Most of the other positives are inclined towards their capacity to maintain a variable displacement and pump out an unyielding pump while performing various functions in a wide variety of equipments, stretching, industrial machinery besides anything else to militial. This article tags along to take a look why the world of axial piston pump manufacturers, why many of them are prominent, detailing the technologies, the accomplished instruments, and the versatile portfolio they offer. There are always aspects of the best hydraulic apparatus makers and others once they are consumable, either by those looking for a hydraulic boost or those who enjoy learning how a volumetric system works in their in-depth studies of the subject.

Overview of Axial Piston Pumps

Definition and Functionality

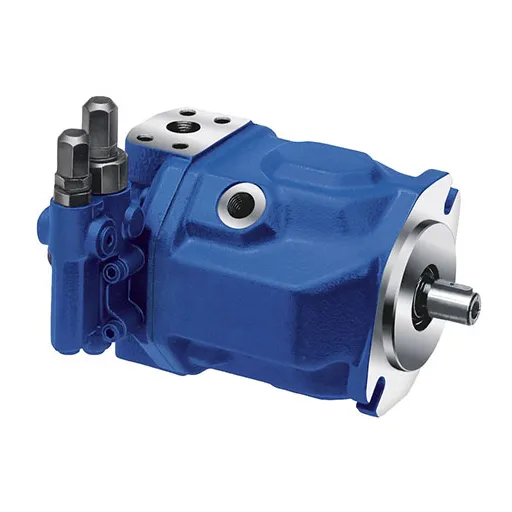

Axial piston pumps are machines that exploit the principle of positive displacement to enable the flow of liquids across very high differential pressure. The Pump consists of a turning block with pistons axial to the driving shaft. These type of pumps are commonly used in hydraulic systems due to their high efficiency, modularity and usability in various industrial and other mobile equipment.

Indeed, the functionality of an axial piston pump is all about driving pistons inside a cylinder block in a reciprocating manner. This involves the well-known process of suction followed by compression. As the pistons move towards the intake port, they suck hydraulic fluid inside the pump. Then, with the same fluid, as the pistons move towards the discharge outlet the hydraulic fluid is compressed and then expelled outside of the pump. The flow rate can be varied using the displacement control mechanism that can be added to many pump models, which in turn increases the range of possible applications of the pump.

They are used in industries which requires them to provide an overall performance that is more advanced and precise, such as civil engineering constructions, product manufacturing plants, air traffic control among other industries. These are precisely designed to withstand the high operating excellence while at the same time delivering high efficiency and thus ideally suited for applications requiring continuous power and durability. Maintenance such as changing the oil, monitoring wear allotment however helps to reduce the aging process and improves their working conditions thereby such pumps being widely used in today’s hydraulics.

Types of Axial Piston Pumps

Axial piston pumps are commonly seen in manufacturing which includes a variety of options related to their working performance and operation. The pressure system comprises of pumps of pattern such as swash plate, bent-axis, and variable displacement. Each category of these pumps has its specific capabilities so as to install for different systems.

Swash Plate Pumps

In this particular diagram, the swash plate axial piston pump technology is used where the swash plate remains fixed and pistons are moved in and out in a linear, reciprocating mode. In relation to this the pistons are extending attaching to the swivel axis and the angle of the swash plate remain fixed regarding to fixed displacement of the pump. These are extremely convenient pumps that are available in a variety of applications and are particularly useful where a constant flow of necessary maxima for instance hydraulic systems where they are generally used.

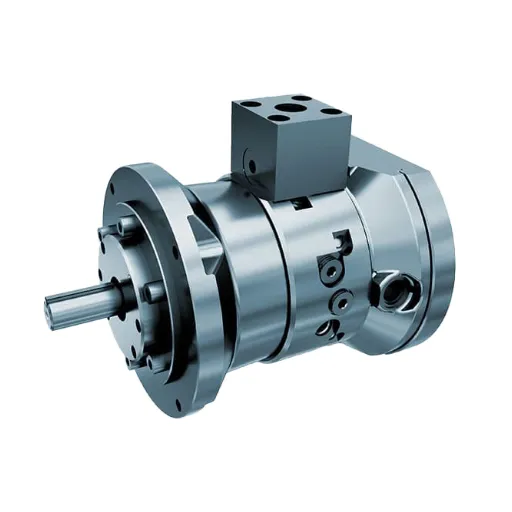

Bent-Axis Pumps

In contrast to the cam of the swash plate pumps, the pistons of the bent axis pumps are not axial but offset (bent) relative to their driving axis. This feature is beneficial as it reduces force gradients and frictional losses in the pump hence accommodating high-pressure loads present in industrial vehicles including earth movers and road vehicles.

