameters to enhance flow and reduce resistance.

- Proper Pump Selection: Check that you have the right size of pump for the task at hand. This may involve consulting performance curves and manufacturer specifications to ensure compatibility with fluid properties and system dynamics.

- Eliminate Obstructions: Look through the upstream system for any barriers, such as valves, filters, etc., that can restrict flow and pressure. When cleaned or fine-tuned, these parts can considerably improve flow conditions.

- Mitigate Temperature Effects: If high temperatures in the fluid causing cavitation then try to cool it down by using heat exchangers or improving pump housing ventilation area.

- Regular Maintenance: Have a maintenance program that keeps checking on performance progress of pumps and systems always on course so as to be able to identify possible problems before they turn into severe cases of cavitation.

How to Troubleshoot Hydraulic Pump Leaks?

- Detecting the Source of the Leak: Begin by visually inspecting the pump and its associated parts, such as hoses, fittings, and connections for any signs of fluid accumulation, discoloration or residue that could give a clue to the precise location of leakage points.

- Verify Seals and Gaskets: The integrity of seals and gaskets in the pump assembly should be inspected since these are common areas for wear and damage that result in leaks. Replace any degraded or mismatched parts to restore proper sealing performance.

- Assess Hydraulic Lines: All hydraulic lines should be checked for indications of wear, abrasion or corrosion. Faulty lines must be replaced immediately to avoid fluid loss and additional system damage. Tight and secure connections have to be ensured at all junctions so that there are no leakages.

- Check Fluid Levels Regularly: Keep an eye on the hydraulic fluid level in the reservoir regularly. Low levels can aggravate leaks as well as cause air ingestion that affect pump efficiency.

- Test Pressure for Inconsistencies: Use pressure gauges to keep watch over any irregular fluctuations within the system which may point out a problem with pump operation or hose connections; this helps to prevent further leakages through fixing any disparities discovered therein.

- Evaluate System Design: Consider whether whole system design is suited for purposes required as well as efficient enough hydraulically evaluating compatibility among components while also appreciating that unbalanced systems might undergo excessive loads leading to leakage issues.

- Apply Routine Maintenance Measures: Inculcate preventive maintenance strategies that will enable regular assessment and servicing activities on hydraulic systems. This will allow early identification and rectification of potential sources before they become major breakdowns.

Detecting Hydraulic Fluid Leaks

When looking for hydraulic fluid leaks, one must comprehensively examine several elements of the hydraulic system. To begin with, check around the pump and hydraulic cylinders for fluid accumulation or drips. Special attention should be paid to connections, fittings, and hoses because these are some of the areas that usually leak. Improved visibility can be achieved by using dye additive; a fluorescent dye can be mixed with hydraulic fluid to enable tracking of leaks under ultraviolet light.

Additionally, listen out for strange noises, such as hissing or whining, which could indicate an escape of fluid. Inconsistent fluctuation in pressure within the system when subjected to normal conditions also indicates presence of faults that may cause leakage. Leakages must occur under real time scenarios thus maintenance personnel must simulate operating environments as they search for them. Routine instruction on this particular issue will significantly beef up ability of a team to respond quickly and efficiently whenever there is a leaking hydralic fluid.

Inspecting Suction Line and Seals for Leaks

It is important to inspect the suction line and seals in order to keep hydraulic systems efficient. Begin by looking at the suction line in order to see signs of wear, corrosion or any physical damage, which may cause it to lose integrity. Ensure that all fittings, clamps, and connections are tight; loose or improperly seated components will let fluid escape. Furthermore, it is crucial to check seals as they bear most of the hydraulic pressure and can get worn out with time. Use a leak detection kit specifically designed for hydraulic fluid so as to identify any leakage from the seals indicating impending failure. Moreover, applying a pressure test can help verify whether the suction line and seals are intact even under operational conditions. Any inadequate information should be rectified with urgency so as not to lead to inefficiencies within the system up to down-time that is expensive. The inspection results should be documented comprehensively for future proactive maintenance.

