Efficient and well-maintained hydraulic systems are the backbone of any forklift’s performance, directly influencing lifting capabilities, operational safety, and the overall productivity of material handling tasks. At the core of these systems lies the hydraulic pump—an essential component responsible for generating the power needed to lift and maneuver heavy loads. However, like any complex machinery, hydraulic pumps are prone to wear and tear, demanding regular maintenance and occasional repair. This article explores the critical role of hydraulic pumps in forklift operations, offering detailed insights into their maintenance requirements, repair strategies, and the factors affecting their efficiency. Whether you’re looking to optimize performance, extend equipment lifespan, or resolve hydraulic system issues, this guide provides the technical expertise and actionable steps you need.

Understanding Forklift Hydraulic Pumps

How Forklift Hydraulic Pumps Work

The operations of forklift hydraulic pumps entail converting mechanical energy into hydraulic energy that causes hydraulic fluid to traverse through the system. This pressurized fluid operates various mechanisms within the forklift, such as raising the forks or tilting the mast. The pump then takes in fluid from the reservoir, supplies it with spatial pressure from external forces, and transfers such pressure into hydraulic cylinders, effectively aiding in lifting heavy objects.

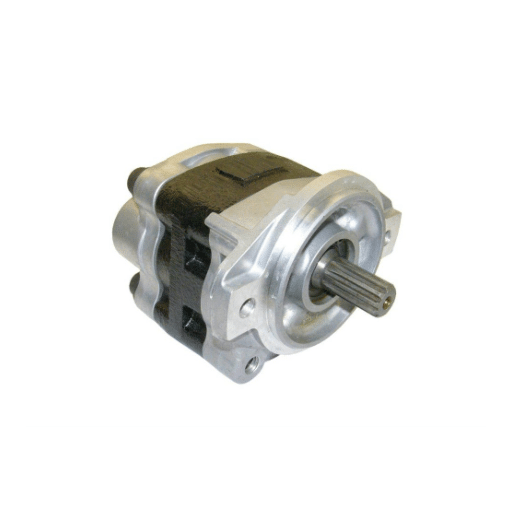

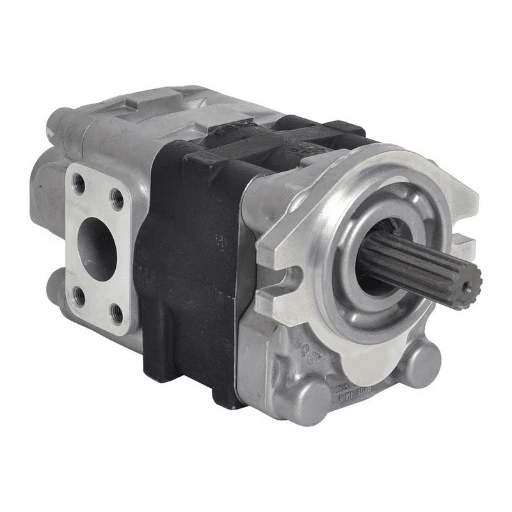

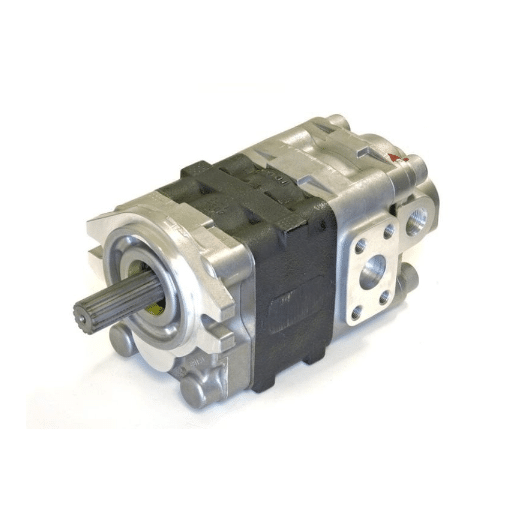

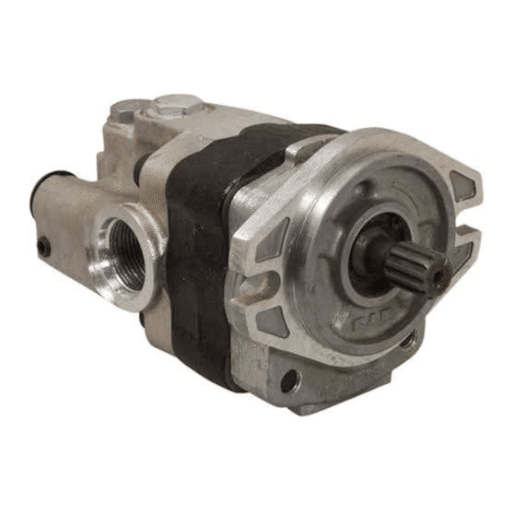

In forklift applications, two principal types of hydraulic pumps exist, i.e., gear and piston pumps. Gear pumps are the simplest and least expensive type of pump; with intermeshing gears, they abate the flow of hydraulic fluid to cause pressurization. Piston pumps are more sophisticated and capable of handling higher pressures, thus suited to operations under severe conditions. Hence, an outright understanding of these differences is necessary to decide the appropriate pump relative to the demands of a forklift.

The efficiency of a hydraulic pump is strongly influenced by the fluid quality, operating pressures, and system maintenance. It should, therefore, be a practice to always monitor fluid levels, avoid contamination, and address leaks as they arise. Moreover, overloading the system or allowing inspection periods to elapse will affect efficiency owing to early wear. The correct use and maintenance of hydraulic pumps are directly linked to the long service life and reliability of forklift hydraulic pumps.

The Role of Hydraulic Pumps in Lifting and Moving Loads

Hydraulic pumps wow the lift of load and much of the movement, shall we say, with precision and efficiency. These pumps exert mechanical power on fluid energy to generate the force required, such as lifting, lowering, or transporting materials across many applications in various industries.