Control of Displacement of Axial Piston Pumps

Controlling of the swash-plate angle can vary the displacement of the pump thus called the variable displacement pump. The control of the pump flow and pressure can be accurately done with modification of these hydraulic pump elements that helps in achieving resiliency with active systems like automotive industry and other pressure systems.

Each type of piston pump of axial design provides benefits resulting from the fundamentals of its schemes and opportunities for application in various types of engineering systems. The correct model selection is however dependent on the specific operating parameters, namely pressure, efficiency, flow rate and others.

Importance in Hydraulic Systems

Axial piston pumps are vital apparatuses that work in hydraulic systems to combine mechanical energy with hydraulic energy. That is the crucial function in operating machinery and transferring power adequately in different applications. These pumps are required in industries such as manufacturing, construction, and transportation when offered great capabilities concerning high-pressure environments.

Flow through these axial piston pumps is controlled adeptly when the working load varies. Getting a tighter control on fluid displacement avoids unnecessary wastage of energy and better reliability of the system. Each one of these efficiencies translates to lower operational costs and higher productivity, making it a worthwhile consideration for heavy-duty hydraulic applications. Coupled with other configurations, they can then be employed to support advanced machines and automation systems that require flexible operations.

In the application of hydraulic systems, amongst the very considerable features stood the bucket that has axial piston pumps, i.e., durability and aptitude to withstand harsh operating conditions.Using the strongest available materials and advanced technology, the pumps could perform ok under more aggressive temperatures, high pressures, and extended usage. The series of failures would have been reduced, and so would have maintenance and system downtime during application in critical industries. Therefore, designing the right axial piston pump according to the working environment is a key consideration to attain best working conditions and life in hydraulic systems.

Top Axial Piston Pump Manufacturers

Global Leaders in Hydraulic Pump Manufacturing

Bosch Rexroth

Bosch Rexroth is globally recognized as a manufacturer of hydraulic system and components, one example being an axial piston pump, with their products used in industrial automation processes, mobile machines, and renewable energy systems. They say innovation means top performance, energy efficiency, and reliability, all going through critical design reviews.

Parker Hannifin

Parker Hannifin concentrates on high technology of motion control and manufacturing of high-quality axial piston pumps for myriad uses. Their pumps are designed using state-of-the-art technology for precise fluid control, versatility, and ruggedness in harsh operational settings.

Eaton

Another subplot within the Eaton hydraulics panorama is a great spectrum of axial piston pumps serving industrial and mobile applications. The philosophy of the company is essentially focused on sustainability and efficiency; hence, energy-conscious operations have continued to choose these products without compromises on power or reliability.

Danfoss Power Solutions

Before, it had been Sauer-Danfoss, Danfoss Power Solutions produced one of those hydraulic pumps that could serve over hard industrial uses. Their axial piston pumps are efficient, are compact in design, and can, therefore, take up those harsher workloads within agriculture, construction, and mining.

Kawasaki Precision Machinery

This firm offers an extensive range of hydraulic pumps famous for accuracy and long-life qualities. Their axial piston pumps are designed for high-performance situations where marine and construction industries have large industrial machinery and equipment. It is a well-known trusted name in hydraulic systems.

Their manufacturers have topped the industry through advanced engineering operations, research and development on current issues, and quality assurance protocols. Such commitment to excellence ensures that they always offer solutions in hydraulic technology to keep up with the changing demands in a world market.

Innovative Companies in Variable Displacement Technology

Variable displacement technology has changed the hydraulic industry forever by bringing in unparalleled precision control, energy efficiency, and versatility. And with Bosch Rexroth standing at the forefront of this technology, their emphasis on cutting-edge processes ensures the most advanced and highest quality manufacturing of axial piston pumps and motors that cater to applications in mobile and industrial hydraulics. Their designs always reflect an eye for energy efficiency so as to really cut down on operational costs and to provide environmentally friendly system performances.

The other competitor in this field innovation is Parker Hannifin. The business produces variable displacement hydraulic pumps reputed for their dependability and extraordinary capacity to withstand pressure. The products make use of modern materials and engineering technology to provide great efficiency and durability under all conditions.

Besides, Kawasaki Precision Machinery produced the best solution; a variable displacement axial piston pump would enhance performance in heavy equipment application. From the R&D perspective, they are from those leaders that supply hydraulic systems to meet the ever-changing industry needs.

For detailed specifications of the pumps, their performance comparison, and supplier information, please consult Hydraulic Pump Suppliers. This rotogravure offers competitive data on state-of-the-art hydraulic technology and links the users with trusted suppliers ranging all over the world.

