Axial piston pumps are at the heart of countless industrial and mobile hydraulic systems, providing the very efficiency and functionality of the machinery for few applications. These are high-performance pumps that can provide a very accurate flow rate, sometimes at very high pressures, and thus they get employed in areas such as construction, manufacturing, construction, and even aerospace. How do they operate, and what differentiates them from other pump types? This article covers the working principle, benefits, and applications of axial piston pumps, thus imparting you with detailed knowledge of the technology and in explaining why this technology is fundamental to contemporary hydraulic systems.

Working Principles of Axial Piston Pumps

How Axial Piston Pumps Work

A series of pistons parallel to a rotational axis work in the axial piston pump. These barrels reside in a cylinder block that rotates with the input shaft of the pump. Fluid pressure changes inside the cylinders cause hydraulic fluid to be sucked in and thrown out to create flow for system operations.

The pistons reciprocate in their cylinders-they are driven by way of the swash plate or inclined disc. After rotation of the cylinder block, the angular displacement of the swash plate imparts reciprocating motion to the pistons. These pistons move alternatively and reciprocate in their cylinders. During the intake stroke, the hydraulic fluid is sucked inside the cylinder through an inlet valve. On the compress stroke, the outlet valve allows the fluid to force out, providing continuing flow for the hydraulic system.

Key Insight:

Axial piston pumps are highly efficient and can withstand very high pressures, making them ideally suited for all applications where fluid power is relied on for precision. Giving high performance in a smaller space, their compact design series, combined with variable displacement capability, provides for adjustments in flow rates as per the needs of the system. With these features, axial piston pumps thus become the very backbone for applications in the construction, manufacturing, and aerospace industries—where precision and reliability are of utmost value.

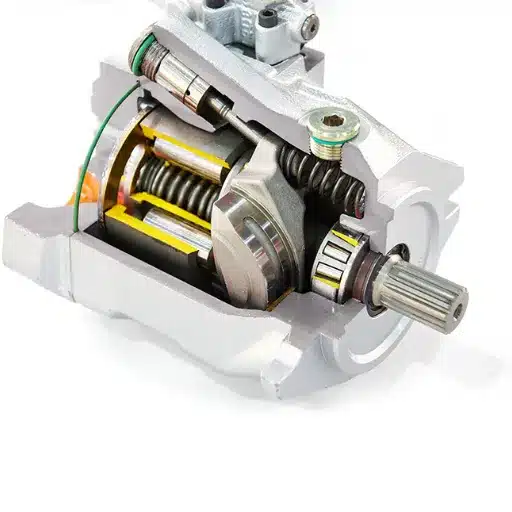

Internal Components of Axial Piston Pumps

Axial piston pumps have many internal components so that the pumps may perform efficiently. The main component in the pump is the cylinder block housing several pistons arranged in a circular pattern. These pistons perform the pumping action by reciprocating within the cylinder block during pump operation. The cylinder block rotates in sync with the pistons to provide a smooth flow of fluid.

The swashplate controls the length of the pistons’ stroke and thus governs the displacement of the pump. In effect, the fluid flow rate is altered by adjusting the angle of the swashplate, and this occurs in variable displacement pumps depending on the demand of the system. At the same time, the shaft carries mechanical energy to impose the pistons into motion inside the cylinder block.

Other components include the valve plate and high-pressure seals. The valve plate controls the flow paths to enable the fluid to enter at the correct time and be discharged at the correct time, whereas the seals prevent any leakage to maintain the system’s integrity. These components enable axial piston pumps to function efficiently at high-pressure operations, wherein precision and durability are paramount.