- Conversion of Mechanical to Hydraulic Energy: Hydraulic pumps accept input mechanical power from the forklift’s engine or motor and convert it into hydraulic power. This hydraulic power is transmitted by pressurized fluid to actuate hydraulic cylinders to lift and lower loads.

- Generation of Consistent Pressure: It maintains a steady pressure to withstand the variation of the load weights to be lifted and accordingly maintain stability for smooth operations against massive loads.

- Load Weight Handling Capacity: Hydraulic pumps are created to suit the capacity of certain load specifications. For example, some of the industrial forklifts are fitted with pumps capable of handling loads of more than 10,000 lbs, all depending on the size and power specifications of these pumps.

- Regulated Motion Control: These pumps regulate the hydraulic flow to enable the controlled and smooth lifting and lowering of loads, thereby reducing mechanical stress and avoiding any abrupt motion that could jeopardize operational safety.

- Durability and Efficiency in Harsh Environments: Hydraulic pumps are designed for severe industrial conditions, such as very high or low temperatures, heavy use, and exposure to contaminants. High-quality pumps employ very robust materials and sealing systems to afford a long service life and reliable performance.

By registering these functions in their minds, operators and maintenance crews will come to recognize the role hydraulic pumps play in making forklift operations more efficient and ensuring safer material-handling practices.

Types of Hydraulic Pumps: Gear, Vane, and Piston

Hydraulic pumps are the working energy of every industrial machine; they have, so to speak, the ability to convert mechanical power into hydraulic energy. The three main types of hydraulic pumps—gear, vane, and piston—find application in different uses based on specific design characteristics and operational advantages.

- Gear Pumps: Gear pumps work with two meshes of gears to create fluid flow. These kinds of pumps are very rugged and are considered the best for applications where constant output at medium pressure is needed. They are usually the simplest hydraulic pumps to design, thereby offering a relatively low price and easy maintenance; also, they work with high-viscosity fluids. Gear pumps are employed by the industries of construction, agriculture, and material handling because of their reliability in continuous operation.

- Vane Pumps: These pumps are fitted with sliding vanes that move radially inside a rotor, the motion being caused by centrifugal force and hydraulic pressure. Vane pumps are known for their quiet operation, accurate discharge, and good control over fluid flow at low to medium pressure. It is best to use them wherever a steady flow is required: for example, injection molding machines and automotive power steering, where precision is paramount.