Technological Innovations in Axial Piston Pumps

Recent Advances in Design and Efficiency

In the evolution of axial piston pumps, technological innovations apply very much in increasing the design and the operational efficiencies. To speak of significant advancements, one must state variable displacement mechanisms. Variable displacement in a system allows the pump to vary its output according to the exact requirements of the application. This reduces the energy consumption and losses into heat, making for a more efficient system. Also, modern axial piston pumps work with electronic control units (ECUs) that enable the real-time monitoring and adjustment of operating parameters so that they can always perform at the best efficiency rating according to load conditions.

Another important evolution in the design of axial piston pumps is in the realm of material selection and production methods. Modern materials like top-grade alloys and composites offer construction ruggedness while reducing weight. Also, advanced manufacturing techniques like CNC machining and additive manufacturing offer minute tolerances that keep the axial piston pump running smoothly-on little noise and vibration. In an application requiring ultra-reliable performance, such as aerospace, automotive, and industrial automation processes, such advances are crucial.

Manufacturers have used innovative flow design techniques to reduce internal leakage while improving volumetric efficiency. For example, they would ensure the hydraulic fluid is distributed with little loss by way of optimum port plate geometry and sealing mechanisms. Also, noise-dampening features are installed to mitigate noise pollution from pumps-withinstallations of anti-cavitation chambers and acoustic shields, for example. These innovations inform the commitment of the industry to the design of axial piston pumps that provide maximum performance in the most environmentally conscious and energy-efficient way possible.

Application of Smart Technology in Hydraulic Pumps

Smart technology has revolutionized the design, operation, and maintenance of hydraulic pumps, including axial piston pumps, by instilling advanced features that contribute to enhancement in performance, reliability, and energy efficiency. Consider the following five critical applications of smart-tech for hydraulic pumps:

1. Predictive Maintenance Systems (PMS)

The systems for predictive maintenance employ sensing devices and machine learning to study traces of real-time operational data such as pressure, temperature, and vibrations. From the data changes, the systems can detect when components might fail, thus providing operators with the ability to schedule maintenance-predictively. According to research, downtime can be reduced by half and maintenance costs by 30% via predictive maintenance.

2. IoT Integration for Remote Monitoring

Hydraulic pump can continuously be monitored with remote access under the Internet of Things (IoT) paradigm. Operators could track KPIs through a centralized dashboard, so they never lose control of their operations regardless of their location. Such integration is said to have enhanced operational efficiency up to approximately 20%, as problems get detected and fixed quickly.

3. Adaptive Control Algorithms

Adaptive control systems dynamically alter hydraulic pump operation in response to changing load conditions. The algorithms optimize output flow and pressure with improvement in energy savings, reduced wear on components, and maximization of output versus resource utilization. It has been reported that energy savings of up to 25% could be attained from the use of such adaptive control technology.

4. Embedded Diagnostics

Smart hydraulic pumps come equipped with embedded diagnostics to provide feedback on system health in real-time. Diagnostics can detect abnormalities like internal leaks, temperature imbalance, or valve malfunction in their early stages. This minimizes unexpected downtime and increases the equipment life by almost 40%.

5. Energy Recovery and Regeneration Systems

Advanced energy recovery systems capture, store, and use excess energy generated during deceleration or idle moments of pump operation. This energy is then used for subsequent operations, imparting a high degree of energy efficiency. Some industrial settings claim energy consumption reductions up to 15% after weaving regenerative technology into their hydraulic systems.

With the application of these two smart technologies, the face of hydraulic pump engineering is changing toward predictive, efficient, and connected systems.

Future Trends in Axial Piston Pump Development

Another relevant factor is the increasing incompatibility of axial piston pumps due to digital developments, new materials, and sustainability considerations. The most important trend is perhaps that of employing advanced sensor technology coupled with IoT (Internet of Things) techniques within pump systems. Among these parameters, instant pressure, temperature, and flowrate parameters are continuously monitored; hence maintenance strategies are deployed, such as predictive maintenance, which eventually results in downtime minimization and operational-cost reduction.

Another powerful trend turns light-weighting high-performance materials. New composites and advanced alloys find their way to improve durability and reduce the weight of the pump to better their efficiency and wear resistance. This enables these axial piston pumps to work in extreme conditions with almost no deterioration of their performance.

For another thing, the obscured demand for energy-efficient solutions has pushed variable displacement pumps to be outfitted with sophisticated electronic controls. Such pumps deliver fluid with total accuracy, in accordance with system requirements, thus minimizing energy waste and promoting sustainability.

