Forklift hydraulic pumps play a critical role in ensuring the machinery operates efficiently, powering essential functions like lifting, moving, and tilting heavy loads. However, like any mechanical component, these pumps are susceptible to wear and tear, which can lead to operational inefficiencies or complete breakdowns. Understanding how to diagnose issues and implement effective maintenance practices is vital for minimizing downtime and extending the lifespan of your forklift. In this guide, we’ll explore key troubleshooting techniques and essential maintenance tips to help you tackle common hydraulic pump problems with confidence. Whether you’re a seasoned technician or a facility manager aiming to optimize equipment performance, this article is designed to serve as a practical resource for addressing hydraulic pump challenges effectively.

Understanding the Forklift Hydraulic System

Components of the Forklift Hydraulic System

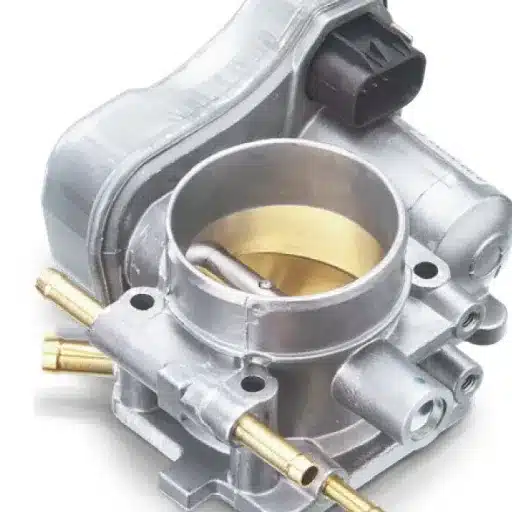

In the hydraulic system of a forklift, some components must be maintained in perfect harmony to carry loads with precision. At the center, a hydraulic pump creates pressure to force fluid to flow through the system. Wherever such pressure is formed by a fluid, it becomes the motive force for power transmission and precise movements.

Second to that is the hydraulic fluid reservoir, which stores the hydraulic fluid that flows throughout the system. It is essential to keep fluid levels up; otherwise, the components may get damaged or experience cavitation. There are filters for eliminating contaminants so that pure fluid is maintained for thus providing optimal performance.”

Another important component is the hydraulic cylinders, as these are what transform the pressure of the hydraulic fluid into mechanical force. These cylinders are usually connected to the forklift’s lifting mechanism to lift and lower loads. Valves and hoses complete the system, routing fluid flow to ensure safe and efficient operation. Regular inspection of the components can go a long way in preventing excessive downtime and in increasing the lifespan of the forklift.

How Hydraulic Pumps Function

Hydraulic pumps provide motion when mechanical energy is transformed into hydraulic energy in the form of pressurized fluid. Initially, the pump’s motor drives its internal components, and a vacuum pressure is created at the pump inlet. This vacuum draws fluid from the reservoir to fill the pumping chamber. After pressurization, the fluid is discharged to satisfy the requirements of the hydraulic system.