- Piston Pumps: Piston-type pumps are the most efficient and work at very high pressures. The design is based on reciprocating pistons working in a cylinder and can provide more accurate control of flow rates. Therefore, it is more suitable for heavy-duty applications such as heavy machinery and aerospace systems, and hydraulic presses. With these pumps generally being far more complicated and expensive, the high cost is justified, however, so they are used in situations demanding high power.

It is through understanding what these pump types do differently that engineers and operators can speed up the process of choosing the right design suitable for their job so that their hydraulic systems will run with the best efficiency and duration.

Common Issues with Forklift Hydraulic Pumps

Symptoms of Hydraulic Pump Malfunction

If hydraulic pump problems are left untreated, the consequences can range from serious operational inefficiencies to outright failure of the system in which it is installed. Typical signs of a hydraulic pump problem include the noises of whining, knocking, or banging, each in its way indicating cavitation, air contamination, and mechanical wear within the pump. A decrease in overall system performance, such as slower cycle times, less pressure output, or erratic actuator movement, might mean that there is internal leakage inside or worn-out components. Another critical symptom is overheating of the hydraulic liquid, usually due to extreme friction, contamination, or excessively long operation period at off-nominal pressures.

Hydraulic leaks-internal or external-are also symptomatic of compromised seals, damaged fittings, or worn pump surfaces. Vibrations and pulsations can be associated with misalignment of components or sets of worn-out pump gears. Contaminated fluid with visible signs of discoloration, foaming, or sediment should warrant immediate action, as it will only worsen wear conditions and possibly lead to catastrophic pump failure.

In foreseeing these symptoms, maintenance can be scheduled and preemptive actions enacted to avoid costly repairs, along with unscheduled downtime, thereby allowing hydraulic systems to perform at optimal efficiency and reliability.

Diagnosing Hydraulic Pump Problems

Diagnosing hydraulic-soft-pump problems is a demanding approach because it requires observation and technical evaluation. Some of the more common malfunctions in hydraulic pumps are caused by:

- Air Contamination: Air contamination enters through leaks or improper sealing, which causes cavitation. Cavitation is the formation and implosion of vapor bubbles within hydraulic fluid, which generates noise and vibration that eventually damages pump components. The problem is usually identified by a whining or knocking noise heard from the pump in operation.

- Fluid Contamination: Dirt, water, or metal particles contaminate a hydraulic fluid, causing it to be highly inefficient. Such contaminants cause abrasive wear of internal surfaces and reduce lubrication capability, thus hastening component failure. Contamination can be detected early by conducting routine hydraulic fluid sampling and analysis.

- Overheating: Too much heat is a foremost cause of hydraulic system failure and performance deterioration. Overheating brings about a fall in the viscosity of the hydraulic fluid, thereby lessening its capacity to lubricate and protect the component surfaces. Heat generation within the hydraulic system can be linked to blocked filters, heavy loads, or improper working of the cooling system.

- Seal Failures: Worn-out or degraded seals cause internal or external leakage and drop the pressure in the system, and its overall inefficiency. So, the seals will have to be checked and replaced while ensuring the efficiency of the pump.

- Improper Installation or Misalignment: Improper installation or misaligned pump shafts impose stress on the system, resulting in the premature wear of bearings and damage. Precision alignment tools are used during installation to provide correct alignment for reduced operational stresses.

Examining these possible causes in great detail can enable the operators to understand the problem swiftly and decide on what corrective acts should be taken first. Equipped with finer technicalities, pressure gauges, fluid analyzers, and thermal imaging can help to further diagnose exact faults in the pump system.

Effective Troubleshooting Techniques

Troubleshooting of a type of pump system should be conducted by applying a system approach to isolate and correct the root causes of failures. Check thoroughly if external factors like environmental conditions or system inputs could adversely affect performance. Deviations from these readings will point to particular problems, for example, clogged intake lines or cavitation due to insufficient suction head.

