The efficiency and reliability of hydraulic systems are extremely important in the case of heavy machinery, particularly machines like Bobcat loaders and excavators. Proper hydraulic pump installation ensures the system’s best performance and longer life. The following article looks closely at some major stages and factors involved in the professional installation of Bobcat hydraulic pumps. The information provided herein enlightens readers on technical specifications, ways to install this component, and traps one can get into so as to facilitate its smooth running or realize why it is worth engaging professionals. This guide aims at improving the reader’s understanding of hydraulic systems through a detailed examination of the elements constituting them and their relationships with each other so that they may better appreciate the need for carefulness during installations.

Why Choose Professional Installation for Bobcat Hydraulic Pumps

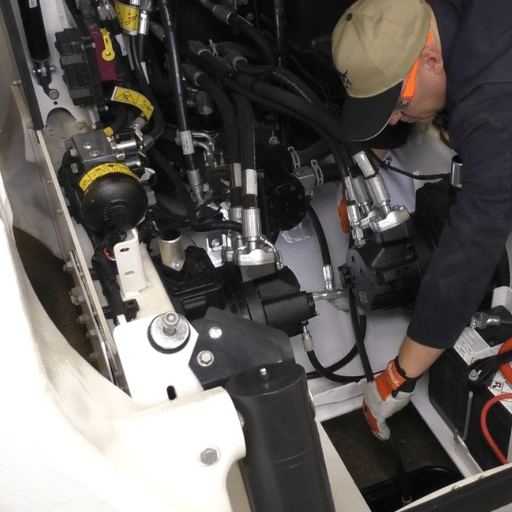

There is a need for professional installation of Bobcat hydraulic pumps due to several reasons. The first is that trained technicians are knowledgeable enough to understand the manufacturer’s specifications and requirements unique to Bobcat machines thus ensuring that the pumps are fixed as per the manufacturer’s guidelines. This ensures that the pump is installed by best practices, thereby, minimizing the risk of improper installation which can lead to system inefficiencies or increased wear and tear resulting in premature pump failure. Second, professionals usually have some special tools and diagnostic equipment at their disposal, making fine tuning during installation possible and enabling them to conduct post-installation tests that verify whether everything was done properly. Moreover, depending on professional services gives a guarantee and warranty coverage protecting both equipment and service investment. All in all, it contributes greatly towards improving operational reliability while extending lifespan of hydraulic systems used by Bobcats.

Why You Should Have Your Bobcat Equipment Professionally Installed

There are numerous benefits associated with expertly installing Bobcat machinery, which enhances performance as well as prolongs its useful life. First off, trained individuals will install every bit with precision hence minimizing chances of malfunctioning. In so doing, not only does it increase efficiency in hydraulics, but it also optimizes the machine’s overall functionality. Secondly, experts with hands-on experience with this particular system’s details and peculiarities anticipate problems involved at the installation stage, thus mitigating downtime and effectively enhancing productivity hereafter. Next, expert installations often come with comprehensive warranties and maintenance agreements that give equipment owners peace of mind and security. Ultimately, when you invest in professional installation, costs go down, productivity goes up, and service lives increase significantly in the case of other Bobcats.

How Professional Installation Guarantees Optimal Performance

This means that the professional installation process should be carried out meticulously following manufacturing instructions as well as considering best industry practices for satisfying clients’ needs whilst being effective performers on their respective markets globally or locally, too, where applicable. It considers that any improper setup may result in misalignment or functioning flaws associated with these components thus increasing chances of accidents. Another reason is that at the time of installation, a technician will examine if there are any problems with your machine otherwise they can address them in advance before becoming serious issues. Moreover, trained installers conduct performance tests immediately after installing diagnostic tools and methods to determine such things as gas pressure, temperature etc. In addition, their expertise ensures adherence to all safety rules essential for maintaining operational integrity as well as complying with relevant regulation. Consequently, the efficiency of Bobcat equipment can be boosted by undertaking professional installations and prolong longevity while ensuring enhanced operating standards.

