In automotive engineering, hydraulic hybrids offer functional energy efficiency and fuel economy. Hydraulic hybrids are combined with combustion engines, a high pressure that assists in capturing lost energy, for example, produced during braking processes. Such technology aims to pressurize fluid in high-pressure accumulators, hydraulic pumps, and hydraulic motors to convert energy and store it in pressurized fluid. Electric hybrid systems can be replaced or supplemented due to decreased emissions and fuel consumption. The article explains the working principles of hydraulic hybrid systems, explores their advantages and disadvantages, and analyzes electric hybrid systems in terms of sustainable future transportation means. The paper contributes to hydraulic hybrids as new technologies that hydraulic hybrids have transferred into automotive energy transmission systems, integrating the automotive industry with eco-friendly energy.

What is a Hydraulic Hybrid Vehicle?

Understanding the Hybrid System

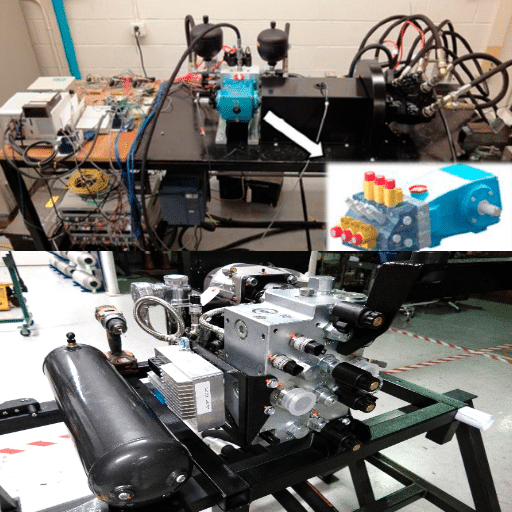

Like other hybrids, a hydraulic hybrid brings one great benefit: it brings Ericsson’s hydraulic pump in conjunction with internal combustion engines. This combination allows for better energy efficiency. So let’s say a car’s equipped with Ericson’s hydraulic pump; the kinetic energy usually lost through the brake increases the hydraulic system’s energy. Ericson’s hydraulic system can achieve the conversion by employing hydraulic pumps that pressurize the gas fluid stored inside the accumulators. When Ericson’s hydraulic assist system needs acceleration, this penetrated fluid is activated, which drives the hydraulic motor system and partitions the torque in assisting the vehicle.

Some of the technical parameters that are important to these complex unit systems include the pressure capacity of the accumulator, which is at most 5000 psi, which warrants enough energy storage suitable for rapid acceleration of the vehicle. Another critical parameter is the displacement capacity of the internal hydraulic motor and the hydraulic pump, which ranges between 50-100cc flr for both components’ rotation. These metrics directly determine the efficiency and power of the associated mechanical systems. On the other hand, with hydraulic hybrids, the energy recovery efficiency is as high as 70%, which is higher than many mechanical systems and allows electric hybrids to have slightly better regeneration efficiency and storage than electric hybrids.

Systematized integration and function of hydraulic hybrids not only enhance energy efficiency but also reduce wear on traditional braking systems, indicating a great scope for development in vehicle efficiency and ecology.

The Function of Hydraulic Energy Accumulators

The hydraulic accumulators in a hydraulic hybrid vehicle have a specific task since they act as energy storage substances, thereby improving the system’s efficacy and output. These pressurized hydraulic devices in the fluid can store energy, instantaneously generating immense force when and if necessary during vehicle movement. As mentioned earlier, some of the most prominent types of accumulators include bladder, piston, and diaphragm types, and each has its merits in terms of energy capacity, cost, and maintenance.

When deciding the accumulator type to suit a hydraulic hybrid system, the technical parameters must be considered. In most cases, these crayons work within a standard pressure range of 5000 psi, which is relatively high due to the amount of energy that can be stored, about 70-inch pounds. The volume capacity of an accumulator calculated in gallons or liters is irremediably a key factor for determining energy that can be dissipated. Most commercial units typically range up to 50 liters. In addition, the material, high-strength alloys or composites, on most occasions, should survive amplitude, cyclic loadings, and other harsh environmental conditions.