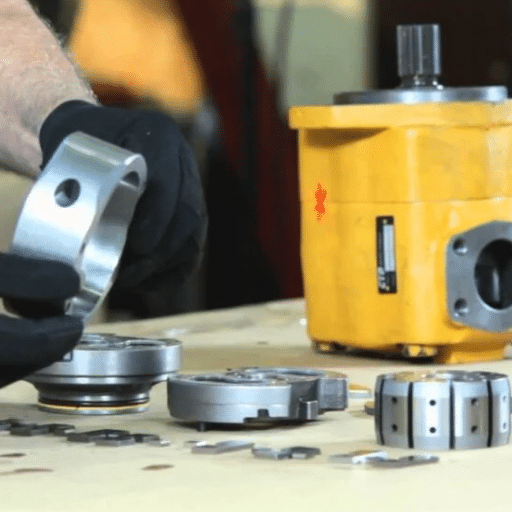

Replacing a Worn Pump Shaft Seal

Replacing a worn pump shaft seal is an essential activity in ensuring hydraulic system integrity as well as preventing fluid leakages. To ensure safety, first isolate the pump from the rest of the hydraulic circuitry while releasing residual pressures on it. When removing this pump from its mounting take note of its orientation and configuration since it will have to be reassembled later on. Get proper tools to remove old seal without damaging shafts or housings while undertaking this process carefully. Clean out sealing surfaces completely in order not to allow debris or particles from the old seal to interfere with the efficiency of the new seal during the installation process. Proper alignment on shafts is required when installing new seals into their positions so that they don’t let fluids leak again in future times ahead. Assemble the pumps back together by reconnecting them into hydraulic systems, then perform a confirmatory pressure test on them once more, showing their effectiveness is back functioning. After replacement, it is advisable to monitor any signs of failure occasionally. Standard environmental protocol should be followed in the disposal of old seals and any contaminated materials.

What to Do When Hydraulic Pump Loses Power?

When a hydraulic pump loses power, it is important to adopt an orderly approach in diagnosing and solving the problem. Firstly, confirm that electrical connections are still intact and that there is no disruption of supply due to blown fuses or tripped breakers. Secondly, verify their condition by examining the control circuit and safety components, such as the relays and limit switches, among others. If, however, the electrical constituents are positively established to be working properly, then check for mechanical failures in the hydraulic system. This involves checking for blockages in lines or filters as well as ensuring that the pump has not been damaged. An examination can also be made through visual senses for any signs of overheating or wear if required. Once the fault causing power loss is identified and fixed, power will be gradually restored while monitoring for any abnormalities within the system so as to confirm that everything works correctly. It is advised that this problem analysis and rectification process be documented for future use.

Possible Sources of Pump Power Loss

- Electrical Supply Issues: The most common cause of power loss in hydraulic pumps is inadequate or interrupted electric supply. These issues may arise from loose connections, damaged wires or broken circuit elements like fuses and overcurrent breakers. A steady watch on electrical input guarantees a reliable performance.

- Control Circuit Malfunctions: Control circuits, including relays, switches, sensors, etc, might develop faults, making it impossible for the hydraulic pump to receive the signals required for its operation. Failure of these parts can make pumps completely packed up hence all other associated controls should be inspected plus tested routine maintenance.

- Mechanical Failures: Problems internal to pump itself can also lead to no power being delivered by it with respect to electricity losses such as bearings wear out, gears wearing out and seals leaking which impede its function among others Blockage of hydraulic line or filter blocked may raise pressure beyond what is expected thus failing pump function optimally or totally ins some cases. This should be a concern for regular checks and repairs.

Testing the Electric Motor and Connections

To effectively test a hydraulic pump system’s electric motor and connections, start by visually examining all wires and connections. Look out for any signs of wear, rusting, or physical impairment that can hinder the flow of electricity. Next, while the system is functioning, use a multimeter to measure voltages at the motor terminals to check if it is receiving the correct voltage as recommended by the experts. Also, check resistance in motor windings using an ohmmeter; this value should match the manufacturer’s specifications. To validate further if there’s any fault, observe how the motor performs under load – look for vibration, unusual noise or heating which are signs of malfunctioning. Finally, confirm that control circuit signals operate rightfully as this directly affects motor operation. Document all findings and repairs made to maintain an elaborate history for future reference.

The Relief Valve and Coupling Inspection

One of the most essential steps in hydraulic pump maintenance is to inspect the relief valve and coupling. Firstly, confirm that the relief valve operates as expected by checking that it opens at a specific pressure to prevent system overload. Watch out for any leaks near the valve – this could indicate failures of seals or incorrect positioning. Check the opening pressure with a pressure gauge to make sure it corresponds to the specifications given by the manufacturer. Moreover, you should also check if there are any alignment problems or signs of wear on the coupling. Misalignment can cause excessive vibration leading to premature failure of both motor and pump. Check for wear or damage on coupling surfaces; change any parts that do not meet operational standards. Regular inspections and timely replacements of these items can considerably improve hydraulic system’s overall reliability and performance.

Why Is My Hydraulic System Overheating?

Possible causes of overheating in hydraulic systems are several. First, inadequate quantities of fluid result in less cooling efficacy, which directly affects the system’s thermal dissipation capability. Also, the quality of the hydraulic fluid is significant; thus, contaminated or degraded liquids may lose their heat-exchanging ability. Besides, high-pressure levels within a system may indicate a wrong part that creates extra heat during its operation. Other reasons comprise failing coolers or blocked cooling lines as inefficient cooling systems and excessive load/demand on the pump causing it to run at extreme temperatures constantly. To mitigate these risks and maintain optimal performance, there is a need for regular monitoring of oil temperature and timely maintenance.