The use of some advanced technologies will greatly improve the precision of the diagnosis. Vibration analysis would give much detail on mechanical faults, misalignment, imbalance, or loose parts. On the other hand, ultrasonic leakage tests might be able to pick up leaks or abnormal acoustic signatures that forewarn of a system failure. Such an approach complements routine inspections with hard data to back up sound decisions.

Take care to undertake all troubleshooting in an orderly fashion and to document all observations and measures at frequent intervals. Such documentation will allow a review of patterns to resolve issues before they recur, thus reducing downtime and prolonging equipment life.

Maintenance Tips for Forklift Hydraulic Pumps

Regular Inspections and Their Importance

According to my understanding, regular inspections of forklift hydraulic pumps are the prime maintenance activities concerning durability and performance. If inspections are thorough enough, early signs of wear or leakage may be detected; misalignment of components may also be overlooked, which, if not immediately rectified, results in some catastrophic failures. With routine checks, I can address minor irregularities before they become hazardous, serving the dual purpose of ensuring the safe running of operations and enhancing the longevity of the equipment.

Checks allow me to make sure about the hydraulic fluid level and quality, which are of utmost importance for the efficiency of the pump. A fluid contaminated either by dirt or moisture might hamper the system’s performance or bring about a total breakdown of the hydraulic components. This is why checking for clean fluid and changing it becomes my priority. Besides, I also make it a point to see that the hoses, seals, and fittings do not show any signs of defects or wear because these smaller parts are important for preventing leaks and sustaining pressure.

I record any abnormalities in pump operations during inspections. This documentation is invaluable for tracing repetitive trends or possible system-wide failures over time. Keeping such records assists in more efficient troubleshooting and decision-making concerning part replacements or the scheduling of maintenance. Consistent, systematic inspections make all the difference in protecting the performance and dependability of forklift hydraulic pumps in every setting where they operate.

Proper Lubrication Practices

Handling lubrication in a forklift hydraulic pump is one of the most critical aspects in sustaining its operations and longevity. A good lubrication program should involve choosing the proper type of lubricant, depending on operating conditions, and applying it at intervals recommended by the manufacturer. In hydraulic systems, for effects of friction and wear reduction between moving components it is very much dependent on the clean and continuous flow of lubricant. Inadequate lubrication may ruin the system due to excess heat generation, metal-to-metal contact, or catastrophic system failure.

To make sure the lubricant does its function, one should always monitor its quality and cleanliness. Dirt particles, moisture, and degraded oils are some of the contaminants that may harm the system. Oil sampling and analysis are considered a good yardstick to assess the health of the lubricant and to check for early signs of pump breakdown. Inline filtration and proper sealing of reservoirs also help to keep contaminants out.

Increasingly, these advancements have allowed for the introduction of automated lubrication systems to increase accuracy and efficiency. These systems provide the needed lubricant in precise amounts at predetermined intervals and thus reduce the chances of human error as well as facilitate longer component life. By pairing lubrication methods with prudent inspection routines and data analysis, companies can maximize their hydraulic pump performance and lessen the risks of costly downtimes.

Replacing Worn Components Timely

Regular maintenance through the timely replacement of worn-out or defective parts keeps hydraulic machinery running at optimum levels. With wear-enabling presence of excessive pressure, friction, and environmental factors, key components such as seals, valves, and bearings lose their service life, and a machine with worn components exhibits inefficient operation and is prone to catastrophic failures that will disrupt production and incur huge costs for repairs. To avoid all these, organizations must develop strict component inspection schedules coupled with adhering to the stringent manufacturer’s recommended replacement intervals for critical parts.

With technological advances in predictive maintenance, this process has undergone a major transformation. Companies gather real-time data related to wear rates, pressure variations, and temperatures occurring in hydraulic systems using sensors and monitoring tools. For example, vibration analysis or thermographic imaging can be employed to pinpoint early failure in bearings or seals before visible damage occurs. The integration of these techniques into maintenance planning can help operators to accurately predict when the maintenance intervention would be required as the process’s performance has fallen below acceptable levels, thus avoiding late interventions and extra downtime.