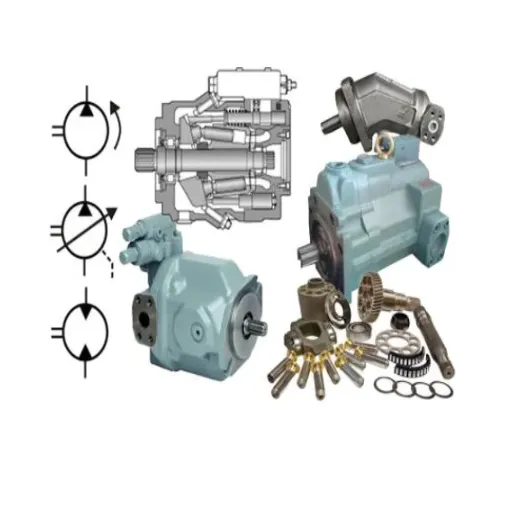

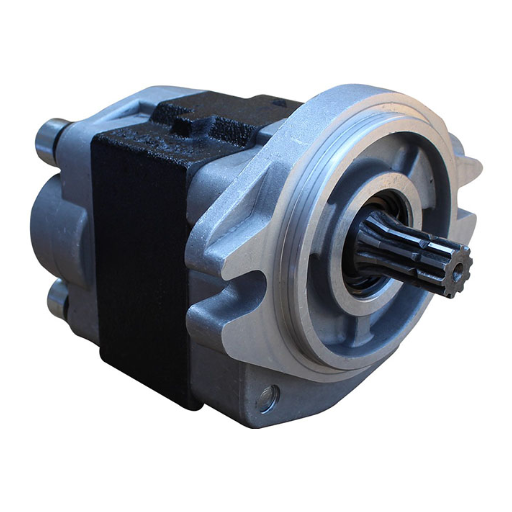

The system must be supplied with a fixed flow of hydraulic fluid due to its function of exerting force and motion by lifting, pushing, or moving heavy loads through the system. Major types of hydraulic pumps include gear pumps, vane pumps, and piston pumps, with each kind depending on its design features and applications. For instance, gear pumps are simple and reliable, whereas piston pumps are more efficient and are used for applications requiring high pressure.

Hydraulic pumps must retain their integrity for systems to perform correctly. Hence, upkeep is considered a must. This includes checking for any leaks on the pump itself, inspection of seals and bearings, as well as ensuring that the hydraulic fluid remains clean. Efficient pump functioning makes for a reliable system; hence, the system does not become an energy-wasting medium but rather becomes safe to engage with on its own through machinery operation.

Common Hydraulic System Problems

Hydraulic systems, while highly efficient, are prone to several common issues that can disrupt operation and reduce performance. Below are some of the most frequent problems encountered in hydraulic systems, along with corrective measures:

- Leaks: Hydraulic leakage is among the predominant failures typically caused by worn seals, loose fittings, or faulty hose lines. Systems lose power to operate, and environmental contamination in return. Periodic inspections need to be conducted on damaged seals or hoses; if found, these should be replaced while checking that all fittings are tightened to the proper torque. Using the best materials and ensuring their proper installation can almost do away with leakage.

- Overheating: The hydraulic system sometimes produces excessive heat due to improper fluid viscosity, clogged filters, or over-worked components. Heat accelerates the degradation of hydraulic fluids, which may at the same time reduce the lifetime of the seals and may even give rise to inefficient systems. Overheating could be solved by ensuring hydraulic fluid has the correct viscosity, filters are kept clean or replaced, and by ensuring that the system’s load is not beyond its design capacity. Good cooling arrangements should also be put in and maintained.

- Air Contamination: Air in the hydraulic system, coupled with aeration formation, leads to erratic operation, noise, or depreciated system performance. Principally, the phenomena occur with loose fittings, failing seals, or low fluid levels. To bleed air from the system, the source of the contamination should be eliminated by tightening connections or sealing replacements, followed by bleeding of the trapped air. Proper fluid maintenance reduces the risk of air contamination with time.

With regular upkeep, quality components, and prompt correction of these common problems, hydraulic systems can run efficiently and reliably, with downtime and operation costs minimized.

Troubleshooting Hydraulic Pump Issues

Identifying Common Hydraulic Problems

A hydraulic mechanism will encounter all kinds of issues depending on the many operating variables, all of which affect its performance. It is imperative to analyze these issues methodically so that they can be resolved in time. Mentioned below are several hydraulic problems frequently encountered, with some of their causes:

- Lack of Pressure Output: Leaks inside the pump, sealing wear, or mechanical damage of some sort might cause loss of pressure. Some wear or defects in the pump housing, valves, or seals that restrict performance should be checked.

- Overheating: Excessive heat causes inefficiency and deterioration of the components. Overheating might be due to low heat levels, contamination of hydraulic fluid, or a wrong cooling arrangement. Proper temperature monitoring and ensuring proper quantity and quality of fluid will negate the possibility of overheating.

