Hydraulic pumps are virtually inseparable in many industries that require power and precision to perform gigs. Among these hydraulic pumps, the heavy duty 12V hydraulic pump is the versatile and efficient solution for mobile and remote applications. One should, therefore, be conversant in the science behind hydraulic power when deciding the operating lifts, construction tools, or enhancing their machinery. Thus, this article will talk about the basics of hydraulic mechanisms, the peculiarities of 12 volt pumps, and their applications. Upon completion, one would appreciate how these heavy-duty systems aid in productivity and efficiency in real tough environments.

Introduction to Hydraulic Power

What is Hydraulic Power?

Hydraulic power, commonly called fluid power, is a technique that utilizes a pressurized liquid, mostly oil or water, to transfer energy for performing work. Pressure is applied to the fluid, which is allowed to flow through hoses, valves, and pistons to produce motion or mechanical action. These systems, able to multiply force, allow for precise control and can hence be utilized for many industrial and mechanical purposes.

Another characteristic of hydraulic power is the efficient application of energy to the components, losing very little in doing so. In contradistinction to mechanical systems that are built on the basis of gears or belts, these systems use liquid materials that are resilient to compression, consequently guaranteeing a steady transmission and application of force. An operator can easily handle heavy machines like cranes or excavators with a very high degree of elegance and precision.

Hydraulic systems are used widely, with industries such as construction, manufacturing, and transportation because of their reliability and versatility. These systems operate forklifts, presses, and landing gears, among a few examples of places where the system has been put to the test in challenging situations. Being able to scale hydraulic power combined with forces that work on hydraulic power under extreme pressure makes for hydraulic power to be an advanced modern engineering technology in almost all industrial processes.

How Hydraulic Power Units Work

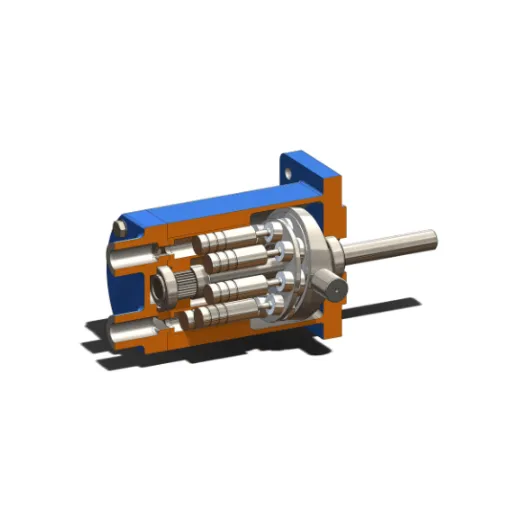

To work, power units convert mechanical energy into hydraulic energy, which through fluid power, is used to perform work. They consist of several important components such as a motor, pump, reservoir, valves, and accumulators, which work together with the generation and regulation of pressurized fluid flow. It is the motor that powers the pump, which in turn withdraws hydraulic fluid from the reservoir, pressurizes it, and releases it for transmission through the system. Hydraulic actuators or cylinders use the energy contained within the pressurized fluid to do work, like lift, press, or rotate.

Hydraulic power units do much of their operations depending on the pump and their control systems. Valves here control the flow rate, pressure, and direction of the hydraulic fluid. These creations allow the system to precisely control its output independently from any variations in loads. The accumulators store energy by first accepting hydraulic energy supplied in excess and releasing hydraulic energy into the system when required to ensure efficiency and to prevent energy wastage.

For longer life and well performance, correct maintenance and operation of hydraulic power units are indispensable. The hydraulic fluid must remain clean and at the proper level to prevent the system from getting contaminated and to cause wear. Components such as seals, hoses, and fittings should be routinely inspected to prevent leaks that could cost pressure loss. When kept well, hydraulic power units are reliable and efficient systems that provide high force and high precision into something that fits an industrial need on different scales.

Importance of Hydraulic Power in Various Industries

Because hydraulic power can provide high force, precise control, and reliable performance, it remains crucial in many industries. Hydraulic systems convert hydraulic energy into mechanical power and find practical applications in heavy lifting, high-pressure operation, or fine control. Industries in which hydraulic power has relevance include construction, manufacturing, aerospace, agriculture, and marine operations.