What Causes Overheating In Hydraulic Systems?

- Low Fluid Levels: Reduced fluid level disables the system from properly dissipating heat hence escalating the operating temperatures. For effective cooling process, maintaining fluid levels should be done accordingly.

- Contaminated or Degraded Hydraulic Fluid: The cleanliness and viscosity of hydraulic fluids have a lot to do with their performance. Blockages caused by impurities can interfere with flow, while inefficiently transferring heat due to fluid decomposition can increase warming tendencies.

- High System Pressure: Elevated pressure often indicates valve problems or blockage inside, which results in more heating when operational. Monitoring this pressure and repairing any failures on time could prevent overheating and maintain the integrity of a given system.

Maintenance Of Oil Viscosity And Level

When checking the oil viscosity and level in hydraulic systems, one must consult manufacturer specifications that provide the recommended viscosity grade required for proper functioning of these systems. Use a calibrated dipstick or sight glass to determine the exact amount of liquid so as not to exceed limit values; otherwise, low levels cause overheating, as earlier mentioned above.To measure viscosity use viscometer kit where resistance to flow at certain temperatures is gauged.It is important to check this frequently since viscosity is influenced by temperature and contamination that could lead to potential failures in case it is not addressed on time. Moreover, for out-of-range viscosity, fluid replacement or filtration may be necessary for normal operation resumption. Monitoring hydraulic system integrity and performance requires close attention to the changes in both levels of fluid and their viscosity.

Ensuring Proper Air Flow And Heat Dissipation

Good airflow and heat dissipation are critical in maintaining the efficiency of hydraulic systems. If not well-managed, excess heat generated during operation due to poor air flow can cause component failure with associated reduced service life. Hence, it is essential to consider that airflow has to be optimized by inspecting the cleanliness of a number of elements, such as filters and vents, so as not to obstruct its movement in any way. At the same time, cooling fans or heat exchangers positioning may increase the rate at which thermal energy gets away especially under loaded conditions. It will be convenient when high loads have been mounted if thermal paste/heat sinks are used for efficient withdrawal of thermal energy from essential components. In order to maintain optimal thermal performance and prevent hydraulic systems from overheating, regular maintenance should include checking air patterns, among others, as well as ambient temperature conditions.

How Do I Maintain and Extend the Life of My Hydraulic Pump?

Some strategies can be implemented to maintain and extend the service life of your hydraulic pump. First, set up a regular maintenance plan that involves changing hydraulic fluid and filters for prevention of contamination as well as wear from debris. Controlling operating temperatures are important: maintaining fluid within the recommended temperature range helps to minimize thermal breakdown risk and component degradation. Moreover, they should make sure that there is no excessive pressure on the pump beyond the limits it has been designed for which could result in early failure. Proper alignment and installation are also critical, whereby misguidedness will cause extra load on a bearing of the pump, hence housing, which may accelerate mechanical defect occurrence. Finally, keep the environment around the pump clean and dry to protect against pollutants that could limit its performance or lifetime; inspect for leaks regularly and fix them immediately so as not to lose fluids or compromise system integrity.

Regular Maintenance Tips for Hydraulic Pumps

- Fluid Quality: Always use hydraulic fluids that meet or exceed manufacturer specifications. Periodically test the hydraulic fluid for contaminants and replace it if necessary to ensure optimal performance.

- Temperature Monitoring: Install temperature gauges to monitor the hydraulic fluid temperature continuously. If temperatures exceed recommended levels, investigate the cause, such as inadequate cooling or system overloads, and take corrective measures.

- Filter Maintenance: Regularly inspect and replace hydraulic filters according to the manufacturer’s recommendations. Clogged filters can restrict fluid flow and increase system pressure, leading to potential damage.

- Sealing Integrity: Conduct routine inspections for signs of leakage at seals and connections. Replace worn or damaged seals promptly to prevent fluid loss and ensure system operability.

- System Pressure Checks: Regularly check that system pressures are within specified ranges. Implement pressure relief mechanisms to avoid exceeding pressure limits during operation, which can result in catastrophic pump failure.

- Environmental Conditions: Maintain a clean operating environment.Dust, moisture or other contaminants deteriorate hydraulic performance; therefore, it is necessary to have a clean surrounding the pump that should be free from debris and high humidity.

Common Practices to Avoid Pump Problems

- Operating Outside Specifications: Ensure the pump is always operated within the manufacturer’s specified parameters, including flow rates and pressure limits. Operating outside these parameters can lead to premature wear or catastrophic failure.

- Neglecting To Monitor Parameters: Implement a comprehensive monitoring system for key performance indicators, such as temperature, pressure, and vibration. Regularly analyzing these parameters can help to detect anomalies early, thus preventing major issues.