Types of Axial Piston Pumps: Fixed vs. Variable Displacement

The two main types of axial piston pumps are fixed displacement and variable displacement pumps.

| Key Point | Fixed | Variable |

|---|---|---|

| Flow Rate | Constant | Adjustable |

| Complexity | Simple | Complex |

| Cost | Low | High |

| Efficiency | Moderate | High |

| Applications | Consistent Load | Dynamic Load |

| Maintenance | Low | High |

| Examples | Gear, Screw | Swash Plate |

Applications of Axial Piston Pumps

Industrial Applications in Manufacturing

Being more precise, efficient, and durable, an interesting axial piston pump falls right within the scope of various industrial manufacturing sectors. A few manufacturing applications where the axial piston pump would play a major developmental role are:

- Injection Molding Machines: Axial piston pumps are used to generate high-pressure hydraulic energy for operations in injection molding, and precise hydraulic operation is maintained for the injection itself. In addition to injection speed controls and pressure controls, such injection molding activities involving axial piston pumps manufacture components requiring sharper precision in geometrical configurations.

- Metal Forming Presses: The hydraulic presses of the metal-forming industry receive forces and pressures of desired intensities from axial piston pumps for stamping, forging, and bending operations. Due to the relatively high capacities of these pumping systems, parts having specified high qualities and precise tolerances are produced.

- CNC Machine Tools: On advanced CNC machining equipment, axial piston pumps are used to operate hydraulic tool changers, clamping systems, and cooling circuits. These pumps ensure enhanced efficiency and precise control that are so necessary to guarantee machining accuracy.

- Paper and Pulp Processing: Since paper and pulp processing is a continuous process, hydraulic systems must be equipped with very reliable pumps. Axial piston pumps supply hydraulic power to control the conveyors, rollers, and cutting devices to ensure uninterrupted production.

- Industrial Robots: Axial piston pumps provide the hydraulic energy required for robotic motions in manufacturing systems. The accuracy of these pumps is critical for the repeatability and accuracy demanded in automated assembly lines or material handling systems.

These are some examples depicting the versatility and reliability of axial piston pumps in modern manufacturing worksites where precision and efficiency are immediate factors affecting productivity and product quality.

Use Cases in Construction

Providing hydraulic power to heavy machinery and tools during construction, axial piston pumps are used with the applications of many construction procedures. Five detailed use cases of axial piston pumps showcase the importance of their applications during the construction process, namely:

- 1

Excavators: With axial piston pumps, the hydraulic system of excavators allows smooth and precise operation of the boom, arm, and bucket. Excavators working across various terrains require a steady pressure and flow from these pumps to carry out efficient digging and trenching. - 2

Cranes: The axial piston pumps maintain pressure to hoist heavy loads and ensure stability and safety standards for lifting and rotation movements related to hydraulic cranes on construction sites. - 3

Bulldozers: The hydraulic systems provided and maintained by the pumps enable blade lifting, tilting, and angling for earth-moving operations. These pumps have their designs configured to withstand constant heavy-duty cycles so they can provide an optimum hydraulic supply to the large-scale processes of grading and leveling. - 4

Concrete Pumps: In concrete pumping, axial piston pumps are used to pump highly viscous materials. These pumps ensure pressure control, acting as the basic criterion for consistent flow rates during concrete placing on large-scale pouring or high-rise construction. - 5

Pavers: Pavers require axial piston pumps as a supply of hydraulic power for their screed and conveyor systems. This ensures the even application of asphalt or concrete on roadways that resulting in a smooth, level surface that is vital for infrastructure projects.

These applications retain the very essence of axial piston pumps in ensuring that hydraulic machinery on construction remains efficient and reliable. The increasing pressure and heavy-duty conditions under which they operate certainly justify their indispensability in modern construction work.

Hydraulic Applications of Axial Piston Pumps

Axial piston pumps are highly versatile, used in various hydraulic applications where conditions of high pressure exist and a steady performance must be delivered. With immense utility, these pumps can be fitted into many systems in various industries. The following are five important considerations of axial piston pumps:

- Heavy Construction Equipment: These pumps find extensive use in construction machinery such as excavators, bulldozers, and backhoes. They offer hydraulic power required to operate the heavy-duty equipment by efficiently converting mechanical energy into high-pressure hydraulic flow for precise control and movement.

