Understanding Cat Triplex Plunger Pumps

What is a Triplex Plunger Pump?

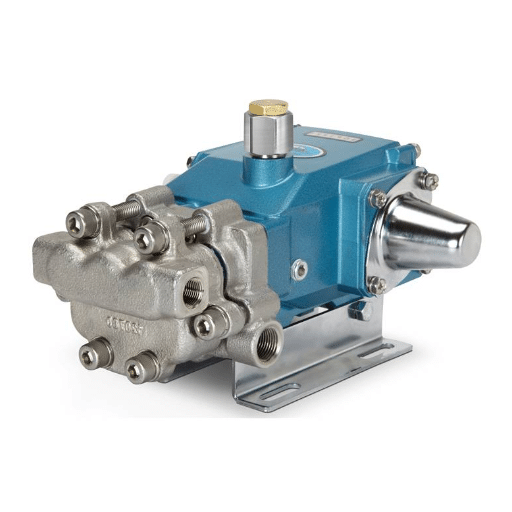

A Triplex Plunger Pump is a high-pressure pump designed to provide efficient and reliable movement of liquids. Key characteristics include:

- Three-plunger design: Three plungers actuated simultaneously for consistent pressure and flow rate

- Coordinated operation: Ensures smooth and steady fluid delivery

- Precision engineering: Rubbing surfaces made from the strongest suitable materials

- Heavy-duty construction: Built to withstand severe working conditions

Key Advantage: The simple design allows for quick servicing and repairs, significantly reducing downtime and maintenance costs.

Key Features of Cat Plunger Pumps

Cat Plunger Pumps are recognized for their exceptional performance across multiple dimensions:

| Feature | Benefit | Application Impact |

|---|---|---|

| High-Pressure Output | Consistent performance under continuous operation | Ideal for demanding cleaning and processing tasks |

| Corrosion-Resistant Materials | Stainless steel construction with advanced sealing | Suitable for harsh environmental conditions |

| Easy Maintenance | Simple design enables fast part replacement | Minimal downtime in critical operations |

| Energy Efficiency | Optimized energy consumption | Reduced operational costs |

Technical Specifications Overview

100-10,000+

PSI Range

PSI Range

0.13-240

GPM Flow Rate

GPM Flow Rate

90%+

Efficiency Rate

Efficiency Rate

Construction materials and features:

- High-grade stainless steel construction

- Brass or bronze internal components for corrosion resistance

- Advanced sealing configuration to prevent leaking

- Built-in cooling mechanisms for high-temperature applications

- Flexible integration with various mounting options

Applications of Cat Triplex Plunger Pumps

Industrial Cleaning Applications

Cat Triplex Plunger Pumps excel in demanding cleaning scenarios:

- High-Pressure Washing: Removing dirt, grease, and grime from machinery, vehicles, and building exteriors

- Tank and Vessel Cleaning: Complete debris and residue removal in food processing, chemical, and pharmaceutical industries

- Offshore Rig Maintenance: Cleaning rigs and pipelines to remove salt buildup and corrosive materials

- Heat Exchanger Cleaning: Efficient removal of contaminants to maintain heat transfer efficiency

- Warehouse and Facility Sanitation: High-power cleaning for floors, walls, and equipment to meet industry standards

High-Pressure Fluid Transfer Applications

Industries leveraging high-pressure fluid transfer systems:

| Industry | Applications | Key Benefits |

|---|---|---|

| Agriculture | Surface irrigation, slurry handling | Efficient long-distance liquid transfer |

| Oil & Gas | Drilling operations, chemical dosing | Handles extreme resistance conditions |

| Mining | Slurry transport, equipment cleaning | Durable performance in harsh environments |

| Renewable Energy | Thermal management, hydropower optimization | Supports sustainability initiatives |

Benefits of Using Cat Triplex Plunger Pumps

Performance and Reliability Comparison

Performance Advantage: While centrifugal pumps lose efficiency at high pressures, triplex plunger pumps maintain consistent performance under extreme operating conditions.

