Hydraulic pumps power equipment with precision and efficiency; thus, they have been referred to as the heart of innumerable industrial and mechanical systems. But what happens if these essential components go out of order? Are they repairable, or do they have to be replaced? In this guide, we will walk through hydraulic pump repair and rebuild to understand the processes involved, its benefits, and the considerations that come with it.

Common Hydraulic Issues

Leaks and Their Causes

Hydraulic leaks are among the most common problems in hydraulic systems. They could result from several factors:

- Worn seals and gaskets: Constant exposure to pressure, heat, and fluid motion causes deterioration

- Loose fittings: Regular operations can cause fittings to become loose over time

- Physical damage: Cracking or abrasions on hoses and cylinders

Prevention strategies include:

- Frequent maintenance and inspection

- Timely replacement of worn-out seals

- Tightening loose fittings

- Regular inspection of hoses and components for visible wear

- Using high-quality parts and fluids

Overheating Problems

Excessive heat generation or inadequate cooling is responsible for various overheating problems in hydraulic systems. High temperatures may degrade the fluid, shorten component life, and reduce efficiency.

Common causes of overheating:

- Dirty or clogged filters

- Wrong fluid viscosity

- Extended operation during high loads

- Blocked cooling systems

- Faulty heat exchangers or fans

Pressure Loss and Worn-out Components

Pressure loss can seriously compromise hydraulic system performance and efficiency. The most common causes include:

- Worn-out components: Seals, fittings, or hoses experiencing wear and tear

- Blockages or restrictions: Dirt and debris in pipes and filters

- Internal leakage: Worn parts allow fluid to bypass intended flow paths

Address pressure loss through proper periodic maintenance, regular inspection for signs of wear, and developing a specific inspection program with record keeping to identify patterns and prevent future issues.

Diagnosing Hydraulic Pump Failures

Identifying Symptoms of Failure

Early identification of symptoms prevents costly repair and system downtime. Key warning signs include:

| Symptom | Possible Cause | Action Required |

|---|---|---|

| Unusual noise (whining, rattling, knocking) | Cavitation, worn components | Immediate inspection |

| Decreased performance (speed, flow, pressure) | Internal leakage, worn parts, fluid contamination | System analysis |

| Excess heat | System stress, overloading | Check the cooling system |

| Fluid leakage | Seal failure, loose fittings | Seal replacement |

| Discolored fluid | Overheating, contamination | Fluid analysis and replacement |

Tools for Troubleshooting

Effective hydraulic troubleshooting requires both advanced tools and systematic approaches:

Essential Diagnostic Tools:

- Pressure gauges: Provide real-time system pressure information

- Digital pressure gauges: Offer precise readings with data logging capabilities

- Infrared thermometers: Identify temperature irregularities

- Thermal-imaging cameras: Detect component overheating or excessive friction

- Fluid analyzers: Check for contaminants and system health indicators

- Particle counters: Detailed fluid condition analysis

- Spectrometers: Advanced contamination detection

Modern Diagnostic Technology:

- Machine learning algorithms for predictive maintenance

- IoT-enabled sensors for continuous monitoring

- Real-time data analysis for actionable insights

- Automated anomaly detection systems

When to Seek Professional Help

Seek professional assistance when:

- Complex system problems persist despite troubleshooting efforts

- Extreme wear, vibrations, overheating, or serious leakage occurs

- Compliance regulations and safety standards require certified intervention

- DIY attempts might worsen the damage or create safety hazards

Cost of Hydraulic Pump Repair

Factors Influencing Repair Costs

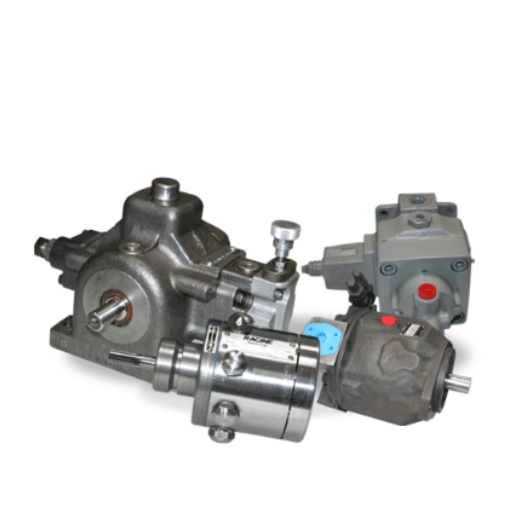

Several key factors determine the final cost of hydraulic pump repairs:

- Repair complexity and damage extent: Minor seal changes vs. full rebuilds

- Pump type and model: Rare or specialized parts may cost more

- Labor expertise required: Skilled technicians command higher rates, but ensure quality

- Parts availability: Common parts vs. custom-ordered components

- Service history: Well-maintained pumps are typically easier and cheaper to repair

Comparing Repair vs. Replacement Costs

| Factor | Repair | Replacement |

|---|---|---|

| Cost Range | $200 – $3,500 | $650+ |

| Time Required | Faster | Slower |

| Complexity | Lower | Higher |

| Decision Rule | When <50% of the replacement cost | When >50% of the repair cost |

| Example Costs | Gasket replacement: $4-$150 | Full pump system: $650+ |

Estimating Labor Charges

Labor costs typically range from $50-$150 per hour, depending on:

- Regional wage rates

- Technician experience level

- Job complexity

- Time requirements

General Rule: If repair costs (including labor) exceed 50% of replacement costs, consider replacement for better long-term value.

Repairing vs. Replacing Hydraulic Pumps

Assessing Cost-Effectiveness

When deciding between repair and replacement, consider both short-term and long-term cost implications:

Factors favoring repair:

- Minor issues or single component failures

- Relatively new equipment

- Readily available replacement parts

- Cost under 50% of replacement value

Factors favoring replacement:

- Frequent breakdowns and ongoing maintenance issues

- Older pumps with poor energy efficiency

- Unavailable or expensive replacement parts

- Repair costs approaching replacement costs

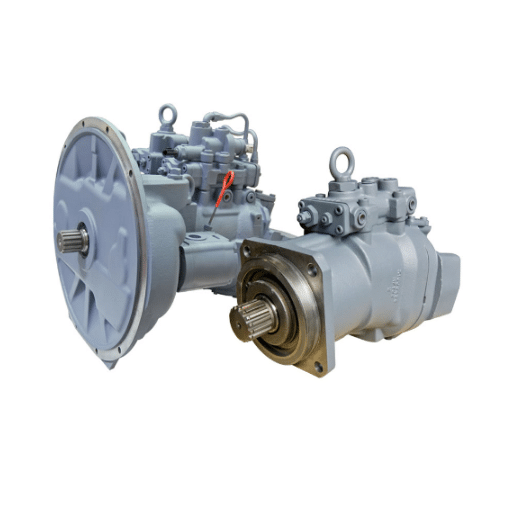

The Age of the Pump

Modern hydraulic pumps have evolved significantly with technological advancement:

- Smart pumps: IoT-enabled systems with real-time monitoring

- Digital integration: Data insights for operation optimization

- Environmental consciousness: Solar-powered and sustainable options

- Modular designs: Easy part replacement without full system overhaul

Future Trend: The pump industry is moving toward adaptable, innovative solutions that combine technology with sustainability, promising better efficiency and environmental responsibility.

Availability of Replacement Parts

The replacement parts market has evolved significantly:

- Modular designs: Easy replacement of individual components

- Standardized parts: Global sourcing capabilities

- Online platforms: Quick identification and ordering

- Sustainable practices: Recycled materials and take-back programs

Maintenance Tips for Hydraulic Pumps

Regular Inspections

Regular inspections ensure long pump life and efficient operation:

Visual Inspection Checklist:

- Check for fluid leaks around seals and connections

- Listen for unusual noises during operation

- Monitor pressure variations

- Inspect for visible damage or corrosion

- Verify proper alignment and secure connections

Operational Checks:

- Monitor hydraulic fluid levels and quality

- Check for contamination or foreign particles

- Verify fluid color and consistency

- Test system pressure and flow rates

Proper Fluid Management

Key Principle: Proper fluid management is crucial for efficient functioning, longer life, and dependable operation of hydraulic pump systems.