- Audible Noise or Vibration: In the everyday language of industry, a strange noise or an unusual vibration signals trouble. Usually, these are also signs of cavitation, aeration, or misalignment within the component. Cavitation may be thought of as a phenomenon where air pockets are created within the fluid, often due to restrictions in flow or a lowered fluid level; whereas aeration refers to air contamination.

- Fluid Contamination: Dirt, water, or metallic particles are common contaminants that severely hamper the performance of a hydraulic system. Using an appropriate filter for the operating environment and carrying out routine fluid analyses will help identify and circumvent contaminant-induced failures.

- Slow or Erratic Actuator Movement: Actuators can move late or sometimes erratically depending on whether there is air in the system, the viscosity of the fluid is inappropriate, or there is a blockage in the hydraulic lines. To prevent this, the hydraulic system should be bled of air, and the hydraulic fluid should be selected according to the manufacturer’s specifications.

If problems arise commonly, diagnosing them in a systematic fashion using structured troubleshooting techniques, such as root cause analysis, can guarantee the lasting effect and absolute reliability of the hydraulic systems. Additionally, working in tandem with maintenance scheduling and improvements in diagnostic tools and predictive analytics enhances system resilience and brings down the number of unplanned downtime occurrences.

Diagnosing Hydraulic Leaks

Leaking hydraulics can be among the most common problems in hydraulic systems and can greatly reduce efficiency and cause mechanical failures if not addressed immediately. Diagnosis of hydraulic leakage requires a systematic procedure comprising visual inspection as well as advanced assessment techniques. One must begin by inspecting prominent external signs such as fluid puddles, poor system performance, or pressure drop in pressure-side lines or chambers. Ageing, wear, and exposure to heat might break down hose lines, deteriorate seals, or weaken loose-fitting and connecting hardware.

Advanced technologies include ultrasound equipment and fluorescent dyes to detect leaks hidden from plain sight. An ultrasonic sensor monitor changes in sound signatures associated with escaping fluids, thus enabling the exact location of the problem. Similarly, fluorescent dye added to hydraulic fluid will indicate leakage points when exposed to ultraviolet light.

Environmental conditions must be considered as well because temperature or pressure fluctuations might increase seal degradation or contribute to fluid viscosity changes. Time-based data recording of operating parameters such as temperature and pressure is helpful while investigating specific operating conditions where the recurrent issue is appearing. This combined approach, therefore, ensures that the leak can be fully understood to implement mitigation efforts that will be very precise and effective, minimizing system downtime at the same time.

Recognizing Unusual Noises from the Pump

An unusual noise coming from a pump is often an early symptom indicating that some mechanical or operational problem is developing within the system. These are immediate signs needing identification, as they can be problems occurring due to cavitation, bearing failure, misalignment, or impeller damage. For example, cavitation almost always produces an unmistakable rattling or “marble-like” kind of sound, caused by the collapsing of vapor bubbles in the pump. This particular event slowly deteriorates the surface of the impeller, thereby reducing the efficiency and life expectancy of the pump. On the contrary, wine or grinding sounds tend to warn of worn bearings; clanging metallic sounds warn of loosened or broken parts.

To correctly diagnose the origin of the noises, technicians have to evaluate the operation of the system, including the suction pressure, the discharge pressure, and flow rates. Now, you will find vibration analysis and acoustic monitoring sensors very useful in pinpointing the very cause of the problem. Operators can use these tools alongside historical-performance-recorder data to analyze patterns and correlations that otherwise would be missed. For example, recurring noise patterns during specific operational circumstances may indicate improper suction line designs or incorrect pump priming.

Early intervention in strange noises would prevent operators from allowing what is considered minor to become a major system failure. Such strategies as proactive maintenance by carrying out periodic auditory inspections and predictive diagnostics will guarantee that the pumps perform to their peak level. Furthermore, documentation of findings and remedial actions would serve as a reference for future troubleshooting and contribute to an increase in system reliability and a decrease in downtime. A disciplined approach toward noise recognition will not only protect the equipment but also increase its system integrity and operational excellence.