- Ignoring Maintenance Schedules: Establish a stringent maintenance schedule that includes regular inspections and preventative maintenance tasks as outlined by the manufacturer. Failing to follow these schedules can increase the risk of unexpected breakdowns and reduce the pump’s operational lifespan.

Critical Checks to Ensure the Hydraulic System Works Efficiently

- Fluid Quality and Integrity: Regularly assess hydraulic fluid for contamination and degradation.Use filtration systems to maintain fluid cleanliness while conducting occasional oil analyses to identify problems that might hinder system operation.

- Seals and Gaskets Inspection: Conduct routine inspections of all seals and gaskets to ensure they are intact and effectively prevent leaks.Worn or damaged seals can lead to fluid loss and reduced pressure, resulting in a decline in system efficiency.

- Component Alignment and Connection Integrity: Ensure that all the parts are accurately positioned and all the linked elements are correctly joined. Mismatched attachments will result in extra wear out and power wastage, whereas a loss fit can be a source of system leakages or reduction of pressure, leading to poor performance overall.

Reference sources

- Berendsen Fluid Power

- Source: Berendsen Fluid Power

- Summary: This guide covers various troubleshooting steps for hydraulic pump pressure problems, including checking directional control settings, ensuring the pump is receiving fluid, and verifying that the drive motor is correctly oriented. These steps help diagnose and resolve common hydraulic pump issues.

- Machinery Lubrication

- Source: Machinery Lubrication

- Summary: This detailed guide provides instructions on testing variable displacement pumps, including using temperature guns and flow meters to diagnose performance issues. The resource aids in identifying and resolving common hydraulic pump problems effectively.

- Advanced Fluid Systems

- Source: Advanced Fluid Systems

- Summary: This comprehensive troubleshooting guide from Advanced Fluid Systems addresses a wide range of hydraulic system issues, including cooling performance, oil levels, and suction line obstructions. It offers practical advice for maintaining and troubleshooting hydraulic systems to ensure optimal functionality.

Frequently Asked Questions (FAQs)

Q: What are common signs that my hydraulic pump is experiencing issues?

A: Common signs of hydraulic pump issues include unusual noises, slow operation, low pressure, overheating, or a loss of power. These can indicate problems like air leaks, low oil levels, or cavitation.

Q: What steps should I take when I suspect my hydraulic pump has an air leak?

A: First, check all joints in the pump inlet line for tightness. Inspect the strainer and pump suction for any blockages or damage. Ensure the breather is clean and functioning properly. These troubleshooting tips for hydraulic pumps can help identify the source of the air leak.

Q: How often should I check the oil level in my hydraulic system?

A: It’s crucial to check the oil level regularly, ideally before each use of the machinery. Maintaining proper hydraulic oil levels can prevent common hydraulic issues like aeration and cavitation, ensuring the system operates smoothly.

Q: What should I do if my pump is producing unusual noises?

A: Unusual noises can be a sign of air bubbles or cavitation. Start by checking for air leaks in the pump intake or inlet line. Ensure the hydraulic fluid is at the correct level and that the strainer or filter is clean or replaced if necessary.

Q: Why might my hydraulic pump experience loss of power?

A: Loss of power can be due to several factors including a low oil level, worn components like the piston or pump body, or aeration. Perform a thorough inspection to check the oil level, look for air leaks, and examine parts for wear and tear.

Q: How can I prevent cavitation in my hydraulic pump?

A: To prevent cavitation, ensure that the pump inlet line is free from obstructions and that the hydraulic fluid is at the recommended level. Regularly check and clean or replace the strainer, and make sure the breather is functioning properly.

Q: What should I inspect if my hydraulic pump is operating at low pressure?

A: Low pressure can indicate an issue with the pump intake or a blockage in the system. Check the system for any obstructions or damage, ensure the correct hydraulic oil is being used, and inspect the pump drive and piston for any signs of wear.

Q: What are some key troubleshooting tips for hydraulic pumps?

A: Key troubleshooting tips for hydraulic pumps include regularly checking the oil level, inspecting for air leaks, ensuring all components like the strainer and breather are clean, and monitoring for unusual noises or performance issues. Keeping up with maintenance can prevent many common hydraulic problems.

Q: How can cavitation occur in mobile hydraulic systems?

A: Cavitation in mobile hydraulic systems can occur when there is an air leak in the pump suction or an obstruction in the inlet line. It can also be due to a low oil level or the wrong hydraulic fluid type. Regular inspection and maintenance can help prevent this issue.

Q: What could be the cause if my new hydraulic pump still isn’t working properly?

A: If a new pump isn’t working properly, ensure it is installed correctly, and that all connections and lines are secure. Check the oil level and ensure that the hydraulic fluid is suitable for the pump. Inspect the system for any return line blockages and make sure the pump is operating in the right direction.