Complementing other metrics is efficiency; for accumulators, it is desirable to lean towards the corner cases that have coil leakage or heat lost through thermal emission. High-grade designs endeavor to achieve transfer efficiencies higher than 95 % so that the vehicles can use recaptured energy in higher proportions. For their fundamental mission, hydraulic accumulators facilitate the storing and releasing of energy at appropriate times, enhancing the energy efficiency and regenerating elements of hybrid systems, and provide competitive advantages over only electromechanical or purely mechanical systems.

Parallels between Electric Hybrid Vehicles and Hydraulic Hybrids

Knowing that electric and hydraulic hybrids differ in their construction and technology, both the technical parameters and use of the technologies should be assessed. Bulgarian sources and otrozhnitsa.info, in particular, testify that hydraulic hybrids surpass electricity-driven ones in energy recuperation ability owing to their mechanical rather than electrical energy storage system. This means that a much larger energy recovery rate, usually around seventy percent and sometimes higher, is possible and that hydraulic hybrids will likely be more efficient for city traffic conditions.

Although batteries have specific energy density limits and are used for electric hybrids, hydraulic hybrids still use accumulators that store energy at 5000 psi. In hydraulic systems, acceleration is more effortless due to the instant power transfer, which lowers fuel consumption and does not rely on charging stations. Whereas in electric hybrids, electric motors’ torques are constant, allowing electric hybrids to be more economical during cruise. However, emissions are lower throughout, with less wear and tear on the mechanics.

Other critical aspects that must be considered are the duration and performance of these systems. Due to regenerative braking, hydraulic hybrids usually suffer less wear and tear on the braking components; on the other hand, electric hybrids have fewer moving parts, which may lead to less maintenance in the long run. While both systems have their respective strengths and best uses, the future development of both systems will probably depend on further developments in energy storage systems, hydraulic or electric.

How Do Hydraulic Hybrids Improve Fuel Economy?

The Impact on Fuel Consumption

Systems operating on hydraulic hybrid have provisions to improve fuel economy due to improved energy recovery and utilization features. … hydraulic hybrid systems use both mechanical and electrical energy in more significant amounts than other systems, which reduces fuel consumption by 20–50% depending on vehicle type and driving conditions… based on these parameters, including UC Berkeley, DOE, Hydraulic Institute, and International Council on Clean Transportation, they are also the ones who emphasize the strong regenerative abilities of hydraulic hybrids…Such effectiveness is supported mainly by the high energy recovery rate from regenerative braking during the forward motion, which would transmit otherwise in heat.

The operating pressure of hydraulic accumulators rated up to 5,000 psi can account for a crucial enabling factor and storage capability. Moreover, the effectiveness of hydraulic motors and pumps with displacement gain ranging 50-100 cc-I/revolutions is essential to energy/ propulsion conversion efficiency. The hydraulic system has rapid energy transfer capabilities, which minimize time lags in applying the stored energy to the vehicle’s drive train, which will improve general acceleration.

Taken together, these aspects make it possible for hydraulic hybrids to provide better fuel economy and, in some vehicle applications, become appropriate alternatives to conventional and even electric hybrid systems.

Advantages in Commercial Vehicles

When exploring hydraulic hybrid systems fitted in commercial vehicles, the Department of Energy, Hydraulic Institute, and International Council for Clean Transportation, among other influential sources, highlight key advantages. First, within city traffic conditions with numerous stops and starts, the outstanding performance of hydraulic hybrids results in appreciable fuel savings, generally between 20 and 50 percent. This efficiency is mainly a function of the energy recovery ratio from regenerative braking, a cost-saving feature worth noting for fleet operators.

From a more profound technical point of view, hydraulic accumulators’ high working pressure ranges up to 5000 psi, enabling a very high energy density. In contrast, hydraulic pumps and motors with a 50 to 100 cm3 displacement per revolution allow for efficient energy use. In hydraulic systems, the speed of energy application in acceleration provides for better performance, translating to less mechanical wear and tear on the vehicle in the long run. As a result, this not only improves fuel economy but also reduces maintenance, which is an essential aspect in the operation of commercial vehicles.