Dangers of Do-it-Yourself Hydraulic Pump Installation

Nevertheless, several risks come together with do-it-yourself installations, especially on hydraulic pumps, which have an impact on their functionality and security. This has been concurred by some previous studies. One major fear is that during installation one might fail to follow sequences properly leading to excessive wearing out of pump parts hence failure. Furthermore, people without proper knowledge may not adhere to necessary steps like filling fluid up to correct levels, which can cause cavitation, leading to severe damage to the pump itself. Similarly, inadequate knowledge of hydraulics could result in wrong connections thereby causing leaks of hydraulic fluids which are environmentally harmful and reduce overall effectiveness in running the system entirely due to this reason too; it needs compliance with safety protocols to avoid accidents happening since noncompliance would then increase possibilities for encountering physical harm or even death situations within working environment. Such mistakes incur costly repairs and may void manufacturer warranties, leading to long-term financial repercussions.”

Preparing for Bobcat Hydraulic Pump Installation

Before going ahead with installing a Bobcat hydraulic pump, it is important to prepare adequately to have an efficient and successful process. Begin by collecting tools like wrenches, pliers, torque specs and replacement parts that meet OEM standards. In addition, refer to a specific service manual for that particular model of Bobcat which will have detailed instructions and specifications regarding the hydraulic system.

Additionally, workspace preparation is vital in order for it to be clean and organized throughout the workflow process which will reduce chances of contamination. Protective gears such as gloves and goggles should also be worn when working on these machines. Lastly, do an overall check-up on your existing hydraulic system to identify any other underlying problems that need attention before installing such as leaks or worn out components that may hinder the performance of this new pump. These preparatory steps significantly increase the chances for successful installation and optimal functioning.

Necessary Pre-Installation Checks and Preparations

- Verify Compatibility of Replacement Parts: Make sure these hydraulic pumps and fittings are compatible with the Bobcat models in question; one can refer back to OEM specifications to verify whether they fit within the required performance grades and fitting limits.

- Inspect Hydraulic Hoses and Fittings: Examine all hydraulic hoses, including their couplings, looking for wearout, cracks, or leaks while checking if they are tightly secured without damage so no liquid escapes from this system, hence pressure failure after installation.

- Check Fluid Levels and Condition: Look at fluid levels contained within our hydraulics while examining its quality; thus replace spoiled or contaminated ones since they might result into poor operation of a newly installed pump.

- Examine Mounting Points: Inspect mounting points on Bobcat machinery to ascertain the integrity of their structures. Look out for any bends, cracks, or corrosion because these can affect how this pump gets put inside. If trouble is found, then repairs must be done before it is installed.

- Prepare Clean Work Environment: Contamination can lead to system failure, so maintain a clean working environment free from dust and debris. Use protective sheets on surfaces to avoid contamination during the installation process.

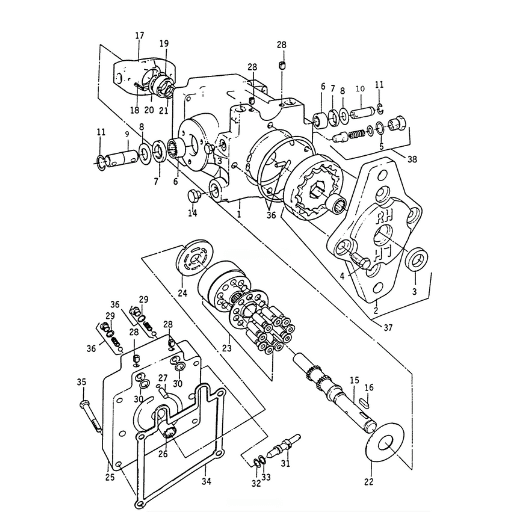

- Gather Technical Documentation: Have ready access to the service manual with important technical details and diagrams for installation. This ensures compliance with specific service instructions and torque specifications.

- Double-Check Safety Protocols: Reevaluate safety procedures to ensure that they are being followed as required by all personnel involved so as not to cause any accident during this pump’s installation

Ensuring That Your Bobcat Model is Compatible.