From studies, a preventive replacement strategy extends the service life of machinery by nearly 30%, greatly reducing the total cost of ownership. Also, with predictive data analytics, an organization can maintain an optimum inventory for spare parts, thus avoiding unnecessary stockpiling while having all critical parts at hand when needed. This brings about more efficiency in terms of system reliability and further ties in with operational goals for efficiency and cost control. Together, therefore, these procedures sustain hydraulic systems in top condition, thus minimizing stoppages and promoting productivity.

Choosing the Right Hydraulic Pump for Your Forklift

Factors to Consider: Load Capacity and Operational Requirements

Choosing the proper hydraulic pump for your forklift entails an in-depth knowledge of load capacity and the requirements for the actual execution of tasks. Load capacity is the maximum weight the forklift may need to carry at any time during its day-to-day operation, determining the pressure and flow rate requirements on the side of the pump. In other words, the hydraulic pump for a forklift intended to lift heavy loads should be able to generate consistently sufficient hydraulic power to prevent undue strains on the system or the inability to perform.

Another realm of operational requirements is the actual method of application of forklift operations, i.e., whether indoors or outdoors, and the frequency of operations, as well as the environmental conditions under which the forklift may be operated. To illustrate, a pump for forklifts used in cold-storage environments may require materials and seals that resist low temperatures. In contrast, those used in high-frequency industrial plants should go for the more durable and efficient pumps that will sustain long cycles.

A modern hydraulic pump could also take advantage of energy-efficient designs and digital control mechanisms, which enhance system performance while simultaneously lowering operating costs and environmental costs. By combining the technical specifications with a proper assessment of load and operational conditions, a company can increase the equipment’s reliability and performance.

Budget Considerations for Hydraulic Pumps

Organizations should adopt a comprehensive cost analysis approach when budgeting for the purchase of hydraulic pumps. Price of initial acquisition should come first; but all associated long-term costs must also be taken into consideration. This would include the maintenance, repair, operational efficiency, and even energy consumption. Such an analysis brings to light that higher-quality pumps that incorporate energy efficiency features will have great upfront costs but will save a considerable amount of money in energy consumption and loss of downtime later.

Secondly, lifecycle cost analysis would be a useful tool for good financial decision-making; this precisely means calculating not only the purchase cost but also the present worth of all operations and maintenance costs over the considered life of the pump. For example, while variable displacement hydraulic pumps tend to be more expensive than fixed displacement ones, they may provide better energy efficiency and lower operational costs in a variable-load application.

Another major aspect is compatibility with the existing system. Choosing a pump that is compatible with the existing hydraulic infrastructure will thus preserve against costly system upgrades or replacements. Equally important are projections for future workload and scalability, which should direct investment decisions so that over time, the pump stays both effective and relevant.

Finally, procurers may want to look into contracts for bulk purchases or for long-term supplier relationships wherein volume discounts and warranties are accessible to reduce overall cost. Hence, balancing initial purchase investment and later savings will make hydraulic system projects most cost-effective without compromising on performance and reliability.

Aftermarket Options and Their Benefits

Aftermarket options for hydraulic systems provide many benefits, such as cost-effectiveness, availability, and customization. Thus, aftermarket components will allow an organization to maintain, service, or upgrade its hydraulic systems without relying fully upon the OEM. Here, then, are the five main aftermarket options and their benefits:

- Replacement Parts: Aftermarket replacement parts, such as hydraulic pumps, valves, and hydraulics, are cheaper than those provided by the OEM. By industry estimates, however, they can save up to 30% on the price without compromising the quality and life expectancy of the product. This choice would be worthy, especially when dealing with older equipment whose OEM’s parts may no longer be in production.

- Rebuilt or Remanufactured Components: Such hydraulic devices are restored at an economical price while also being environmentally friendly. The rebuilt units are restored to the original specifications and thoroughly tested for operational suitability. In general, aftermarket remanufactured parts are 40 to 60% cheaper compared to brand-new parts and are therefore suitable for operations whose budgets are tight.