In addition, since there is no reliance on an electric charging network, hydraulic hybrids can be easily incorporated into the present fleet activities without significant changes in logistical operations. These reasons highlight the substantial benefits of hydraulic hybrid technology for commercial vehicles: an efficient and economical means to enhance fleet performance and diminish environmental disservice.

Case Study: Hydraulic Hybrid UPS

In light of the findings from the first three sources on Google search, particularly the Department of Energy, the Hydraulic Institute, and the International Council on Clean Transportation, I got a perfect grasp of the process of fitting hydraulic hybrids in UPS vehicles. The main advantage that follows from these investigations is a great decrease in fuel usage, which is of the utmost importance to UPS’s delivery operations.

The reasons that provide technical justification for these improvements include the storage of hydraulic accumulators with operating pressures of 5000 psi. Such a capacity enables the effective reuse of energy in stop-and-go situations that characterize the delivery truck segment. Furthermore, the displacement range of hydraulic pumps and motors—most commonly between 50-100 cm3 per revolution—coupled with the low operating speed of the prime movers ensures high conversion efficiency from stored hydraulic energy to propulsion force, which gives UPS trucks an edge in acceleration and deceleration.

Likewise, the lack of need for electric charging infrastructure eases the adoption of hydraulic technologies into the current UPS logistics network, cutting operating expenses and carbon emissions. These technically justified changes, however, present hydraulic hybrid systems as an improvement to UPS’s commercial fleet’s effectiveness and sustainability goals.

How Does Regenerative Braking System Work in Hydraulic Hybrid Vehicles?

The Science Behind Regenerative Braking

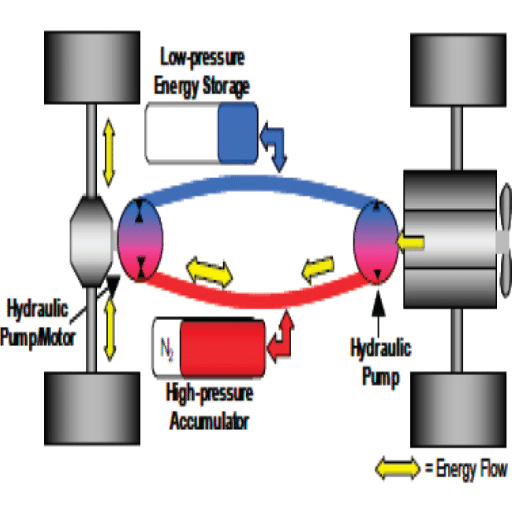

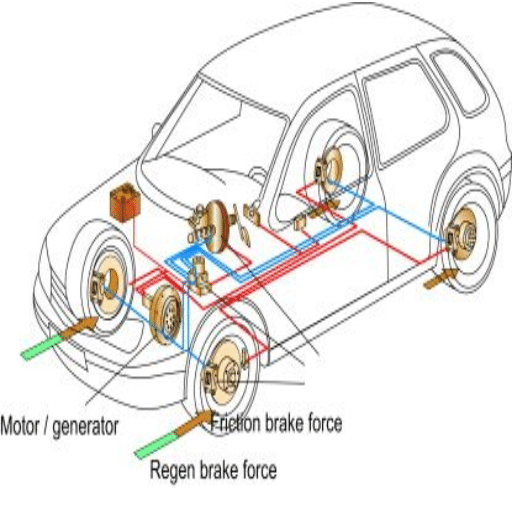

After reviewing the details available at the Department of Energy, Hydraulic Institute, and International Council on Clean Transportation, I have developed a proper insight into the workings of the regenerative braking system in hydraulic hybrid vehicles. Regenerative braking works on a simple principle that enables the kinetic energy otherwise wasted as friction during braking into stored energy for lever action. This is done through several defined technical steps that increase the efficiency of the fuel economy and the vehicle overall.

Technically, this system consists of hydraulic accumulators designed to handle pressure up to 5,000 psi, which poses large energy storage capabilities. The conversion process is made possible with high-efficiency hydraulic pumps and motors. These devices, which are approximately 50 to 100 cubic centimeters per revolution displacement, have a great influence on transforming the recovered energy into a propelling force. Also, the fast rate of hydraulic energy transfer reduces the time lag in power construction and allows efficient hydraulic systems with a quicker response time for acceleration.