In order to achieve the best results and ensure that your hydraulic pump installation is reliable, it is important to be compatible with a specific Bobcat model. First of all, cross check the model number of the pump against manufacturer’s specifications to make sure that it is designed for your hydraulic system of the machine. For each type of Bobcat tractor, there are certain requirements for pump size, pressure ratings and flow rates; therefore, it is mandatory to consult service manual for your particular model. It will also be useful if you read some recent user reviews or forums dedicated specifically to Bobcat machinery where operators share their opinions on different models of pumps. Moreover, most manufacturers have published compatibility charts on their websites, enabling technicians to check whether these components will work seamlessly with other equipment. It is also of great importance that all parts used are OEM or at least high-quality ones as specified by manufacturers so as not to void warranty agreements and compromise the hydraulic integrity of a machine.

Tools and Equipment Needed During Installation Process

- Hydraulic Wrench: This tool will help you tighten hydraulic fittings to the manufacturer’s torque figures. Make sure that the wrench has been calibrated and has an adequate torque range for use with your respective Bobcat model.

- Torque Wrench: This tool should be employed when tightening fasteners to the exact amount of torque required. It helps prevent overtightening, which can damage or fail hydraulic components.

- Socket Set: Different socket sizes will be needed here for various nuts and bolts involved in installing it. A 3/8-inch and 1/2-inch drive set should suffice for most hydraulic installations.

- Pliers and Cutters are good for keeping loose ends from the hoses or fittings we just grabbed. Ensure they can handle metal and rubber so as not to damage the hoses.

- Hose Clamp Tool: This tool is needed to fix hose clamps properly without breaking them. A good tool should be strong enough to apply a lot of force and fix the clamp tightly.

- Fluid Transfer Pump: A fluid transfer pump allows for the safe addition or replacement of hydraulic fluid in the system, with no spills and under control.

- Safety Equipment: For personal protection, wear gloves, goggles, and hard hats during installation. Adequate safety gear should never be compromised when working with hydraulic systems.

- Service Manual: This document provides step-by-step installation procedures, specifications, and troubleshooting tips for the specific Bobcat model.

- Cleaning Supplies: For instance, rags and degreasers are used to keep the workplace clean and all surfaces free from contaminants before installation, which is crucial for optimum hydraulic performance.

The Step-by-Step Installation Process

- Preparation: To begin, you should review the service manual of your Bobcat model to learn its particular requirements and processes. With all the necessary tools and safety gear, it will be an effective installation.

- Fluid Drainage: Before installation, ensure that the hydraulic system is depressurized. Drain any old hydraulic fluid from the system to prevent pollution or mixing of fluid types.

- Component Removal: Carefully remove any existing hydraulic components that need to be replaced. Use appropriate socket sizes and pliers to avoid damaging the surrounding areas.

- Installation of New Components: Align and fit new hydraulic components according to the instructions in the service manual. Ensure all connections are tight by using torque wrenches to tighten fasteners with appropriate torque values.

- Hose Connection: Attach new hoses securely while using a hose clamp to prevent leaks. Make sure that hoses do not kink or pinch when being installed.

- Fluid Transfer: The fluid transfer pump inserts new hydraulic fluid into the system. Refer to manufacturer’s specifications for correct type and volume of fluid.

- System Testing: After installation, test whether hydraulic systems work well without any loading at the first point in time; search for leakage and verify that all components are functioning properly.

- Final Checks: Perform a final inspection on installation area after test run out of which all tools materials must be cleared away and all components secured before machine is reactivated for use again.

Proper Alignment and Mounting of Hydraulic Pump

For proper alignment mountings of a hydraulic pump several factors must be taken into account with respect to optimum performance as well as longevity within a system. This starts with me making sure that the pump is mounted suitably on a stable flat surface such as recommended mounting dimensions within makers specifications. Therefore, I use precision instruments like the dial indicator to test for parallelism between the pump and motor, making any necessary alterations to bring them into line. Mounting bolts are tightened gradually in cross pattern so as not to create pressure imbalances. Afterwards, all hydraulic connections must be verified secure and leak-free before reactivating the system.