- Industrial Hydraulic Presses: They now contribute to forming metals, forging, and stamping hydraulic presses. Axial piston pumps, by virtue of their high-pressure output, ensure that force is applied consistently throughout the entire pressing cycle, increasing production and product quality.

- Agricultural Machinery: Tractors and harvesters use axial piston pumps to power hydraulic systems for steering, lifting, and braking functions. These pumps have proven reliable and never stopped working, even in demanding agricultural environments.

- Aerospace Hydraulic Systems: In aerospace, axial piston pumps provide crucial hydraulic power to systems of aircraft, including landing gear, flight controls, and braking. They fit the aviation application because of the light design and ability to work under extreme conditions.

- Marine Hydraulic Systems: Axial piston pumps find usage in marine hydraulics by way of serving steering gear and stabilization systems for ships. They ensure smooth maritime operations with their excellent high-pressure performance.

In all such applications, axial piston pumps—a precise and reliable source of hydraulic power—are integral and support the efficient operation of complex systems across many domains.

Advantages of Axial Piston Pumps

Efficiency and Performance Benefits

- High Volumetric Efficiency: These pumps provide up to 98% efficiency, minimizing fluid leakage and practically using energy. Fluid leakage leads to an energy loss, therefore, low levels of leakage mean high energy savings. Thus, the pumps with greater efficiency help in reducing energy consumption and are best suited for those systems that run continuously with high pressure.

- Wide Pressure Range: Axial piston pumps can take pressure up to 450 bar or even more, as required in demanding hydraulic applications. This vast pressure range gives them flexibility, thereby rendering them usable in various industrial and marine systems.

- Accurate Flow Control: Axial piston pumps permit variable displacement control, which means that the desired flow rate can be very accurately set to meet a particular system’s needs. This gives better control and system performance optimization, particularly in ship steering or heavy machinery applications.

- Small Size and Less Space Requirement: Though capable of handling very high pressures and powers, these pumps have a small footprint. This helps integrate the pump into hydraulic system layouts that are very constrained or complicated without a performance penalty.

- Durability and Long Life: Made from tough materials using ingenious component design, axial piston pumps endure the grim operating environment. Research shows that, if well maintained, they develop satisfactorily for 10,000 hours of operation, thereby minimizing operational downtime and life cycle costs.

Reliability in Various Conditions

Axial piston pumps are designed to work reliably under a wide range of demanding operational conditions. The construction and design utilize state-of-the-art materials, precision manufacturing, and an array of performance-enhancing techniques, so that the pumps offer consistent performance even in adverse conditions. However, these conditions offer the top five situations where axial piston pumps are most reliable:

- 1

Pressure Applications: Axial piston pumps can operate at pressures beyond 350 bar (5,000 psi) while being stable and efficient. This allows them to be used in heavy-duty applications such as hydraulic presses and other industrial machinery. - 2

Extreme Temperatures: The pump is designed to work comfortably at a wide temperature range from -40°C to 120°C (-40°F to 248°F), ensuring operational reliability in far northern and hot environment settings. - 3

Contaminated Fluids: With good filtration and tough wear-resistant components, an axial piston pump could probably tolerate the contamination of fluids to some extent, minimizing possible failure under sub-optimum operating conditions. - 4

Continuous Run: Being optimally designed for cooling and using the finest endurance properties, these pumps can run continuously for hours or days, thus making them fit for applications that need heat from an operation going at all times. - 5

Shock and Vibration Resistances: Axial piston pumps are well structurally sound and rightly balanced against materials that could provide shock and vibration resistance to mechanical shocks and vibrations.

The features are of utmost importance to reliability, along with converting downtime into running time, in making operations efficient in these systems.

Versatility Across Industries

The versatility and efficiency of axial piston pumps render them usable across numerous industrial applications. Their design and built-in efficiencies, along with great handling of high-pressure operations, support them in meeting the cross-industry demands. Below are five major industries in which axial piston pumps are used, along with their roles:

- Construction and Mining Hydraulic Systems: Axial piston pumps are used extensively in heavy equipment like excavators, loaders, and drilling rigs. Their ability to work at high pressures and allow definite control of flow supports hydraulic systems to lift, dig, and operate in a rather harsh environment.