Essential Tools for Hydraulic Pump Repair

Must-Have Repair Tools

- Torque Wrench: A torque wrench is necessary for tightening bolts and fasteners in accordance with manufacturer-prescribed torques. Over- or under-tightening affects the proper working of the pump and its safety, hence, making this tool an essential item for precision work.

- Dial Indicator: This tool is indispensable for checking for shaft alignment and any deviation. Strict alignment avoids undue stress on the bearings and other components, and so they are at lower risk of premature wear or failure.

- Hydraulic Test Bench: Using the hydraulic test bench, one can assess the pump’s behavior in conditions that simulate the working ones. The system measures flow rate, pressure, and temperature and uses these data points to verify the repair.

- Micrometer and Vernier Caliper: Used to measure the dimensions of critical components such as shafts, bearings, or seals, both of these tools have been used to obtain measurements accurate enough to guarantee proper replacement or good adjustment of parts within a very tight tolerance.

- Seal Installation Tools: The proper installation of seals prohibits any leakage and finalizes the retention of hydraulic pressure in the pump. Special seal installation tools are used so that no damage is done to the delicate sealing surfaces during assembly.

- Bearing Puller/Installer Kit: A major activity during pump repair is the swift removal and installation of the bearing. The bearing puller/installer kit helps in this process while minimizing the risk of damage to the related components.

- Pressure Gauges and Flow Meters: These diagnostic tools are essential for assessing the operation of the system. They help examine discrepancies in pressure or flow that can attest to a blockage, wear, or miscalibration.

- Cleaning Equipment: Ultrasonic cleaners or industrial degreasers are required to clean contaminants from pump components. Ensuring the cleanliness of components is fundamentally necessary for driving the life and efficiency of hydraulic systems.

In a repair shop, a technician leverages these tools along with industry best practices for a more streamlined workflow and higher repair quality. The regular use and maintenance of this set of equipment make its performance and reliability optimal for the hydraulic systems.

Using Wrenches and Pressure Gauges

A tool like a wrench, or a pressure measuring instrument, is of great importance in the proper fitting of and the proper fitting out of, plus the diagnosis of, hydraulic systems. Specifically, torque wrenches ensure that fittings and connectors are tightened to recommended specifications to prevent problems such as leakage, over-tightening, or damage to components. The correct application of torque provides structural strength for hydraulic connections when pressured at high levels; any slight variation in torque may result in system inefficiency or failure.

Pressure gauges are essential as they offer a real-time assessment of system performance through monitoring fluid pressure inside hydraulic circuits. Technicians can verify pressure readings routinely to determine system defects relative to a pressure drop, obstructions, or unsteady pumping actions. The gauges would have to be calibrated against factory standards so that the readings may be trustworthy, and it is also often recommended to have recalibrations done to prevent any sources of error while interpreting performance data.

Together, these tools permit a more comprehensive and exact examination of the hydraulic functioning system, making the diagnosis of malfunction or fine-tuning of adjustment measures data-driven from pressure readings, while the torque wrench assures precision-based fine-tuning is a huge advantage towards upholding prime performance and the end of least risk of downtime. The accuracy and capability of maintenance are top-notch if we implement newly built technologies such as digital pressure gauges featuring enhanced sensitivity and automatic torque monitoring tools.

Importance of Seal Kits in Repairs

Seal kits are vital maintenance and repair items for hydraulic systems, ensuring that a process is performed with due integrity and efficiency. Such kits contain basic components such as O-rings, gaskets, or seals, which prevent leakage of fluids and maintain the requisite pressure inside the system. Without working seals, hydraulic machinery quickly loses pressure, gets contaminated, and finally finishes with mechanical breakdown.

Good seal kits are built to resist extreme temperatures, high pressure, and corrosive fluids, and most importantly, such are made of strong substances, like Viton or Teflon. Choosing the correct seal kit depends on particular operating conditions: fluid type, pressure in the system, and environmental conditions. For instance, where there is high heat, it would be best to apply fluorocarbon elastomer-made seals due to their excellent thermal and chemical resistance.