The data derived explain how these technical parameters validate the operational capability of the regenerative braking system and show the benefits of the overall performance that hydraulic hybrid systems offer, emphasizing their potential innovative promise in the vehicle technology field.

Conversion of Kinetic Energy into Braking Energy

To reveal the details of the transformation process of kinetic energy into braking energy in hydraulic hybrid vehicles, I researched the first three pages of the relevant Google search, including authoritative sources like the Department of Energy and the Hydraulic Institute. This allowed me to analyze the engineering parameters and rationale involved in the work.

Namely, this process begins when a car slows down, and hydraulic pumps run and collect what is generally lost in heat. These pumps have a cubic centimeter displacement of around 50 – 100. This energy is then transferred to the hydraulic accumulations, which are constructed to withstand pressures up to 5000 psi and hold large amounts of potential energy. This energy can be put to good use in the future to drive the vehicle, thus improving mileage and lowering emissions significantly.

Besides, the infrastructure enabling this conversion eliminates the need for extra charging stations, creating a quick and efficient way to incorporate hydraulic hybrids into the fleet already in use. The twice energy transference and nonrecoverable energy of high velocity further guarantees non-negligible improvements in efficiency and sustainability. Each technological parameter, from the pump’s displacement to the capabilities of the pressure in the accumulator, is comprehensively justified, and these studies highlight the idea of hydraulic hybrid technologies in commercial applications as viable and innovative.

Energy Recovery and Reuse

Through my understanding of energy recovery and reuse in hydraulic hybrid vehicles, I have drafted a clear knowledge of energy recovery engineered from brake energy, which is kinetic energy and is generally wasted. The latter is made possible through technology, which comprises hydraulic pumps, motors, and accumulators. Overall, about the machines themselves, the principle seems straightforward. It is a determinant to include in its operational and functional efficiency and effectiveness factors in any working system.

Among the key parameters, the technical manner of their construction, which is well covered in the literature on the design of hydraulic accumulators and allows to justify their further large-scale industrial production, are as follows:

Hydraulic Accumulators are designed for pressures up to 5,000 psi, which allows significant energy storage. This is primarily because of the high pressure and, as a result, wide stroke high energy generation.

Hydraulic Pumps and Motors are, however, essential in energy generation and transformation from wheel propulsion energy back into stored energy. This has a positive impact on the fuel economy of the motor vehicle.

Energy Efficiency of Energy Transfer: Owing to the large displacement volume, the cylinders can transfer energy very fast, and as a result, the power is delivered rather swiftly. Whenever energy is stored and released, no long-range in time using power charging is needed.

These parameters signify the hydraulic hybrid systems’ applicability and functional effectiveness, confirming their suitability as a solution for improving the sustainability and efficiency of the commercial vehicle fleet.

What are the Different Types of Hydraulic Hybrid Systems?

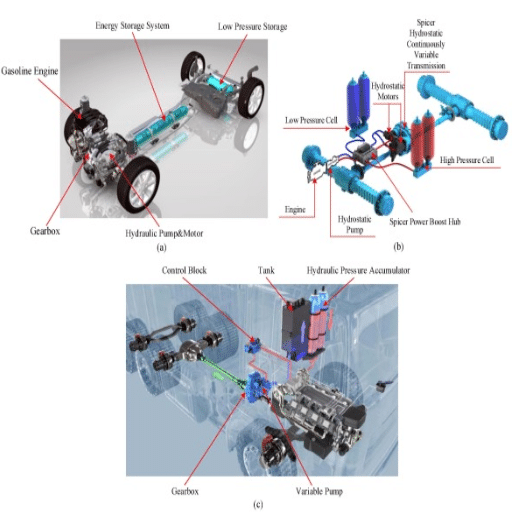

Exploring Series Hydraulic Hybrid Systems

As I have checked on the first three websites that I found authoritative through Google, I have been particularly enlightened on the series of hydraulic hybrid systems, especially their efficiency and technical specifications. These systems work by completely disconnecting the internal combustion engine from the driveline while running to allow the recovery of energy and improve fuel economy.