- Aerospace and Defense: In aviation systems, these pumps are used in processes like flight control hydraulics, landing gear deployment, and braking systems. Extreme pressures and conditions require these systems to ensure safe performance during mission-critical operations.

- Industrial Manufacturing: Axial piston pumps are essential for industrial manufacturing and factory automation systems, and die-casting, injection molding, and high-speed machining. The construction of axial piston pumps to work with constant pressure and flow rate enhances the changes in industrial processes in terms of efficiency and throughput.

- Energy Production, Oil, and Gas: From hydroelectric power stations to offshore drilling platforms, axial piston pumps are used in the hydraulic systems for energy generation, well drilling, and subsea operations. Their rugged build transports them to maximum upgrade on both onshore and offshore conditions.

- Marine and Shipbuilding: Serving propulsion, deck machinery, and steering systems, the pumps provide enough efficiency on all levels while handling the rigorous duties cast upon them by the marine environment. With corrosion-proof construction, they promise a long life coupled with efficient performance.

Their multifarious nature makes it impossible to ignore the indispensable place that axial piston pumps take in making the various industries perform smoothly and reliably.

Limitations and Challenges

Maintenance Considerations for Piston Pumps

Maintenance is the most important factor responsible for maintaining the long-term quality and efficiency of axial piston pumps. As the operation under high pressure causes manufacturing components to wear down, periodic inspections and servicing for pistons, cylinders, and seals should be undertaken. Contamination is still one of the major drawbacks; that is, impurities in the hydraulic fluid may cause abrasion and surface damage. Employing a high-quality filtration system and maintaining a fluid cleanliness standard (e.g., ISO 4406) substantially helps in limiting this risk.

Another vital factor to check is the operating conditions because abnormal values could point to the onset of faults. Excessive heat or vibrations can cause misalignment or insufficient lubrication and other failures within the component, which require urgent correction. Sampling and testing the fluids regularly will help catch signs of oil degradation, water ingress, or particulate contamination and protect you from costly stoppage.

Important Note: Although the axial piston pump is intended for use in heavy-duty applications, performance-related issues can be aggravated by external factors such as poor installation, incorrect torque settings, or working in an improper environment. Following the maintenance recommendation of the manufacturer and keeping to original-equipment-manufacturer (OEM) spare parts will assist the pump to still perform according to its original design specifications, and also increase the system efficiency and working span.

Cost Implications of Axial Piston Pump Design

Material choice, manufacturing precision, and latest technologies impart cost implications to axial piston pump design. Above-average materials, like hardened steel or a high-class alloy, are chosen for long life and wear resistance in high-pressure applications; however, such expensive materials inflate production costs. Precise machining and assembly with advanced manufacturing methods and highly skilled labor are required because of complex interior geometries, further increasing costs.

Variable displacement mechanisms, electronic controls, and improved sealing technologies are evolutionary features in modern axial piston pump design to improve efficiency and reduce energy consumption during operation. These enhance overall operational costs but increase initial investment. Environmental considerations are taken into account in the design, contributing further to the design and production cost concerning compliance with stricter emission regulations.

Cost Analysis: Then, the total cost of ownership for an axial piston pump balances between the initial purchase price and maintenance, repair, and operational costs in the long run. Careful analysis of these factors and following best practices in installation and maintenance would then allow one to purchase a technically viable and cost-efficient solution throughout the life cycle of the pump.

Potential Issues with Hydraulic Systems

Too many issues may be confronted, causing hindrance to performance and reliability if not resolved promptly. One common issue is fluid contamination, which happens when particles, water, or air enter the hydraulic fluid, thereby reducing its effectiveness and causing wear on system components. Contaminated fluid will clog fine tolerance points in valves and pumps, thus compromising efficiency and possibly causing component failure.