Further consideration is given to regular inspections and the proactive replacement of seals during maintenance checks so as to minimize unscheduled outages and also to extend the lifespan of some running parts. The rise of newer technologies in seal manufacturing in the form of precision molding and polymer composites ensures that these components are made more durable and perform better. Armed with high-performance seal kits, hydraulic systems ensure minimum downtime and maximum performance.

Step-by-Step Repair Guides

Repairing Hydraulic Leaks

A detailed inspection to pinpoint the location of the fault is the first step in remedying any leaks in a hydraulic system. Visually examine all hoses, couplings, seals, and fittings with adequate lighting. Hydraulic systems are usually under pressure, and it is essential to ensure that the system is depressurized before moving on for your safety and so as not to worsen the leak. I also suggest cleaning the zones around suspected leak points to rid those areas of dirt and oil that might prevent true leak sources from being identified.

I first attempt to finalize the diagnosis of the leak and then work to replace the defective element; if the defective item is a seal or gasket, the damaged part is carefully removed, and another one is installed according to the procedure and tools recommended by the manufacturer. The installation of high-performing replacement seals manufactured from modern materials is an absolute necessity to ensure durability. I also check various adjacent components for any sign of wear and damage, as fixing secondary ones will prevent any future failures during the repair process. Finally, after all the repairs are completed, I proceed with reassembling the system while respecting torque specifications for all fittings and fasteners.

In the last phase, complete system testing is performed. After repressurizing the hydraulic system, any recurring leaks or irregularities are observed while ensuring maximum operational pressure without any indication of fluid loss. Also, the hydraulic fluid levels and quality are checked, subsequently topped off or drained and filled as necessary. The entire process focuses on utmost precision and safety, adhering to technical best practices, restoring the functionality of the system, and decreasing the chances of probable future failures.

Fixing Low-Pressure Issues

Four considerations give a low-pressure operation within a hydraulic system: fluid contamination, failure of the pump, or internal leakage within the other components. It is through a diagnostic approach that the source of the problem is identified. Measuring the system pressure with calibrated pressure gauges follows my first analysis; I compare the readings to the range the manufacturer specifies for the operation of that particular system. Simultaneously, I check the hydraulic pump for abnormal operation, such as output of an insufficient volume of fluid or mechanical wear.

The subsequent stage involves checking the hydraulic lines, connectors, and components for causes of leaks or any obstruction that could affect pressure stability. Contaminants such as debris or air are often the cause of pressure inefficiency and may require extensive filtration or fluid flushing to bring the system back to performance.

Furthermore, depending on the assessment, the pressure relief valve might need to be adjusted to set the pressure at the required operational level. This is done using an adjustment tool so the pressure in the system cannot be unnecessarily increased or allowed to decrease any further.

A data-driven approach aided with state-of-the-art diagnostic tools ensures the acquisition of very accurate measurements; thus, by correlating the results with the technical specification, this allows me to assign an authoritative solution for the low-pressure problem and increase the overall reliability and working life of the hydraulic system.

Addressing Noisy Hydraulic Pumps

The noises large hydraulic pumps make generally indicate in-system problems that, left unattended, could result in loss of efficiency or even a potential failure of components within. Primary noise sources include aeration, cavitation, and mechanical vibrations. Aeration happens when air elements enter hydraulic fluid, giving rise to the crushing collapse of air bubbles and a sort of an obnoxious chattering sound. This should be avoided by making sure all fittings, seals, and connections are properly secured and are dry from any composition of leakage.

If this phenomenon is happening due to the insufficient inlet pressure at the pump, then there will be the formation of vapor cavities inside the fluid. These cavities undergo pressure-induced collapse, unlike cavitation, creating excessive noise and potential damage to pump components. Ensuring that accurate pressure gauges are used and strictly observing the pump manufacturer’s specifications will help eliminate occurrences of cavitation. Moreover, mechanical vibrations might arise from either incorrect mounting or misaligned components, which would need some calibration and good damping treatment.