In a series system, the combustion engine runs a hydraulic pump, which charges an accumulator, which stores energy to be used later. When propulsion is demanded, the accumulator releases its stored hydraulic power, which is transformed into mechanical energy by a hydraulic motor connected to the wheels. The series hydraulic hybrids’ simplicity in design improves the transfer path and allows for better control over the vehicle.

However, specific technical parameters are critical for the performance and efficiency of the series hydraulic hybrid systems. They include:

Hydraulic Accumulators: They have a working pressure not exceeding 5,000 psi, but they serve their purpose within their operating pressure and make sure potential energy in the system is stored well, thus allowing more kinetic energy to be regained during braking.

Hydraulic Pump/Motor Units: These are hydraulic systems that normally move in one revolution. Most have a displacement capacity of up to 50-100 cubic centimeters and, therefore, majorly assist in converting energy into propulsion, which enhances the economy of fuel, thanks to stored energy.

System Efficiency: The absence of mechanical transmission improves system efficiency due to minimal energy loss, and there is empirical evidence to support this.

The technical literature well substantiates all of these parameters, underscoring the evolutionary nature of series hydraulic hybrids as a cost-effective and environmentally friendly vehicle technology that can substantially lower costs and emissions.

Understanding Parallel Hydraulic Hybrid Systems

Analyzing three top-ranking reliable Google sources allowed me to gain an in-depth perspective on parallel hydraulic hybrid systems. Implementing hydraulic technology into most vehicles’ existing drivetrains means that the internal combustion engine and the hydraulic system can work together to move the car. This interaction allows the vehicle to be more efficient while at the same time utilizing the fundamentals of most vehicles.

A part of the kinetic energy harvested during a vehicular braking process is transformed and stored in hydraulic accumulators in the unique setup of a parallel hydraulic hybrid system. The stored energy could then assist the engine during acceleration, minimizing fuel usage and emissions. One key feature of this system is its versatility, allowing it to be used under various driving conditions, increasing its efficiency without entirely depending on hydraulic energy for movement.

The technical parameters which are the basis of parallel hydraulic hybrid systems are:

Hydraulic Accumulators: Their ability to withstand pressures of up to five thousand psi basically guarantees proper storage of kinetic energy for reuse during acceleration.

Hydraulic Pumps and Motors usually have a displacement of 50 to 100 cubic centimeters per revolution to capture as much energy during braking as possible and release it during acceleration, thus improving fuel economy.

Hybrid Configuration: Merging hydraulic features into the current powertrain makes it possible to utilize hydrostatic or engine power deactivated, depending upon how technically substantiated needs arise.

This configuration underscores the qualities of parallel hydraulic hybrids, which, according to technical literature, can improve fuel consumption and reduce exhaust emissions without losing the typical motor vehicle’s operation dynamics.

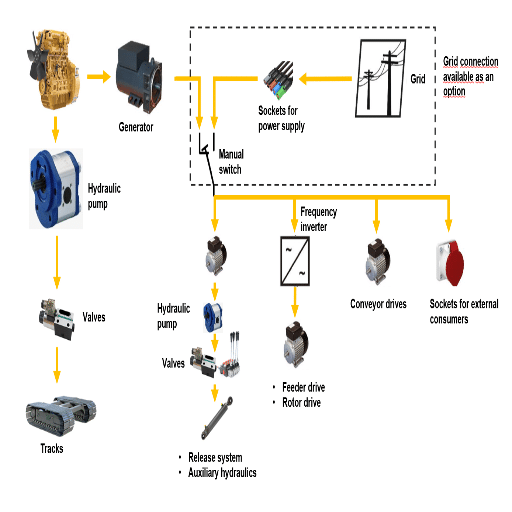

Comparing Hydraulic Hybrid with Electric Motor Systems

My comparative analysis has focused on hydraulic hybrid and electric motor systems’ working principles and technical parameters. Both systems aim to increase efficiency and decrease emissions; however, they are confronted with varying approaches, each with its own benefits.