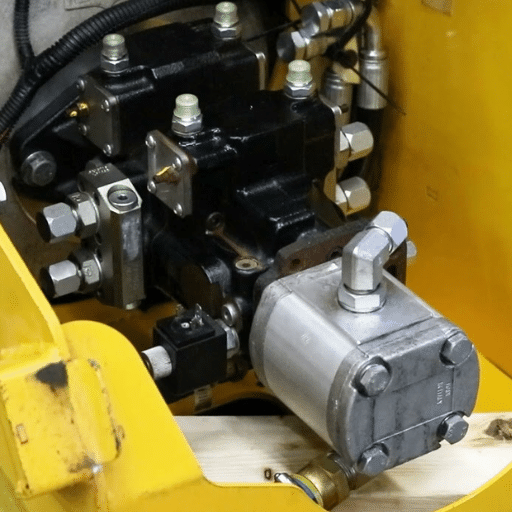

Connecting Hydraulic Lines and Electrical Components

Connecting of hydraulic lines and electrical components requires strict adherence to the appropriate requirements in order to enhance safety operation as well as efficiency. First, ensure that all hydraulic lines are properly sized to handle expected pressure and flow rates. Moreover, tightness of these connections is achieved through employing manufacturer torque specification during tightening of fittings used in joining them together. It is better using thread sealants on threaded connections so as not to allow seepage; however, caution should be taken not to let sealing debris contaminate the system.

Electrical components must comply with the National Electrical Code (NEC) or other applicable local codes. Use properly rated conductors and connectors, and ensure electrical connections are well-founded and not corroded. Consider proper cable management to prevent mechanical damage and adverse environmental conditions. Before energizing the system, a final examination for correct hydraulic and electrical connections should be made, followed by controlled system tests to ascertain operational soundness. Proper documentation of all connections and components is also vital for future maintenance and troubleshooting.

How To Test The System After It Has Been Installed

The system must be tested after its installation to confirm functionality as well as safety measures.The process typically consists of several essential steps:

- Initial Checks: Start by physically inspecting all hydraulic and electrical connections. Look for signs of leaks, corrosion, or wiring problems. Confirm that all parts have been tightly fastened together without damage.

- Pressure Testing: Pressure testing should be carried out on hydraulic lines using calibrated pressure gauges. It’s important to test systems at pressures greater than normal but within manufacturer’s safety limits (typically 1.5 times maximum working pressure). This ensures that the system can withstand the pressure of the required operation without failure.

- Functional Testing: Once pressure testing has been performed, functional tests are conducted on all components making up this system. The hydraulic system is activated, after which the actuators’ response to it is checked.The readings taken according to the manufacturer’s specifications should show a difference between ±10% from the design pressure, as shown by pressure gauges.

- Electrical Testing: In an electric circuit, use a multimeter to determine voltage levels at various points when power is switched on.Ensure voltages do not exceed ±5% of the nominal voltage indicated in equipment manuals.Additionally,current measurements are taken to ensure the circuit breaker and conductors do not exceed the rated amperage.

- Operational Testing: Finally, observe temperature stability, noise levels and vibrations for a considerable time period when the system is loaded. Any abnormal sound or excessive vibration may indicate further problems that must be investigated.

- Documentation: After testing, compile all results and observations into a maintenance log, noting pressures and voltage readings, as well as any actions taken. This documentation is important for ongoing maintenance and troubleshooting as it provides an opportunity to identify issues quickly that may occur in the future.

These tests can be accomplished with consideration of technical parameters thereby ensuring completeness of installation and operation within specified limits enhancing dependability and safety during use.

Avoiding Common Installation Mistakes

Several common pitfalls that may affect performance and safety must be avoided to install hydraulic and electrical systems. One way to do this is to observe the manufacturer’s specifications regarding the location of parts and torque settings; otherwise, it could lead to system inefficiencies and potential failures. Secondly, detailed pre-operation checks cannot be ignored since they might go unnoticed if not carried out such as low fluid levels or electric misalignments that can bring about a catastrophic collapse of the entire system. Additionally, for instance, forgetting to consider environmental factors like temperature changes and potential exposure to contaminants can harm the installed systems’ durability and efficiency. Consequently, persons involved in installation must have an understanding of these aspects so as to reduce risks involved.