In construction, hydraulic systems operate excavators, loaders, and cranes, providing the necessary force for the movement and lifting of heavy materials. Likewise, hydraulic presses and injection molding machines shape materials and assemble components in a manufacturing set-up. These systems supply a steady pressure, which ensures that operations remain precise and efficient on the production lines.

Being hydraulic power, the aerospace and marine industries are reliant on different systems for critical functions, such as flight surface control, landing gear deployment, and ship steering. In the agricultural sector, hydraulic systems increase work capacity and reduce manual labor involved in tractor and harvester operations. Indeed, having its watering systems being versatile and sturdy is why one sees their application in various sectors, being at the heart of any modern technological and industrial stride.

Understanding 12 Volt Hydraulic Systems

What is a 12 Volt Hydraulic Pump?

The 12V hydraulic pump is a compact and efficient device that converts electrical power from a 12V DC source into hydraulic energy. The basic arrangement of the system consists of an electric motor, a hydraulic pump, a reservoir, and control valves. These pumps find widespread use in mobile applications, including trailers, dump trucks, and snowplows, where the pump is specifically designed to create an optimum solution for situations in which portability with a dedicated power supply is important.

A fundamental feature giving a 12-volt hydraulic pump commercial appeal is its adaptability and ease of interfacing with mobile machinery. Such pumps can generate powerful hydraulic pressures ranging from about 1,500 up to 3,500 PSI, depending upon the type of pump and application. Being lightweight, these units can be placed in confined spaces without losing required functionality, generally running off a 12-volt battery, perfect for applications where there is no provision for connection to the regular power grid. Moreover, their construction tends to be rugged and of high quality so as to be able to withstand adverse operating conditions.

Modern 12-volt hydraulic pump systems have now been modernized to enhance their functionality and promote efficient working. For instance, in many models, remote control capabilities are present, variable flow rates are allowed, and pressure relief mechanisms are built-in to relieve pressures that could overload the system. Modernized motors are indeed reducing energy consumption and noise levels. These improvements, together with a steady demand for portable hydraulic setups, cemented the vital role of 12V hydraulic pumps in modern industries-from agricultural to automotive applications-and at air, they offer indispensable tools capable of a myriad of technical operations.

Benefits of Using 12V Hydraulic Pumps

The 12-volt hydraulic pump has a lot of benefits that are required for efficient and reliable performance in various industries. Here is a detailed list of five major benefits:

-

Portability and Compact Design

Being lightweight in design, these pumps have portability; thus, they are well-suited for use where space is limited, or mobility is important. Their compact design allows the setting up of the pumps into equipment, such as utility vehicles or trailers, without any installations. Hence, operators may just carry the pump to some distant location where the work needs to be done.

-

Energy Efficiency

Modern motor design mechanisms have basically made 12V hydraulic pumps consume the least power available. With data supporting measurement of the newer systems using about a 20%-less-energy consumption rate compared to the older ones, they are viable to be cost-competitive for long-standing applications that require lifting or material handling.

-

Various Industrial Applications

Due to their adaptability, 12-volt hydraulic pumps are compatible with a wide array of machinery: agricultural equipment, industrial tools, and automotive systems. Given all these applications, they can be designed to operate small hydraulics or even emergency response equipment where utmost reliability is demanded.

-

Durability Under Extreme Conditions

The pumps are designed for prolonged use in harsh environmental conditions, be it dust, moisture, or temperature fluctuations. Proper choice of materials, plus corrosion-resistant coatings, assures performance and longevity even in rough outdoor or industrial environments, mitigating maintenance and downtime.

-

Cost-Effectiveness and Increased ROI

Lower operational charges, less energy consumption, and little time for maintenance work make 12-volt pumps a choice that’s cost-effective for companies. Analysis shows over a 30% potential service life extension for the systems if maintained appropriately and hence sustained over time for higher return on operators.

By providing these key advantages, 12-volt hydraulic pumps continue to play a critical role in streamlining operations and enhancing system capabilities across diverse industries.