That is another concern that brings about overheating. Causes for heating usually include friction, overload, and less-than-adequate cooling. Extended use under high temperatures will break down the hydraulic fluids, reduce their strength for further lubrication, and damage seals and other components. With systems compromised by heat, further repair will ensue, and it will be very costly.

Leakages are another issue that the hydraulic circuit faces. When seals, hoses, and fittings age or get damaged, the ability of the circuit to hold fluid and keep pressure drops away is compromised. Even tiny leaks put efficiency at risk and threaten the environment if left unattended.

Finally, improper upkeep or installation leads to misalignment or pressure settings or poor lubrication, all contributing to the inefficiency or damage of the system. Tackling such potential problems will call for working maintenance schedules, regular fluid analysis, and quality components to guarantee the best outcomes from hydraulic systems.

Advancements in Axial Piston Pump Technology

Innovations in Pump Design

In axial piston pumps, the idea has always been to raise efficiency, durability, and precision in very aggressive operating environments, based on technological developments over time. Recent developments include the incorporation of new materials developed to enhance wear resistance and minimize friction. These materials ensure that internal components operate to their best efficiency even under very high pressures and temperatures, thereby increasing pump life and shrinking maintenance requirements.

More improvements made to piston and cylinder geometry have also been implemented by manufacturers. Precision components can be manufactured to tighter tolerances, with the result being reduced leakage and increased volumetric efficiency. Variable displacement mechanisms have also been improved to allow the pump flow rate to be changed on the fly as system demands require. They thus consume less energy, operate more quietly, and vibrate less.

Revolutionary Development: A revolutionary development is in smart sensors and real-time monitoring technologies embedded in axial piston pumps. Sensors give operators vital information such as pressure levels, fluid temperature, and flow rates, allowing for maintenance beforehand and spotting potential problems early. The implementation of these IoT-related advances creates a predictive maintenance framework that will reduce downtime and increase overall system reliability. Collectively, these advances signal a strong push toward optimally aligning performance with sustainability in hydraulic systems.

Enhancements in Performance and Durability

In current developmental phases of hydraulic systems, the incorporation of performance optimization with durability is being stressed. With the increase in the use of modern materials, such as advanced polymer composites and high-strength alloys, in manufacturing critical components, the technology advances towards improved reliability of the system. These materials do offer a high strength-to-weight ratio while resisting wear, corrosion, and fatigue under tough operating conditions. With increased reliability, they also require less frequent replacement, thereby reducing life cycle costs and the impact on the environment.

Sealing techniques have also seen some advancement to make the system more efficient with leakage minimized. The recent innovations in sealing technologies involve low-friction seals and highly polished contact surfaces that have reduced internal friction levels, assuring smoother operation and longer life for all moving parts. Systems with higher internal resistance need more energy to operate, producing unnecessary energy losses. Hence, enhancement in this field directly translates to hydraulic systems that are energy-efficient for sustainable engineering.

These are then complemented by control systems that utilize real-time data analytics to maximize performance under dynamically changing conditions. Such adaptive control algorithms can alter system like pressure and flow rate according to the dynamics of load requirements. Through integration of machine learning and predictive algorithms, a hydraulic system can anticipate modifications to its operating states in order to alleviate sufficiently harsh stress before failure occurs. The result is mechanical elegance augmented by computational genius to enhance operational integrity and ensure durable performance.

Sustainability Trends in Hydraulic Piston Pumps

Sustainability pursuit in hydraulic piston pumps thus changes the landscape of the industry with the emphasis placed on energy-efficient applications, use of green materials, and the least harmful effects on the environment. Innovative designs make use of low-friction components to avoid the loss of energy, thus increasing the efficiency of the system. Meanwhile, manufacturers are also increasingly promoting the use of biodegradable hydraulic fluids in place of the traditional petrochemical-based oils to ensure that leakage or spillage presents little or no danger to the environment. The adoption of environmentally friendly design methods thus reflects the transition into sustainable resource management.