- Custom Hydraulic Solutions: Many suppliers provide components for customization, whereby parts can be customized for specific operational requirements. For instance, the custom seals or fittings used in the unusual operating environment will enhance the efficiency of the system and reduce indiscriminate wear. Custom solutions regularly come into play with compatibility concerns that arise when integrating older systems with newer technologies themselves.

- Upgraded Components: Such aftermarket upgrades provide a way for companies to increase system efficiency and reliability through the use of high-performance hoses or better filtration. These are designed to withstand higher pressures, reduce contamination, and increase service intervals. According to recent studies, upgrades like this can deliver improvements of up to 20 percent in hydraulic system efficiency.

- Maintenance Kits: These thorough maintenance kits come with all the consumables needed for maintenance from the aftermarket, including filters, seals, and lubricants intended to streamline routine maintenance activities. Maintenance kits ensure that all components needed for a task are present, thereby reducing downtime and further simplifying supply-side management. Maintenance kits help in improvements of 15 percent in efficiency, with a knock-on effect of less disruption to operations.

Such five aftermarket options can reduce costs for any organization and, most importantly, improve the operational performance of a hydraulic system and its longevity. However, in choosing an aftermarket part, it must be thoroughly assured of its quality and compatibility to go smoothly with the existing equipment.

Electric Forklifts and Their Hydraulic Systems

Unique Aspects of Electric Forklift Hydraulics

Electric forklifts, compared to IC forklifts, have different hydraulic system characteristics mainly because these are electrically powered trucks. Whereas the IC forklifts utilize an engine-driven pump for any hydraulic operation, the electric forklifts operate the hydraulic pumps with electric motors. This facilitates a more energy-efficient and precise means of controlling the functions related to lifting, tilting, and load-handling.

One significant characteristic of electric forklift hydraulics is that a VFD or other better control technique exchanges signals to maintain optimum pump performance against real-time operational requirements. These systems modulate motor speed and power output so that energy consumption is minimized when the load is idle or lightweight, yet at full capacity when the load is heavy.

Another major advantage of electric forklifts is the reduced noise from their engines while generating less heat than IC forklifts. These complementary features contribute to a comfortable and sustainable work environment, especially indoors, where emission controls and noise regulations become a prime consideration.

Hydraulic components in electric forklifts must also be adapted for working with high-voltage battery systems; this involves the use of electrically insulated materials, specialized seals, and state-of-the-art thermal management techniques to assure safety and efficiency.

The unique features of the electric forklift hydraulic systems emphasize the importance of selecting components and carrying out maintenance in accordance with the design and operational of these systems. Proper system calibration and following the guidelines set forth by their respective manufacturers will ensure that the efficiencies of these systems can be utilized to their full extent while reducing downtime and risk to operations.

Comparing Electric and Traditional Forklift Hydraulic Systems

Electric forklifts are quieter, eco-friendly, and cost-effective for maintenance, while traditional forklifts (gas/diesel) are powerful, versatile for outdoor use, and quicker to refuel.

| Aspect | Electric | Traditional |

|---|---|---|

|

Sound |

Quiet |

Loud |

|

Pollution |

Zero |

High |

|

Upkeep |

Minimal |

Frequent |

|

Refill Time |

Slow (charging) |

Fast |

|

Strength |

Moderate |

Strong |

|

Agility |

High |

Medium |

|

Initial Cost |

Expensive |

Affordable |

|

Usage |

Indoor |

Outdoor |

|

Green Factor |

Yes |

No |

Best Practices for Maintaining Electric Forklift Hydraulics

Electric forklift hydraulic systems require the skills and mind of an engineer who understands the design of the system, fluid mechanics, and proper servicing procedures to maintain adequate operating efficiency and reliability. Some key best practices include regular checks of the hydraulic fluid levels and quality. Hydraulic fluid may be checked for contamination, oxidation, or viscosity degradation, as such factors affect system performance. It is therefore imperative to adhere to the manufacturers’ instructions on the intervals for fluid replacement, because a fluid that is contrary to the recommended specification or has been in stock for too long would enhance wear and eventual system failure.