Fluid Selection Criteria:

- Adequate viscosity for system requirements

- Thermal stability

- Proper additives for wear protection

- Manufacturer-recommended specifications

Ongoing Fluid Maintenance:

- Continuous monitoring and systematic maintenance

- Prevention of contamination through proper filtration

- Regular fluid analysis and replacement

- Maintaining proper fluid levels

- Seal integrity maintenance

⚠️ Critical: Running a hydraulic system with deficient or excessive fluid may cause overheating, foaming, or cavitation, all of which will damage components and reduce performance.

Frequently Asked Questions

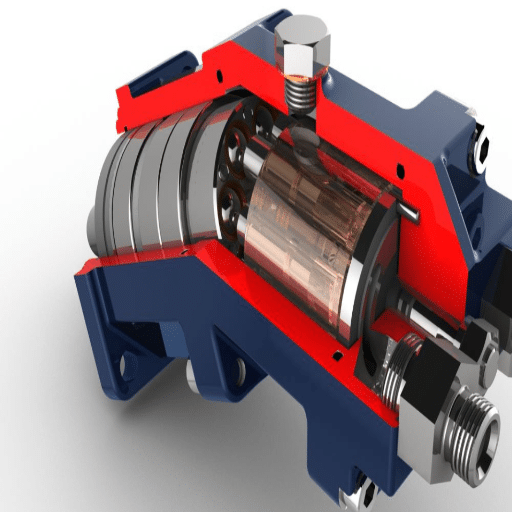

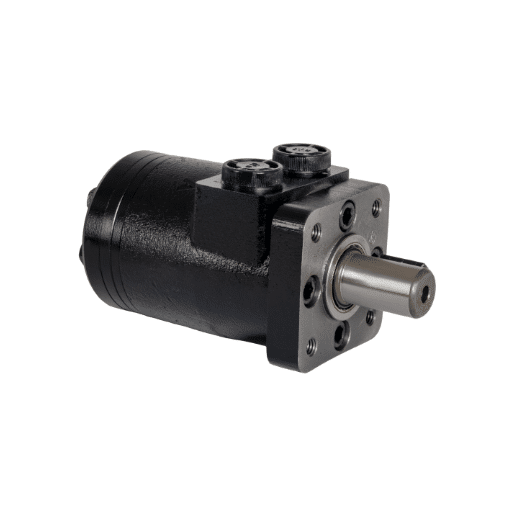

A: Yes, hydraulic pumps are generally repairable. Repair usually involves disassembling the equipment, checking for damage, and replacing worn or unsuitable parts. The complexity depends on the pump type (gear, piston, etc.).

A: Common causes include low hydraulic oil levels, contaminated hydraulic fluid, aeration, and improper maintenance. These conditions reduce pump efficiency and eventually require repair.

A: Failing hydraulic pumps typically exhibit unusual sounds, vibrations, leaks, pressure drops, and reduced flow. Address these symptoms immediately to prevent further damage.

A: Yes, pumps with eroded surfaces can be repaired through re-machining of affected surfaces or replacement of damaged components to restore optimal performance.

A: Most hydraulic pumps are repairable, including vane pumps, gear pumps, and piston pumps. Each type may have specific considerations during the repair process.

A: Clean hydraulic fluid is essential for optimal pump performance. Contaminated or degraded fluid causes increased wear and tear and risks complete system failure.

A: Minor maintenance issues may be handled independently, but major problems are better handled by professionals specializing in hydraulic equipment. Proper knowledge and tools are essential for safe, effective repairs.

A: The repair process usually involves:

- Disassembly of the pump

- Inspection of components for damage

- Cleaning of all parts

- Replacement of worn components

- Reassembly with proper alignment

- Testing and calibration

A: Ensure adequate reservoir levels, check for leaks or blockages in the fluid flow path, maintain proper fluid levels, and address any identified issues promptly.

A: Regular maintenance includes:

- Checking fluid levels regularly

- Replacing old hydraulic oil as scheduled

- Inspecting for leaks

- Monitoring system performance

- Following manufacturer maintenance schedules

Conclusion

Key Takeaway: Hydraulic pumps are indeed repairable, and understanding when to repair versus replace can save significant time and money. The decision should be based on a comprehensive analysis of repair costs, pump age, parts availability, and long-term operational efficiency. Regular maintenance and early problem identification remain the best strategies for maximizing hydraulic pump lifespan and performance.