Correlating such advancements in monitoring technology, technicians can now measure noise levels with far greater precision and identify the causes. When combined with a rigorous troubleshooting methodology, such advances will maximize hydraulic pump operational reliability with little downtime.

Forklift Hydraulic System Maintenance

Best Practices for Regular Maintenance

- Routine Check of Hydraulic Fluid: It is important to check on a regular basis that the levels of hydraulic fluid conform to the limits given by the manufacturer. A low hydraulic fluid level may cause cavitation, increased wear, and a lowering of system efficiency. Furthermore, test the quality of the hydraulic fluid for contamination, such as discoloration, foaming, or particles, as these factors may affect great performance of the system or lessen the life of its components.

- Replacing Filters: Hydraulic filters are installed to trap debris and contaminants from circulating through the system. Keep to the recommended replacement time given by the equipment manufacturer so as to keep the system clean. Late replacement can clog filters, restrict fluid flow, or just damage extremely sensitive components.

- Checking of Hoses and Connections: Visual or external observation must be carried out to check the condition of hydraulic hoses, seals, and fitting connections for any leakage, abrasion, or signs of wear. Leakages reduce not only the system efficiency but also could become potential safety hazards. Therefore, damaged components must be changed or repaired promptly to avoid any further damage and interruptions.

- Diagnosing system pressure: Regularly check and keep monitoring the operating pressure of the hydraulic system to make sure it is within specified limits. Variations from normal pressure usually signify a problem that could be due to worn pump parts, or the valves malfunctioning, and it will require immediate investigation and rectification.

- Lubrication and Seal Maintenance: Lubricate the moving parts of the hydraulic system to lessen friction and make the life of the components longer. Also, seals shall be checked and replaced to avoid any leakage of fluid and to maintain the integrity of the system.

- Calibration of Hydraulic Components: Calibrate at periodic intervals critical components such as pressure relief valves and flow regulators. Calibration ensures that these components work according to their specifications. If improperly calibrated, inconsistent performance could result; also, efficiency could be reduced, or equipment could be damaged.

By following these best practices, forklift hydraulic systems will run efficiently and reliably, thereby creating less downtime and enhancing the longevity of equipment. It is always necessary to keep up with the manufacturer’s specifications and advances in diagnostic tools to solve any issues before they become problematic.

Checking Fluid Levels and Quality

Keep fluid levels optimum, and ensure a good hydraulic fluid for performing well with a forklift hydraulic system and maintaining longevity. Start by consulting the manufacturer’s manual concerning the type of hydraulic fluid to be used and the required level. In regular inspections, ensure that the fluid is checked visually in the reservoir to ascertain its level on the dipstick or in the reservoir.

Equally important is assessing the quality of the fluid. Prolonged use and its operation can induce such actions by way of settling contamination, oxidation, and thermal breakdown. Tests can be undertaken to check color, viscosity, and smell of the fluid, as either darker or cloudy fluids indicate contamination or wear of internal components. Advanced diagnostic instruments like particle counters or spectrometric analyzers yield precise data on contamination levels with their source traceability-analyzing them for metal particles, water, etc. Timely hydraulic fluid changes, as per set-time intervals or as suggested by the manufacturer, eliminate performance problems while circumventing damages to the system due to bad quality of the fluid.

As a last note, from an inspection standpoint and with the advancement of industry, sensor-based fluid-monitoring systems give an actual update on the status of fluids or performance so operators can act on data in maintenance decision-making processes. Routine attention to such matters will ultimately ensure reliability with fewer chances of expensive repair or operational downtime.

Importance of Cleaning Filters

Filtration system maintenance forms a critical piece in upholding system efficiency and durability. These filters trap contaminants, particulate matter, and other debris that may degrade system efficacy or induce premature wear in mechanical components. With time and the collection of particles, the filters cannot perform as efficiently; the liquid flow in the system gets restricted, undue pressure builds on the system, and adjacent components can also be stressed.