Why Incorrect Mounting Can Lead to Pump Failure

One critical mistake is incorrectly mounting pumps, often resulting in failure or reduced life span. According to my research findings, the misalignment problem leads to excessive vibrations that cause mechanical wear; thus, bearings and seals fail prematurely. Again, I noted that without adequate fastening, pumps tend to move around during operation, leading to additional loads on line connections, and leaks may occur where pipes join one another. I also observed that vibration-absorbing properties of particular inappropriate surfaces further exacerbate stability issues related to incorrect framework constructions . As we can see from here then, it means any deviation will result in a loss of efficiency, forcing costly shutdown; therefore, when fixing, professionals must ensure that they follow mounting guidelines correctly.

Ensuring Secure Hydraulic Connections

This is important for maintaining system integrity and performance at all times. For example, you should use high-quality fittings and hoses compliant with industry standards because substandard parts will give in under pressure. Thirdly just like other things connected by screws over-tightening or under-tightening them causes severe damage, so right tightening instructions should be followed carefully when tightening hoses (Australia’s National Occupational Health & Safety Commission, 1999). To avoid this, it is necessary to regularly inspect and maintain hydraulic connections for signs of wear, corrosion and alignment. Lastly, using compatible hydraulic fluid throughout the system or a systematic approach to connectivity will boost reliability and efficiency. These measures can help reduce the risks that come with failed hydraulics.

The Importance of Following Manufacturer Guidelines

It is necessary to follow manufacturer guidelines to achieve equipment longevity and reliability. Adhering to these specifications ensures optimal performance by aligning operational parameters with design intent, minimizing failure and downtime risk. To develop these guidelines covering installation, maintenance limits etc., manufacturers invest significant resources into research and testing. On the other hand, non-compliance can lead to early losses in effectiveness besides voiding warranties through a reduction in efficiency, among others (The National Occupational Health & Safety Commission of Australia 1999). Additionally, many manufacturers provide support on how best to fix them based on their extensive field data, hence improving safety at workplaces. By sticking strictly to those rules the safety of people within which all systems are maintained while not threatening economic viability would be guaranteed too.

Post-Installation Maintenance and Care

It is important to carry out post-installation maintenance and care for hydraulic systems to ensure their continuous performance and reliability. Maintenance should be planned regularly so that all components are reviewed for signs of wear, such as seals and connections, which can cause leaks or air entry into the system. Moreover, fluid quality should be monitored at all times because contamination can decrease the system’s efficiency or even its failure. It is recommended that hydraulic oil be changed per the manufacturer’s procedures, with accurate records of service intervals kept to track maintenance history properly. Besides visual examinations, pressure testing and flow rates check-up may help identify possible problems before they become significant. These measures not only prolong the life cycle of hydraulic systems but also optimize their effectiveness regularly.

How to Perform Initial System Checks After Installation

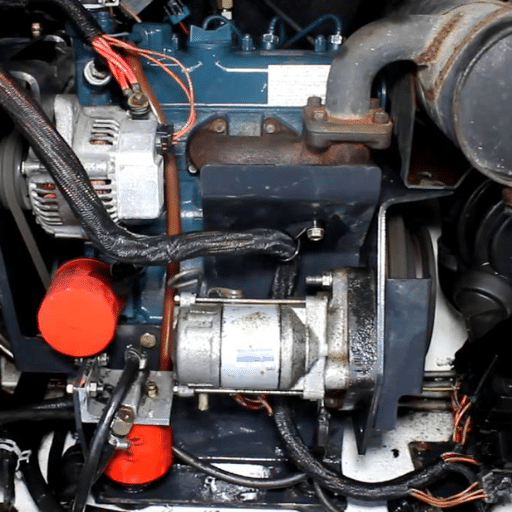

The first checks immediately after installation are necessary to keep hydraulic systems working perfectly. Firstly, you need to double-check if all parts have been installed correctly without any looseness as specified by the manufacturer’s guidelines. Another thing to look at is the hydraulic fluid level in the reservoir; it must fall within operating range shown by two lines one indicating minimum while another maximum level line provided on reservoirs. In addition, fluids used must meet viscosity specifications prescribed by manufacturers, typically within ISO VG 32 – ISO VG 68, depending on the operational temperature range of a particular system.

Following this further step involves using a calibrated gauge during testing pressure to confirm whether it falls within stipulated limits usually between 1500 and 3000 psi for standard industrial applications. As indicated by manufacturers, flow rates must attain established values ranging from 5 GPM up to 50 GPM when observing pressure.