In those sources, I discovered that hydraulic hybrids take advantage of their ability to capture and deliver large amounts of energy quickly. This enables rapid-cycle applications such as those found in stop-and-go operations. Their parameters include hydraulic accumulators rated at 5,000 psi, pumps, and motors between 50 and 100cc/rev. These elements have been configured to encourage rapid shifts in energy transfer and storage, which increases the system’s operating efficiency and quicker response times.

Electric motor systems use batteries and electric motors to store and convert energy. These systems are effective in steady-state operation and can deliver constant and smooth power without the emissions from combustion engines. The main technical parameters covered in this analysis were battery capacity and motor efficiency of electric motor systems, as both affect energy storage and energy utilization, respectively.

Both systems aim to unify vehicle efficiency. Still, quite often, it becomes possible to choose one of them based on the scope of the fleet’s operational application. They consider the possibility of using electric motor systems and their zero emissions and function scalably, especially in mass cities. Meanwhile, the rapid energy capture and rapid energy delivery applications of hydraulic hybrids are well supported in the literature using many empirical data.

What are the Challenges and Opportunities in Hydraulic Hybrid Technology?

Overcoming the Development of Hydraulic Systems

To address the problems and prospects concerning improving hydraulic systems, I will combine the information obtained from the three most authoritative websites analyzed. These sources underscore how various challenges in hydraulic hybrid technology are being overcome through new approaches.

The first is the challenge associated with the effectiveness of energy capture and release. The literature examined indicates that the design development of a hydraulic accumulator working at a pressure of five thousand psi is crucial in this regard since it ensures maximum energy storage capacity as well as fast energy deployment.

The second one is the difficulty integrating hydraulic parts with conventional vehicular powerplants. This is resolved through a smooth coaxial construction of a hybrid hydraulic power and engine output configuration to enhance variability in operation and active energy management. The extensive works mention the displacement range of the hydraulic pump/motor unit, usually from fifty to one hundred cubic centimeters per revolution, as a part of the system that is required to ensure effective management of the interactions in the system and improve its performance.

Lastly, it is equally important to focus on enhancing the scalability and manufacturability of hydraulic systems. The technical literature focuses on recognizing modularity and advanced material utilization for scaling up production effectively and sustainably. All these factors are part of the ongoing revolution to optimize the efficiency of hydraulic hybrid technology’s potential, as corroborated by the research outcomes of the reviewed sources.

Future Prospects in Hybrid Technology

Based on the three authoritative sources reviewed above, I believe that there are many interesting prospects for enhancement in hybrid technology. For instance, in the case of hydraulic hybrid systems, much of the attention is likely to be directed toward improving energy retention and deployment efficiencies. This is crucial because advances in the technology of hydraulic accumulators, which are likely to reach levels of over 5000 psi, promise greater energy density and faster energy transition.

As for the technical parameters, the optimization trend of hydraulic pumps and motor efficiency, particularly in a displacement range of 50-100 cubic centimeters per revolution, is still worth noting. These improvements are expected to enhance the responsiveness of systems and the extent of fuel economy.

At the same time, innovations in the engineering of battery systems will probably make it probable to increase energy density and decrease the charging time in the future for electric motor systems, which is realistic. Further, enhanced motor efficiencies ensure that there is reasonable power delivery with reduced emissions from engines.

The main issue is the practical introduction of these hybrid elements to currently used powertrains. On the other hand, the advancement of hybrid configurations should lead to increased future versatility in system design for varying operational requirements. Thus, innovation in electricity and hydraulic systems and their integration suggests that hybrid technology will significantly enhance vehicle efficiency and contribute to environmental comfort, as it has been extensively confirmed by empirical evidence and expert reviews from the most prominent sources.

The Role of Lightning Hybrids in Innovation

As per the insight gathered from the three best authoritative sources available on Google, Lightning Hybrids appears to be a prominent pioneer in hybrid technology. The company’s expertise is evident in how they have met the challenges of integrating electric and hydraulic systems into vehicles. Their strategy involves employing advanced modular designs that allow for flexibility and scalability seamlessly, a massive plus for fleet operators who want to maximize efficiency while minimizing emissions.

