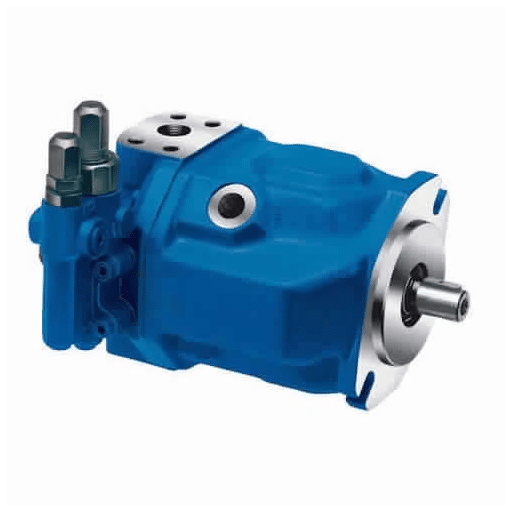

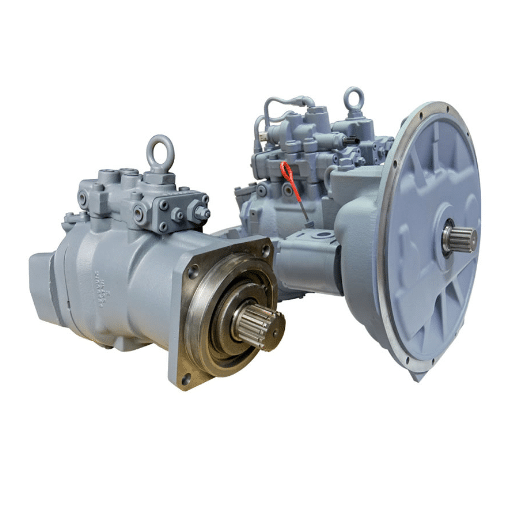

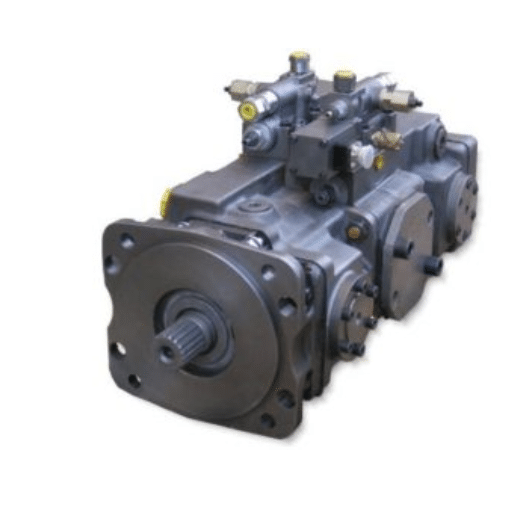

Overview: Hydraulics finds application in a variety of industries, including manufacturing, construction, aviation, and agriculture. The hydraulic pumps and motors are in the middle of the system because they convert mechanical power into hydraulic energy and vice versa. This comprehensive guide covers problems and repair solutions for hydraulic pumps and motors, helping you identify common issues, execute suitable repairs, and maintain optimal system performance.

Identifying Common Hydraulic Pump and Motor Issues

Signs and Symptoms of Hydraulic Pump Failure

Hydraulic pump failure manifests through several key indicators that require immediate attention:

| Symptom | Possible Causes | Impact |

|---|---|---|

| Pressure Variations | Worn internal parts (pistons, vanes) | Slow system operation, inefficient load handling |

| Excessive Noise (whining, banging, knocking) | Cavitation, aeration, and mechanical wear | Accelerated pump wear, potential system damage |

| Hydraulic Fluid Leaks | Worn shaft seals, gaskets, and housing cracks | Energy losses, system overheating, contamination |

Key Detection Methods:

- Pressure Gauge Monitoring: Regular monitoring helps detect performance variations early

- Audible Inspections: Listen for unusual sounds that indicate cavitation or aeration

- Visual Leak Checks: Inspect for external and internal fluid losses

Common Motor Malfunctions and Their Indicators

Motor faults typically present through these observable symptoms:

- Overheating: Caused by lack of ventilation, excessive load, or motor winding faults

- Abnormal Vibrations: Result from imbalance, misalignment, or bearing wear

- Unusual Noises: Grinding or whining sounds indicate bearing wear or electrical faults

Important: Motors operating above recommended temperatures risk insulation breakdown and shortened lifespan. Regular vibration analysis serves as a predictive approach to detect faults before system-wide failures occur.