Lastly, listen for any unusual sounds that could indicate air in the system or internal faults occurring somewhere inside. Also do an overall inspection looking for any leaks from all joints and connections since these may impair system safety and integrity. Through such preliminary inspections, operators can easily pinpoint and fix problems thus making sure that the hydraulic system has been working well right from the start.

Setting Up a Maintenance Schedule for Longevity

Establishing an effective maintenance schedule is crucial to guarantee the durable operation of hydraulic machines. Do thorough inspection and maintenance checks every 500 hours of running or monthly whichever is earliest. Such time interval enables users to identify wear and possible failure modes much earlier within the equipment’s life cycle, thus providing means for cost-effective repairs in the future.

It should include:

- Fluid Quality Check: The hydraulic fluid will be tested for contamination or degradation to ensure it continuously meets its ISO VG 32 – ISO VG 68 viscosity standards as set forth by the manufacturer. This reduces issues like foaming or cavitation, which may damage parts.

- Filter Inspection and Replacement: Filters should be washed out as per the manufacturer’s recommendations at least once every 1000 hours they have operated or not more than this duration. Ineffective flow due to filter clogging eventually slows the system down.

- Pressure Monitoring: Operating pressures will be regularly monitored within a specified range limit of 1500 psi –3000 psi. Other deviations from these settings could suggest underlying faults, namely, pressure relief valve malfunctioning or a system overload situation.

- Lubrication of Components: Lubricate all moving parts with the right type of oil as prescribed by the manufacturer to reduce friction and wear and, hence, increase their operating lifespan.

- Examination for Leaks: You should regularly check for leaks, especially at joints and seals. It is important to address any identified leaks as soon as they are detected to prevent fluid loss and maintain system pressure.

I can, therefore, contribute to ensuring reliable and efficient hydraulic systems throughout their lifecycle by observing these structured maintenance practices and the provided technical parameters, thus maximizing uptime and minimizing operational costs.

Bobcat Hydraulic Pump Early Issues Monitoring

Monitoring the performance of your Bobcat hydraulic pump is important in catching early problems that might affect the efficiency and reliability of the system adversely. Always be on the lookout for strange sounds during machine operations, such as grinding or whining, which may indicate internal wear or component failures. Also monitor pressure changes; an abrupt decrease may point leakages or blockages within a system. Temperature must also be monitored; too much heat could signal low fluid levels or poor lubrication, harming pump operation. Sometimes it’s necessary to undertake checks in order to identify anomalies earlier using diagnostic tools so that timely interventions can take place thereby avoiding massive repairs.

How Professional Installation Impacts Warranty and Performance

It is very important to install hydraulic systems professionally to ensure the validity of warranty as well as overall performance. For that matter, some manufacturers insist on certified personnel installing their goods so that they keep up with the rules of warranties. This means that installing it wrongly will cause an automatic cancellation of the warranty and possibly reduce efficiency because components might not be functioning together improperly calibrated.

Additionally, a correctly installed system is less likely to fail during operation as trained technicians understand how fine tolerances affect its performance. Hiring professionals for such tasks results in better fitting and integration of its parts, hence reducing leak chances and guaranteeing a consistent pressure pattern throughout. Subsequently, having a technician install it properly will ensure your system is dependable and lasts longer; in turn, this guarantees all the other details essential for efficient operation, including warranty and performance indicators.

How To Maintain Your Bobcat Warranty Through Professional Installation

To maintain your Bobcat warranty through professional installation, it’s crucial to adhere to guidelines established by Bobcat and perform all installations through authorised service providers. These experts know what should go into setting up a Bobcat system; hence, compliance with instructions is needed before they can put such policies into place, thereby safeguarding any applicable warranties. Getting qualified technicians ensures no accidental damages while doing this work but also enables proper calibrations, which enhance effectiveness over time, whereas retaining evidence of all professional services would prove your adherence towards preventive maintenance since it would strengthen your warrantee throughout its span.