Lastly, the environmental regulations and decarbonization goals that stand before the industry are bringing forth new innovations related to bio-compatible hydraulic fluids and systems with an aim of low carbon footprints. In conjunction with regenerative energy recapture technologies, they help in producing hydraulic systems that are least harmful toward the environment, without any drawbacks on pure capabilities.

This intersection of digital technologies and materials innovation with sustainable engineering is truly transformative for axial piston pumps, thereby cementing their place as centerpieces for the next generation of industrial and mobile hydraulic systems.

Factors to Consider When Selecting a Manufacturer

Evaluating Quality and Performance Standards

The selection of a manufacturing house for axial piston pumps calls for careful evaluation of their focus on quality and standards of performance. A very good manufacturer conforms to international standards such as ISO9001 for Quality Management Systems and ISO14001 for Environmental Management Systems to maintain consistency in the precision of manufacture and environmentally-conscious working methods.

Another thing to consider is, and should be considered as crucial besides material integrity; manufacturers that use newer alloys or composites have products with arguably better strength and performance. Continuity tests, thermal stress tests, volumetric efficiency tests, etc., serve as a yardstick of whether or not the manufacturer pays attention to reliability and long-term performance.

Clearly, it is innovative to integrate modern diagnostic systems into hydraulic components coupled with predictive maintenance functionality. For instance, being able to monitor pressure, flow rates, and temperature through sensors residing within the pumps enables implementing predictive analytics that cuts away a lot of downtime.

Manufacturers of such pumps should also provide comprehensive technical documentation detailing performance curves, installation, and maintenance procedures to guarantee the proper application and maximize operational efficiency of these units. When considered side by side, these two considerations provide a blueprint for manufacturers that can supply good quality and high-performance axial piston pumps.

Assessing After-Sales Support and Service

After-market service and support are very important aspects to foster reliability and longevity for axial piston pumps. Buyers must consider if the manufacturer can complement good-time customer support, in the form of prompt availability of spare parts, technical advice, and any other assistance with troubleshooting. Service support has to consist of a senior technician who resolves issues promptly, since this would largely mitigate downtime costs and keep operations running without interruptions.

The manufacturer warranty must also be evaluated. A long warranty is a sign of confidence by the manufacturer in the durability and performance of their product. The manufacturer will put in place feedback systems to collect data on operational problems and utilize it in the further improvement of product design.

Present-day service-support systems take a predictive approach, using data analytics and technical monitoring to identify trends and potential failures. Lowering maintenance cost and ensuring performance at peak is what this approach opted to consider. Preparing manufacturers based on a history of data-driven and responsive after-sales support is fundamental to protect an investment in high-precision equipment, such as axial piston pumps.

Applications of Variable Displacement Axial Piston Pumps

Industrial Applications and Use Cases

Variable piston pumps with axial displacement are the heart of hydraulic solutions, necessarily applied in very many industrial scenarios for their ability to allow fine control, low flow disturbances, synergies with low loss mechanisms, efficiency, and long life. These pumps are heavily employed in factory operations where constant hydraulic power is given to the automated machines, press systems, and injection molding machines. Besides being put together with flow and area adjustments on-demand to work in line with operational efficiency and precise preset requirements of high-end machine systems, these pumps also reduce energy wastage and operation waste.

The other crucial use of hydraulics is in the construction sector, using pumps that drive hydraulic systems for heavy machinery, such as excavators, loaders, and cranes. Given the nature of construction activity, equipment capable of responding to variable loads and performance conditions is in high demand. Variable displacement axial piston pumps help address these requirements by providing smooth output modulation to achieve the best working conditions while simultaneously lengthening equipment life by reducing mechanical stresses. The very construction of the pumps allows them to undertake the harsh working environment and strenuous demands mostly faced in the construction industries.

In addition, these pumps find their ultimate application in aircraft and defense, where engineering design criteria revolve around the very value of reliability and precision. They find use in aircraft hydraulic systems to perform critical tasks in landing gear, flight control surfaces, and braking systems. These pumps need to flawlessly ensure the safety of the aircraft and guarantee smooth operations under all circumstances by providing exact flow rates of hydraulic fluid against load demand variation. Their engineering superiority coupled with integration with safety monitoring systems places them in the top tier of applications requiring highest technical reliability. These industrial examples clearly demonstrate how indispensable variable displacement axial piston pumps are in modern engineering and technology operations.