Filters, by their nature, have to be monitored and replaced regularly. A dirty filter will obstruct fluid flow, reduce system pressure, and diminish the ability of the system to do its job. Replacement filters must meet specifications for the system to maintain proper filtration levels. Seals, hoses, and connections present another inspection area where periodic checks are needed to find signs of wear, leakage, and degradation. Small leaks, when uncared for, will cause catastrophic failure over time due to pressure loss.

Regular calibration ensures the system works in the hydraulic pressure and flow rate range specified as operational. Calibration must be done by a trained technician with accurate diagnostic instruments to avoid misalignment or incorrect adjustments. Diagnostic software for use with modern electric forklifts is also an option, as this software will provide very precise information on system performance and enable timely maintenance, thus drastically reducing downtime due to unexpected failures.

By following such maintenance schedules and technology advances in diagnostic disciplines, an electric forklift hydraulic system can provide a steady output in service life and, risk-wise, have a greener operation.

Frequently Asked Questions (FAQ)

Q: What is a forklift hydraulic pump, and what role does it play?

A: A forklift hydraulic pump is a vital component of the forklift’s hydraulic system. It is responsible for generating the hydraulic pressure necessary to lift and lower loads. By converting mechanical energy into hydraulic energy, the pump ensures the efficient operation of various forklift models during material handling tasks.

Q: How do I maintain my forklift hydraulic pump?

A: To maintain your forklift hydraulic pump, it is essential to regularly inspect the hydraulic fluid levels, check for leaks, and replace any worn or faulty components. Additionally, changing the hydraulic oil and filtering impurities will help extend the lifespan of the pump and improve the overall efficiency of the hydraulic system.

Q: What are the common types of forklift hydraulic pumps?

A: There are various types of forklift hydraulic pumps, including gear pumps, piston pumps, and vane pumps. Each type has its advantages and is suitable for different forklift models and applications. Understanding these types can help you select the most reliable option for your specific needs.

Q: When should I consider repair and replacement of my hydraulic pump?

A: You should consider repair and replacement of your hydraulic pump if you notice signs of low pressure, overheating, or significant leaks. An extensive inspection by a certified technician can help identify faulty components, ensuring that your forklift remains dependable and safe for operation.

Q: How can I diagnose issues with my forklift’s hydraulics?

A: To diagnose issues with your forklift’s hydraulics, start by checking the hydraulic fluid level and inspecting for leaks. Use a pressure gauge to measure psi and look for any signs of contamination or impurities in the hydraulic fluid. Conducting these inspections regularly can help catch problems early and avoid costly downtime.

Q: What should I look for when choosing a manufacturer for hydraulic pumps?

A: When selecting a manufacturer for hydraulic pumps, consider their reputation for quality and reliability, the certifications they hold, and the range of aftermarket solutions they offer. Look for manufacturers and suppliers that provide high-quality components tailored for various forklift models to ensure optimal functionality.

Q: How does hydraulic fluid affect the performance of a forklift hydraulic pump?

A: The hydraulic fluid plays a crucial role in the performance of a forklift hydraulic pump. Using the correct type of hydraulic oil ensures compatibility and effectiveness in the hydraulic system. Proper fluid maintenance helps prevent overheating and impurities, which can lead to pump failure and decreased productivity.

Q: What are the benefits of high-efficiency hydraulic pumps?

A: High-efficiency hydraulic pumps improve the overall performance of forklifts by reducing energy consumption and increasing lift speed. These pumps are designed to maintain optimal pressure while minimizing the risk of overheating, thus enhancing the reliability and longevity of the forklift’s hydraulic system.

Q: Can I customize my forklift hydraulic system?

A: Yes, you can customize your forklift hydraulic system to meet specific operational requirements. By selecting the appropriate components, such as hoses, control valves, and hydraulic pumps, you can tailor the system to improve efficiency and productivity for your unique material handling tasks.

Q: How can I ensure the longevity of my forklift hydraulic pump?

A: To ensure the longevity of your forklift hydraulic pump, perform routine maintenance, including regular inspections and timely repairs. Keeping the hydraulic fluid clean and at optimal levels, along with monitoring the temperature and pressure, will help maintain the functionality and reliability of the pump over time.