Key performance differentiators:

- Positive displacement design: Delivers exact fluid quantities regardless of pressure changes

- Low RPM operation: Reduces component stress and extends maintenance-free periods

- Superior pressure capability: Maintains high-level pressure variations better than diaphragm pumps

- Efficiency rates: Achieve over 90% efficiency where many centrifugal pumps fall short

Cost-Effectiveness and Energy Efficiency

Financial and environmental benefits include:

| Benefit Category | Impact | Long-term Value |

|---|---|---|

| Energy Consumption | Up to 30% reduction vs. less optimized technologies | Significant operational cost savings |

| Maintenance Requirements | Minimal servicing under variable load conditions | Reduced downtime and service costs |

| Environmental Compliance | Reduced carbon footprint | Meets regulatory requirements |

Maintenance Tips for Cat Plunger Pumps

Regular Servicing and Inspection Practices

Essential maintenance components:

- Critical Component Inspection:

- Seals, valves, and plungers for wear and tear

- Leakage detection and abnormal vibration monitoring

- Crankcase oil level maintenance and periodic changes

- Cleaning Procedures:

- External component cleaning

- Suction and discharge valve line flushing

- Filter and inlet strainer inspection and cleaning

- Documentation:

- Maintenance record keeping

- Component replacement tracking

- Predictive maintenance scheduling

Common Maintenance Mistakes to Avoid

Critical Mistakes: Avoiding these common errors will significantly extend your pump’s lifespan and maintain optimal performance.

- Neglecting regular inspections – leads to unnoticed gradual wear

- Inadequate lubrication – causes excessive friction and component damage

- Using non-approved spare parts – may not meet exact specifications

- Operating beyond specifications – exceeds pressure or temperature ratings

- Inadequate staff training – improper handling and maintenance procedures

- Ignoring manufacturer guidelines – affects preventive maintenance scheduling

Extending Pump Lifespan

Best practices for maximum longevity:

- Conduct regular performance monitoring and early problem detection

- Use only manufacturer-recommended replacement parts and seals

- Maintain proper lubrication schedules with recommended lubricants

- Operate within prescribed pressure and flow limits

- Implement proper cleaning schedules and debris removal

- Utilize IoT-enabled monitoring systems for predictive maintenance

Industry Trends and Innovations

Technological Advancements in Pump Design

Recent breakthrough technologies:

| Technology | Features | Benefits |

|---|---|---|

| IoT-Enabled Smart Systems | Real-time parameter monitoring, predictive analytics | Increased uptime, reduced failure risk |

| Variable Frequency Drives | Precise motor speed control | Energy consumption matches demand |

| Advanced Materials | Composites and corrosion-resistant alloys | Extended service life in harsh conditions |

| 3D Printing Integration | Rapid component prototyping | Reduced production lead time and costs |

Future Outlook for Plunger Pumps

Industry-specific developments:

- Oil & Gas: Enhanced materials for high-pressure, high-temperature applications

- Water Treatment: Advanced designs for precise chemical dosing and waste minimization

- Agriculture: Robust pumps handling abrasive fluids under variable pressure demands

- Chemical-Pharmaceutical: Precision and robustness for complex fluid transfer processes

Frequently Asked Questions (FAQ)

Q: What is a cat triplex plunger pump?

A: A cat triplex plunger pump is a high-pressure pump designed for various applications, including pressure washing. It features three plungers that reciprocate to generate high pressure, making it suitable for heavy-duty cleaning tasks.

Q: What are the benefits of using a cat triplex plunger pump?

A: Benefits include high efficiency and durability, maximum pressure of 3500 psi for tough cleaning jobs, ceramic plungers for enhanced wear resistance, and extended unit lifespan.

Q: What is the typical flow rate of a cat triplex plunger pump?

A: Cat triplex plunger pumps typically offer flow rates around 2.5 gpm to 2.7 gpm, ideal for effective cleaning while maintaining high pressure.

Q: How does a cat triplex plunger pump compare to other pressure washer pumps?

A: The cat triplex plunger pump is known for superior strength and reliability. While many pumps use aluminum components, cat pumps utilize high-quality materials like ceramic plungers, enhancing performance and durability.

Q: Can I use a cat triplex plunger pump with a belt drive?

A: Yes, cat triplex plunger pumps can be used with belt drive systems. This setup allows for efficient operation and reduces vibrations, resulting in smoother power washer performance.

Q: What accessories are available for cat triplex plunger pumps?

A: Available accessories include unloader valves, shafts, and various fittings. These accessories enhance pump performance and extend functionality for different applications.

Q: How do I maintain my cat triplex plunger pump?

A: Regular maintenance includes checking oil levels, inspecting the gearbox, replacing worn components like belts or plungers, and keeping the pump clean and debris-free to maintain optimal performance.