Common Applications for 12 Volt Hydraulic Pumps

12-volt hydraulic pumps are versatile components acting across industries due to their efficiency, portability, and adaptability. Here are five applications wherein these pumps are commonly used along with their insights concerning specific usages:

-

1

Agricultural Machinery

12-volt pumps are mainly used in tractors, plows, and harvesters to elevate, steer, and hydraulically operate power take-off (PTO) systems. The pumps exert pressure to carry out heavy-duty possible operations, enhancing productivity while sustaining energy efficiency in rural and in-field surroundings. According to studies, hydraulic cycle times have been shown to be 20% faster than manual systems.

-

2

Material Handling Equipment

Equipment like forklifts, pallet jacks, or aerial work platforms uses the 12-volt pumping systems to power their lift and position mechanisms. The pumps are ideally suited for jobs in warehouses and industrial facilities, given their small footprint and reliable performance. Data are available indicating these pumps can carry up to 10,000-pound load with absolute precision and consistency.

-

3

Automotive Maintenance and Repairs

Hydraulic pumps play an important role in mobile automotive applications that include car lifts and tow trucks. The 12-volt systems give the mobility and controlled force necessary to lift vehicles or operate a recovery mechanism safely and reliably. Today, automotive hydraulic tools have become 15% more efficient because of technological advances.

-

4

For Construction and Heavy Equipment

In the realm of construction equipment requiring portable power, 12-volt hydraulic pumps must be present-a wise adage better left unexplained. Working through rugged conditions yet delivering before time sufficiently ensured site operations are enhanced. Research shows a near 25% reduction in operational downtimes when well-maintained hydraulic systems power an operation.

-

5

Marine Applications

Hydraulic pumps power winches, steering systems, and lifting operations aboard boats and yachts. The 12-volt type seems to have gained much popularity since it fits well with marine batteries, offering integration with the electrical systems. Testing indicated that the pumps could thrive in harsh saline environments, maintaining their performance level through five years of regular usage.

Such applications display how central the role of 12-volt hydraulic pumps is in maximizing efficiency, putting less manual effort into production, and maximizing performance across diverse sectors. Since they continue to evolve, these pumps continue to represent a primary asset for use in both conventional and contemporary industry.

Types of Hydraulic Pumps

Single Acting vs. Double Acting Hydraulic Pumps

Single-acting hydraulic pumps are used to generate pressure in one direction, while double-acting hydraulic pumps generate pressure in both directions.

| Aspect | Single-Acting | Double-Acting |

|---|---|---|

| Force Flow | One-direction | Bi-directional |

| Connections | Single port | Dual ports |

| Return Method | External aid | Hydraulic power |

| Expense | Economical | Costly |

| Design | Basic | Advanced |

| Tasks | Simple lifts | Complex motions |

| Precision | Limited | High |

| Performance | Average | Superior |

| Operation | Slower | Quicker |

| Field | Light work | Heavy work |

Overview of 12V DC Hydraulic Pumps

A 12-volt DC hydraulic pump offers compact power and efficiency to serve applications requiring hydraulic pressure by a 12-volt direct current electrical supply. These pumps find their common applications in mobile and automated systems and are ideally applied in certain situations where electrical energy is available, but compactness and portability are on the higher priority.

From the technical side, this 12V DC hydraulic pump converts electrical energy drawn from the battery into mechanical energy which drives the pump mechanism to create hydraulic flow and pressure. Most systems embrace a reservoir, pump motor, valves, and hydraulic lines to deliver precise and consistent performance.

With modern advancements, 12V DC hydraulic pumps have been capable of going into high-pressure ranges with pressures that usually go beyond 3000 PSI, depending on model and brand. They are built very tough to withstand the rigors of hard working conditions, ranging from powering agricultural machinery, industrial equipment, and construction tools. This makes the pumps best owing to their hydraulic efficiency and less noise compared to other hydraulics. Also, several models offered come with safety features such as overload protection or pressure relief systems, thus adding extra areas of durability and competent operation.

The versatility of 12V DC hydraulic pumps makes them essential in different industries, especially in mobile hydraulics, where they continue to be enhanced for durability, precision, and performance in versatile operating areas.

