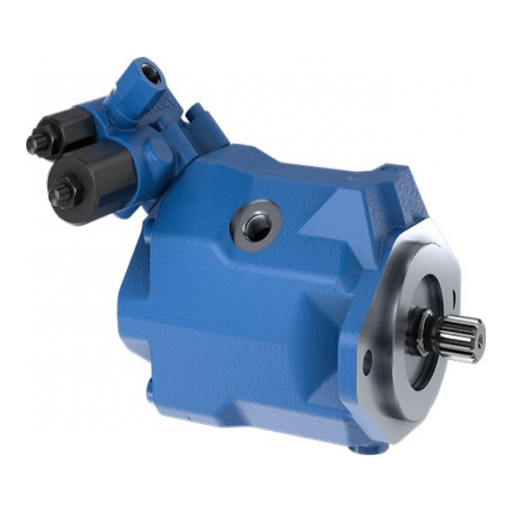

Understanding Bosch Rexroth Axial Piston Pumps

What is an Axial Piston Pump?

Axial piston pumps work on the principle of positive displacement and are designed to transfer fluids at high pressure efficiently. The working principle involves the motion of several pistons parallel to the rotation axis of a cylinder block. The pistons’ linear motion is created by the angled swash plate or bent axis, thus generating suction and discharge.

Axial piston pumps may find their fair share of applications in engineering, as they can handle high-pressure systems efficiently while possessing the advantage of being compact and efficient. They are found in applications, including:

- Construction equipment

- Industrial machines

- Aerospace systems

Their reliability, control, and variation to flow demand make for a system of great importance. Axial piston pumps excel compared to other pumps in the direct conversion of energy and transfer of fluid, providing accurate control over flow and pressure to attain superior system performance.

Key Features of Bosch Rexroth Axial Piston Pumps

High Pressure Capability

Bosch Rexroth axial piston pumps are capable of very high pressure capacity and can impose pressure up to 450 bar, fulfilling a wide array of requirements in hydraulic systems.

Key features that set these pumps apart include:

- Application Variety and Adaptability: Useful for both open and closed hydraulic loop systems

- Variable Displacement: Enables operators to control flow rates easily and set to actual operational requirements

- Energy Efficiency: Improves efficiency and reduces energy consumption

- Durability and Reliability: Manufactured with fine materials and put through rigorous testing

Benefits of Using Bosch Rexroth Pumps

Applications Across Various Industries

Construction Industry Applications

| Equipment Type | Application | Key Benefits |

|---|---|---|

| Hydraulic Excavators | Control of boom, arm, and bucket | Smooth and accurate operation under high pressure |

| Cranes | Lifting and lowering heavy loads | Precise and secure movements, operational safety |

| Concrete Pumps | High-pressure concrete distribution | Long-distance pumping capability for high-rise construction |

| Bulldozers | Blade movement control | Efficient and precise ground leveling |

| Wheel Loaders | Load and bucket mechanism control | Fast and dependable material handling |

Agricultural Sector Utilization

The agricultural sector has increasingly embraced hydraulic systems to bring automation for varied operations and foster efficient working. Key applications include:

- Tractors: Hydraulic systems for plowing, lifting, and spraying operations

- Harvesters: Hydraulic-powered combines for crop harvesting with adjustable cutting heights

- Irrigation Systems: Precise water distribution across large agricultural lands with sensor integration

Smart Irrigation Technology

Hydraulic-powered irrigation systems regulate water supply to different divisions depending upon soil moisture content, promoting water conservation with optimal irrigation efficiency.

Manufacturing and Energy Sector Implementations

Manufacturing Applications:

- Assembly line power machinery for stamping, molding, and heavy component lifting

- Hydraulic-powered robotic arms for precise and repeatable motions

- Quality control systems with minimal downtime requirements

Energy Sector Applications:

- Hydroelectric Power Plants: Hydraulic turbines for energy capture from moving water

- Oil and Gas Extraction: High-pressure hydraulic fracturing systems

- Renewable Energy: Ecosystem-compatible energy extraction systems

Maintenance Tips for Optimal Performance

Routine Maintenance Practices

- Component Inspection: Periodic checks of hoses, seals, and fittings for wear and damage

- Fluid Level Monitoring: Maintain appropriate hydraulic fluid levels to prevent overheating

- Filter Management: Regular cleaning and replacement of filters to prevent contamination

- Temperature Control: Monitor operating temperature and maintain cooling systems

- Documentation: Keep detailed maintenance records for pattern analysis

Predictive Maintenance Benefits

Companies incorporating predictive and proactive maintenance report up to 30% savings on maintenance costs and 45% less downtime.

Long-Term Care for Durability

Modern long-term maintenance programs benefit from breakthrough technologies:

- IoT Sensors: Real-time monitoring of temperature, vibration, and pressure

- AI Analytics: Predictive breakdown analysis with timely corrective insights

- Cloud Systems: Enhanced data storage, analysis, and sharing capabilities

- Quality Components: Use of the best materials and parts to prevent early failures

Performance Comparison with Other Technologies

| Feature | Bosch Rexroth Axial Piston Pumps | Traditional Fixed Displacement Pumps | Gear Pumps |

|---|---|---|---|

| Energy Efficiency | Advanced pressure control, intelligent drive systems | Continuous full-speed operation regardless of demand | Limited efficiency in variable applications |

| Adaptability | Multiple configurations, digital system integration | Limited configuration options | Minimal adaptation capabilities |

| Durability | Premium materials, precision engineering | Moderate durability | Good for general applications |

| Maintenance | Predictive maintenance, IoT monitoring | Scheduled maintenance | Regular maintenance required |

Cost-Effectiveness Analysis

The cost-effectiveness of Bosch Rexroth pumps extends beyond initial investment:

- Reduced Replacements: Superior durability means fewer system replacements

- Energy Savings: Optimized energy usage reduces operational expenses

- Predictive Maintenance: Early fault detection prevents costly shutdowns

- Enhanced Productivity: Higher performance with fewer resources

- Environmental Benefits: Reduced energy consumption and environmental impact