Energy recovery technologies are becoming essential in recent hydraulic piston pump systems. These regenerative systems recover energy during load deceleration, store it, and then somehow reuse it to power other stages of the system or auxiliary functions. Such developments save energy and considerably reduce the cost of operating the equipment for its entire life cycle. With these systems being integrated with intelligent monitoring systems, operators now have the means to optimize energy usage through real-time data feedback and precision control.

Circular Economy Approach: Another trend working towards sustainability is modular and flexible designs for increased serviceability. The modern hydraulic piston pumps are now produced with serviceability in mind. Along with replaceable parts that lengthen product life and provide for less waste, the modular setup helps ease upgrades with minimal disruption to the environment under the circular economy principle. Furthermore, pumps manufactured with an increasing amount of recycled materials and even lightweight materials help reduce the carbon footprint of pump manufacture. These developments thus emphasize the commitment of the industry to deliver high-performing systems without any compromise on environmental sustainability.

Frequently Asked Questions (FAQ)

Q: What are the common applications of axial piston pumps?

A: Axial piston pumps find extensive applications in hydraulic systems across various industries. They are commonly used in mobile machinery, industrial equipment, and automotive applications where high-pressure and precise fluid control is required. Their ability to convert mechanical energy into hydraulic energy makes them indispensable in hydraulic circuits.

Q: How do axial piston pumps differ from radial piston pumps?

A: The primary difference between axial piston pumps and radial piston pumps lies in their design and operation. Axial piston pumps utilize a bent axis design, allowing for a more compact structure and higher efficiency. In contrast, radial piston pumps have pistons arranged radially, which can affect their fluid displacement characteristics. Each type of pump serves specific applications based on the hydraulic requirements.

Q: What is the efficiency of axial piston pumps compared to other pump types?

A: The efficiency of axial piston pumps is generally higher than that of many other pump types, such as vane pumps or radial piston pumps. This is due to their positive displacement mechanism, which allows for excellent control over hydraulic output and minimal energy loss during operation.

Q: How does the piston move in an axial piston pump?

A: In an axial piston pump, the piston moves linearly within a cylinder. The motion is typically driven by a rotating swash plate or bent axis design, which causes the pistons to extend and retract, thereby creating fluid displacement. This movement is essential for generating the hydraulic pressure required in various applications.

Q: What are the advantages of using axial piston pumps in hydraulic systems?

A: Axial piston pumps offer several advantages, including high efficiency, compact design, and the ability to generate high pressure. They also provide a wide range of pump outputs, making them suitable for diverse applications. Additionally, their positive displacement mechanism ensures consistent fluid flow, which is critical for the performance of hydraulic systems.

Q: What are the typical components found in axial piston pumps?

A: Typical components of axial piston pumps include the piston and the valve plate, swash plate or bent axis mechanism, housing, and the inlet and outlet ports. The number of moving parts in these pumps is relatively low, which contributes to their reliability and ease of maintenance.

Q: Can axial piston pumps handle varying fluid viscosities?

A: Yes, axial piston pumps can handle a range of fluid viscosities. However, the efficiency of these pumps may be affected by very high or very low viscosity fluids. Pump manufacturers often provide guidelines for the specific application to ensure optimal performance within the hydraulic system’s requirements.

Q: What role do axial piston pumps play in mobile machinery?

A: In mobile machinery, axial piston pumps play a pivotal role by providing the hydraulic power necessary for various functions such as lifting, steering, and propulsion. Their ability to generate high pressures and control fluid displacement makes them essential for the efficient operation of equipment like excavators, loaders, and forklifts.

Q: How do axial piston pumps contribute to the overall performance of hydraulic systems?

A: Axial piston pumps enhance the overall performance of hydraulic systems by ensuring reliable and efficient fluid delivery. They excel in applications requiring precise pressure control and fluid displacement, making them vital for maintaining the requirements of the hydraulic system. Their design allows for minimal energy loss, thereby maximizing the system’s operational efficiency.