Choosing Between Single and Double Acting Pumps

In deciding between a single-acting and a double-acting hydraulic pump, one must understand with each other their functional differences and application needs. Single-acting pumps merely pressurize the hydraulic fluid in one direction; external force, such as a spring or a counterweight, moves the pistons back to the starting position. They are usually simpler in design, less expensive, and preferred in situations where unidirectional force is sufficient, e.g., log splitters or lift mechanisms in certain industrial applications.

Double-acting pumps, in contrast, pressurize hydraulic fluid both ways from each end, thus enabling uninterrupted control of movement in multiple directions without the need for any external force. With such a dual-featured setup, greater efficiency and precision become possible, thereby necessary in systems that require constant and repetitive motion, such as automated machinery, robotics, or heavy construction equipment.

Among factors taken into consideration when deciding on the type are output forces required, cycle speed, operational intricacy, and budgetary constraints. Double-acting pumps are better suited for high-demand or load-intensive environments, whereas settings in the single category serve economical and low-complexity solutions. The best pump selection can improve system performance and life expectancy, depending on the hydraulic system’s particular operational requirements.

Applications in Dump Trailers and Trucks

Using 12V Hydraulic Pumps in Dump Trucks

In the modern dump truck industry, a very important part of operations is the 12V hydraulic pumps, which supply power, by very precise means, for raising or lowering a dump-bed. Operating at 12 volts DC, usually supported by the vehicle’s power system, these pumps marry well with the hydraulic fluid reservoirs and the actuators to become a reliable source of pressurized fluid for maximum efficiency.

Factors and definitions important to 12V hydraulics used in dump trucks range from load capacity to duty cycle and operating pressure. Depending on the model of pump, a standard 12V pump generates between 1500 and 3200 PSI of pressure, very sufficient in terms of heavy loads of dump trucks. The flow rate of the pump, measured mostly in gallons per minute (GPM), also directly influences the speed of articulation of the bed, thus governing onsite productivity.

The modern-day 12V hydraulic pump designs focus on creating durability with efficiency; it features things such as anodized aluminum housings and thermal protection to sustain long operational hours even in adverse conditions. Plus, compact and lightweight designs ensure easier installation and enable compatibility with different truck configurations. Whether in construction, agriculture, or material handling, 12V hydraulic pumps increase dump truck versatility and augment operational performance.

Maintenance is crucial for continuing the working of the pump and increasing the service life of the dump truck’s hydraulic system. The hydraulic pump should be checked for cleanliness of the hydraulic fluid, and the level of hydraulic fluid should remain in accordance with the prescribed level.

Hydraulic Power Units for Dump Trailers

Hydraulic power units provide fundamental support to the dumping trailer systems with regard to exerting the necessary forces to lift and lower heavy loads efficiently. The system comprises electric motor, hydraulic pump, and reservoir to generate and store hydraulic pressure. The design of hydraulic power units for dumping trailers generally consists of a 12V DC motor, which is compatible with the standard vehicle battery system and is thus very versatile for mobile operations.

Key features of hydraulic power units for dump trailers include adjustable flow rate, pressure relief valve for optimized safety, and very compact and lightweight, allowing easy integration with trailers of various sizes. Recent improvements in valve control technology and heat dissipation methods guarantee their reliability and efficiency even under continuous high-performance applications.

When choosing an HPU for a dump trailer, lifting capacity, cycle times, and the durability of the system should be discussed. Pressures rated for most commercial tools range from 2,500 to 3,500 PSI, responding to the heavy-duty industry demands from construction, waste, and agriculture.

Regular inspections are imperative for preempting operational problems. Important maintenance urgently include the checking of hydraulic fluid levels, verifying the connections for possible leaks, replacements, and checking manufacturer specifications. Such maintenance will behave in concert with the desired performance of the equipment and reduce down-time, all while safeguarding against equipment failures on the long haul.

Best Practices for Operating Dump Trailer Hydraulic Pumps

The dump trailer hydraulic pumps must be operated efficiently and safely in accordance with prescribed protocols, and an understanding of the latest technological advances must complement this. Following are given the detailed best practices for gaining the most of the hydraulic system in terms of performance and longevity.

-

Pre-Operational Checks

Conduct thorough inspections before operating the equipment to identify potential issues. Check for hydraulic fluid levels, hoses, and connectors for any visible leaks or wear; ensure in all cases that all fittings are well-secured. Also, be sure that the system pressure is according to manufacturer specifications for any overload on the components.