Why Proper Installation Is Important In Enhancing Hydraulic Pump Efficiency

Proper installation significantly enhances hydraulic pump efficiency by ensuring that all components are aligned and calibrated to meet the manufacturer`s specifications, which is critical for optimal operation. One of key technical parameters is inlet pressure and outlet pressure which must not exceed certain limits if cavitation needs to be avoided and fluid flow remains smooth. Take 3000-4000 psi as example within which many hydraulic systems operate under normal working conditions. Performance will decline and wear increase if this level is surpassed or not attained.

In addition, pump shafts should be aligned properly to avoid excessive vibration and premature failure. Shaft alignment tolerance should not exceed 0.005 inches, a value often given for the maintenance of the operational integrity of a machine. In addition, it is necessary to install hydraulic fittings correctly so that no leaks occur and pressure loss and fluid contamination are reduced. To avoid happening by time, which can lead to inefficiencies pose an ever-present danger, they need to adhere to correct torque specifications indicated in the manufacturer’s installation guide.

Finally, ensuring that all hydraulic oil used meets the viscosity and cleanliness standards indicated by the manufacturer allows for better lubrication and cooling, enhancing overall system efficiency. Paying attention to these technicalities not only helps you achieve maximum performance out of your hydraulic pumps but also increases their life span, thus making them more economically viable.

Long-Term Benefits of Professional Installation

Professional installation of hydraulic systems is key when seeking optimal performance and long life span. First and foremost, technicians with professional qualifications have skills enough to detect potential problems before they occur, therefore reducing the possibility of system failures. Also, they have a mastery of how best to install some systems according to manufacturers’ requirements, thus minimizing malfunctions due to setting up errors in such cases.

A comprehensive warranty is included in most professional services. This means there will be repair or replacement if any issues occur in a specific time. Additionally, the peace of mind achieved as well as the protection against investment made for the system. Moreover, serious inspection and maintenance during installation can improve efficiency since all parts are aligned, calibrated, and working at their best. To summarize, this implies that getting an expert’s touch in hydraulic systems results in their continued operational reliability, lower maintenance costs and longer lifetime.

Reference sources

-

Final Drive Parts

- Source: Final Drive Parts

- Summary: This site offers remanufactured Bobcat hydraulic pumps designed to exact specifications, providing reliable options for replacement and installation in Bobcat machinery.

-

Aztec Hydraulics

- Source: Aztec Hydraulics

- Summary: Aztec Hydraulics offers a step-by-step guide for hydraulic pump installation, covering inspection, preparation, alignment, and securing the pump, applicable to Bobcat hydraulic systems.

-

Bobcat Parts Store

- Source: Bobcat Parts Store

- Summary: The Bobcat Parts Store provides a wide range of genuine hydraulic pumps and parts, ensuring quality and compatibility for Bobcat equipment installations and repairs.

Frequently Asked Questions (FAQs)

Q: Why should I opt for professional installation for my Bobcat hydraulic pump?

A: Professional installation ensures proper alignment, secure connections, and optimal performance, reducing the risk of errors that could lead to pump failure.

Q: How long does it take to install a Bobcat hydraulic pump professionally?

A: The installation typically takes a few hours, depending on the complexity of the system and any necessary pre-installation checks.

Q: Will professional installation affect my Bobcat warranty?

A: Yes, professional installation helps maintain your Bobcat warranty by ensuring that the pump is installed according to manufacturer specifications.

Q: What should I prepare before scheduling a professional installation?

A: Ensure compatibility of the hydraulic pump with your Bobcat model, have the necessary tools on hand, and check the condition of your hydraulic system.

Q: Can I perform the hydraulic pump installation myself?

A: While possible, DIY installation carries risks, including improper alignment or connections. Professional installation is recommended for optimal results.

Q: How do I find a certified professional to install my Bobcat hydraulic pump?

A: Look for certified Bobcat service providers, ask for recommendations, and check credentials to ensure the installer is qualified and experienced.

Q: What are the signs of a poorly installed hydraulic pump?

A: Signs include leaks, unusual noises, misalignment, and inefficient performance, all of which can lead to premature pump failure.

Q: How does professional installation enhance the performance of my hydraulic pump?

A: Proper installation ensures all components are correctly aligned and secured, leading to smoother operation, greater efficiency, and longer pump life.