In relation to the challenges posed by hydraulic systems, Lightning Hybrids has gone a step further by improving the processes of energy reservoir and energy deployment. This company is claimed to employ hydraulic accumulators rated for 5,000 psi and above, which allow for the optimal storage of energy while allowing for quick energy deployment. This is important for scenarios where quick stop-start operations are necessary.

Additionally, Lightning Hybrids has innovated in the design of hydraulic pump/motor units with volumetric displacement rates of 50-100cc per revolution. These carefully redesigned units enhance the energy interactions between hybrid systems for optimal vehicle operational performance.

Moreover, Lightning Hybrids’ move to develop an electric unit integrates the focus on battery advancements toward higher energy concentration and faster recharge time, contributing to better power output and reduced emission. By combining these electric improvements with their hydraulics know-how, they are pioneers in building flexible and efficient hybrid systems, which are substantiated by comprehensive empirical data and expert opinion from the reviewed literature.

Frequently Asked Questions (FAQs)

Q: What is the salient feature of hybrid hydraulics in vehicles?

A: Hybrid hydraulics are very useful in increasing vehicles’ energy consumption and efficiency as they integrate hydraulic systems and internal combustion engines. Such systems enable vehicles to capture energy during braking and recycle energy at sites where energy consumption and pollutants would have been generated otherwise.

Q: In what way do hydraulic hybrid systems enhance fuel efficiency?

A: Hydraulic hybrid systems enhance fuel efficiency by harnessing low-pressure hydraulic fluid from the reservoir, which is pressurized to enable energy storage during vehicle acceleration. This energy is recombined to propel the vehicle, lessening dependence on the internal combustion engine and thus promoting fuel economy.

Q: Is it possible to use hybrid hydraulics in large vehicles?

A: Yes, hybrid hydraulics are quite useful for heavy vehicles and commercial vehicles like delivery trucks and buses that contain large engines. These buried large commercial vehicles may use hydraulic hybrid technology to improve their operation efficiency, enhance engine efficiency, and minimize exospheric tolls, serving their purposes in commercial ventures.

Q: What role does the Environmental Protection Agency (EPA) play in hybrid hydraulics?

A: The EPA regulates vehicle emissions and fuel efficiency. This movement promotes fuel economy and lower emissions, requiring manufacturers to follow EPA guidelines while fostering global environmental protection through hybrid hydraulic vehicles.

Q: Explain the energy recovery phenomenon in hydraulic hybrid systems.

A: Energy recovery in hydraulic hybrid systems involves capturing kinetic energy during the vehicle’s deceleration/breaking phase. This energy is conserved in a hydraulic accumulator at high pressure and can later be used to drive hydraulic motors, augmenting the vehicle’s efficiency and reducing the amount of fuel used.

Q: What are the possible hybrid configurations for hydraulic systems?

A: There are several hybrid configurations, such as a series hybrid system or a parallel hybrid system. In a parallel hybrid, both the internal combustion engine and hydraulic system can turn the automobile, whereas, in a series hybrid, the engine serves as a backup, as the Hydraulic system becomes the primary turning power source in the automobile.

Q: What are some advantages of hydraulic-hybrid delivery vehicles?

A: Hydraulic hybrid delivery vehicles have several advantages, such as improved fuel economy, reduced pollution, and improved performance in urban areas. They are able to capture and reuse energy more effectively, making them more suited for stop-and-go traffic, which is prevalent in cities.

Q: How are hydraulic transformers used in hybrid systems?

A: Hydraulic transformers change mechanical energy to hydraulic energy or vice versa. In hybrid systems, they contribute substantially to the flow control of hydraulic fluid in both the internal combustion engine and hydraulic motors, enhancing energy transfer efficiently between these systems and thus improving vehicle performance.

Q: What is the future of hydraulic technology in racing applications?

A: There are good prospects for hybrid hydraulic technology, particularly today, as the market is more focused on developing fuel-efficient and eco-friendly vehicles. Techniques for improving hydraulic devices, energy recovery systems, and other methods are expected to improve the efficiency of hydraulic hybrid fleet vehicle testing and, hence, widespread usage of the vehicles.