-

Hydraulic Fluid Maintenance and Quality

Hydraulic fluid should be safe for system compatibility and performance. Contaminants or moisture could hamper system efficiency and cause premature wear; fluid purity is to be tested and regularly checked. Hydraulic fluid should be replaced as per the interval mentioned in the operator’s manual.

-

Temperature Monitoring

As hydraulic systems are sensitive to temperature extremes, fluid and system operating temperatures should be periodically checked to prevent overheating-which causes seal failure or poor lubrication. For best accuracy, thermal sensors or infrared tools should be utilized, and in said situations, a prolonged operation tolerant in the hot environment must be strictly avoided.

-

Alignment of Loads and Distribution of Loads

The load must be distributed so as not to place unnecessary strain on the hydraulic pump before entering the dumping cycle. Uneven loads imparting high-pressure differences would very well contribute to system failure or damage to mechanical components.

-

Operate within Safe Duty Cycles

Hydraulic pump ingestion within a relatively brief period can cause overheating and reductions in potential efficiency. Embark on the recommended duty cycle, in other words, use the system only after it has been given time to cool between operations.

-

Periodic Calibration and Adjustment

Pressure relief valve should be calibrated periodically for maximum performance according to design parameters. System inefficiencies or overpressure problems will arise if the setting is off, with possible component failure.

-

Proper Storage and System Cleaning

This dump trailer, along with the hydraulic pump, must be stored in a clean and dry area during non-use to minimize dust, moisture, or corrosive agent exposures. Clean the hydraulic system periodically to prevent debris buildup that may block flows or cause seal damage.

By incorporating these best practices, operators can not only maximize the efficiency and lifespan of dump trailer hydraulic pumps but also reduce operational costs and downtime caused by unexpected failures. Staying informed about technological advancements and updates from manufacturers enhances the ability to troubleshoot issues effectively and integrate newer, more reliable components into the system.

Installation and Maintenance of 12 Volt Hydraulic Pumps

Installation Guidelines for 12V Hydraulic Systems

For a guaranteed successful installation of a hydraulic system operating under 12 volts, one must maintain a disciplined and systematic procedure. Firstly, one must read the manufacturer’s manual thoroughly to fix specific guidelines and requirements on the model of the pump. Ensure the power source, usually a 12V battery, is rated for voltage and amps as given to the hydraulic pump; otherwise, the pump does not develop minimum pressure or gets damaged. Also, all tools and compatible parts, i.e., hoses, fittings, and filters, should be available and checked for any defects in quality assurances.

Install the hydraulic pump on a flat, rigid surface using the mounting brackets and hardware supplied by the manufacturer. This reduces excessive vibration during operation that could cause premature wear or inefficiency. Proper alignment of the pump’s ports with the hydraulic hoses is essential in order to avoid undue stress on the connections. Always use thread sealant or Teflon tape on the fittings as per requirements for leak prevention. Also, consider the torque specifications to avoid overtightening when securing the bolts.

Pay attention to the wiring configuration during the electrical installations. The wires must be adequately sized for the power and grounding connections, which are established at points that offer strong electrical contact and are free from corrosion. Connect the positive leads on the positive side and the negatives on the negative side, avoiding reverse polarity. Finally, check every aspect of the hydraulic system for fluid levels, tight connections, and the presence of air within the hydraulic lines. Perform the test run under controlled conditions, ensuring everything works correctly and adjusting it when necessary before going into regular operation.

Regular Maintenance Tips for Longevity

-

Component Routine Inspection

Perform an engineering visual examination every week for all components of a given system, focusing on wear-prone areas such as seals, hoses, or moving parts. Detecting early damage such as cracks, leaks, or corrosion will be of huge benefit, preventing complete failure and minimizing downtime.

-

Fluid Analysis and Replacement

Analyze fluids at scheduled times for contamination level, viscosity, or chemical stability. Hydraulic or lubricating fluids must be replaced as directed by a manufacturer or when an analysis indicates degradation. Contaminated fluids can accelerate wear and reduce system efficiency.