Evaluating Hydraulic Cylinder Performance

Comprehensive cylinder evaluation involves monitoring these critical parameters:

- Operational Parameters: Pressure, fluid flow, and mechanical force output

- Leak Testing: Check for internal and external fluid losses

- Stroke Consistency: Ensure smooth, consistent cylinder movement

- Component Inspection: Examine seals, rods, and bearings for wear

- Fluid Quality Testing: Test for contamination with water or particulates

- Performance Comparison: Compare actual values against manufacturer specifications

Step-by-Step Guide for Hydraulic Pump Repair

Basic Repair Techniques for Hydraulic Pumps

Follow this systematic approach to restore maximum pump functionality:

| Step | Process | Key Considerations |

|---|---|---|

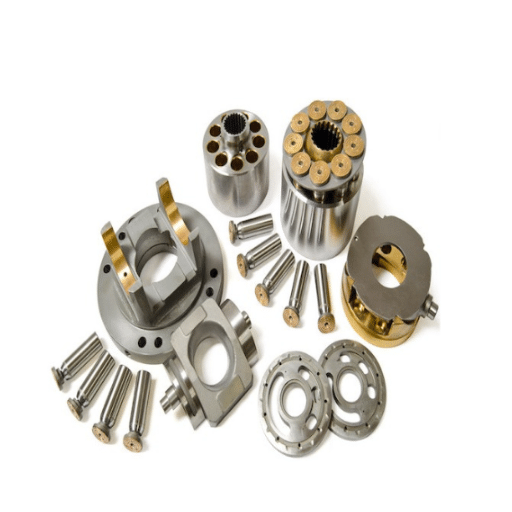

| 1. Inspection and Diagnosis | Examine seals, bearings, rotors, and housing components | Use diagnostic tools to measure pressure and flow rates |

| 2. Disassembly and Cleaning | Carefully disassemble, noting component locations | Use industry-approved cleaning methods and agents |

| 3. Component Replacement | Replace damaged seals, o-rings, and bearings | Use only manufacturer-approved replacement parts |

| 4. Surface Refurbishing | Address scoring or pitting through honing/polishing | Severe damage may require component replacement |

| 5. Reassembly | Reassemble with proper alignment and torque specifications | Use quality lubricants to minimize initial friction |

| 6. Testing | Comprehensive performance testing under load | Verify pressure output, flow rates, and temperature stability |

Advanced Repair and Rebuild Techniques for Motor Components

Advanced motor repair techniques require precision and specialized knowledge:

Non-Destructive Testing (NDT) Methods:

- Magnetic particle inspection

- Ultrasonic testing

- Dye penetrant testing

Precision Machining Processes:

- Grinding: Restores dimensional tolerance to original specifications

- Honing: Ensures functional mating and minimizes energy losses

- Precision Boring: Maintains critical component relationships

Surface Restoration Techniques:

- Thermal Spraying: Enhanced wear resistance and corrosion protection

- Laser Cladding: Superior surface enhancement capabilities

- Dynamic Balancing: Prevents premature failure from vibration

Essential Tools for Effective Hydraulic Repair

| Tool Category | Specific Tools | Primary Function |

|---|---|---|

| Testing Equipment | Hydraulic Test Bench, Pressure Gauge Kits | System performance verification and troubleshooting |

| Precision Tools | Torque Wrenches, Calibration Tools | Accurate component assembly and fitting |

| Seal Management | Seal Installation/Removal Tools | Prevent component damage during seal work |

| Surface Preparation | Honing Tools | Cylinder interior finishing for optimal seal engagement |

| Fluid Management | Filtration Units, Particle Counters | Fluid decontamination and cleanliness verification |

| Diagnostic Equipment | Circuit Analyzers, Software Tools | Real-time monitoring and complex issue diagnosis |

Professional Tip: Proper training in tool usage is equally important to fully leverage their capabilities in professional repair scenarios.