Fluid Power Systems in Mobile Equipment

In mobile equipment across various industries wherein efficiency and reliability are crucial, fluid power systems are vital for the operation. These systems utilize hydraulic and pneumatic forces to render high power-to-weight ratio work-grades essential to construction, agriculture, mining, and forestry. The mobile hydraulic systems are used to augment machine capability by providing precision controls and high force output even under severe working conditions and undulating terrains. The main components, which include pumps, motors, valves, and actuators, are specially designed to handle changes in dynamic load to perform at their quintessential level.

Energy-saving benefits of new controls and operational systems for variable displacement pumps have been considered during their recent evolution applied to this industry. Less fuel is consumed during operation due to energy lost in transmission being avoided, thus leading to operational cost reduction-giving room for other economic and environmental objectives like reducing the carbon footprint of equipment and placing it on an eco-friendly platform. In addition, modern mobile equipment has control systems and electronic diagnostics that can measure and monitor pressure, flow, or temperature. Potential fault conditions can be predicted and prevented based on predictive maintenance until downtime is reduced and the equipment life cycle is enhanced.

Such systems provide a significant linkage in the development of smart and autonomous systems, wherein fluid power joins with control algorithms and sensor networks, thereby making a solution to address all safety and productivity challenges of modern engineering applications.

Role in Renewable Energy and Other Emerging Sectors

A great number of applications with fluid power have been contemplated by the renewable energy sector and other burgeoning industrial fields. Control of blade pitch is managed by the hydraulics so that correct pitch is attained for energy capture in wind energy and structural safety during adverse wind conditions. The system must therefore assure reliability and extreme precision, as any inefficiency existing in a large-scale wind turbine will be magnified. Similarly, fluid power mechanisms, in hydroelectric power generation, allow for operational control of gates, valves, and turbines to produce energy efficiently while coping with changes in water levels and runoff rates.

Emerging applications such as wave and tidal energy also use fluid power systems for their processes of energy conversion, their ability to handle high force densities, and provide operation in harsh environmental conditions-innerworking situation suitable for these sectors. In another way, electro-hydraulic control system advances increasingly raise the precision and adaptability of the design, thereby allowing integration into highly complex energy grids on a system-wide basis. This helps answer the rising demand for clean and sustainable power generation, which is in line with the worldwide agenda of greenhouse gas reduction and foster energy independence.

Apart from electricity generation, fluid power systems are trickling down into robotics, autonomous vehicles, aerospace, etc. Offering the best rate of force versus weight, combined with recent advancements in digital controls systems, thus making fluid power key in the evolution of next-generation solutions in these emerging markets.

Frequently Asked Questions (FAQ)

Q: What are axial piston pump manufacturers known for?

A: These manufacturers are known for the manufacture of high-performance pumps suited for various applications. These manufacturers specialize in the manufacture of fixed displacement piston pumps as well as variable displacement piston pumps that are hydraulic system components where fluids need to be moved efficiently.

Q: What types of pumps do axial piston pump manufacturers produce?

A: There is a large variety of pumps manufactured by axial piston pump manufacturers, including fixed displacement pumps and variable displacement piston pumps. Such pumps are able to withstand pressure levels in excess of 3500 psi and are designed to provide a certain flow rate dependent on the application.

Q: How do axial piston pumps compare to radial piston pumps?

The design and operation of axial piston pumps versus radial piston pumps differ. Whereas radial piston pumps are of greater torque and are commonly used in heavy construction type applications, axial piston pumps, by virtue of their compact design and high power density, are used in the hydraulic applications.

Q: What are the benefits of using variable displacement piston pumps?

A: Variable displacement piston pumps come with the advantage of controlling the flow rate and having a better performance and efficiency. These pumps vary their output as the requirements of the application change, lending greater control to the hydraulic circuits, at the very least reducing energy consumption.

Q: What should be considered when selecting a pump?

A: When selecting a pump, displacement sizes required, operating pressure, and fluid viscosity should be considered. One should also check the technical specifications and expertise of the manufacturer to have an idea about the pump and its performance and service life.

Q: What action do axial piston pumps take when contaminated?

A: Axial piston pumps are built strongly to withstand contamination. To enhance durability and life expectancy, manufacturers include different features, such as filtering systems and seals that exclude foreign particles from entering the pump, thereby assuring smooth operation.

Q: What is the average service life of an axial piston pump maker?

A: In general, the pump can have different service lives depending upon the application and operating conditions; however, a good axial piston pump is quite durable and can run an operation of thousands of hours. Proper maintenance and using manufacturer-certified replacement parts increase the life-span.

Q: Can axial piston pumps be customized for particular applications?

A: Yes, most axial piston pump manufacturers customize pumps to suit specific application requirements. Displacement sizes, control options, and in some cases, even the designs can be modified to ensure that the pump performs ideally in a special system.