An isolated cleaning or replacement of the filter at specified intervals will minimize contamination and ensure that the system always runs consistently. Studies also show that dirty filters can reduce the efficiency of the system up to 20% in fluid-based systems, which is a concrete testimony to the neglect of filter maintenance. Likewise, automated filter monitoring technologies can assist the predictive maintenance by offering real-time data on pressure differentials and dirt buildup.

Through the employment of a rigorous filter maintenance protocol, operators can circumvent critical failures, conserve energy, and lengthen the service life of system components. Up-to-date filtration technology acting in concert with these practices serves as the backbone of a sturdy, cost-effective maintenance philosophy.

Frequently Asked Questions (FAQ)

Q: What are the common signs that indicate a need for forklift hydraulic pump repair?

A: Common signs that indicate a need for forklift hydraulic pump repair include unusual noises, decreased lifting capacity, and hydraulic fluid leaks. Additionally, if you notice a drop in the hydraulic fluid level or if the system temperature gets too hot, these could be indicators of underlying issues that require immediate attention.

Q: How can I check the hydraulic fluid in my forklift?

A: To check the hydraulic fluid in your forklift, first ensure the machine is on a level surface. Locate the hydraulic fluid reservoir and remove the cap. Use a dipstick or gauge to check the fluid level. If the level is low, add the recommended hydraulic oil until it reaches the appropriate level. Always refer to the specifications provided by the manufacturer for the correct type of fluid.

Q: What maintenance practices can help prevent costly repairs on the hydraulic pump?

A: Regular forklift maintenance, including checking hydraulic fluid levels, replacing the filter, and inspecting seals and hoses, can help prevent costly repairs. Implementing preventative maintenance schedules can help identify issues early and extend the life of the hydraulic system.

Q: How does water contamination affect forklift hydraulic systems?

A: Water contamination can lead to corrosion and damage to the components within the hydraulic system. It can cause hydraulic oil to aerate, similar to aeration, which reduces the fluid’s effectiveness. Regularly checking for water contamination and maintaining proper fluid levels can help mitigate these issues.

Q: What should I do if my forklift’s hydraulic system fails?

A: If your forklift hydraulic system fails, first ensure safety by stopping all operations. Check for visible signs of damage, such as leaks or broken hoses and fittings. If the issue is not apparent, it may be necessary to consult a forklift service professional to diagnose and repair the hydraulic pump.

Q: How can I extend the life of my forklift hydraulic pump?

A: To extend the life of your forklift hydraulic pump, ensure you regularly check hydraulic fluid levels, replace filters, and monitor system temperatures. Keeping the hydraulic oil clean and free from contaminants, as well as removing air from the system, can also significantly enhance the pump’s longevity.

Q: What are the typical hours of operation before I should consider hydraulic maintenance?

A: The hours of operation before considering hydraulic maintenance depend on the specific forklift model and its usage. Generally, it is advisable to perform hydraulic maintenance every 500 to 1,000 hours of operation, or as recommended by the manufacturer. Regular checks can prevent hydraulic system failures.

Q: How can I identify problems with the control valve in my forklift?

A: To identify problems with the control valve, listen for unusual sounds during operation and observe the responsiveness of the lift truck. If the mast does not move smoothly or if there are fluctuations in flow and pressure, it may indicate a control valve issue. Regular inspections and checks can help catch these problems early.

Q: What role do hoses and fittings play in the hydraulic system?

A: Hoses and fittings are critical components of the forklift hydraulic system, as they transport hydraulic fluid under pressure. Damaging the components, such as through wear or corrosion, can lead to leaks and system failures. Regularly inspecting these parts can help ensure the system functions correctly and efficiently.

Q: What should I look for when performing forklift hydraulic maintenance?

A: When performing forklift hydraulic maintenance, look for signs of fluid leaks, check the fluid level, and inspect hoses and fittings for wear. Additionally, check for corrosion on components and ensure that the hydraulic oil is clean. Following a thorough checklist will help maintain optimal performance of the hydraulic system.