Preventive Maintenance for Hydraulic Systems

hydraulic pump and motor repair

Essential Maintenance Tips to Extend Hydraulic Pump Lifespan

- Regular Fluid Analysis: Monitor contamination, oxidation, and particle levels

- Filtration System Maintenance: Replace filters per manufacturer specifications

- Component Inspections: Regular checks of seals, hoses, and fittings

- Temperature Management: Maintain recommended operating temperature ranges

- Pressure Relief Valve Calibration: Prevent unnecessary system stress

Routine Motor Performance Checks

| Check Category | Inspection Points | Frequency |

|---|---|---|

| Physical Condition | Housing cracks, mounting bolts, corrosion signs | Weekly |

| Electrical Systems | Insulation resistance, connection tightness | Monthly |

| Mechanical Alignment | Motor-to-load alignment, vibration levels | Quarterly |

| Temperature Monitoring | Operating temperature ranges | Continuous |

| Lubrication | Bearing lubrication per manufacturer specs | As scheduled |

Importance of Regular Fluid Changes and Filter Replacements

Key Benefits:

- System Efficiency: Clean fluids minimize friction and heat generation

- Component Protection: Proper filtration removes harmful contaminants

- Extended Equipment Life: Proper filtration can increase equipment life by 50%

- Cost Reduction: Prevents expensive unplanned downtimes and repairs

Hiring Expert Hydraulic Repair Services

hydraulic pump and motor repair

Benefits of Choosing Certified Technicians

| Benefit | Description | Impact |

|---|---|---|

| Superior Technical Skills | Rigorous training and certification requirements | Accurate diagnosis and problem resolution |

| Quality Parts and Tools | Manufacturer-approved components and equipment | System compatibility and industry compliance |

| Efficient Service | Specialized training enables faster repairs | Up to 30% reduction in system downtime |

| Safety Compliance | Adherence to the latest safety standards | Personnel protection and legal compliance |

| Cost-Effectiveness | High precision work with quality components | 20% reduction in long-term maintenance costs |

Cost Considerations for Professional Services

Several factors influence professional hydraulic repair service costs:

- Repair Complexity: Heavy damage or specialized parts increase costs

- Service Provider Quality: Certified technicians may cost more initially, but provide long-term value

- Downtime Impact: Consider indirect costs from operational interruptions

- Parts Quality: OEM vs. aftermarket component considerations

Cost-Effective Repair Solutions

hydraulic pump and motor repair

Budget-Friendly Approaches

Recommended Strategies:

- Preventive Maintenance: Regular monitoring prevents costly failures

- Remanufactured Components: Quality refurbished parts at reduced costs

- Compatible Aftermarket Parts: High-quality alternatives to OEM components

- Experienced Service Providers: Faster diagnosis and reduced downtime

DIY Repair Tool Selection

Essential tools for DIY hydraulic motor repair:

- Precision Tools: Torque wrenches, circlip pliers, calipers, micrometers

- Testing Equipment: Hydraulic test bench for diagnosis and verification

- Contamination Control: Lint-free cloths, particle counters, fluid sample kits

- Specialized Components: Motor-specific seal kits

Frequently Asked Questions

A: Common issues include leaks, unusual noises, overheating, and reduced performance. These problems typically result from wear and tear, improper maintenance, or hydraulic fluid contamination. Early diagnosis and prompt repair help restore efficient system operation.

A: Look for repair shops with experienced technicians specializing in hydraulic systems. Check customer reviews, warranty offerings, and parts inventory. The best services provide comprehensive system evaluation with reasonable turnaround times.

A: The process involves initial diagnosis, disassembly for component inspection (gears, pistons, valves), repair or replacement of damaged parts, calibration, reassembly, and final testing to ensure proper working condition.

A: Hydraulic pumps should generally be serviced at least once annually or after every 1,000 hours of operation, depending on usage intensity and manufacturer recommendations. Regular service prevents unexpected breakdowns and costly repairs.

A: While minor maintenance tasks may be possible for knowledgeable individuals, major hydraulic pump repairs require specialized skills and equipment. For significant repairs or complete rebuilds, employ qualified technicians to ensure safety and proper standards.

A: Repair is generally more cost-effective than replacement, particularly for equipment in good working condition. Professional repairs restore functionality while extending component lifespan, minimizing downtime, and avoiding new equipment purchases.

A: Most hydraulic motors can be repaired, including gear motors, piston pumps, and vane motors. Each type has specific characteristics and applications, and qualified repair shops can diagnose and repair various motor types.

A: Preventive maintenance is key to avoiding hydraulic pump issues. Regularly check fluid levels, inspect for leaks, ensure proper filtration to prevent contamination, follow manufacturer maintenance schedules, and use high-quality replacement parts.

A: Reputable repair services usually guarantee their work, though warranty periods vary by provider and repair extent. Always clarify warranty terms before proceeding with repairs to ensure quality service and coverage against future problems.

Key Takeaways

Successful hydraulic pump and motor repair requires proper diagnosis, quality tools, skilled technicians, and regular maintenance. Whether choosing professional services or DIY approaches, prioritize safety, use appropriate tools, and follow manufacturer specifications for optimal results and system longevity.