-

Cleaning and Lubrication

Accumulations of dust, dirt, or grime can jeopardize the functioning of critical components. Clean the system regularly and lubricate bearings, hinges, or other moving parts. Only approved cleaning agents and lubricants must be used to avoid damage.

-

Alignment and Calibration

Mechanical parts that are misaligned strain the system and cause inefficiencies or uneven wear. Perform alignment and calibration tests using precise instruments at periodic intervals to assure peak performance.

-

Test Safety Systems

Make sure safety systems like pressure relief valves and emergency shut-offs are functioning properly. Conduct tests in controlled scenarios at regular intervals so that the fail-safes will reliably work in a critical situation.

-

Monitor Patterns of Usage

Maintain records of operational workloads and observe prescribed duty cycles to lower the chances of overheating or overload. Aggrandized monitoring tools and IoT-enabled systems will supply real-time analysis information that supports maintenance schedules.

These maintenance activities will increase the operational life of your equipment and keep them performing at peak efficiency. As a benefit, technical rigor combined with proactive maintenance reduces repair costs and maximizes productivity over time.

Frequently Asked Questions (FAQ)

Q: What is a heavy duty 12 volt hydraulic pump?

A: A heavy duty 12 volt hydraulic pump is a power unit-type hydraulic pump designed to run on 12V DC power source. It is designed with the capability of lifting heavy loads efficiently and is often employed in applications like dump trailers and lift gates.

Q: How does a hydraulic cylinder work with a 12 volt hydraulic pump?

A: A hydraulic cylinder works with a heavy duty 12 volt hydraulic pump by converting hydraulic pressures created by the pump into mechanical forces that can be used to lift or move heavy objects, making it suitable for the dump trailer applications and other lifting tasks.

Q: What are the advantages of using a double acting hydraulic power unit?

A: A double acting hydraulic power unit works to allow the control both of extension and retraction of the hydraulic cylinder, thus providing for efficiency and versatility. Some examples of applications would include very fine control, like those acting on dump truck hydraulic pump applications.

Q: Can I use a single-acting pump on dump trailer applications?

A: Single-acting pumps can be used for dump trailer applications, especially if the load needs to be lifted only in one direction. However, more complex operations will require the double acting alternative.

Q: Pressure rating for heavy-duty 12V hydraulic pumps?

A: Pressure rating for heavy-duty 12V Hydraulic pumps varies per model, with many of the pumps capable of attaining a max pressure rating somewhere around 1500 to 3000 PSI. In order to ensure safety and efficiency, one should select a pump that fits the specifics of the application in question.

Q: How is lifting power calculated, and how do I decide how much I want for an application?

A: Lifting power required is based on weights the loads will be put through; the cylinders used; and heavy-duty specification requirements set for the 12v hydraulic pump. Basically, the pump should be able to handle the capacity required or more.

Q: What are some applications of the 12v hydraulic power unit?

A: The applications of 12v hydraulic power units are numerous, such as lifting extremely heavy loads, operating lift gates, powering hydraulic cylinders for dump trailers, among many favorites. Due to their flexible nature, they serve commercial and residential purposes quite well.

Q: How can you differentiate a hydraulic power pack from a hydraulic pump?

A: A hydraulic power pack will usually have a hydraulic pump with a reservoir, valves, and other components-constituting a complete hydraulic system. A hydraulic pump on its own is concerned solely with generating hydraulic pressure and therefore needs other components capable of completing it.

Q: What is the efficiency of 12v DC hydraulic power pumps?

A: 12v DC hydraulic power pumps are efficient and reliable. They draw less power to give sufficient pressure for applications that are moving from on-location to portable and require consistent performance, such as dump trailers and electric lift systems.

Q: Are there special requirements for oil tanks used with hydraulic pumps?

A: Yes, it must be of a sufficient size to contain the hydraulic fluid needed by the system. It should also be compatible with the heavy duty 12 volt hydraulic pump in use to proceed with operations smoothly and to avoid malfunctioning of the whole system.

Ready to Power Your Next Project?

Heavy duty 12V hydraulic pumps offer the perfect combination of power, portability, and precision for modern industrial applications. Choose the right system for your needs and experience enhanced productivity and reliability.